MPI PCB Maker: Your Guide to High-Quality Prototype PCBs

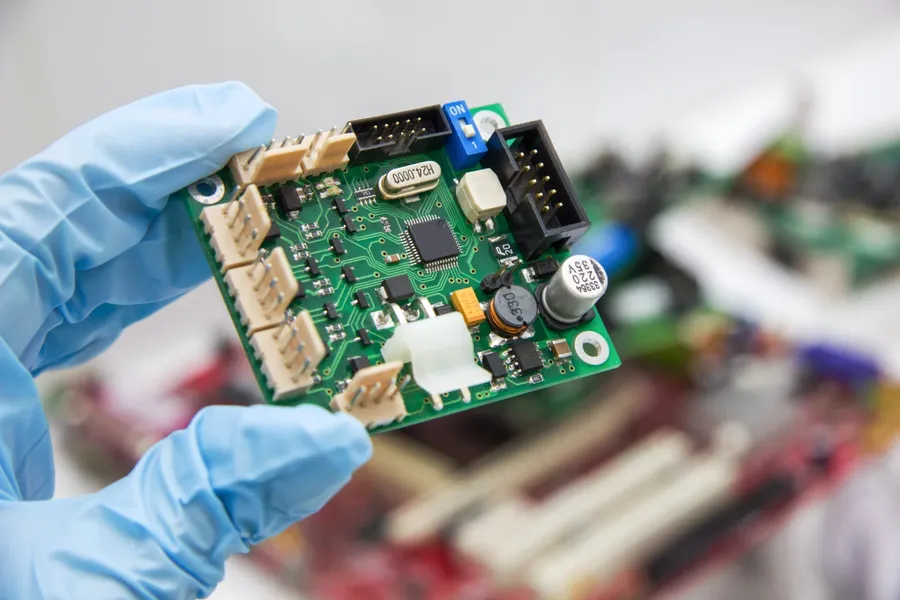

In today's fast-paced electronics industry, the need for reliable and high-quality printed circuit boards (PCBs) is paramount. MPI PCB Maker stands out as a leader in providing quick-turn prototype PCB fabrication, essential for bringing innovative ideas to life. This article delves into MPI's expertise, exploring their commitment to quality and the versatile solutions they offer to meet diverse needs.

MPI PCB Maker: A Legacy of Quality and Innovation

Multilayer Prototypes, Inc. (MPI) stands as a leader in the quick-turn prototype PCB fabrication sector. Their commitment to quality and innovation directly addresses the complex demands of the electronics industry, making them a pivotal partner for rapid development cycles and cutting-edge product iterations.

MPI's 20 years of experience provides a robust foundation, with a focus on delivering high-quality PCBs that are essential for both innovative research and product development.

They specialize in producing prototype PCBs with a focus on quick turnaround times. This allows electronics manufacturers to rapidly test designs and refine products, reducing overall time to market, a crucial advantage in today's competitive landscape.

Quick-Turn Prototype PCB Fabrication at MPI

Multilayer Prototypes, Inc. (MPI) excels in providing rapid turnaround for prototype PCB fabrication, a crucial service for accelerating product development cycles in the electronics industry. This capability allows engineers and designers to quickly test and refine their designs, reducing time-to-market and minimizing development costs.

MPI’s quick-turn service is particularly beneficial for projects requiring iterative design improvements. By providing rapid prototypes, MPI enables a streamlined workflow, allowing for more efficient troubleshooting and design validation prior to mass production. This approach is instrumental in ensuring the final product meets the required specifications and performance criteria.

| Feature | Description | Benefit |

|---|---|---|

| Rapid Turnaround Time | Fast fabrication of prototype PCBs. | Accelerates development, reduces time to market. |

| Design Iteration Support | Quick modification and testing of design changes. | Enables efficient design refinement and optimization. |

| Cost-Effective | Minimizes expenses associated with lengthy development cycles. | Reduces overall project budget, particularly for prototypes. |

| High-Quality Prototypes | Fabricates prototypes to precise specifications. | Ensures product performance validation and reliability testing. |

