PCB Power India Ltd: Your Comprehensive Guide to PCB Solutions

In today's rapidly evolving electronics landscape, Printed Circuit Boards (PCBs) are the backbone of nearly every electronic device. PCB Power India Ltd has established itself as a key player in this domain, providing a wide array of services. This article delves into the offerings of PCB Power India Ltd, exploring their manufacturing capabilities, component sourcing, and commitment to quality. Through understanding PCB Power’s role, we’ll uncover the importance of reliable PCB solutions in connecting innovative technologies with everyday life.

Overview of PCB Power India Ltd

PCB Power India Ltd stands as a prominent printed circuit board (PCB) manufacturer in India, leveraging over 25 years of industry expertise. They provide a comprehensive suite of PCB solutions, encompassing design, fabrication, and assembly, to meet the diverse needs of their clients.

Comprehensive PCB Manufacturing Services

PCB Power India Ltd provides a full spectrum of PCB manufacturing services, encompassing fabrication, design, and assembly, with a strong emphasis on online PCB board design capabilities. Their integrated approach aims to streamline the entire process for their customers, offering a single-source solution from initial concept to finished product. This comprehensive offering is designed to reduce lead times and ensure a higher degree of quality control through every stage of development.

Key aspects of their comprehensive PCB manufacturing services include:

