Get Instant Flex PCB Online Quote: A Comprehensive Guide

In today's fast-paced electronics industry, flexibility isn't just a buzzword—it's a necessity. Flexible printed circuit boards (PCBs) are revolutionizing product design, and getting a quick, accurate quote online is crucial. This article will guide you through the process of obtaining a flex PCB online quote, highlighting the key factors that impact pricing and delivery, ensuring you are well-equipped to make informed decisions for your next project. We'll explore various online quoting platforms and provide actionable insights to streamline your design and production process, offering you a competitive edge using [flex pcb online quote].

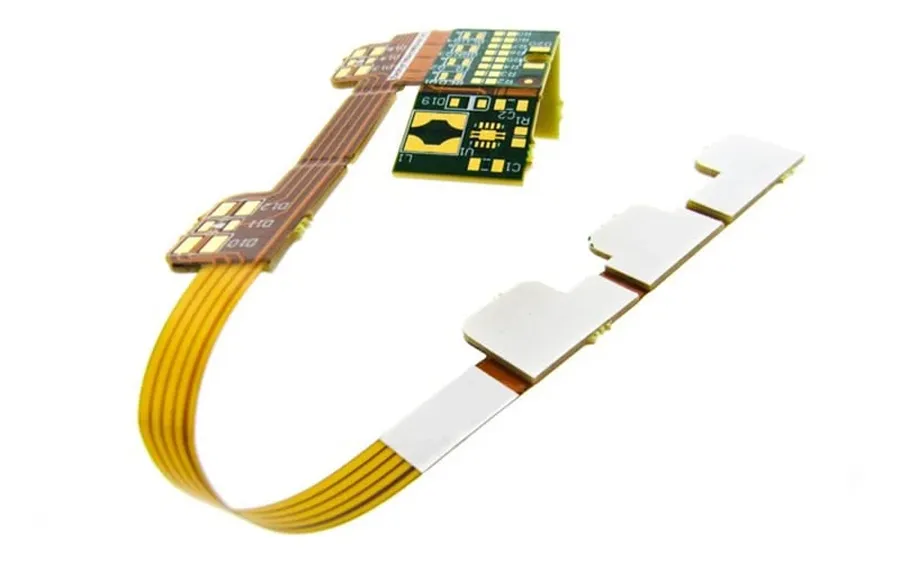

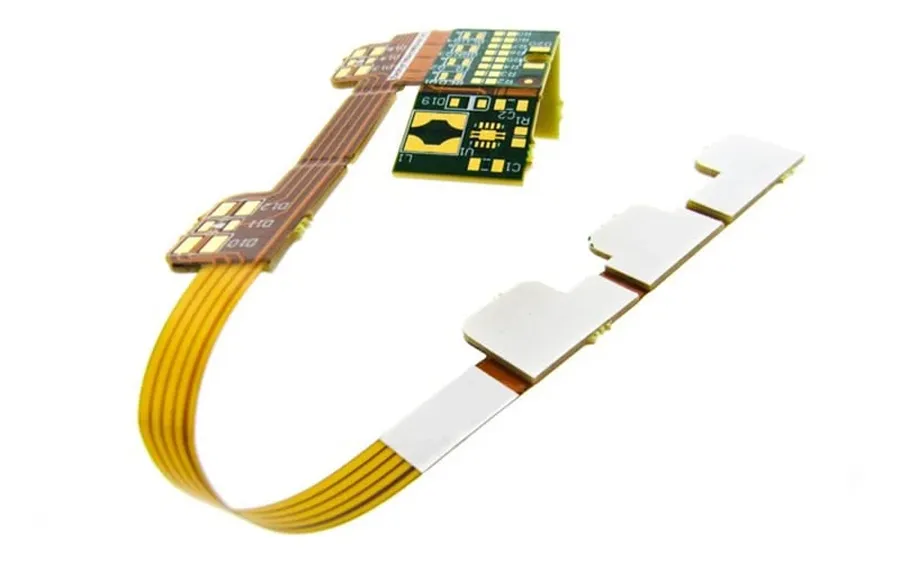

Understanding Flex PCB Basics

Flexible PCBs, or flex PCBs, are circuit boards constructed on a flexible substrate, offering significant advantages over traditional rigid PCBs. Their inherent flexibility enables them to conform to various shapes and spaces, optimizing designs and reducing overall system size while enhancing reliability due to fewer interconnects. Common applications span consumer electronics, automotive, and aerospace, where space constraints and dynamic movement are critical design considerations.

Flex PCBs are primarily categorized into three types based on their conductive layer structure:

- Single-Sided Flex PCBs

These PCBs have a conductive layer on only one side of the flexible substrate, making them suitable for basic circuits with simple interconnections. - Double-Sided Flex PCBs

Featuring conductive layers on both sides of the substrate, these PCBs enable more complex circuit designs and component placements via plated through-holes or vias. - Multilayer Flex PCBs

These PCBs consist of three or more conductive layers separated by dielectric layers, offering the highest level of circuit density and design flexibility for advanced applications.

Key Factors Influencing Flex PCB Online Quote

Obtaining an accurate online quote for flexible printed circuit boards (PCBs) requires a thorough understanding of the various factors that influence the final price. These factors encompass not only the physical characteristics of the PCB but also the complexity of the design and the manufacturing processes involved. A detailed consideration of these elements ensures cost-effective and efficient production.

| Factor | Description | Impact on Quote |

|---|---|---|

| PCB Size | The overall dimensions of the flex PCB. | Larger PCBs generally require more material and processing time, thus increasing the cost. |