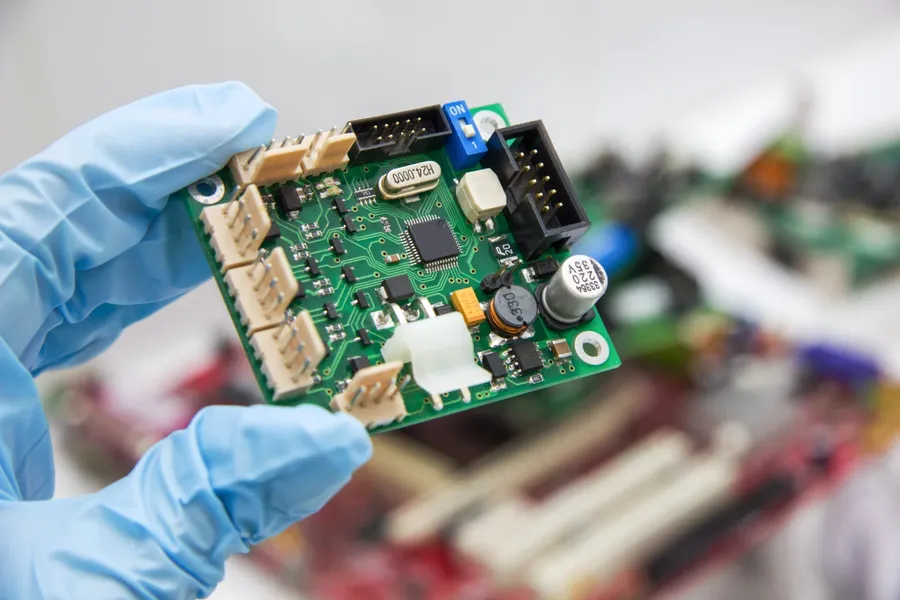

MPI PCB Probe Systems: Ensuring Signal Integrity

MPI's manual probe systems are critical for ensuring signal integrity (SI) in PCB design and manufacturing. These systems allow for precise measurements of electrical signals on PCBs, a crucial step in verifying the performance of electronic devices. By enabling detailed analysis of signal behavior, MPI probe systems help identify and address potential issues early in the development process, ensuring that finished products operate reliably and efficiently.

- Versatile Manual Probe Systems

MPI offers a range of manual probe systems designed to accommodate various PCB layouts and testing requirements, allowing for flexible and precise probing. - Key components

Includes precision positioners, probe heads, and measurement instrumentation, all designed for seamless integration and ease of use. - Accuracy in Signal Measurements

These systems are engineered to deliver accurate and reliable signal integrity measurements, enabling engineers to validate their designs against specifications. - Critical for Performance Verification

The accurate SI data obtained by MPI probe systems is vital for verifying and optimizing the performance of PCBs in real-world conditions. - Early Issue Detection

By identifying signal integrity problems early, these systems help prevent costly redesigns and delays in product development.

