Get Instant PCB Fabrication Online Quote: A Comprehensive Guide

In today's fast-paced electronics industry, getting a quick and accurate [pcb fabrication online quote] is crucial for project planning and budgeting. Whether you're a hobbyist or a seasoned engineer, understanding the factors that influence PCB manufacturing costs and navigating the online quoting process is essential for turning your designs into reality. This guide will walk you through the process, helping you secure the best value for your PCB fabrication needs.

Understanding the Basics of PCB Fabrication Quotes

Obtaining an accurate PCB fabrication online quote requires understanding the fundamental factors influencing the final price. These factors encompass material selection, the number of layers, board dimensions, and overall design complexity. This section provides a foundational overview of these elements and defines commonly used industry terms encountered during the quotation process.

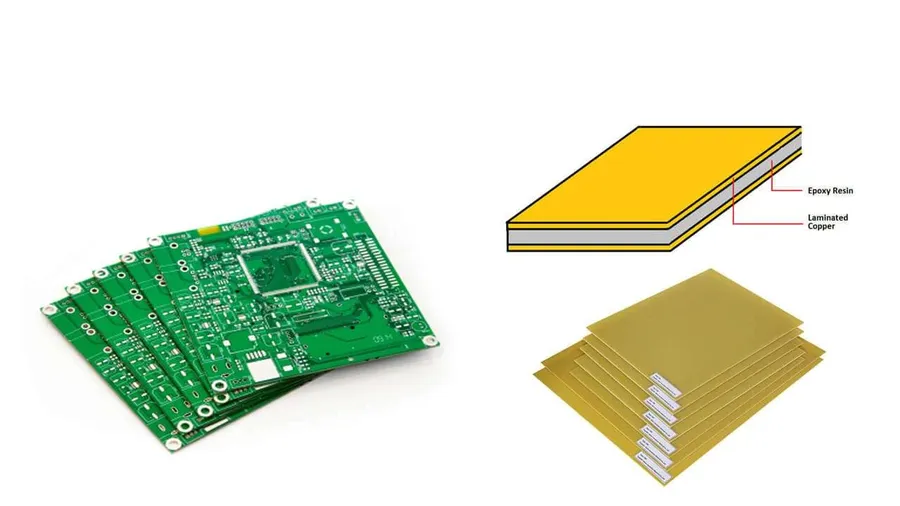

- Material Type

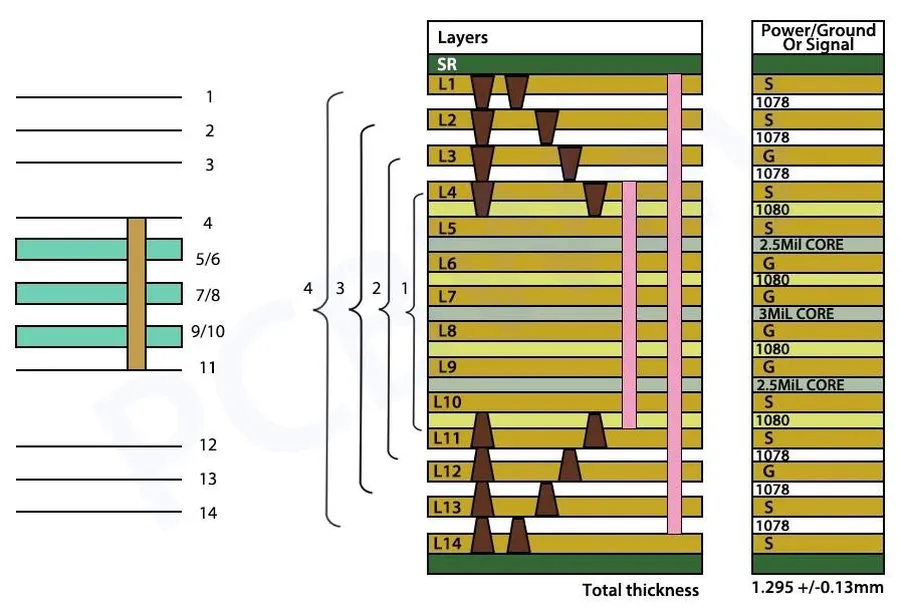

The substrate material, typically FR-4 but can also include materials like aluminum or polyimide, significantly impacts cost. FR-4 is a common and cost-effective option for many applications, while other materials with enhanced thermal or electrical properties are more expensive. - Number of Layers

