Navigating the Global PCB Landscape: Top Manufacturers & Trends

Printed circuit boards (PCBs) are the unsung heroes of modern electronics, forming the backbone of everything from smartphones to sophisticated medical equipment. The PCB manufacturing industry is a complex global ecosystem, with top players like AT&S, TTM Technologies, and Zhen Ding Technology driving innovation and production. This article delves into the key players in this vital industry, exploring market trends and offering insights into what makes these companies leaders in the world of PCB fabrication.

Global Leaders in PCB Manufacturing

The global PCB (Printed Circuit Board) manufacturing landscape is dominated by a select group of companies that drive innovation and production to meet the ever-increasing demands of the electronics industry. These leaders, through their substantial production capacity, advanced technological capabilities, and strategic market positioning, shape the direction of the industry. This section provides a high-level view of these key players, their specializations, and their influence on the global market.

| Company | Specialization | Market Share (Approx.) | Geographic Presence |

|---|---|---|---|

| AT&S | High-end PCBs, HDI, substrate-like PCBs | 6-8% | Austria, China, India, South Korea |

| TTM Technologies | Aerospace and Defense, Automotive, Data Center PCBs | 5-7% | USA, China, Taiwan |

| Unimicron | HDI, Flexible PCBs, IC Substrates | 4-6% | Taiwan, China, Germany |

| Nippon Mektron | Flexible PCBs | 4-5% | Japan, China, Thailand |

| Compeq | Rigid PCBs, High-Density Interconnect (HDI) boards | 3-5% | Taiwan, China |

| Zhen Ding Technology | Flexible PCBs and Rigid-Flex PCBs | 3-4% | China, Taiwan, India |

| Samsung Electro-Mechanics | Package Substrates, HDI, Rigid PCBs | 2-4% | South Korea, China |

Key Players: Detailed Analysis

This section provides a focused examination of several leading PCB manufacturers, delving into their specific strengths, technological focuses, and global market positions. Understanding these key players offers insights into the diverse landscape of PCB manufacturing and the distinct approaches each company takes.

The PCB manufacturing sector is dominated by a few major players, each with unique capabilities and specializations. Below, we profile three such companies: AT&S, TTM Technologies, and Unimicron.

| Company | Headquarters | Key Strengths | Specializations | Market Focus |

|---|---|---|---|---|

| AT&S | Austria | Advanced HDI, substrate solutions, strong R&D | High-end PCBs, IC substrates, microelectronics | Automotive, industrial, medical, and high-performance computing |

| TTM Technologies | USA | Broad range of PCB technologies, quick turn services, North American presence | Aerospace & Defense, data centers, medical devices, automotive | North American and global markets with a focus on complex designs |

| Unimicron | Taiwan | High-volume manufacturing, extensive production capacity, advanced technologies | HDI, rigid-flex, IC substrates, mass production | Consumer electronics, computing, communication sectors |