| Material Type | The substrate material used (e.g., polyimide, polyester). | Polyimide, known for its superior thermal and mechanical properties, is typically more expensive than polyester. The specific material and the thickness will affect the final price. |

| Layer Count | The number of conductive layers in the PCB (single-sided, double-sided, multilayer). | Multilayer PCBs involve more complex fabrication processes, leading to higher costs. |

| Surface Finish | The type of coating applied to the copper traces (e.g., ENIG, HASL). | Surface finish affects the price of a flex PCB; gold plating (ENIG) can increase cost compared to HASL. The material required for the finish and the complexity of the process impact costs. |

| Copper Thickness | The thickness of the copper layer measured in ounces (oz). | Thicker copper layers are more expensive due to greater material usage and require more complex processing. |

| Trace Width and Spacing | The width and spacing of conductive traces. | Extremely fine traces and spaces may demand more precise manufacturing methods, and increase the cost of manufacturing. |

| Via Types | Type of vias used (through-hole, blind, buried). | Blind and buried vias are more complex to create, increasing costs. Through-hole vias are typically simpler and less expensive to manufacture. |

| Panelization | The arrangement of multiple PCBs on a single manufacturing panel. | Panelization can reduce costs for large-volume orders by optimizing material usage, but also increase costs depending on the process and spacing needed. |

| Design Complexity | The intricacy of the PCB layout, including the number of components and routing density. | Highly complex designs require more time and care in manufacturing, impacting the quote. |

| Quantity | The number of PCBs being ordered. | Unit costs generally decrease with larger quantities due to economies of scale. |

| Manufacturing Tolerances | Tighter manufacturing tolerances. | Requiring very tight tolerances or unique manufacturing parameters can increase costs. |

Design for Manufacturing (DFM) is a crucial aspect to consider when aiming to reduce costs. Following DFM guidelines can lead to simpler, more efficient manufacturing, resulting in lower costs for your flexible PCB. This can include optimizing via types, standardizing trace widths, avoiding excessively fine pitch, panelization and ensuring proper spacing to reduce the chance of manufacturing errors. Always review the manufacturer's DFM guidelines before finalizing your PCB design.