The number of conductive layers in your PCB directly correlates with the fabrication complexity and cost. Single-layer boards are the least expensive, while multi-layer boards with complex routing require more intricate processes and increased material usage. - Board Dimensions

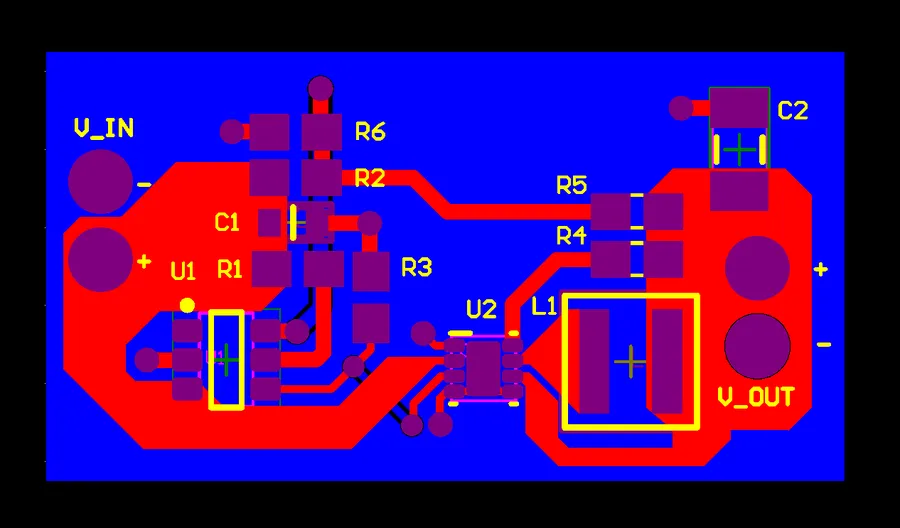

The physical size of the PCB affects the material usage and processing time, directly impacting the final price. Larger boards will naturally cost more than smaller ones for the same design. - Design Complexity

The intricacy of the circuit layout, including the density of components, the width of traces, and the spacing between features, influences manufacturing complexity. High-density designs require more precision and may increase costs. - Common Industry Terms

Understanding terms such as ‘Gerber files’, ‘via’, ‘solder mask’, ‘silk screen’ and ‘copper weight’ is crucial when seeking a PCB quote. These terms describe different aspects of the PCB design and manufacturing process.

Key Factors Influencing PCB Fabrication Costs

The cost of PCB fabrication, reflected in a PCB fabrication online quote, is determined by a multitude of factors that relate to the design, materials, and manufacturing processes. Understanding these factors is crucial for optimizing costs without compromising the quality or performance of your printed circuit board.

| Factor | Description | Impact on Cost |

|---|---|---|

| Number of Layers | The count of conductive layers in the PCB stack-up. More layers increase complexity and manufacturing time. | Higher layer count leads to significantly increased cost due to material, fabrication complexity and processing time. |

| Material Choice | Type of substrate material (e.g., FR-4, Aluminum, Rogers). Each material has unique electrical, thermal, and mechanical properties. | Advanced materials (e.g. Rogers) can be significantly more expensive than standard FR-4 due to higher performance characteristics. |

| Board Dimensions | The overall size of the PCB. Larger boards require more material and processing time. | Larger PCB dimensions directly correlate with increased costs due to material usage, processing and handling. |

| Copper Thickness | Thickness of the copper layers on the PCB. Thicker copper is needed for high-current applications. | Thicker copper layers increase material costs, manufacturing complexity and cost. |

