PCB World Solutions Pty Ltd: Your Partner in Advanced PCB Solutions

In today's rapidly evolving electronics landscape, the need for reliable and high-performance printed circuit boards (PCBs) is paramount. PCB World Solutions Pty Ltd stands as a beacon of innovation and quality in this field, leveraging over 25 years of experience to deliver cutting-edge solutions. From intricate PCB designs to seamless manufacturing and assembly, PCB World Solutions Pty Ltd is your trusted partner in navigating the complexities of PCB technology, ensuring your projects succeed.

Decades of PCB Expertise: PCB World Solutions' Legacy

For over 25 years, PCB World Solutions Pty Ltd has been a cornerstone in the electronics industry, building a strong reputation for excellence in printed circuit board (PCB) manufacturing. Their journey reflects a commitment to adapting to technological advancements while consistently delivering high-quality PCBs, meeting the evolving needs of their global clients.

This extensive experience translates to a deep understanding of PCB manufacturing processes, allowing them to anticipate challenges and implement effective solutions. This long-standing history has cultivated a culture of precision, quality, and customer focus within the company.

Comprehensive PCB Services: From Design to Delivery

PCB World Solutions Pty Ltd offers a complete suite of services encompassing the entire PCB lifecycle, from initial design to final product delivery. This integrated approach ensures seamless project execution, minimizes potential errors, and optimizes workflows for our clients.

Our services are structured to provide a holistic solution, addressing every critical step in the PCB production process:

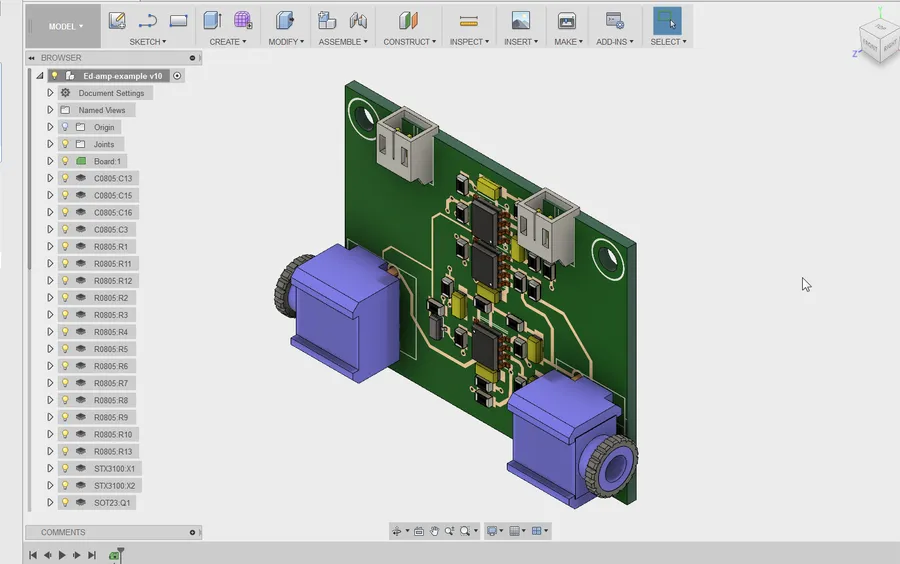

- PCB Design

Our experienced design engineers utilize advanced CAD tools to create precise and optimized PCB layouts based on your specifications. We support various design complexities and ensure that the design meets the functional requirements, while also considering manufacturability. - PCB Manufacturing