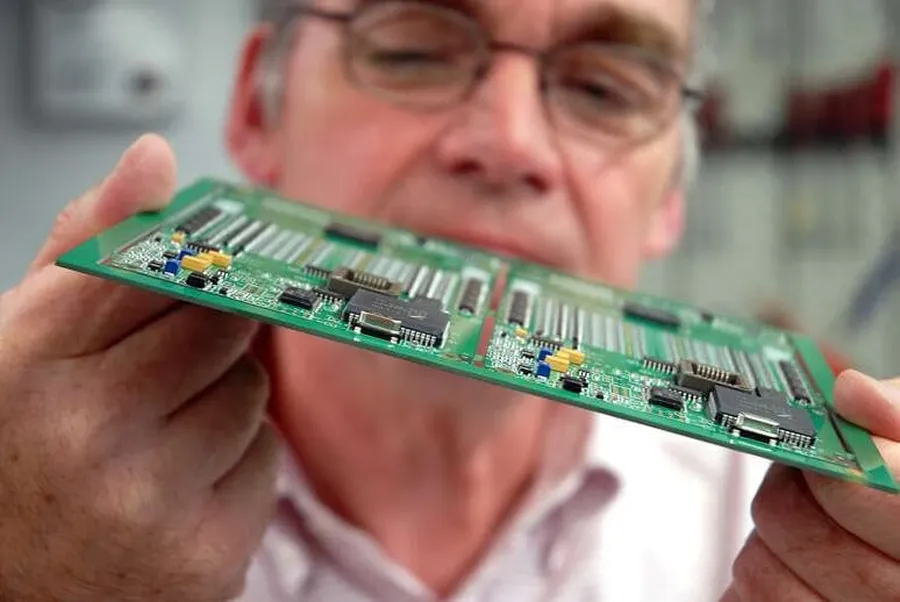

Each of these companies holds a significant position in the global PCB market due to their continuous innovation, specialized technologies, and diverse product offerings. Their strengths allow them to serve different markets, further highlighting the complexity and specialization within the industry.

Regional PCB Manufacturing Hubs

The global PCB manufacturing landscape is not uniformly distributed, with certain regions emerging as dominant hubs due to a confluence of factors including technological expertise, established infrastructure, and supportive government policies. Taiwan, China, and the United States represent key centers of PCB production, each with distinct strengths and specializations that cater to diverse market demands.

| Region | Strengths | Specializations | Market Share (Approximate) |

|---|---|---|---|

| Taiwan | High concentration of manufacturers; strong R&D capabilities; advanced technology adoption | High-end PCBs; HDI boards; mobile device PCBs | 30-40% |

| China | Massive production capacity; cost-competitive manufacturing; broad range of PCB types | Standard PCBs; large-volume production; consumer electronics PCBs | 40-50% |

| United States | Advanced technology; focus on aerospace and military applications; high-reliability PCBs | Aerospace and defense PCBs; high-reliability boards; advanced materials PCBs | 10-15% |

Taiwan’s strength lies in its established ecosystem of PCB manufacturers, coupled with advanced research and development capabilities. This has allowed them to capture a significant share of the high-end PCB market. China's competitive edge comes from its sheer manufacturing scale and lower production costs, making it a global leader in large-volume PCB production. The United States, while having a smaller overall market share, specializes in high-reliability PCBs, catering to demanding sectors such as aerospace and military.

Technological Advancements in PCB Manufacturing

The PCB manufacturing industry is in constant evolution, driven by the demand for smaller, faster, and more reliable electronic devices. This section explores the cutting-edge technologies and innovations that are shaping the future of PCB production, encompassing advanced materials, high-density interconnect (HDI) technologies, and flexible circuit board manufacturing.

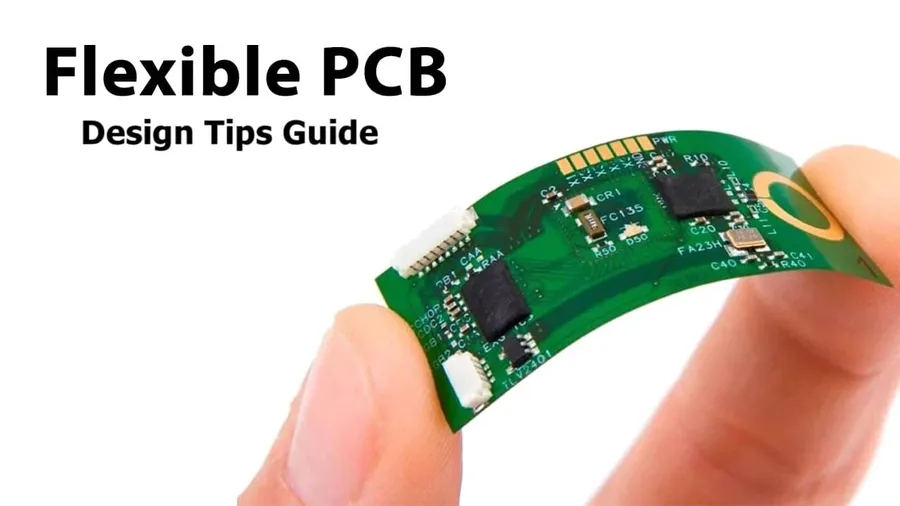

Advanced materials are crucial in meeting the increasing demands of modern electronics. These materials must offer superior thermal, electrical, and mechanical properties to enable high-performance, reliable PCBs. High-Density Interconnect (HDI) technology, which enables higher component density and improved signal integrity through microvias and finer lines, is a key focus of innovation. Additionally, flexible PCB manufacturing is a growing area due to its ability to create lightweight and compact electronic devices, particularly for wearables and other emerging applications. These technologies are not only essential for current electronic devices, but also pave the way for future advancements in the electronic industry.

