GCE PCB Manufacturer: Your Guide to High-Quality Circuit Boards

In today's tech-driven world, printed circuit boards (PCBs) are the backbone of countless electronic devices. Among the top players, GCE stands out as a leading global PCB manufacturer. With decades of experience, GCE is known for delivering high-quality PCBs that power various industries. This article explores the depth of GCE's capabilities, their commitment to innovation, and what makes them a reliable partner for your PCB needs.

GCE's Global Footprint and History

Gold Circuit Electronics (GCE), established in 1981, has evolved into a major global player in the PCB manufacturing sector. This section details GCE's strategic expansion and pivotal milestones that have shaped its current stature in the industry.

From its inception, GCE has demonstrated a commitment to growth and technological advancement, initially focusing on the domestic market before expanding its reach internationally. This strategic expansion has involved setting up manufacturing facilities in key locations, allowing GCE to efficiently serve a global client base. Their evolution from a local manufacturer to an international enterprise underscores their adaptability and commitment to meeting the increasing demands of the electronics industry.

Key Milestones in GCE's History include the establishment of advanced production facilities, the adoption of cutting-edge technologies, and the expansion of product offerings to include a wide range of PCB types. These milestones not only highlight GCE's growth but also their proactive approach to staying at the forefront of PCB manufacturing technology. The company's journey from a smaller local entity to a globally recognized PCB manufacturer reflects their success in innovation and strategic planning.

Core Capabilities of GCE PCB Manufacturer

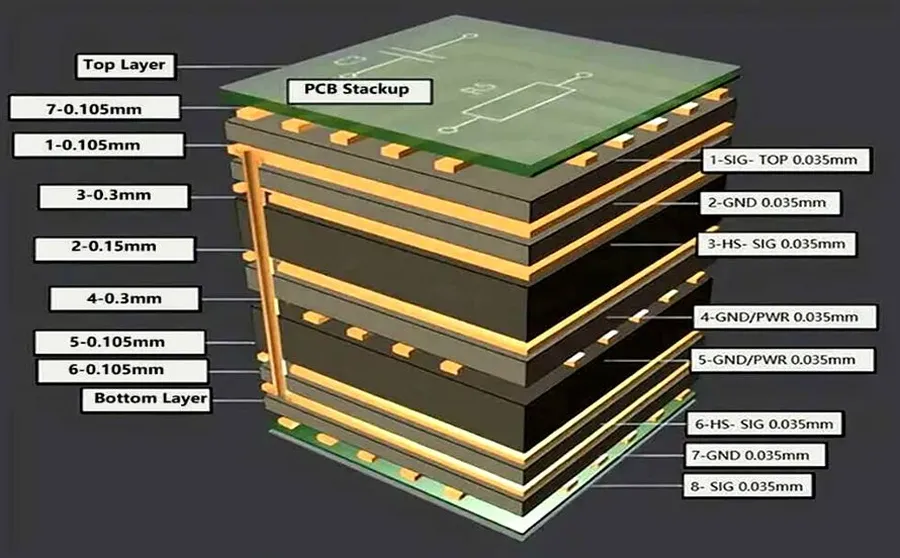

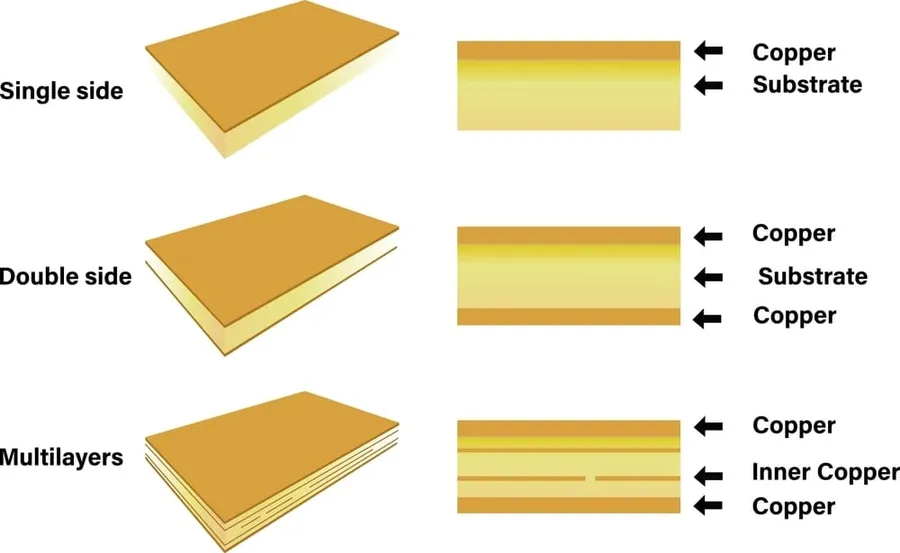

GCE distinguishes itself in the PCB manufacturing sector through its robust core capabilities, particularly in the production of high-layer count (HLC) PCBs and specialized manufacturing processes. These capabilities underscore GCE's commitment to meeting the complex demands of modern electronics.