Navigating Online Flex PCB Quote Platforms

Online platforms have revolutionized the process of obtaining quotes for flexible printed circuit boards (PCBs). These platforms offer a convenient and efficient way to solicit bids from multiple manufacturers, compare prices, and manage the fabrication process of your flex PCB design. Successfully navigating these platforms requires a clear understanding of their functionalities and how to leverage them effectively to secure the best possible quote.

Key aspects of using online flex PCB quote platforms include:

- Gerber File Upload

Gerber files are the standard format for PCB designs. These files contain all the necessary information about the PCB layers, pads, traces, and other design elements. Ensure your Gerber files are accurate, complete and error free before upload. Many platforms offer a Gerber viewer to confirm upload validity. - Specification Selection

Accurately specify your flex PCB requirements, including: Material (e.g., Polyimide, Polyester), Layer Count (single-sided, double-sided, multi-layer), Board dimensions, copper thickness, surface finish (e.g., ENIG, HASL), Minimum trace width and spacing, Via type and size, Impedance control requirements and any other unique features. Incomplete or incorrect specifications can result in inaccurate quotes. - Quote Comparison

Carefully compare quotes from different manufacturers, paying attention to: Price (unit price and total cost), Turnaround time, Shipping cost and delivery timeframe, Manufacturing capabilities, and any additional services offered. A focus on more than just price will ensure that you are getting the right product for your design. - Communication and Support

Prior to ordering your flex PCBs, assess the quality of customer service provided by the platform. Determine their responsiveness to your queries and the quality of their technical support. Effective communication is key to resolving any issues that may arise during the process.