| Technology | Description | Key Benefits | Application Areas |

|---|---|---|---|

| Advanced Materials | Use of materials with enhanced electrical, thermal, and mechanical properties. | Improved signal integrity, thermal management, and durability | High-speed computing, aerospace, automotive electronics |

| High-Density Interconnect (HDI) | Production of PCBs with microvias, fine lines, and tight spacing. | Smaller board size, increased component density, improved electrical performance. | Smartphones, tablets, wearable devices |

| Flexible PCB Manufacturing | Production of PCBs on flexible substrates. | Lightweight, flexible, and compact electronic designs. | Wearable electronics, medical devices, automotive systems |

Market Trends and Future Outlook

The global PCB market is currently experiencing dynamic shifts, driven by technological advancements and evolving industry demands. This section provides an in-depth analysis of these current market trends and provides a glimpse into the future of PCB manufacturing, exploring potential growth areas, emerging technologies, and critical challenges.

- Miniaturization and High-Density Interconnect (HDI)

The demand for smaller and more compact electronic devices is pushing the industry towards miniaturization. This trend is fueling the growth of HDI PCBs, which enable higher component density and better performance in smaller form factors. This includes microvias, fine-line traces, and advanced lamination techniques. - Flexible and Rigid-Flex PCBs

Flexible PCBs (FPC) and rigid-flex PCBs are gaining popularity, offering advantages in terms of space utilization, weight reduction, and design flexibility. These PCBs are increasingly used in applications such as wearable devices, automotive electronics, and medical equipment. - Advanced Materials

There is an increasing focus on the development and adoption of advanced materials for PCB manufacturing. This includes high-performance laminates with improved thermal, electrical, and mechanical properties. These materials are essential for supporting the higher frequencies and greater speeds of modern electronic devices. - Sustainable and Eco-Friendly Practices

Environmental concerns are prompting the industry to adopt sustainable manufacturing practices. This involves reducing waste, using eco-friendly materials, and implementing energy-efficient processes. The move towards RoHS compliant and lead-free PCBs is gaining momentum. - Growing Demand from Automotive and Healthcare Sectors

The automotive sector and healthcare sectors are witnessing significant growth, increasing the demand for specialized PCBs. This includes PCBs for advanced driver-assistance systems (ADAS), electric vehicles, medical imaging, and diagnostic devices. These sectors often require PCBs with high reliability and stringent quality standards. - Integration of IoT and AI

The rise of the Internet of Things (IoT) and Artificial Intelligence (AI) is driving the need for advanced PCBs that can support complex functionalities and connectivity. This includes PCBs used in smart devices, data centers, and edge computing applications. - Supply Chain Resilience

The recent global events have highlighted the need for a robust and diversified supply chain in the PCB industry. Companies are exploring strategies to mitigate risks, including nearshoring and diversifying their manufacturing locations. The geopolitical situation is influencing sourcing and manufacturing decisions.

| Trend | Description | Impact |

|---|---|---|

| HDI PCBs | High-density interconnect PCBs for miniaturization. | Smaller, more powerful electronic devices. |

| Flexible PCBs | PCBs that can bend and flex. | Design flexibility and space efficiency. |

| Advanced Materials | High-performance laminates and substrates. | Improved electrical and thermal performance. |

| Sustainable Practices | Eco-friendly and waste-reducing manufacturing. | Reduced environmental impact and enhanced sustainability. |

| IoT and AI Integration | PCBs with advanced functionalities for smart devices. | Increased connectivity and data processing capabilities. |