| Capability | Description | Significance |

|---|---|---|

| High Layer Count (HLC) PCBs | Production of PCBs with a high number of layers, often exceeding 12 or more. | Essential for advanced electronics requiring high density interconnections, such as servers, telecommunications equipment, and high-performance computing systems. |

| HDI Microvia PCBs | Manufacturing of PCBs with high-density interconnects using microvias. | Enables smaller form factors and increased performance, crucial for compact and advanced devices. |

| Rigid-Flex PCBs | Fabrication of PCBs that combine rigid and flexible sections. | Provides design flexibility, durability, and space-saving solutions for applications with unique mechanical requirements. |

| Backplane PCBs | Manufacture of PCBs used for connecting multiple circuit boards or other electronic components. | Critical for large systems, such as industrial control systems, and telecommunications infrastructure. |

| Specialized Materials | Utilization of advanced materials like high-Tg FR-4, polyimide, and other materials to meet specific application requirements. | Ensures enhanced performance, reliability, and thermal management in challenging environments. |

| Advanced Surface Finishes | Application of high-quality surface finishes, such as ENIG, ENEPIG, immersion silver, and gold plating. | Provides excellent solderability, corrosion resistance, and long-term reliability. |

| Controlled Impedance | Precision control of impedance to ensure signal integrity. | Essential for high-speed data transmission in modern electronic devices and systems. |

| Automated Optical Inspection (AOI) | Implementation of advanced AOI systems to ensure every PCB is free from defects. | Achieves higher quality standards and reduces the likelihood of errors. |

GCE's Technological Advancements in PCB Manufacturing

GCE distinguishes itself through its commitment to advanced manufacturing technologies, ensuring the production of high-quality and precise PCBs. These technologies not only enhance the performance and reliability of the circuit boards but also allow for the manufacturing of complex designs that meet stringent industry requirements.

GCE employs a range of cutting-edge technologies in their PCB manufacturing processes:

- High-Layer Count (HLC) PCB Technology:

GCE specializes in producing HLC PCBs, catering to high-performance electronic applications that require complex interconnectivity. These PCBs are characterized by their ability to accommodate a large number of layers, which greatly increases the circuit density and functionality within a compact area. - Advanced Drilling and Plating Techniques:

Precision drilling and plating processes are vital for achieving reliable interconnections between different layers of a PCB. GCE utilizes advanced drilling technologies, including laser micro-via drilling for high-density boards, and sophisticated plating methods to ensure consistent and high-quality vias and connections. - Automated Optical Inspection (AOI):

Automated Optical Inspection is implemented at multiple stages of the manufacturing process to identify defects such as shorts, opens, and misalignments. This technology enables a proactive detection and correction of issues early in the manufacturing cycle, thereby reducing waste and enhancing overall quality. - Controlled Impedance Manufacturing:

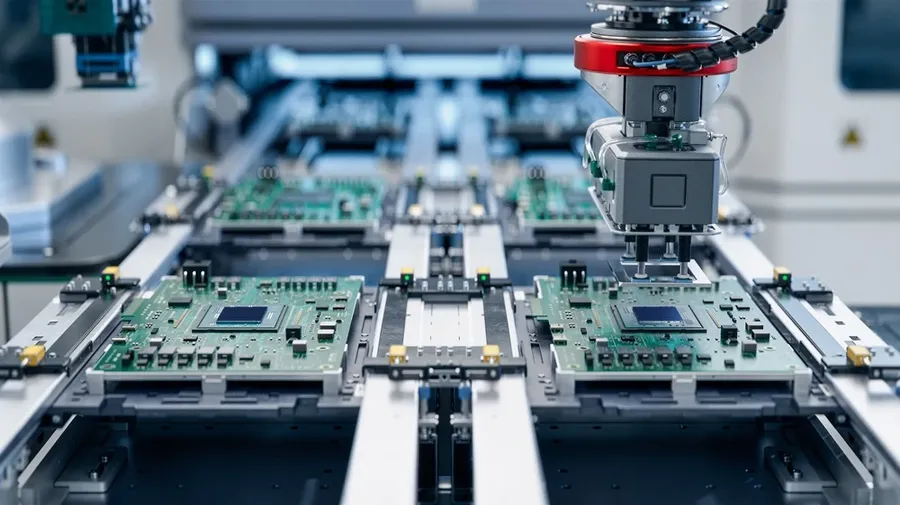

GCE offers controlled impedance PCB manufacturing, critical for high-speed applications where signal integrity is paramount. They precisely control the board's impedance characteristics to ensure signals are transmitted accurately and reliably. - Surface Mount Technology (SMT):

GCE uses automated SMT lines for precision placement of components on the PCB, optimizing efficiency and accuracy in assembly. This ensures high reliability in component attachment, especially for surface-mount devices.