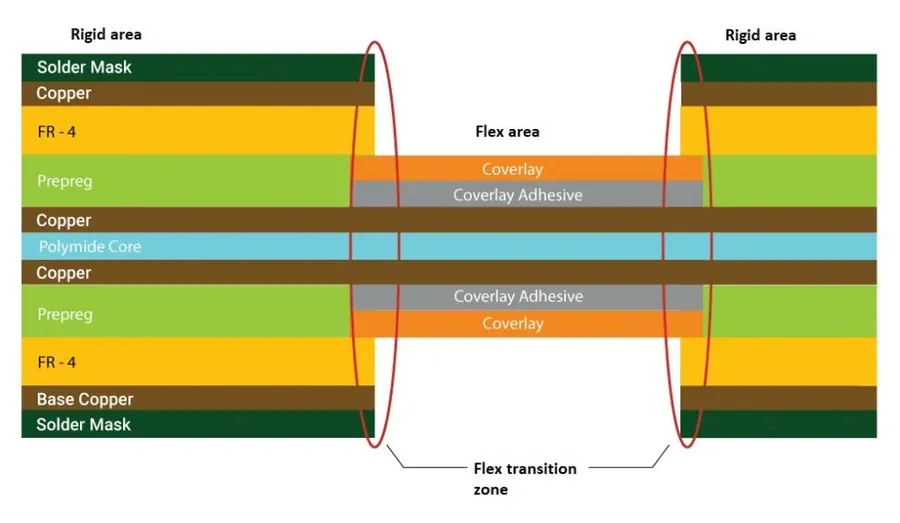

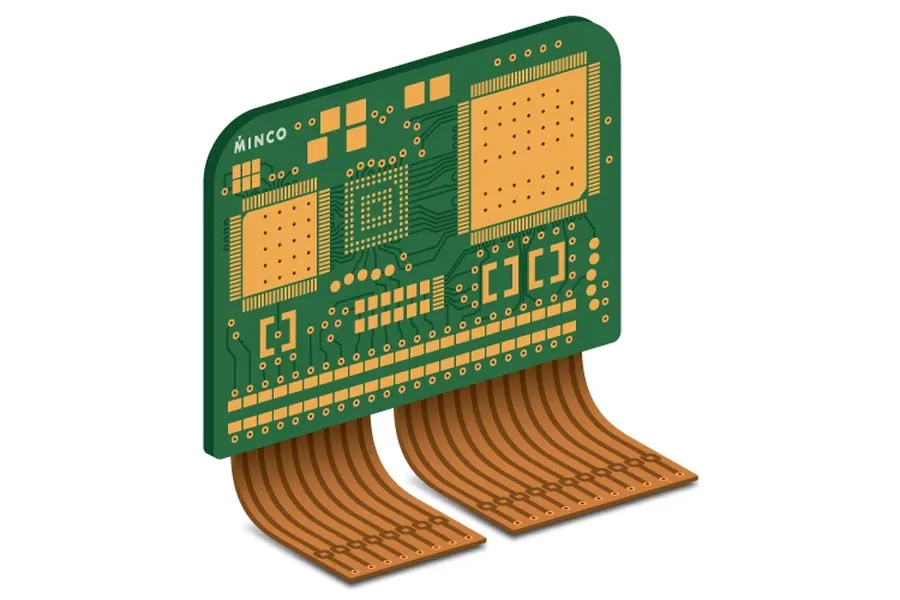

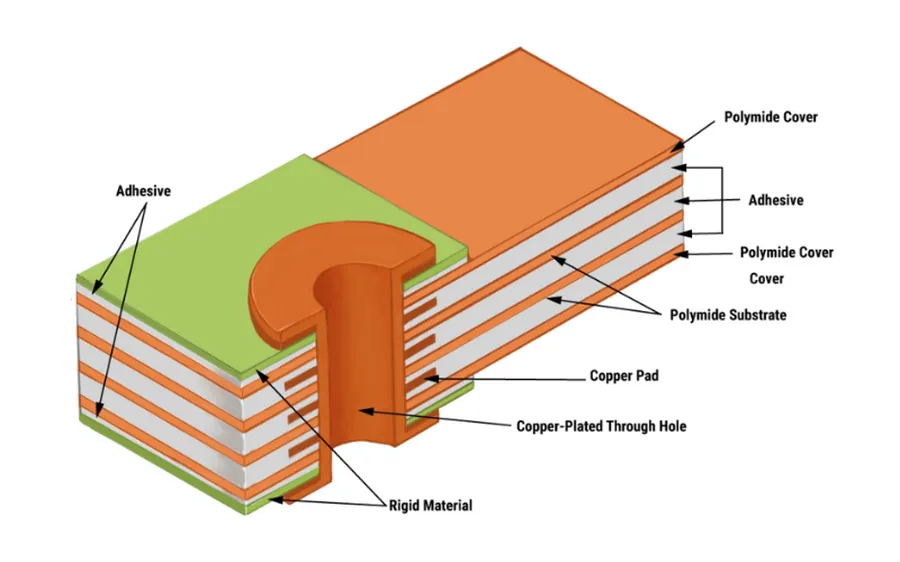

Rigid-Flex PCB Considerations

Rigid-flex PCBs represent a sophisticated evolution in circuit board technology, integrating the benefits of both rigid and flexible substrates into a single, cohesive design. This hybrid approach allows for complex three-dimensional packaging and interconnectivity, addressing challenges that neither rigid nor flexible PCBs can solve independently. Obtaining a [flex pcb online quote] for rigid-flex PCBs requires an understanding of their unique design and manufacturing considerations.

The core concept involves rigid sections, typically fabricated from materials like FR4, providing structural support and mounting surfaces for components, and flexible sections constructed from polyimide or similar materials, enabling dynamic bending and folding to fit complex enclosures. This integration allows for a reduction in the need for connectors and cables, leading to increased reliability and reduced assembly costs. The ability to incorporate both rigid and flexible elements within a single board makes rigid-flex PCBs ideal for applications where space, weight, and mechanical stress are primary design concerns.