MPI's Diverse PCB Offerings

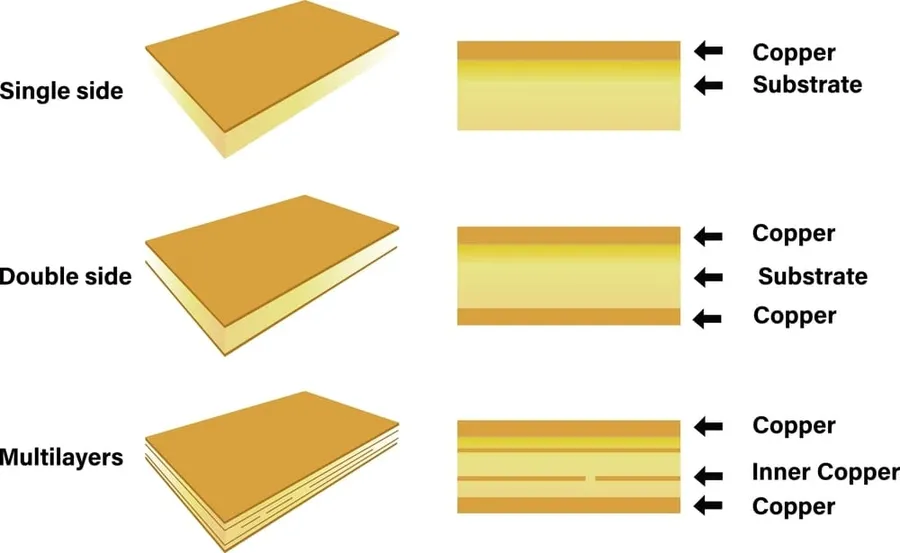

MPI distinguishes itself by providing a wide spectrum of PCB solutions, encompassing multilayer boards and flexible circuits, tailored to meet the rigorous demands of diverse applications, including high-frequency antennas. This variety allows clients to select the optimal PCB technology for their specific project requirements, ensuring performance and reliability.

| PCB Type | Description | Typical Applications | MPI Advantage |

|---|---|---|---|

| Multilayer Boards | PCBs with three or more conductive layers, enabling complex routing and high-density designs. | Complex electronic devices, high-speed digital circuits, advanced telecommunications. | High precision fabrication with advanced materials, ensuring signal integrity and reliability. |

| Flex Circuits | PCBs built on flexible substrates, allowing for bending and dynamic applications. | Wearable devices, medical equipment, automotive sensors, compact and curved electronics. | Customizable designs to meet stringent spatial constraints, durable and lightweight solutions. |

| High-Frequency PCBs | PCBs fabricated with materials optimized for high-frequency signal transmission, crucial for radio and microwave applications. | Antennas, radar systems, high-speed data transfer, wireless communication equipment. | Precise impedance control and low-loss material selection, optimizing performance for high-frequency applications. |

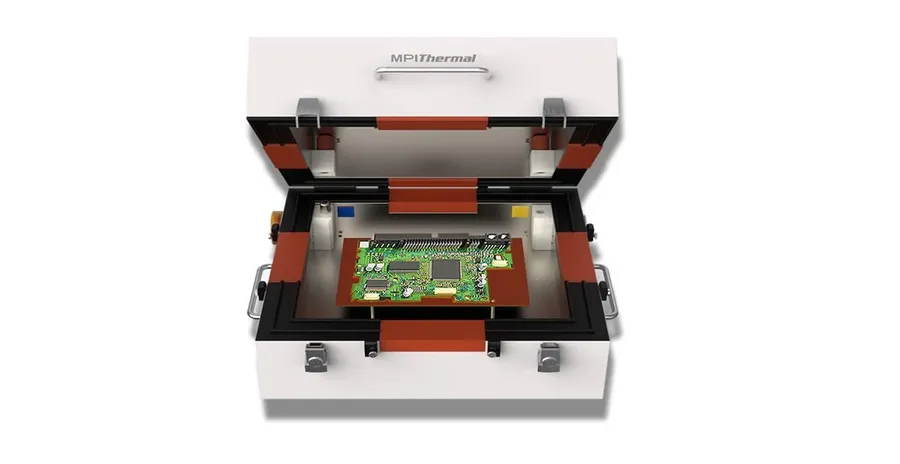

Thermal Testing Solutions for PCB Reliability

MPI Thermal provides advanced thermal cycling testing systems, crucial for assessing the reliability and performance of high-performance ICs, chips, and PCBs under varying temperature conditions. These systems simulate real-world operating environments, enabling manufacturers to identify potential failure points and optimize their designs for durability and longevity.

The importance of thermal testing cannot be overstated in the design and manufacturing of electronic components and PCBs. Electronic devices generate heat during operation, and temperature variations can cause material expansion and contraction, leading to stress, cracks, and premature failure. MPI Thermal’s solutions provide the necessary tools for rigorous testing to mitigate these issues, ensuring products meet stringent performance and reliability standards.