- PCB Fabrication

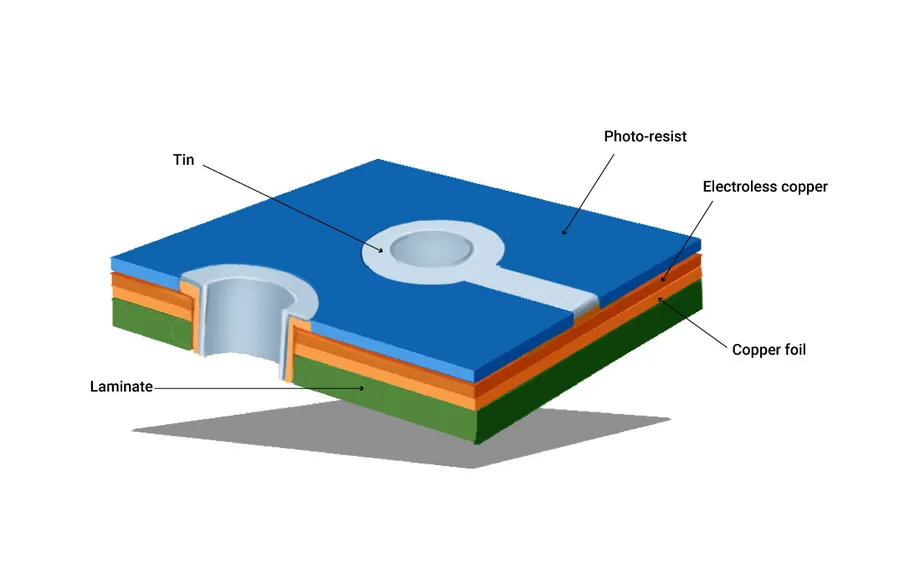

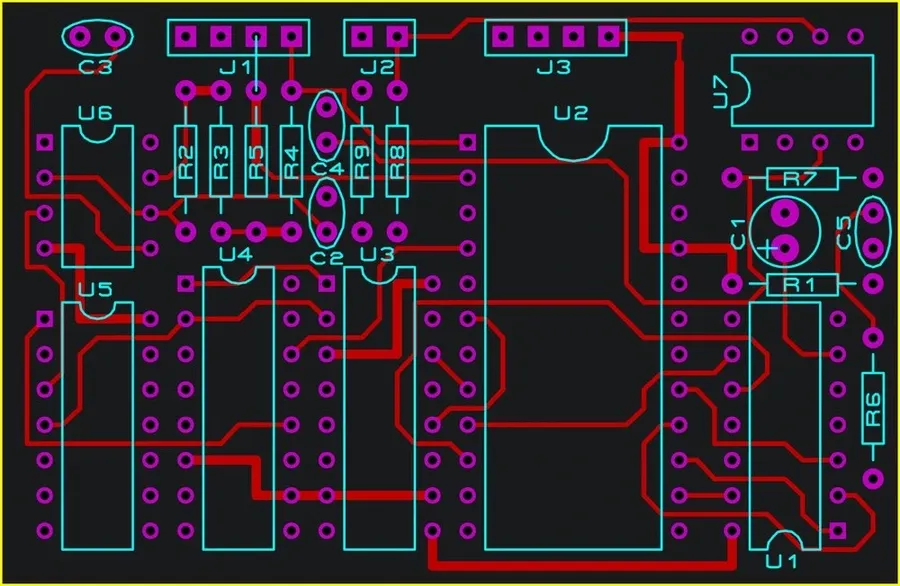

This involves the actual production of the bare printed circuit boards, including processes like etching, drilling, and plating. PCB Power handles various PCB types including single-sided, double-sided, and multilayer boards with advanced materials and technologies. - PCB Design

PCB Power offers comprehensive PCB design services, assisting customers in transforming their electronic schematics into functional PCB layouts. This includes component placement, routing, and design rule checking to ensure manufacturability and optimal performance. - PCB Assembly

Once the bare PCBs are fabricated, they offer complete PCB assembly services, which include component placement, soldering, and testing. This service is essential for clients who require a turnkey solution for their electronic devices. - Online PCB Board Design

Their online platform provides tools and services for customers to design and order PCBs directly, making the process more accessible and efficient. This includes online Gerber file uploads, instant quotations, and order tracking.

PCB Fabrication and Layout Expertise

PCB Power India Ltd. demonstrates significant expertise in printed circuit board (PCB) fabrication and layout, utilizing advanced technologies and rigorous quality control to ensure the delivery of highly reliable PCBs. Their capabilities extend across various complexities, catering to diverse industry needs.

The core of their fabrication process includes:

- Advanced Material Selection:

Employing a variety of materials like FR-4, high-Tg FR-4, Aluminum, and flexible substrates to meet different operating conditions and performance requirements. Selection is based on parameters like thermal resistance, electrical insulation, and mechanical strength. - High-Precision Manufacturing:

Using state-of-the-art equipment for etching, drilling, and plating to achieve tight tolerances and high accuracy in PCB dimensions and feature sizes. This allows for complex designs and high-density interconnects. - Multi-Layer PCB Capabilities:

Providing fabrication of multi-layer PCBs, which are crucial for complex electronic circuits requiring multiple layers for power distribution, signal routing, and grounding. Their technology enables up to 32 layers with specific impedance control. - Surface Finish Options

Offering diverse surface finishes such as HASL, ENIG, Immersion Silver, and OSP. The choice of surface finish impacts solderability and reliability. The ENIG process, for example, provides good solder joint reliability and corrosion resistance. - Automated Optical Inspection (AOI)

Implementing AOI at various fabrication stages to ensure detection of any defects like open circuits, shorts, and other anomalies, to improve yield rates and quality. Each board is scanned and compared with the design to meet the stringent quality requirements.

Their layout expertise includes:

- Design for Manufacturability (DFM):

Offering layout services that consider DFM to optimize designs for efficient manufacturing, which reduces costs and lead times, and ensures that the design meets industry standards for reliability and performance. - Signal Integrity Analysis:

Performing signal integrity analysis to address issues related to signal reflections, crosstalk, and impedance mismatches, ensuring high-speed data transmission and consistent performance. This is critical for high frequency circuits. - Thermal Management:

Designing layouts that consider thermal management, incorporating elements like heat sinks, thermal vias, and proper component placement to manage heat dissipation effectively, which prevents failures caused by overheating.

PCB Power’s proficiency in both fabrication and layout is backed by robust quality assurance processes and technological investment, positioning them as a reliable partner for advanced PCB solutions.

Component Sourcing and PCB Assembly

PCB Power India Ltd provides a complete end-to-end solution by offering robust component sourcing and comprehensive PCB assembly services. This integrated approach streamlines the manufacturing process for clients, ensuring quality and efficiency from design to finished product.