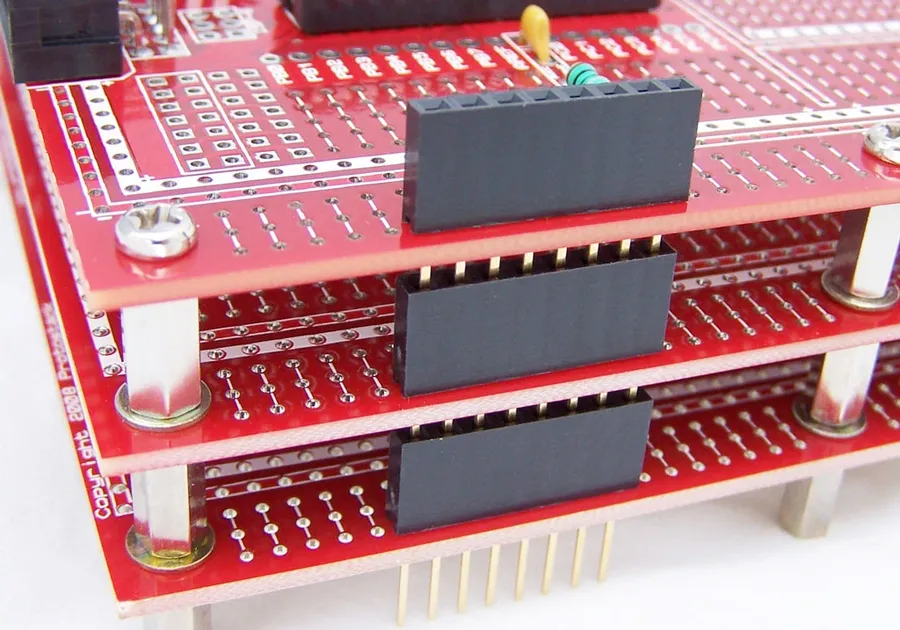

PCB Material and Complexity

The performance and reliability of a Printed Circuit Board (PCB) are significantly influenced by the materials used in its construction and the complexity of its design. Material selection affects factors such as thermal resistance, signal integrity, and mechanical durability, while design complexity dictates the board's functionality and manufacturing challenges.

| Material Type | Common Uses | Key Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|

| FR-4 (Flame Retardant 4) | Most common for general-purpose PCBs | Good mechanical strength, flame retardant, moderate cost | Widely available, cost-effective, easy to process. | Moderate thermal resistance, not suitable for high-frequency applications. |

| High-Tg FR-4 | High-temperature applications, automotive | Higher glass transition temperature, improved thermal performance | Improved thermal performance over standard FR-4, more robust | Higher cost compared to FR-4 |

| Polyimide | Flexible PCBs, high-reliability applications | Excellent thermal stability, high flexibility | Excellent high temperature performance, chemically resistant | More expensive, can be difficult to process. |

| Teflon (PTFE) | High-frequency applications, microwave circuits | Excellent electrical performance, low dielectric constant | Very low signal loss, superior high-frequency performance | Expensive, mechanically challenging to handle. |

| Metal Core PCBs (MCPCB) | LED lighting, power electronics | High thermal conductivity, efficient heat dissipation | Excellent heat dissipation, allows for higher power density | Heavier and more expensive than standard PCBs. |

PCB complexity is determined by the number of layers, the density of components, and the intricacy of the routing. Different levels of complexity include:

- Single-Sided PCBs

Components are mounted on one side with conductive traces on the other, simplest design. - Double-Sided PCBs

Components and traces on both sides, increased routing flexibility, through-hole components can be used - Multilayer PCBs

Three or more layers of conductive traces, used for complex circuits, high density interconnections - High Density Interconnect (HDI) PCBs

Extremely fine lines, small vias, complex design, and advanced manufacturing techniques - Flexible PCBs

Made with flexible materials like polyimide. Can be bent and folded to fit various shapes, for applications where flexibility is needed, and are more durable for extreme conditions.

Choosing the right PCB materials and managing design complexity is critical. It requires a balance between performance, cost, and manufacturability. Engineers must carefully consider the application requirements, including thermal demands, signal frequencies, and operating environment, to make the best material and design decisions.