| Surface Finish | Type of finish applied to the copper pads (e.g., HASL, ENIG, Immersion Silver). Affects solderability and environmental resistance. | Advanced finishes like ENIG and Immersion Silver have higher material costs and processing complexity compared to HASL. |

| Solder Mask | The colored protective layer applied over the copper traces. | Specific colors or complex mask patterns can increase processing and cost. |

| Via Types | The type of vias used, including through-hole, blind, or buried vias. Complexity affects manufacturing time and precision requirements. | Blind and buried vias require more precise manufacturing techniques, increasing costs. |

| Minimum Trace Width and Spacing | The smallest copper trace and space that the manufacturer can reliably produce. Finer lines demand more precision. | Finer traces and spaces increase the complexity of the manufacturing process, leading to higher costs. |

| Panelization | Number of boards on a production panel. How boards are arrayed on the panel can affect the efficiency of the manufacturing process | Complex panelization with irregular shaped boards may increase costs. |

| Quantity | The total number of PCBs required. Volume discounts typically apply. | Higher quantity orders reduce the cost per unit due to economies of scale. |

How to Prepare Your Files for an Accurate Quote

Accurate PCB fabrication quotes hinge on the quality of your submitted design files. Properly prepared Gerber files, along with necessary supporting documentation, are critical for avoiding delays and ensuring precise cost estimations. This section will guide you through the essential steps to prepare your files for a successful online quote.

The primary file format for PCB fabrication is the Gerber format. Gerber files are a set of vector files containing all the necessary information to define each layer of your PCB design, including copper traces, pads, vias, silkscreen, and solder mask. In addition to Gerbers, some manufacturers may also require drill files (Excellon format) and a netlist for verification.

- Gerber File Preparation

Ensure each layer of your PCB design is exported as a separate Gerber file. This typically includes copper layers (top, bottom, and internal layers), solder mask layers (top and bottom), silkscreen layers (top and bottom), and board outline. Verify that each file is properly named for its corresponding layer. Use RS-274X format for Gerber files as it is the industry standard and includes aperture information. - Drill File Preparation

Drill files specify the locations and sizes of all holes on your board. These files should be exported in Excellon format, which is specifically designed for numerical control drilling machines. Include a drill tool list with the diameters of each drill bit used. - Additional Documentation

Provide a README file that includes important information, such as units (mm or inches), number of layers, board thickness, copper weight, surface finish, and materials. Including a netlist will enable verification of the design against the schematic. - Verify Accuracy

Use a Gerber viewer to ensure all layers are aligned and to detect errors prior to submission. If the files contain errors, the quote will be inaccurate, or fabrication may fail

| File Type | Description | Format | Required for Quote |

|---|---|---|---|

| Gerber Files | Defines each PCB layer (copper, solder mask, silkscreen, outline) | RS-274X | Yes |

| Drill Files | Specifies hole locations and sizes | Excellon | Yes |

| Netlist | Describes the connectivity of the design | Various | Recommended |

| README file | Details board parameters like units, layers, thickness, etc. | Text | Recommended |

Navigating Online PCB Quote Calculators

Online PCB quote calculators are essential tools for obtaining rapid cost estimations for PCB fabrication. These calculators allow users to input their design specifications and receive an instant price quote. Understanding how to use these tools effectively is crucial for accurate budgeting and efficient project planning.

These calculators typically operate by translating your design parameters into manufacturing costs. Factors such as board size, layer count, material type, and complexity directly influence the calculated price. The accuracy of the quote is entirely dependent on the precision of the input parameters you provide and the sophistication of the calculation engine of the online tool.

- Common Input Parameters

Most calculators require details like PCB dimensions, number of layers, material type (e.g., FR-4, aluminum), copper thickness, surface finish (e.g., HASL, ENIG), solder mask color, and quantity. Ensure these specifications match your project requirements precisely. - Information Interpretation

The output includes the unit price per board and the total cost. Pay attention to the cost breakdown, noting additional fees such as tooling, setup, and shipping costs. Some platforms might show the lead time which is the manufacturing time, and shipping time separately, which is valuable for project timeline planning. Be careful to understand the full price of a PCB order. - Platform Differences

Different PCB manufacturers may use slightly different algorithms and have varying production costs. This can lead to discrepancies in quotes from different platforms. Always compare quotes from several manufacturers and check their reputation and customer service before choosing one. - Accuracy Limitations

Online calculators are generally accurate for standard PCB specifications but may not fully accommodate complex designs or special requirements. For intricate designs, you may need to contact the manufacturer directly for a custom quotation.