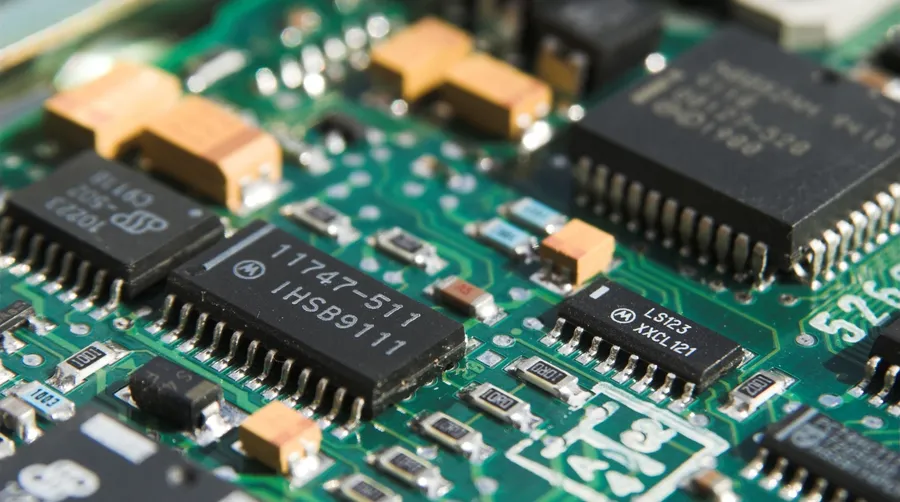

Leveraging state-of-the-art manufacturing facilities, we fabricate PCBs with high accuracy and consistency. We handle diverse material types and board configurations, adhering to the highest quality standards throughout the production process. - PCB Assembly

Our comprehensive assembly service integrates high-precision equipment to mount components onto the manufactured PCBs, covering both surface-mount and through-hole technology, offering a turnkey solution that minimizes delays and streamlines the production process.

By offering an integrated service model, PCB World Solutions ensures consistent quality, reduces lead times, and provides a single point of contact for all PCB-related needs. This integrated approach allows for greater control over project timelines, minimizes the risk of errors between separate entities, and allows us to pass cost savings on to our clients.

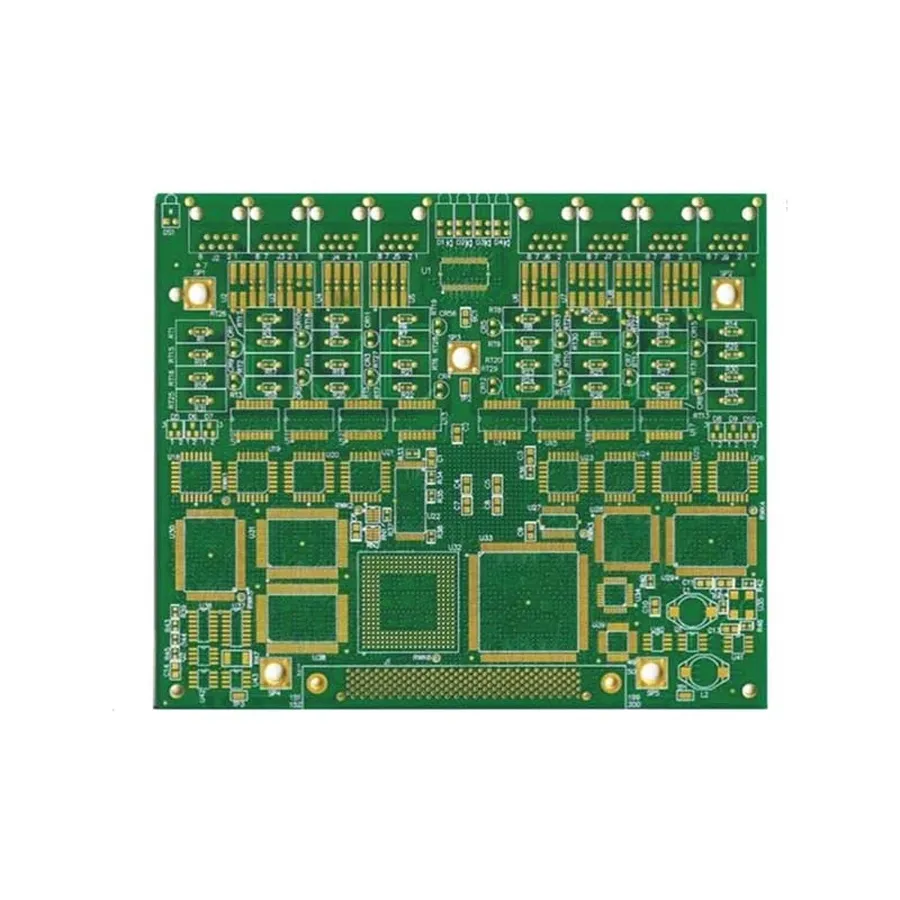

Quality Printed Circuit Boards: The Core of PCB World Solutions

At the heart of PCB World Solutions' operations lies an unwavering commitment to delivering printed circuit boards (PCBs) of the highest quality. This dedication is manifested through meticulous material selection, precise manufacturing processes, and rigorous quality control measures, ensuring both reliability and peak performance in every board produced.