Frequently Asked Questions About PCB Manufacturing

This section addresses common inquiries regarding PCB (Printed Circuit Board) manufacturing, offering clear, concise answers to guide understanding of this complex process. We delve into questions about leading manufacturers, geographical manufacturing hubs, and the defining characteristics of top PCB companies.

- Who are considered the best PCB manufacturers?

Identifying the 'best' PCB manufacturer is subjective and depends on specific needs, such as technology requirements, production volume, and budget. However, companies like AT&S, TTM Technologies, and Unimicron are consistently ranked among the top global PCB manufacturers due to their technological capabilities, production capacity, and market share. The 'best' should be determined based on a manufacturer's ability to meet precise project specifications, offer high-quality products, and provide reliable services, considering parameters such as design for manufacturability (DFM), testing and quality control processes, material selection, and certifications. - Which country is the largest manufacturer of PCBs?

China currently holds the position of the world's largest PCB manufacturer, accounting for a substantial portion of global PCB production. This dominance is attributed to factors including well-established manufacturing infrastructure, significant investments in technology and capacity, a large workforce, and favorable government policies. Taiwan is also a significant player, particularly in high-end PCB manufacturing, and it possesses a high concentration of highly specialized manufacturers. The position of the leading countries will continuously change due to investment and global markets. - What factors make a PCB company the best?

A company's quality is a critical indicator that is evaluated by a number of factors. The 'best' PCB manufacturers typically exhibit several key characteristics: advanced manufacturing technologies (including HDI and flexible PCB capabilities), strong DFM analysis capabilities, stringent quality control processes (including IPC certifications and adherence), use of high-quality materials, reliable supply chains, and robust customer support. Additionally, the flexibility to handle both prototype and mass production runs, expertise in various PCB types and technologies, and commitment to R&D distinguish leading companies. Also, lead times, cost-effectiveness, and customer satisfaction play a vital role. - Who is the largest PCB manufacturer in the USA?

While the USA has several notable PCB manufacturers, TTM Technologies is often recognized as one of the largest, and most influential, within the region. Their influence spans various high-tech sectors. However, it's important to note that the specific rankings can vary based on different metrics and may be determined by revenue, product type, or geographic location within the USA. - What are the key considerations when choosing a PCB manufacturer?

Selecting a suitable PCB manufacturer involves assessing several crucial factors. These include evaluating their technological proficiency in relation to your project requirements (e.g., multilayer, HDI, flex PCBs), verifying their compliance with industry standards and certifications (e.g., IPC standards), understanding their quality control practices and testing methods, assessing their capacity to fulfill your volume requirements, investigating their design for manufacturing (DFM) services, and exploring their proficiency in materials management. Furthermore, factors such as lead times, pricing, and geographical location must also be considered to ensure project viability. - What is the role of material selection in PCB manufacturing?

Material selection is paramount in PCB manufacturing, influencing a board's performance, reliability, and cost. Factors such as the dielectric constant, thermal performance, mechanical strength, and resistance to chemicals of the selected material directly impact the PCB functionality. High-frequency applications will require special materials with lower signal losses and specific dielectric properties, whereas high-temperature applications demand materials with superior thermal resilience. Common materials include FR-4, polyimide, and Teflon, each having its advantages and disadvantages. Choosing the correct material is an important design process that directly affects the quality, performance and price of the PCB.

Selecting the Right PCB Manufacturer

Choosing the appropriate PCB manufacturer is a critical decision that can significantly impact the quality, cost, and time-to-market of your electronic products. It requires careful evaluation of several key factors to ensure a successful partnership.