The component sourcing service leverages established supply chains to procure high-quality components, mitigating the risks of counterfeit parts and ensuring that all materials meet stringent quality standards. This process is crucial for the reliability and performance of the final PCB.

Their PCB assembly services use state-of-the-art technology, including automated pick-and-place machines and advanced soldering techniques, to achieve precise and consistent assembly. This reduces the risk of defects and ensures that each board is manufactured to the highest standards. The combination of these services simplifies the process for customers, providing a single point of contact for both PCB fabrication and assembly.

| Service | Description | Benefits |

|---|---|---|

| Component Sourcing | Procurement of necessary electronic components from trusted sources. | Ensures component quality, reduces counterfeit risk, simplifies supply chain. |

| PCB Assembly | Mounting of electronic components onto the fabricated PCB. | High precision and efficiency, reduces defects, quick turnaround. |

| Integrated Solution | Combined sourcing and assembly services | Streamlined process, single point of contact, increased production efficiency |

Serving Diverse Industries

PCB Power India Ltd. caters to a wide spectrum of industries, demonstrating its versatility and capability to meet varied and stringent requirements. Their extensive experience and robust manufacturing processes position them as a trusted partner for sectors demanding high-reliability PCBs.

- Aerospace:

The aerospace industry requires extremely reliable PCBs, capable of withstanding extreme temperatures, vibrations, and radiation. PCB Power India Ltd provides PCBs that meet these exacting specifications. - Industrial:

Industrial applications range from simple control circuits to complex automation systems. PCB Power's expertise ensures reliable performance in harsh industrial environments. - Medical Devices:

The medical field requires PCBs with high precision and reliability, meeting strict regulatory standards. PCB Power delivers dependable PCBs for medical equipment. - Telecommunications:

The telecommunications sector needs high-speed and high-frequency PCBs for network equipment. PCB Power provides the necessary technology and expertise. - Automotive:

Automotive electronics demands PCBs that can withstand extreme temperature variations, vibration, and shocks, ensuring consistent and long-lasting performance. - Consumer Electronics:

From everyday gadgets to smart home devices, PCB Power India Ltd. delivers quality PCBs for a range of consumer applications, balancing cost-effectiveness with performance requirements. - Renewable Energy:

The renewable energy sector is rapidly expanding, and PCB Power supports this growth with PCBs that enable efficient power conversion and energy management.