| Feature | Rigid PCB | Flexible PCB | Rigid-Flex PCB |

|---|---|---|---|

| Flexibility | Rigid | Highly Flexible | Hybrid (Rigid and Flexible) |

| 3D Packaging | Limited | Good | Excellent |

| Interconnect | Connectors and Cables | FPC Connectors | Integrated |

| Cost | Lower | Moderate | Higher |

| Application | General Electronics | Wearables, Displays | Aerospace, Medical, High-Performance |

When seeking a [flex pcb online quote] for rigid-flex PCBs, there are specific parameters to consider in addition to those for flexible PCBs. These include the number of rigid and flexible layers, the thickness of each layer, the type of material for both rigid and flexible sections, the transition zone design, and any specific requirements for connectors or reinforcements. Furthermore, understanding the design for manufacturing (DFM) guidelines for rigid-flex PCBs is critical. DFM helps ensure the manufacturability of the design, including considerations for the bend radius and stress points in the flexible area. Early engagement with the manufacturer is highly advisable for complex rigid-flex designs to optimize the design for cost and manufacturability.

Material Selection Guide for Flex PCBs

The selection of materials for flexible PCBs (Flex PCBs) is paramount, directly impacting cost, flexibility, and overall performance. This section provides an in-depth analysis of commonly used materials like polyimide and polyester, along with their unique properties and applications. Optimal material selection is critical for a successful and cost-effective design when considering a flex pcb online quote.

| Material | Properties | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|---|

| Polyimide (PI) | High temperature resistance, excellent chemical resistance, superior mechanical strength, good electrical properties, and excellent dielectric properties. | High-temperature stability, excellent flexibility, reliable performance in harsh environments, long-term reliability. | Higher material cost compared to polyester, can be more difficult to process. | Aerospace, medical devices, high-reliability electronics, automotive, and applications requiring high temperature endurance. |

| Polyester (PET) | Good flexibility, moderate temperature resistance, cost-effective, and good dielectric properties. | Lower material cost, good for less demanding applications, readily available, and easy to process. | Limited temperature range, less durable, and not suitable for high-stress applications. | Consumer electronics, disposable medical devices, and applications that do not require high-temperature resistance. |

| Liquid Crystal Polymer (LCP) | Exceptional dimensional stability, high-temperature resistance, excellent electrical performance, low moisture absorption. | Superior electrical properties, high-temperature performance, good chemical resistance, allows for fine line etching. | Higher cost, specialized processing may be required, availability may be limited. | High-frequency applications, advanced medical devices, complex wearable devices, and antennas. |

| Modified Epoxy | Good mechanical strength, moderate flexibility, cost-effective. | Lower cost, good adhesion, and suitable for applications requiring medium flexibility. | Lower temperature resistance than polyimide, may be brittle with extensive bending. | Simple flex circuits, low-cost applications, LED lighting, and flexible sensors. |

Design Tips for Cost-Effective Flex PCB Manufacturing

Optimizing your flex PCB design is crucial for minimizing manufacturing costs and ensuring a smooth production process. By adhering to specific design guidelines and best practices, you can significantly reduce expenses associated with flex PCB fabrication, particularly when seeking a competitive flex pcb online quote. This section provides actionable insights into design considerations that contribute to more affordable and efficient flex PCB manufacturing.

| Design Aspect | Recommendation | Impact on Cost |

|---|---|---|

| Via Types | Use through-hole vias where possible; avoid microvias unless absolutely necessary. | Microvias add complexity and cost. Through-hole vias are simpler and less expensive to fabricate. |

| Trace Width and Spacing | Maintain standard trace widths and spacing that meet design requirements, increase trace width where possible. | Smaller trace widths and spacing require higher precision and increase the probability of manufacturing defects. Standardized dimensions are more cost-effective. |

| Panelization | Panelize your PCB designs efficiently, aiming for maximum utilization of the manufacturing panel. | Effective panelization reduces material waste and manufacturing time, lowering overall production costs. |

| Bend Radius | Avoid sharp bends; ensure a minimum bend radius to prevent damage to traces and vias. | Excessive bending can cause stress to the board which can lead to trace cracking and failure, increasing cost. |

| Material Usage | Minimize non-essential features and cutouts to reduce material usage. | Reduced material usage directly translates to lower costs. |

| Layer Count | Optimize the number of layers to the minimum needed for your design. Consider design tradeoffs and carefully evaluate requirements. | Reducing layers reduces manufacturing process complexity and material costs. |

| Component Placement | Orient components to accommodate easy assembly and avoid manual hand placement. | Manual assembly can be costly and time consuming, making automated assembly an advantage |