Choosing the Right PCB Manufacturer for Your Project

Selecting the appropriate PCB manufacturer is critical to the success of your project, as it directly influences the quality, cost, and turnaround time of your printed circuit boards. Beyond simply obtaining a pcb fabrication online quote, the right partner will align with your specific needs, from prototype to large-scale production.

- Prototyping Needs

If your project is in the prototyping phase, prioritize manufacturers that offer flexible order quantities, quick turnaround times, and cost-effective options for small batches. Some manufacturers specialize in rapid prototyping services which may be beneficial. - High-Volume Manufacturing Capabilities

For projects that require mass production, select manufacturers with high-capacity facilities, robust quality control processes, and the ability to handle large-volume orders. Look for options like automated assembly lines, and capacity to provide consistent quality at scale. - Lead Times

Consider the required lead time for your project. Some manufacturers can provide expedited services for faster turnaround times, but this typically comes at a premium. Check the manufacturer's standard lead times and if they align with your project timelines. - Certifications and Quality Standards

Ensure the manufacturer adheres to relevant industry certifications and quality standards (e.g., ISO 9001, UL). Certifications provide assurance of their manufacturing processes and the quality of the products. Compliance to specific standards may be mandatory for some applications. - Technology and Capabilities

Assess if the manufacturer possesses the technology and capabilities required for your PCB design requirements. This includes multilayer boards, high-density interconnect (HDI) designs, specific materials, surface finishes, and other specialized processes. Verify their equipment can meet the unique needs of your design. - Customer Support and Communication

Evaluate the manufacturer's customer support. Prompt, clear, and effective communication channels are essential to avoid misunderstandings and handle any issues that might arise. Check customer reviews and testimonials as well.

Comparing PCB Fabrication Online Quotes: What to Look For

Effectively comparing multiple PCB fabrication online quotes is crucial for securing the best value without compromising quality. A comprehensive comparison goes beyond just price, encompassing service, lead times, material quality, and potential hidden costs that could impact the overall budget.

| Factor | Description | Considerations |

|---|---|---|

| Price | The base cost of manufacturing the PCBs based on the specifications provided. | Compare the total cost, not just per piece, and check for volume discounts. Be wary of exceptionally low prices, which may indicate lower quality or hidden fees. |

| Service | The manufacturer's responsiveness, communication, and the level of customer support. | Look for clear communication channels, prompt responses to inquiries, and access to technical support if needed. A manufacturer that's responsive and helpful can save valuable time and reduce potential errors. |

| Lead Time | The time it takes from the order placement to the shipment of the completed PCBs. | Consider your project timeline and ensure the lead time aligns with your project schedule. Check if expedited options are available and note their cost implications. |

| Quality | The standards of materials, manufacturing processes, and adherence to specifications. | Review the manufacturer's certifications and testimonials, and if possible, request sample boards to verify the quality. Check for compliance with industry standards. |

| Hidden Costs | Additional fees such as setup charges, tooling costs, expedited shipping, or amendment fees. | Ask for a detailed breakdown of all potential costs. Clarify any fees upfront to avoid surprises. Verify what the manufacturer charges for design rule checks, and revisions. |

Frequently Asked Questions About PCB Fabrication Online Quotes

This section addresses common questions regarding PCB fabrication online quotes, providing clarity on various aspects from minimum order quantities to DFM checks. Understanding these frequently asked questions will streamline the process of obtaining accurate quotes and choosing the right manufacturer for your PCB fabrication needs.

- What are the typical minimum order quantities (MOQ) for PCB fabrication?