- Thermal Cycling Testing:

MPI Thermal systems subject PCBs and electronic components to repeated cycles of extreme temperature changes, uncovering weaknesses in material and construction. - High-Performance ICs and Chips:

By simulating the thermal conditions, MPI helps to ensure that the high-performance ICs and chips within the circuit boards maintain their functional properties even in extreme temperature conditions. - PCB Reliability:

Thermal testing aids in predicting the long term reliability of a PCB by simulating the conditions the board will experience during its life, allowing for early correction of any design or manufacturing flaws that will lead to premature failure. - Design Validation:

Thermal testing allows engineers to identify potential design flaws by verifying the heat dissipation properties of PCBs, allowing for improvements before mass production.

| Testing Parameter | Description | Importance |

|---|---|---|

| Temperature Range | Minimum and maximum temperatures of the thermal cycle. | Determines the range of operating conditions the PCB can withstand. |

| Cycle Duration | Time spent at each temperature in a thermal cycle. | Affects the stress and fatigue experienced by PCB materials. |

| Ramp Rate | Rate at which the temperature changes between extremes. | Can induce thermal shock and reveal weak spots in the construction. |

| Number of Cycles | Total number of temperature cycles the PCB is subjected to. | Simulates the longevity and resilience of the PCB under real-world operation conditions. |