These advancements are coupled with rigorous process control and quality assurance protocols to ensure that every PCB meets the exacting standards required by various industries. GCE’s technological prowess directly contributes to the reliability and performance of the final product.

Industries Served by GCE PCBs

GCE's printed circuit boards (PCBs) are integral to a wide array of industries, demonstrating the company's ability to meet diverse and demanding specifications. Their PCBs are found in everything from high-performance computing to everyday consumer electronics.

| Industry | Application | Specific Use Cases |

|---|---|---|

| High-Performance Computing | Servers, Data Centers | Motherboards for servers, complex backplanes, accelerator cards, high-speed networking equipment. |

| Personal Computing | Desktops, Laptops | Motherboards, graphic cards, peripherals interfaces, storage controllers. |

| Telecommunications | Network Infrastructure | Routers, switches, base stations, fiber optic transceivers, mobile communication devices. |

| Consumer Electronics | Smartphones, Tablets, Wearables | Main boards, camera modules, display interfaces, sensor boards, power management units. |

| Automotive | Vehicle Control Systems | Engine control units (ECUs), infotainment systems, advanced driver-assistance systems (ADAS), lighting controls. |

| Industrial Equipment | Manufacturing, Automation | Process controllers, robotics, power supplies, test and measurement equipment. |

| Medical Devices | Diagnostic, Monitoring Equipment | Imaging systems, patient monitoring devices, medical robotics, implantable devices. |

Quality Assurance and Environmental Responsibility at GCE

GCE, a leading PCB manufacturer, places significant emphasis on both stringent quality assurance and environmental responsibility. Their commitment to these principles ensures high-reliability products and sustainable manufacturing processes, vital for maintaining industry leadership and meeting customer expectations.

GCE's Quality Assurance Framework is founded on a comprehensive suite of testing and inspection protocols, combined with adherence to internationally recognized standards.

- Stringent Quality Control Measures

GCE employs rigorous quality control measures at each stage of the manufacturing process. This includes incoming material inspection, in-process checks, and final product testing, ensuring minimal defects and consistent product performance. These measures are crucial for maintaining the high reliability required in electronics applications. - Adherence to International Standards

GCE's production processes adhere to international quality standards such as ISO 9001 for quality management, ensuring that products meet global benchmarks. This commitment to quality standards guarantees product reliability and consistency, which are essential for industries like aerospace and healthcare where performance is critical. - Advanced Testing Equipment

GCE uses advanced testing equipment, such as Automated Optical Inspection (AOI) systems, flying probe testers, and in-circuit testers, to verify the integrity and performance of each board. These advanced tools enable the identification of even minor deviations or defects, ensuring that the produced PCBs meet or exceed the performance specifications required by customers.

GCE's commitment to environmental responsibility is demonstrated through their implementation of sustainable manufacturing practices, targeting waste reduction and energy efficiency.

- Sustainable Manufacturing Practices

GCE incorporates sustainable methods into their manufacturing processes, including waste minimization, efficient water management, and the reduction of hazardous materials usage. These practices aim to reduce their ecological footprint, contributing to environmental protection and sustainable development. - Compliance with Environmental Regulations

GCE adheres to environmental regulations such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals), ensuring that its products are environmentally compliant and do not contain restricted materials. This adherence not only meets regulatory requirements but also aligns with the growing global trend towards eco-friendly electronics manufacturing. - Continuous Improvement

GCE is committed to continuously improving its environmental performance by setting targets for energy reduction and waste minimization and investing in green technologies. This dedication reflects their long-term perspective on sustainable manufacturing, and ensures that their products are manufactured with minimal environmental impact.

GCE vs Other PCB Manufacturers: A Comparative Analysis

A rigorous comparison of GCE with other PCB manufacturers reveals key differentiators, particularly in technology, quality, and manufacturing scale, highlighting GCE's competitive positioning within the industry.

| Feature | GCE | Typical Competitor |

|---|---|---|

| Technology Focus | Advanced HLC, HDI, and Embedded Substrates | Primarily Standard Multilayer PCBs |

| Quality Control | Stringent testing protocols, certifications (e.g., ISO, IATF) | Standard quality measures, may vary by vendor |

| Manufacturing Scale | Large-scale facilities, high-volume capacity | Varying capacity, often smaller scale production |

| Specialization | Server, PC, and high-end electronics | Broad range, may not specialize in HLC |

| R&D Investment | Significant investment in research and development | Often less investment in advanced technology |

| Environmental Responsibility | Strong focus on sustainable practices, certifications | Varying levels of environmental commitment |

GCE consistently demonstrates a superior capability in producing high-layer count (HLC) and High-Density Interconnect (HDI) PCBs, catering to the needs of high-performance applications. GCE's commitment to quality, backed by rigorous testing and adherence to stringent industry standards, sets them apart from many competitors. Furthermore, their substantial manufacturing capacity enables them to handle large-volume orders effectively, ensuring a reliable supply for their clients.