Minimum order quantities vary significantly among PCB manufacturers. Some may offer prototyping services with no MOQ, while others might have minimums ranging from a few units to hundreds or even thousands. The MOQ often depends on the complexity of the design, material, and manufacturing processes involved. It is recommended to always clarify the MOQ with the manufacturer prior to obtaining a PCB fabrication online quote. Larger MOQs often lead to lower per-unit costs. - What are typical turnaround times for PCB fabrication?

Turnaround times for PCB fabrication vary widely depending on the complexity of the board, the manufacturer's production schedule, and the chosen shipping method. Standard lead times can range from a few days for simple prototypes to several weeks for more complex, high-volume orders. Expedited services are often available, but these come at an additional cost. Before obtaining a PCB fabrication online quote, understand the manufacturer's stated lead times for your design parameters. - What file formats are required for obtaining a PCB fabrication online quote?

The standard file format required for obtaining a PCB fabrication quote is the Gerber file format, which is an industry standard. Additionally, most manufacturers also accept drill files in Excellon format, and a bill of materials (BOM) for assembled boards. For complex or multi-layer boards, it is often helpful to include a netlist and any CAD files generated by your PCB design software. Always confirm the specific file requirements with the manufacturer before submitting your files for a PCB fabrication online quote to avoid any delays. - What payment methods are typically accepted by PCB manufacturers?

Most PCB manufacturers offer various payment options for fabrication services, including bank transfers, credit/debit cards, and online payment platforms (like PayPal or Alipay). For large volume orders, or ongoing projects, some manufacturers may offer a credit account. Always verify the acceptable payment methods with your chosen PCB manufacturer before requesting a fabrication online quote. Some vendors may also offer discounted rates for payment in their local currency. - What is 'Design for Manufacturability' (DFM) and how does it affect a PCB fabrication online quote?

Design for Manufacturability (DFM) refers to the design practices that ensure a PCB can be efficiently and cost-effectively manufactured. Many PCB manufacturers offer free DFM checks that review your design files for common issues such as spacing, trace width, via size, and layer stack-up errors. Addressing these issues prior to manufacturing can help avoid costly mistakes and rework, ultimately affecting the accuracy of your PCB fabrication online quote. Always ask the manufacturer to conduct a DFM review before finalizing your quote. - What should I do if I need to make changes after receiving a quote?

If you need to make changes after receiving a PCB fabrication online quote, immediately notify your chosen manufacturer. Any change to the design or the materials requested may require a new quote, as this affects the cost of production. This may involve re-evaluation of the design and updated files to reflect the changes. Failing to update the design may lead to delays, additional costs, or the production of a product different than your expectations. Always be transparent in your communications with the manufacturer. - Are there any standards or certifications I should look for in a PCB manufacturer?

Yes. ISO 9001 is a standard that certifies quality management practices, demonstrating the manufacturers ability to meet regulatory standards. IPC standards for PCB design and manufacturing ensure that products meet industry wide requirements for quality. UL certification, while specific to the US market, can indicate testing and product safety for the use case. Always inquire about relevant certifications from the PCB manufacturer for adherence to quality and safety standards.

Tips for Reducing PCB Fabrication Costs

Minimizing PCB fabrication costs requires a strategic approach that combines intelligent design choices, material selection, and efficient manufacturing processes. By proactively addressing these areas, significant savings can be achieved when requesting an online quote.

- Optimize PCB Design

Reducing the board size, using fewer layers, minimizing the number of vias, and selecting components with smaller footprints can dramatically cut down on material usage and manufacturing time, which directly lowers the fabrication costs. For instance, consolidating multiple smaller boards into a single larger panel can improve fabrication efficiency. - Standardize Component Selection

Choosing commonly available and cost-effective components can reduce prices and simplify the supply chain. Opting for standard footprints and pad sizes whenever possible also helps to avoid tooling charges and reduces the complexity of the manufacturing process. - Material Selection