PCB Power’s Commitment to Quality and Reliability

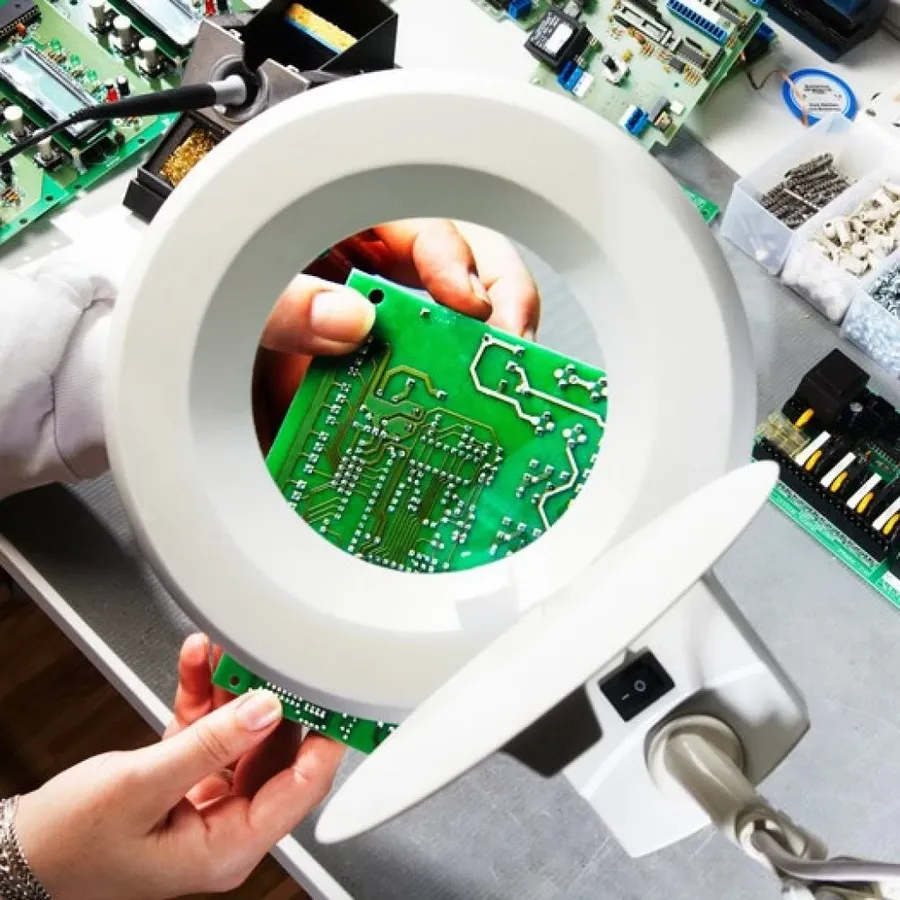

PCB Power India Ltd. prioritizes quality and reliability as core tenets of its manufacturing processes, understanding that these factors are paramount for the performance and longevity of electronic devices. Their commitment extends beyond mere compliance, embedding a culture of excellence throughout their operations.

This dedication to high standards involves rigorous quality control measures at every stage of PCB manufacturing, from initial design review through to final product inspection. Utilizing advanced testing methodologies, they ensure that every PCB produced meets stringent specifications and industry benchmarks, minimizing the risk of failure and maximizing product performance for their diverse client base.

Key aspects of their commitment to quality and reliability include:

- Advanced Testing and Inspection

Employing sophisticated tools such as Automated Optical Inspection (AOI) and electrical testing to identify defects early in the process, ensuring high production standards. - Material Selection and Traceability

Implementing a strict selection process for raw materials, coupled with rigorous traceability measures to guarantee the use of high-grade components and adherence to international standards. - Process Control and Monitoring

Maintaining meticulous control over each step of the PCB fabrication process, ensuring consistency and predictability in manufacturing outputs. - Industry Standard Compliance

Adhering to recognized international standards and certifications, demonstrating their commitment to quality management and continuous improvement. - Skilled Workforce

Employing a team of highly skilled professionals with expertise in PCB design, fabrication, and testing to maintain quality standards and continuously improve processes.

Frequently Asked Questions About PCB Power India Ltd

This section addresses common inquiries regarding PCB Power India Ltd, providing clear, concise answers to help you understand their operations and services.

- Who owns PCB Power India Ltd?

While specific ownership details may not be publicly available, PCB Power India Ltd. is a well-established entity in the PCB manufacturing sector in India. Details about the owners are not typically relevant to the quality and reliability of their services. - Why are some PCBs offered at low prices?

The cost of a PCB is influenced by several factors, including the complexity of the design, the materials used, production volumes, and manufacturing processes. Automation, optimized supply chains, and large-scale production can reduce costs, resulting in more competitive pricing for some PCBs. However, extremely low prices may also indicate compromises in quality or material. - Who is the largest PCB manufacturer in India?

Determining the absolute 'largest' PCB manufacturer can be challenging due to the dynamic nature of the industry. Several companies operate at large scales, and their standings can vary based on different parameters like volume, revenue, and technology used. PCB Power India Ltd is one of the leading players. For the most current rankings, industry analysis should be consulted. - Are PCBs manufactured in India?

Yes, there are a significant number of PCB manufacturers in India, including PCB Power India Ltd, who produce a wide variety of PCBs for both domestic and international clients. The country's PCB manufacturing sector is growing, offering both basic and advanced PCBs. This has resulted in a good competitive market with a broad range of PCB suppliers to choose from. - What are PCB Power India Ltd's key capabilities?

PCB Power India Ltd excels in PCB fabrication, design, and assembly, including online PCB board design. They have a well-established capability to produce PCBs ranging from simple single-layer boards to complex multi-layer and HDI boards, with a focus on high quality and reliability. - Can I order PCBs online through PCB Power India Ltd?