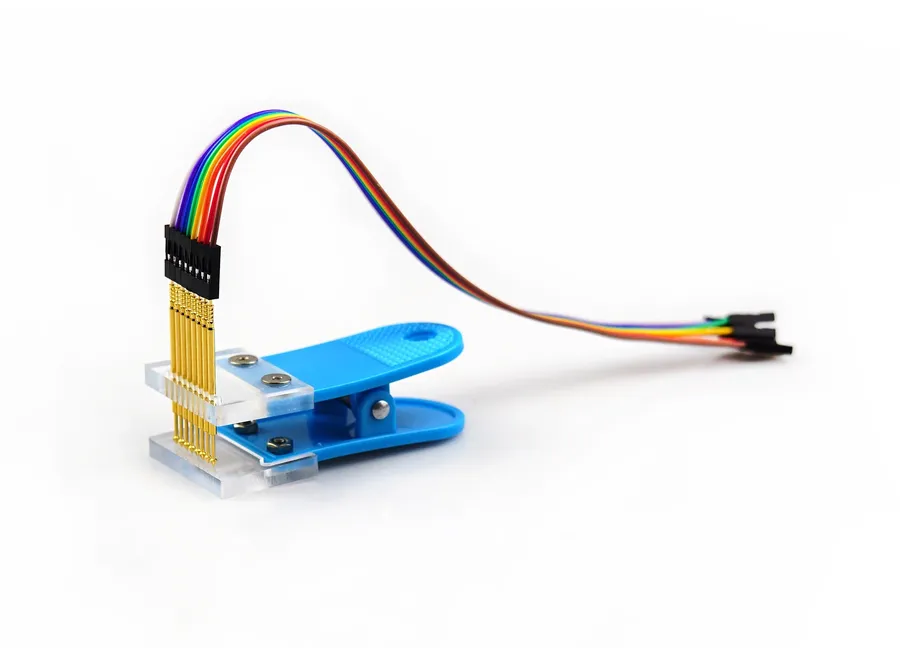

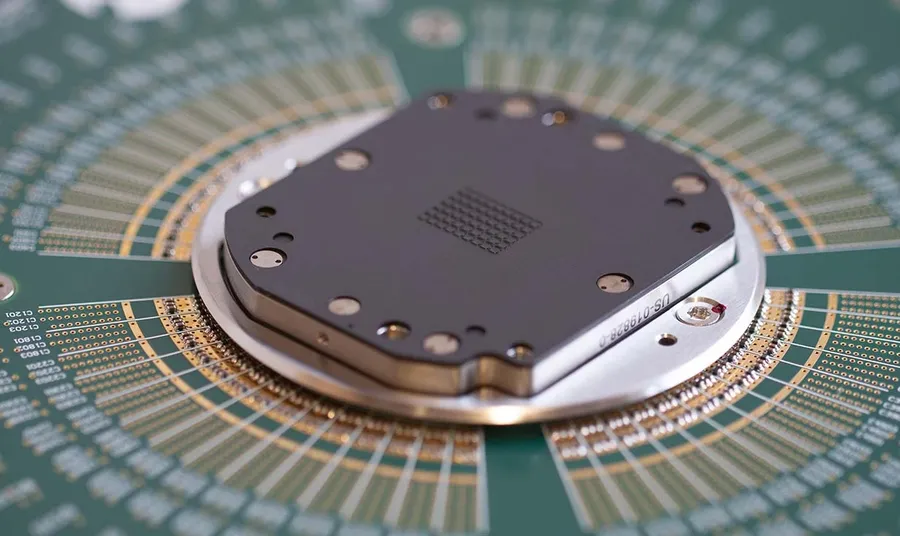

MPI Probe Card Technology for Semiconductor Testing

MPI's Probe Card division is a leader in providing cutting-edge solutions for semiconductor testing, ensuring the highest levels of performance and reliability in electronic devices. Their innovative technologies are crucial for validating the integrity of semiconductor components before they are integrated into finished products.

MPI's probe card technology addresses the critical need for accurate and dependable semiconductor testing. The probe cards act as an electrical interface, establishing contact with the minute pads on semiconductor devices, allowing for a comprehensive assessment of their functionality. These advanced probe cards are designed for high-precision measurements and to accommodate the rigorous demands of both research & development and large-scale manufacturing environments.

Frequently Asked Questions About MPI PCB Manufacturing

This section addresses common questions about MPI's PCB manufacturing capabilities, covering topics from selecting the right manufacturer to understanding the nuances of prototype costs and multilayer PCB fabrication. By providing clear and concise answers, we aim to equip you with the necessary knowledge for informed decision-making.

- Who is the best PCB manufacturer for my specific needs?

The 'best' PCB manufacturer depends heavily on your project's specific requirements. Factors to consider include the complexity of the board (single-layer, multilayer, flex), required quantities (prototype, small batch, mass production), turnaround time, certifications, and material specifications. MPI excels in quick-turn prototypes and offers solutions for diverse PCB types including multilayer and flex circuits, catering to a range of applications. - What is the typical cost of a PCB prototype?

The cost of a PCB prototype is influenced by factors like the board's complexity, size, layer count, material, surface finish, and the required turnaround time. Generally, multilayer boards and those with special materials or finishes will be more expensive. MPI provides competitive pricing and can offer specific quotes based on your design specifications. It is crucial to engage with the manufacturer directly to get an accurate estimate, and consider the long-term cost benefits of working with a quality-focused fabricator. - Who are the leading PCB manufacturers globally?

The global PCB manufacturing landscape is vast with many players, with leaders in different regions often excelling in various areas. Some of the largest manufacturers, by volume, are located in Asia, while other companies may focus on specific technologies or markets. It's essential to consider your specific needs and priorities when choosing a manufacturer, instead of focusing solely on size or global presence. MPI’s focus is on high quality, quick-turn prototype PCBs. - How are multilayer PCBs manufactured?

Multilayer PCBs are constructed by layering several thin boards together, each with its own copper circuitry. These boards are laminated together under heat and pressure with insulating layers in between to form a single board with multiple conductive layers. Vias (plated through-holes) or blind/buried vias are used to create electrical connections between layers. This process demands precision and specialized equipment. MPI has proven capabilities in manufacturing these complex boards, adhering to strict quality standards. - What considerations are important when selecting a PCB manufacturer?

Choosing a PCB manufacturer involves assessing several key factors. Quality control measures, certification (such as ITAR, FDA, ISO 13485 for medical devices), turnaround time for prototypes and production runs, pricing, technical support, and the ability to handle specific design complexities (like impedance control or blind vias) are all important. MPI offers comprehensive support and has certifications to meet stringent needs. - What type of PCB probe systems does MPI offer?

MPI provides a variety of manual probe systems specifically engineered for accurate signal integrity measurements on PCBs. These systems are designed for precision testing to ensure that PCBs meet performance criteria. The systems offer versatility and ease of use, particularly in prototype and design verification stages. - Does MPI offer thermal testing solutions for PCB reliability?

Yes, MPI Thermal specializes in systems for thermal cycling testing. This capability is crucial for ensuring the long-term reliability of PCBs, ICs, and chips by identifying potential issues from thermal stress. MPI's solutions help manufacturers design more robust and dependable electronic products through rigorous thermal testing regimes.