| Aspect | Description |

|---|---|

| Material Selection | Only high-grade materials from reputable suppliers are used to ensure the long-term reliability and performance of the PCBs. This includes FR-4, high-frequency laminates, and other specialized materials tailored to specific applications. |

| Precision Engineering | State-of-the-art equipment and meticulous engineering practices guarantee the accuracy and precision of each PCB produced. Tolerances are strictly controlled to meet even the most demanding specifications. |

| Rigorous Quality Control | A comprehensive quality control system, adhering to industry best practices, is in place at every stage of production. This includes incoming material checks, in-process inspections, and final testing to ensure adherence to stringent quality standards, such as IPC standards. |

| Reliability and Performance | The focus on quality ensures that PCB World Solutions' products consistently perform to the specifications and reliability requirements demanded by the electronics industry, reducing product failures and increasing customer satisfaction. |

This dedication to quality is not just a process; it is a deeply ingrained philosophy at PCB World Solutions. It underpins every decision and action, ensuring that each printed circuit board meets the high standards expected by our customers.

Competitive Pricing: Achieving Value Without Compromise

PCB World Solutions Pty Ltd understands the importance of balancing cost and quality in today's competitive market. By optimizing our manufacturing processes and leveraging strategic sourcing, we offer competitive pricing without compromising the high standards of quality and service that our clients expect, ensuring that customer's financial goals are met.

| Cost Factor | Description | Impact on Pricing |

|---|---|---|

| Material Costs | Strategic sourcing of high-quality materials. | Reduced material costs contribute to competitive pricing while maintaining quality. |

| Manufacturing Efficiency | Optimized production processes using advanced technology. | Streamlined production reduces overhead and production time, resulting in cost savings. |

| Volume | Bulk ordering of components and materials. | Larger orders receive volume discounts, which can be passed on to customers. |

| Technology | Utilizing advanced automated systems to decrease labor costs. | Efficient operations result in lower manufacturing costs |

| Supply Chain Management | Strong relationships with suppliers for better pricing and just-in-time inventory. | Effective management minimizes delays and costs. |

Timely Delivery: Meeting Critical Project Deadlines

PCB World Solutions Pty Ltd understands that in today's fast-paced electronics industry, meeting project deadlines is crucial. Our commitment to timely delivery is a cornerstone of our operations, achieved through meticulous production planning, streamlined logistics, and a proactive approach to project management.

We recognize that delays can have cascading effects on your project timelines and budgets. To mitigate these risks, we implement several key strategies:

- Rigorous Production Planning

Detailed production schedules are developed for each project, taking into account all phases of the process, from raw material procurement to final packaging, ensuring optimal resource allocation and workflow efficiency. - Efficient Logistics Management

We have established reliable logistics partnerships and robust processes that expedite shipping, reducing transit times and enhancing tracking capabilities to provide real-time updates. - Proactive Project Communication

Regular updates and open communication channels ensure that clients are informed about the project’s progress, and potential challenges are addressed swiftly. Our project teams are dedicated to maintaining clear and responsive contact with each customer. - Flexible Production Capabilities

Our production facilities are equipped to handle diverse project demands, allowing us to adapt to tight deadlines and variable quantities without compromising our rigorous quality control standards. We can adjust our manufacturing schedules to meet customer deadlines. - Inventory Management

We maintain strategic inventory levels of common materials to eliminate potential delays arising from material shortages. This allows for a faster start to manufacturing.

Our dedication to on-time delivery is not just a process, but a reflection of our commitment to our clients' success, where each project is approached with the utmost precision, ensuring that your PCB requirements are met with quality and efficiency.