Yes, PCB Power India Ltd has an online platform which enables users to upload designs and specifications. This platform streamlines the ordering process, allowing for efficient order placement and tracking, designed to benefit customers seeking a quick turnaround. - What industries does PCB Power India Ltd serve?

PCB Power India Ltd provides PCBs to diverse sectors, including aerospace, industrial, medical, and consumer electronics. This wide spectrum of industries highlights their capacity to meet varied and stringent application requirements.

PCB Power’s Online Ordering System and Services

PCB Power India Ltd offers a streamlined online platform that significantly simplifies the process of ordering custom PCBs. This system provides a user-friendly interface where customers can upload their design files, specify their requirements, and obtain instant quotes, thereby accelerating the prototyping and production phases. This digital approach not only enhances convenience but also reduces the potential for errors associated with manual order processing.

- Online PCB Order Placement

Users can directly upload Gerber files or other standard PCB design files to initiate an order. The system supports various file formats, ensuring compatibility with popular design software. This eliminates the need for manual email exchanges, making the order process faster and more efficient. - Instant Quotation

The online platform provides instant price quotations based on the user's uploaded design and specified parameters, such as board dimensions, material, layer count, and finish. This immediate feedback allows users to adjust design parameters to meet their budgetary constraints. - Design Rule Checking (DRC)

PCB Power’s platform often includes design rule checking capabilities. These checks automatically scan the uploaded design files for any errors that might affect the fabrication process, such as trace width violations or insufficient spacing between components, allowing users to correct issues before production. - Order Tracking

Once an order is placed, customers can track its progress through each stage of manufacturing. This transparency allows for efficient project management and timely planning. Notifications are often sent at key milestones like production completion, quality checks and shipment. - Secure Payment Options

The online platform supports multiple secure payment methods, ensuring a safe transaction process. Various payment gateways and channels make the payment process smooth and user-friendly. - Technical Support

Even with an online platform, PCB Power typically offers technical support through chat, email, or phone. This ensures that users can get assistance with any issues or questions they might have, offering critical support if needed.

Comparing PCB Power India Ltd with Competitors

A thorough comparison of PCB Power India Ltd against its competitors is crucial for businesses seeking reliable PCB manufacturing. This section highlights the key differentiators, leveraging a table format for a clear and concise side-by-side analysis. The evaluation encompasses various factors, including technology, cost, turnaround time, expertise, and customer support, to provide a comprehensive overview.

| Feature | PCB Power India Ltd | Competitor A | Competitor B |

|---|---|---|---|

| Manufacturing Capabilities | Advanced multi-layer PCBs, online ordering, wide range of materials | Standard PCBs, limited online ordering, fewer material options | Advanced PCBs, online ordering, good material range |

| Turnaround Time | Standard 3-7 days, express options available | Standard 5-10 days, limited express options | Standard 4-8 days, express available |

| Technology and Expertise | 25+ years of experience, advanced technology, ISO certified | 10+ years of experience, standard tech, ISO certified | 15+ years experience, advanced technology,ISO certified |

| Component Sourcing | Complete in-house component sourcing and assembly | Limited sourcing, separate assembly required | Partial sourcing,separate assembly required |

| Quality Control | Stringent quality control measures, reliability focus | Standard quality control, moderate reliability | Good quality control, high reliability |

| Cost | Competitive pricing with good value | Slightly higher pricing, limited value | Competitive pricing, good value |

| Customer Support | Dedicated support team, responsive service | Basic support, slower response times | Good support, quick response times |

PCB Power India Ltd stands as a reliable and experienced partner in the PCB manufacturing industry. Their comprehensive approach, from design to assembly, ensures that clients receive high-quality and dependable PCB solutions. As the electronics industry continues to grow, PCB Power India Ltd will be at the forefront with their commitment to quality, technology, and customer satisfaction. Choosing PCB Power India Ltd means ensuring your projects receive top-tier electronic components.

AnyPCBA

AnyPCBA