Frequently Asked Questions About GCE PCB Manufacturer

This section addresses common questions about GCE, a prominent PCB manufacturer, focusing on their capabilities, reach, and product offerings. We aim to provide clear, concise answers to assist potential clients and partners.

- Where are GCE PCB manufacturer locations?

GCE operates multiple manufacturing facilities strategically located across the globe, including sites in China and Taiwan, and sales and support offices in other countries. These locations allow them to serve a global customer base efficiently. - What products does Gold Circuit Electronics Ltd offer?

Gold Circuit Electronics (GCE) specializes in a wide range of printed circuit boards (PCBs). These include, but are not limited to, high-layer count PCBs, rigid PCBs, flexible PCBs, and rigid-flex PCBs, catering to diverse industry needs from consumer electronics to complex telecommunications infrastructure. - What is GCE's manufacturing capacity?

GCE possesses substantial manufacturing capacity, capable of producing large volumes of PCBs while maintaining stringent quality standards. Their facilities are equipped with advanced machinery and technologies for efficient mass production and customized solutions, ensuring scalability for clients' needs. - What industries does GCE serve?

GCE's PCBs are integral to numerous industries. These include server and PC manufacturing, telecommunications, automotive, industrial control systems, and consumer electronics, which reflect the broad applicability and reliability of GCE products across various sectors. - Does GCE offer design support for PCBs?

Yes, GCE provides comprehensive design support, including design for manufacturability (DFM) analysis, signal integrity simulations, and material selection advice. This ensures that their PCBs are not only functional but also optimally designed for efficient production and long-term reliability. - What certifications does GCE hold?

GCE is committed to quality and environmental responsibility, holding certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and IATF 16949 for the automotive industry. These certifications underscore GCE's dedication to meeting global standards for quality and sustainability. - How does GCE ensure the quality of its PCBs?

GCE employs rigorous quality control measures throughout the manufacturing process. These include automated optical inspection (AOI), electrical testing, and a series of dimensional checks. This multi-faceted approach ensures every PCB meets high-quality standards, minimizing defects and maximizing reliability.

How to Partner with GCE PCB Manufacturer for Your Project

Engaging with GCE for your PCB manufacturing needs is a streamlined process designed to facilitate efficient collaboration and project success. This section outlines the practical steps to initiate a partnership with GCE, from initial contact to project launch, ensuring a clear path for customers seeking high-quality PCB solutions.

- Initial Contact

Begin by reaching out to GCE through their website, email, or phone. Provide a brief overview of your project requirements and specify the type of PCBs you are looking for. This initial contact allows GCE to assign a dedicated contact point for your project. - Needs Assessment and Consultation

Following the initial contact, a GCE representative will engage with you to conduct a detailed needs assessment. This step involves discussing the specific technical requirements of your PCBs, including layer count, material specifications, performance characteristics, and any special considerations. GCE’s expert team can advise on design optimization, material selection, and cost-effective manufacturing approaches. - Quotation and Proposal

Based on the consultation, GCE will prepare a comprehensive quotation outlining the scope of work, manufacturing timelines, cost breakdown, and project deliverables. This proposal will allow you to evaluate the feasibility of the project in terms of budget and schedule. Ensure all aspects of the quotation are clear and aligned with your requirements. - Project Initiation and Design Review

Once the quotation is approved, the project officially begins. GCE will initiate a design review process to check and optimize your PCB design for manufacturability. This involves verifying that your design meets GCE’s manufacturing capabilities, identifying any potential issues, and suggesting improvements to ensure the highest quality product. - Manufacturing and Production

After design finalization, GCE will proceed to the manufacturing phase, utilizing their advanced production facilities and stringent quality control measures. GCE will keep you informed on the production progress and address any challenges that may arise, ensuring that manufacturing is executed as planned. - Delivery and Support

Upon completion of manufacturing, GCE delivers the PCBs and provides necessary support and documentation. This includes shipping the PCBs and ensuring they arrive according to the agreed timelines and specifications. GCE may also provide post-delivery support, addressing any technical queries or feedback.

GCE stands out as a top-tier PCB manufacturer, offering cutting-edge technology, a commitment to quality, and a global presence. Their decades of experience make them a reliable partner for a wide range of industries seeking high-performance PCBs. Whether you are designing for servers, PCs, or other complex electronics, GCE, a leading global PCB manufacturer, has the expertise and resources to deliver on your most demanding projects. Partnering with GCE can ensure that your projects are backed by the best in PCB technology.

AnyPCBA

AnyPCBA