- Quality Standards and Certifications

A manufacturer's adherence to quality standards, such as ISO 9001, and specific industry certifications, like IPC standards, is a strong indicator of their commitment to product reliability. Verify that they possess the necessary certifications relevant to your industry. - Manufacturing Capabilities

Assess whether the manufacturer has the capacity and technology to produce your desired PCB specifications, including layer count, material type, and tolerances. This is especially critical for complex designs or high-volume production. - Technological Proficiency

Evaluate the manufacturer’s expertise with advanced technologies, such as HDI, microvias, and flexible PCBs if your design requires it. Their willingness to adapt to cutting-edge techniques demonstrates a future-proof approach to technology advancements. - Cost Efficiency

While cost is a significant factor, it should not be the sole determinant. Obtain detailed cost breakdowns and compare quotes from multiple vendors, considering all factors such as tooling, materials, and fabrication processes. - Turnaround Time and Lead Times

Ensure the manufacturer can meet your project timelines. Inquire about their standard lead times, and verify if they offer expedited services for prototypes or urgent orders. Lead times can vary based on order size and board complexity. - Geographic Location and Logistics

Consider the geographic location of the manufacturer relative to your supply chain. Lead times, shipping costs, and potential communication barriers need to be considered. Local manufacturers may offer the advantage of streamlined logistics, while overseas production may offer cost savings. - Customer Service and Communication

A reliable manufacturer should have responsive customer service, with effective communication channels. This ensures any design issues or modifications can be addressed promptly and any technical queries can be easily resolved. - Sample and Prototype Evaluation

Before committing to large-scale production, request sample boards. Perform rigorous testing on these samples to verify the manufacturer’s output quality and capabilities before proceeding further. - Minimum Order Quantities (MOQ)

Determine if their minimum order quantity requirements align with your production volume. Some manufacturers may have limitations for small runs that might not fit with your project needs.

The Impact of Top PCB Manufacturers

The leading PCB manufacturers, such as AT&S and TTM Technologies, exert a substantial influence on the global electronics industry by driving technological advancements, setting industry standards, and shaping the supply chain. Their impact extends beyond mere production, affecting the pace of innovation in numerous sectors.

- Technology Advancement

Top manufacturers invest heavily in R&D, leading to innovations in materials science, high-density interconnect (HDI) technologies, and flexible PCB manufacturing. This constant push for advancement translates into higher performance and more compact electronics, thereby benefiting the entire industry. - Market Standardization

These companies often set the benchmark for quality, reliability, and performance. Their processes and practices are frequently adopted by other manufacturers, creating de facto industry standards and promoting consistency and interoperability across the supply chain. - Supply Chain Dynamics

The sheer scale of operations of top PCB manufacturers influences the entire supply chain. They negotiate large contracts with material suppliers, set the pace for manufacturing capacity, and establish delivery timelines. These actions affect both upstream and downstream participants in the industry. - Future Technology Development

The innovations pioneered by top PCB manufacturers are often foundational for emerging technologies. For instance, advancements in HDI and flexible PCBs are directly contributing to the development of smaller, more efficient, and flexible wearable devices, medical implants, and high-performance computing systems. The capacity to manufacture these complex boards is often a critical element in the success or failure of a new product.

| Impact Area | Influence Mechanism | Example |

|---|---|---|

| Technological Innovation | R&D investments and adoption of advanced manufacturing techniques | Development of high-density interconnect PCBs, enabling smaller and more powerful devices |

| Market Standards | Setting benchmarks for quality, reliability and manufacturing processes | Adoption of IPC standards by many PCB manufacturers to maintain quality and interoperability |

| Supply Chain | Large production volumes and influence on material suppliers | Impact on material pricing and lead times, which affects the entire supply chain |

| Emerging Technologies | Enabling advanced applications with novel PCB designs | Development of flexible PCBs for wearable devices and medical implants |

In summary, the top PCB manufacturers are not just producers of circuit boards but are vital agents of innovation and development within the broader electronics ecosystem. Their actions have repercussions across the entire technology landscape and are critical for the advancement of future technologies. Their success is inextricably linked to the advancement of electronics as a whole.

The PCB manufacturing industry is a constantly evolving landscape, shaped by technological innovation and the demands of the global electronics market. Companies like AT&S, TTM Technologies, and Zhen Ding Technology are at the forefront of this industry, driving the development of advanced PCBs and playing a crucial role in the advancement of modern technology. Staying informed about these top manufacturers and understanding market trends is crucial for anyone involved in the electronics industry. As technology continues to evolve, these PCB manufacturing leaders will undoubtedly continue to shape the future of electronic devices and the world as a whole.

AnyPCBA

AnyPCBA