Frequently Asked Questions About Flex PCB Online Quotes

This section addresses common questions and concerns regarding obtaining online quotes for flexible PCBs (flex PCBs), aiming to provide clarity and practical guidance for users seeking this service.

- What is a Gerber file, and why is it needed for a flex PCB online quote?

A Gerber file is a standard file format used in the PCB manufacturing industry to represent the layers of a printed circuit board design. It is essential for obtaining an accurate quote because it provides the manufacturing details such as copper traces, pads, vias, and board outline. Without it, manufacturers cannot assess the complexity and material requirements of your design, leading to inaccurate quotes. - How do I handle complex flex PCB designs when requesting an online quote?

Complex designs should be well-documented with clear layer stack-ups, specific material requirements, and critical impedance considerations detailed in accompanying documentation. Many online quoting platforms allow you to upload additional documents, such as detailed fabrication notes, assembly drawings, and 3D models. Providing clear and complete documentation helps manufacturers understand your needs and ensures accurate pricing and minimizes potential for errors during manufacturing. - What is the typical lead time for receiving a flex PCB online quote?

The lead time for receiving a quote can vary depending on the complexity of the design and the platform's workload. Simple, standard designs may receive quotes within a few hours, while more complex designs or those requiring engineering review might take 1-2 business days. Some platforms offer instant quoting for standard designs. Check with each service for specific lead times. It’s always recommended to check the quote lead times before uploading your gerber files to avoid unnecessary delays. - What kind of technical support is typically offered by flex PCB manufacturers during the design and production process?

Reputable flex PCB manufacturers typically offer a range of support services. This includes design rule checking (DRC) to identify potential manufacturing issues, design for manufacturability (DFM) feedback, material selection guidance, and support during the production process. Some also offer engineering consultations to help optimize your design for both performance and cost. Always enquire about the availability and scope of technical support, it can be a significant value add especially for new customers and complex designs. - How can I ensure the accuracy of my flex PCB online quote?

To ensure accuracy, provide complete and accurate design files and specifications. Double-check your Gerber files and fabrication notes for any discrepancies and clearly state all material requirements and any specific tolerances. It is also good practice to compare quotes from several reputable manufacturers. If a quote seems too good to be true, it may indicate a compromise in quality or the quote is not accurately based on the requirements. Detailed and accurate design files and specifications are essential. - Are there any hidden costs associated with flex PCB online quotes that I should be aware of?

Potential hidden costs can include tooling charges, shipping fees, and costs for specific finishing options or testing requirements. Some manufacturers may also charge extra for small order quantities or expedited production. Before confirming your order, always clarify these potential extra costs and check the overall terms and conditions to ensure transparency and avoid surprises. It's always advised to ask for a breakdown of the quote to avoid any confusion. - What are the common causes of delays in receiving my flex PCB order?

Delays can be caused by various factors, including insufficient design documentation, unclear design specifications or complexity which requires iterative design process, issues with the Gerber files which may require additional communication between the manufacturer and the customer, material availability, or production bottlenecks. To minimize delays, always ensure that your design files are complete, clear, and adhere to the manufacturer's guidelines, and be proactive in resolving any queries from the manufacturer.