MPI's Commitment to Advanced Manufacturing

MPI's dedication to advanced PCBA manufacturing is underscored by its adherence to stringent industry standards and certifications, particularly in the demanding field of medical devices. MPI's facilities are equipped to handle complex manufacturing processes while maintaining the highest levels of quality and precision.

- ITAR Certification

MPI maintains ITAR (International Traffic in Arms Regulations) compliance, ensuring the secure handling of sensitive technology and defense-related projects. This certification is critical for projects involving controlled technologies, providing assurance of data protection and secure manufacturing practices. - FDA Registration

MPI is registered with the FDA (Food and Drug Administration), demonstrating its ability to meet the stringent requirements for manufacturing medical devices. This registration signifies that MPI's manufacturing processes and quality management systems are rigorously controlled and compliant with FDA regulations, crucial for producing safe and effective healthcare technology. - ISO 13485 Certification

MPI holds the ISO 13485 certification, a globally recognized standard specifically for quality management systems in the medical device industry. This certification ensures that MPI's processes are designed to consistently meet customer and regulatory requirements, guaranteeing the production of high-quality, reliable medical devices. This is of utmost importance for medical applications, where performance and reliability are paramount. - Precision Manufacturing

MPI employs advanced manufacturing techniques and equipment to achieve precise fabrication of printed circuit boards, ensuring the highest level of functionality and performance. Their meticulous approach addresses the strict requirements of medical and other high-reliability applications. - Focus on Quality Control

Stringent quality control measures are in place at every stage of the manufacturing process, from initial design review to final inspection. This proactive quality system minimizes errors and increases reliability for every PCB produced.

Selecting MPI as Your PCB Fabrication Partner

When choosing a PCB fabrication partner, MPI distinguishes itself through its commitment to rapid prototyping, specialized solutions, and unwavering quality. MPI's emphasis on quick-turn prototypes allows clients to iterate on designs efficiently, significantly reducing time-to-market. The company's ability to cater to diverse needs with specialized solutions, coupled with its consistent delivery of high-quality PCBs, makes it a compelling choice for demanding applications.

- Quick-Turn Prototyping

MPI excels in rapid turnaround times for PCB prototypes, enabling faster design iterations and quicker product launches. This capability is crucial for companies that need to rapidly test and refine their electronic designs. - Specialized PCB Solutions

MPI offers a range of specialized PCB solutions, including multilayer boards and flex circuits, catering to diverse application requirements like high-frequency antennas. Their flexibility in handling specialized needs ensures clients receive the precise type of PCBs required for their specific projects. - Quality Assurance

MPI prioritizes quality in every stage of the fabrication process, delivering reliable and high-performance PCBs. Their commitment to quality assurance ensures that the final product meets stringent industry standards. - Advanced Manufacturing Capabilities

MPI's facilities are equipped with advanced manufacturing capabilities, including certifications such as ITAR, FDA, and ISO 13485, demonstrating their capability to produce high-quality PCBs, especially for sensitive applications like medical devices. - Comprehensive Testing Solutions

MPI provides thermal and probe testing solutions that can ensure PCB reliability and optimal signal integrity. They don't just manufacture; they provide testing to help ensure the long-term functionality of the designed product.

| Factor | MPI Advantage | Client Benefit |

|---|---|---|

| Turnaround Time | Rapid Prototype Fabrication | Accelerated Design Iterations |

| Solution Diversity | Specialized PCBs like Multilayer and Flex | Meets diverse application needs |

| Quality | Strict adherence to industry standards | Ensured reliability and performance |

| Certifications | ITAR, FDA, and ISO 13485 | High-quality PCBs, especially for medical devices |

| Testing | Thermal and Signal Integrity Testing | Ensures product longevity and performance |

MPI PCB Maker stands out as a leader in the PCB industry, providing not just PCBs but comprehensive solutions for prototype development and semiconductor testing. By choosing MPI, clients gain access to high-quality, reliable PCB manufacturing backed by advanced technology and rigorous testing, which ensures their electronic designs are top tier. From rapid prototyping to specialized probe systems, MPI is your go-to partner for PCB excellence, guiding you through every stage of your product’s development.

AnyPCBA

AnyPCBA