While FR-4 is the most common substrate, understanding your specific application can allow you to choose a less expensive option, if possible. For example, if high thermal conductivity is not a requirement, a standard FR-4 laminate would be cheaper than aluminum or copper clad options. If your project allows, consider using a thinner copper layer, which can reduce the raw material costs. - Panelization Strategies

When the board is small and the quantity is large, panelizing multiple PCBs on a single manufacturing panel can cut costs. You can choose the panelization approach and specify the array layout, which may reduce costs. The method of panelization must be optimized for the manufacturer’s equipment and requirements, this could be done by consulting with your PCB fabricator or manufacturer before fabrication. - Optimize Solder Mask and Silkscreen Layers

Using a standard solder mask color and simple silkscreen designs can reduce processing costs. If your design allows, using fewer silkscreen layers simplifies the process and lowers cost. You can specify areas where solder mask is not required, if you do not need all the board covered in solder mask, for example, a non-conductive area that does not require soldering. - Avoid Complex Features

Complex shapes or features like slots, cutouts and unusually small holes increase fabrication time and may necessitate specialized tooling, leading to higher costs. Simplify your board layout if possible, reduce the number of complex features to reduce manufacturing steps. Aim for standard rectangular shapes with standard drilled hole sizes. - Plan Production

Planning ahead and ordering at least a few weeks in advance allows manufacturers to schedule your order at the most efficient point, avoiding rush charges and expedited manufacturing fees. Consider your lead time and plan to order during slower periods to benefit from more competitive pricing. - DFM Compliance

Adhering to Design for Manufacturability (DFM) guidelines from the manufacturer prevents unexpected production delays and added fees for design adjustments. Checking for minimum trace width or spacing and the required via diameter to make sure they are compliant with the manufacturer's capability can help eliminate additional costs.

Understanding Hidden Costs in PCB Fabrication

While obtaining a PCB fabrication online quote provides an initial estimate, it's crucial to be aware of potential hidden costs that can significantly impact the final project expense. These costs, often not immediately apparent, can arise from various aspects of the manufacturing process and should be carefully considered to ensure accurate budget planning.

- Setup Fees

Many manufacturers charge a one-time setup fee, especially for smaller production runs. This covers the initial preparation of machines and tooling for your specific PCB design and should be factored in. The fee can vary significantly between manufacturers. - Tooling Charges

Some PCB designs, particularly those with custom shapes or requiring specific drilling patterns, may necessitate the creation of specialized tooling. These custom tooling costs will be added to the overall price. The complexity of the PCB design directly influences these tooling costs. - Expedited Shipping Fees

If your project requires faster turnaround times than standard, expedited shipping will incur additional costs. These can sometimes be substantial, especially for international shipments or tight deadlines. Consider the lead times offered against the required timeline to understand potential shipping costs. - Amendment Fees

Any changes made to the design after the initial fabrication process has begun will likely result in amendment fees. These costs cover the expenses of halting, adjusting, and restarting the manufacturing process. It's vital to double-check design files to avoid amendment costs. - Minimum Order Quantity Surcharges

If the PCB order quantity is less than a manufacturer's minimum, a surcharge may be added. This is to make up for the fact that the setup costs are the same regardless of the number of boards and this cost is being spread over a smaller amount of boards. Manufacturers need a minimum order quantity to cover fixed expenses. - Testing and Inspection Fees

Depending on the level of testing and inspection required for the PCBs, additional charges may be added. For example, impedance testing, or 100% electrical testing and micro section analysis can increase the cost, particularly for more complex boards. - Panelization and Array Costs

Manufacturers often prefer to manufacture PCBs in panels to improve production efficiency. If you have a complex or unusual order that requires custom panelization there will likely be an added cost.

Getting an accurate [pcb fabrication online quote] is the first step to successfully manufacturing your electronic designs. By understanding the factors that influence costs, preparing your files carefully, and comparing multiple quotes, you can ensure that your project stays on budget and is completed on time. As technology evolves, the ease of access to online PCB fabrication continues to provide great opportunities for innovation, making it crucial to stay informed to get the best value.

AnyPCBA

AnyPCBA