Comparing Flex PCB Manufacturers and Their Services

Selecting the right flex PCB manufacturer is crucial for ensuring the quality, reliability, and cost-effectiveness of your project. This section provides a guide to help users navigate the landscape of flex PCB manufacturers, focusing on key factors that should influence the selection process. Evaluating capabilities, turnaround times, certifications, and support services will enable users to choose a manufacturer that aligns with their specific requirements.

| Factor | Description | Importance |

|---|---|---|

| Manufacturing Capabilities | Range of technologies, materials, and layer counts the manufacturer can handle. | High: Directly impacts the feasibility of producing the required flex PCB. |

| Turnaround Time | The time it takes from design submission to delivery of the finished PCBs. | Medium to High: Critical for projects with tight schedules. |

| Quality Certifications | Standards such as ISO 9001, ISO 13485, and UL certifications demonstrate adherence to quality practices. | High: Indicates the manufacturer's commitment to consistent quality. |

| Support Services | Level of technical assistance provided during design, manufacturing, and assembly processes. | Medium to High: Essential for resolving issues and ensuring a smooth process. |

| Quoting Process | Ease of obtaining a quote, transparency of pricing, and flexibility of order quantities. | Medium: Affects the overall cost and project management. |

| Sample Availability | The ability to receive samples for testing and quality verification before placing a large order. | Medium: Reduces the risk of product quality issues. |

| Minimum Order Quantity (MOQ) | The smallest number of PCBs the manufacturer will produce per order. | Medium: Needs to be aligned with your project's volume. |

| Geographic Location | Location of the manufacturer and shipping costs. | Low to Medium: Can impact lead times and total project costs. |

The Future of Flexible PCBs and Their Impact

The flexible printed circuit board (flex PCB) industry is on a trajectory of continuous innovation, driven by the demand for smaller, more adaptable, and higher-performance electronic devices. These advancements not only affect the technical capabilities of electronics but also influence the accessibility and cost-effectiveness of flex PCBs, particularly in the context of online quoting and manufacturing.

Future trends in flex PCB technology indicate a move towards more complex multilayer designs, finer trace widths, and increased integration with other components. Advanced materials with enhanced thermal and electrical properties are also under development. These innovations will expand the applicability of flex PCBs in industries such as aerospace, medical, and automotive, where reliability and performance are paramount.

The evolution of online quoting platforms will further streamline the design and manufacturing process. Expect to see more sophisticated tools capable of handling increasingly intricate PCB designs, providing more accurate and faster quotes, and offering greater transparency in the manufacturing process. This will likely lead to reduced costs and shorter lead times, making flex PCBs accessible to a broader range of projects and applications, and this will allow users to better plan future designs when they are looking for a [flex pcb online quote].

The convergence of artificial intelligence (AI) and machine learning (ML) with flex PCB manufacturing is also on the horizon. These technologies will optimize processes, predict potential manufacturing issues, and refine material selection, ultimately leading to higher-quality PCBs and reduced waste. This shift will impact the way designers, engineers, and manufacturers interact, resulting in more collaborative and streamlined workflows.

- Miniaturization

Continued reduction in size and weight to fit in increasingly compact devices. - Advanced Materials

The development of new materials with enhanced performance characteristics, such as better thermal and electrical conductivity. - AI-Driven Manufacturing

Integration of AI and ML to optimize processes and improve yields in manufacturing. - Enhanced Online Platforms

Advanced online tools for design and quoting with improved accuracy and efficiency.

Obtaining a [flex pcb online quote] is the first step in bringing your innovative designs to life. By understanding the nuances of flexible PCB manufacturing, utilizing online platforms effectively, and optimizing your designs for cost-efficiency, you can leverage flexible PCB technology to enhance your product's functionality and market appeal. With continual advancements in material and manufacturing technologies, flexible PCBs are not just a trend but a staple in next-generation electronics, making it essential to be well-informed and ready to adapt. As you move forward with your projects, keep in mind the core principles of design and cost-optimization that we have covered in this guide.

AnyPCBA

AnyPCBA