Advanced PCB Technologies: Catering to Diverse Needs

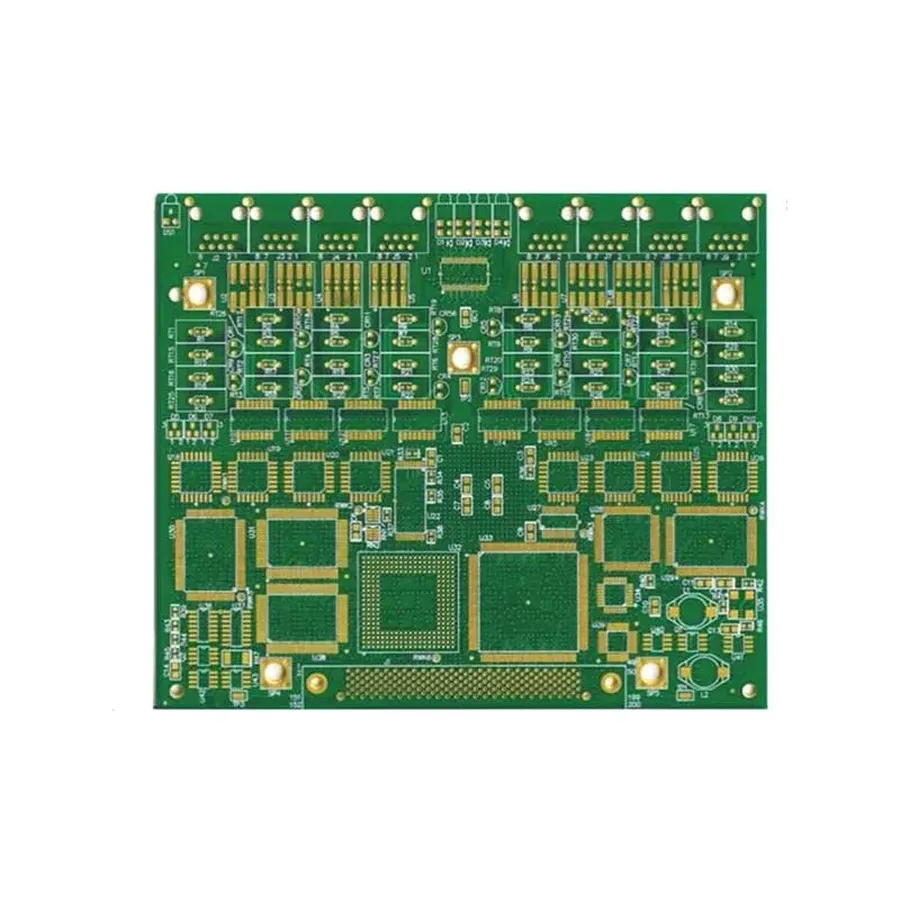

PCB World Solutions Pty Ltd demonstrates its proficiency in a wide array of PCB technologies, encompassing single-layer, double-layer, and complex multi-layer printed circuit boards. This capability ensures they can meet the diverse requirements of projects with varying complexities, from simple electronic devices to highly sophisticated applications.

| PCB Type | Description | Typical Applications | Complexity |

|---|---|---|---|

| Single-Layer PCB | Consists of a single layer of conductive material. Simplest type of PCB, where all components are on one side. | Basic electronic devices, simple LED circuits, low-density applications. | Low |

| Double-Layer PCB | Has conductive material on both sides of the board. Offers increased circuit density. | Consumer electronics, power supplies, more complex electronic gadgets. | Medium |

| Multi-Layer PCB | Comprises three or more layers of conductive material, increasing design flexibility and circuit density. These boards are often used in high performance and advanced systems where signal integrity, miniaturization, and design complexity are important. | Advanced electronics, high-speed communication equipment, complex controllers, high-density systems, telecommunication systems, medical equipment, aerospace equipment. | High |

PCB World Solutions leverages its advanced manufacturing capabilities to ensure the precise fabrication of each type of PCB, accommodating a range of design specifications and performance requirements. Their expertise extends from producing basic circuits to intricate multi-layered systems, allowing them to cater to a diverse range of project needs.

PCB World Solutions: A Trusted Partner in the Electronics Industry

PCB World Solutions Pty Ltd stands as a preeminent supplier of printed circuit boards (PCBs), distinguished by its unwavering commitment to quality and customer service. With a robust reputation cultivated over two decades, the company has consistently delivered high-performance PCB solutions, solidifying its position as a trusted partner within the electronics industry.

The company’s dedication extends beyond mere manufacturing. PCB World Solutions emphasizes collaborative partnerships, working closely with clients to understand their specific needs and provide tailored solutions that align with their project requirements and objectives. This approach ensures that clients receive not just PCBs, but optimized solutions that contribute directly to the success of their electronic products. Through its commitment to quality, reliability, and customer satisfaction, PCB World Solutions continues to lead the way in the PCB sector.

Frequently Asked Questions About PCB Solutions from PCB World Solutions Pty Ltd

This section addresses common inquiries about PCB design, manufacturing, and assembly, providing clear and concise answers to help you understand PCB World Solutions Pty Ltd's capabilities and processes. These FAQs are designed to provide clarity and build confidence in our services.

- What is the typical lead time for PCB manufacturing at PCB World Solutions?

Lead times for PCB manufacturing can vary depending on the complexity of the design, the quantity ordered, and current production schedules. However, PCB World Solutions Pty Ltd strives to provide efficient turnaround times, typically ranging from a few days for simple designs to several weeks for more complex multi-layer boards. Contact us with your specific requirements for a more precise estimate. - What types of PCB designs does PCB World Solutions support?

PCB World Solutions Pty Ltd has the capability to handle a wide range of PCB designs, including single-layer, double-layer, and complex multi-layer PCBs. We can also accommodate various material types, such as FR-4, Aluminum, and flexible substrates. Our expertise extends to both analog and digital circuits. - What quality standards does PCB World Solutions follow during PCB manufacturing?

PCB World Solutions Pty Ltd adheres to stringent quality standards throughout our manufacturing processes. We are committed to complying with industry standards such as IPC Class 2, and we utilize high-grade materials, precision engineering techniques, and rigorous quality control measures at every stage of production. This ensures that our printed circuit boards meet the highest reliability and performance standards. - Can PCB World Solutions assist with PCB design services?

Yes, PCB World Solutions Pty Ltd offers comprehensive PCB design services. Our skilled engineers can work with you from initial concept through to final design, utilizing industry-standard software and adhering to best practices. We ensure that the final design is both manufacturable and meets the desired specifications. - Does PCB World Solutions offer PCB assembly services?

Absolutely. PCB World Solutions provides full PCB assembly services, including surface mount technology (SMT), through-hole assembly, and mixed technology assembly. Our experienced technicians and state-of-the-art equipment ensure accurate and reliable assembly of your PCBs. We also provide component sourcing and testing services to ensure a seamless process. - How does PCB World Solutions handle order quantities for PCBs?

We are flexible when it comes to order quantities, and can cater to small prototyping runs and high volume production orders. Our processes are structured to accommodate different scales, ensuring competitive pricing without compromising on quality, regardless of the order size. - What information should I provide to receive an accurate quote?

To provide an accurate quote for your PCB project, we require a few key pieces of information. This includes the Gerber files, board specifications (such as layer count, material type, and board dimensions), quantity required, and any specific assembly or testing needs. Providing detailed information enables us to deliver a precise and competitive quotation. Please contact our sales team and we will guide you through the process.

PCB World Solutions Pty Ltd provides cutting-edge PCB solutions with a focus on high quality and efficiency. With over 25 years of experience, PCB World Solutions Pty Ltd is your dedicated partner, providing not just printed circuit boards, but also building trust and ensuring that your electronic projects are completed successfully. Their commitment to quality, competitive pricing, and timely delivery solidifies their position as a leader in the PCB industry and your first choice for quality and reliable PCB solutions.

AnyPCBA

AnyPCBA