Pioneer PCB Factory: Leading the Way in Advanced Circuit Board Manufacturing

In today's rapidly evolving tech landscape, the demand for high-quality, reliable printed circuit boards (PCBs) is ever-increasing. Pioneer PCB Factory stands as a testament to innovation and precision in this field. From pioneering techniques to serving crucial sectors like aerospace and defense, this factory plays a pivotal role in powering the future. We delve into the history, capabilities, and impact of Pioneer PCB Factory on the global stage, highlighting their unique contributions to the PCB industry.

The History and Evolution of Pioneer PCB Factory

Pioneer PCB Factory's journey reflects a commitment to innovation and quality in the printed circuit board (PCB) manufacturing sector. From its inception, the company has strategically evolved, adapting to technological advancements and industry demands to become a leading manufacturer. This section details the critical milestones and expansions that have shaped Pioneer PCB Factory into the significant player it is today.

The factory's early years were marked by a focus on establishing a robust foundation in traditional PCB manufacturing techniques. As technology progressed, Pioneer PCB Factory invested heavily in research and development, allowing them to expand into more specialized areas such as rigid-flex PCB production. These advancements were crucial for attracting clients from high-reliability industries.

Key milestones include the adoption of advanced manufacturing processes, which significantly improved production efficiency and product quality. Expansion into new geographical markets has increased the company's global presence, specifically across the Middle East. Strategic partnerships with technology providers and research institutions have further solidified Pioneer PCB Factory's reputation for technical expertise and innovation. The timeline of Pioneer PCB Factory’s evolution illustrates a continuous process of development and strategic growth.

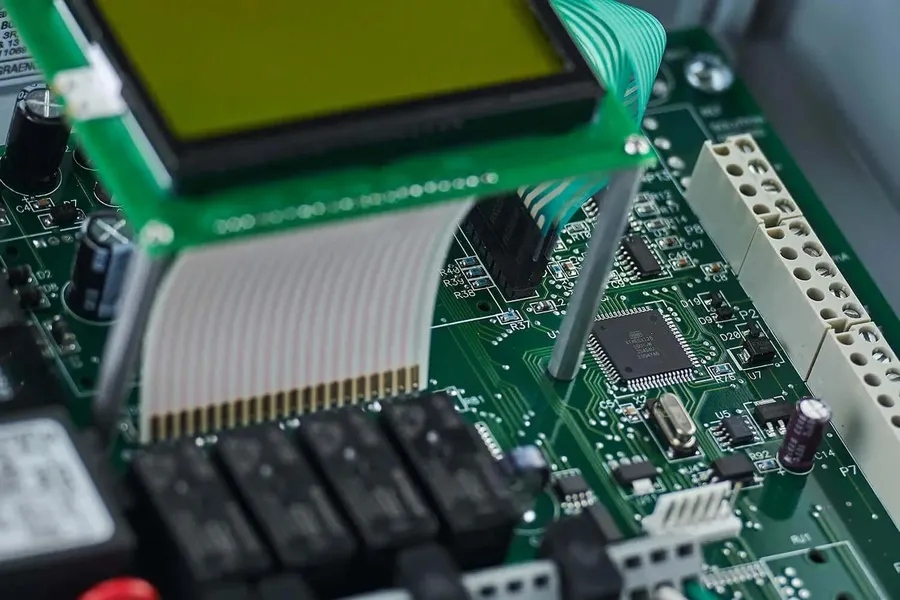

Core Technologies and Manufacturing Capabilities

Pioneer PCB Factory distinguishes itself through its mastery of advanced PCB manufacturing technologies, specializing in the production of highly intricate and reliable circuit boards. Their core competencies span a wide array of techniques, with a particular emphasis on rigid-flex PCB manufacturing, enabling them to cater to the exacting needs of industries demanding high precision and durability.

| Technology | Description | Applications | Key Advantages |

|---|---|---|---|

| Rigid-Flex PCB Manufacturing | Combines rigid and flexible circuit board elements in a single design. This technology integrates the advantages of both rigid and flexible PCBs. | Aerospace, Medical Devices, Automotive, Wearable Electronics | Reduced size and weight, improved reliability, dynamic flexing capabilities, enhanced design flexibility |

| Multilayer PCB Fabrication | Production of PCBs with three or more conductive layers, offering increased circuit density and complexity. | High-performance computing, telecommunications, advanced industrial controls | High component density, improved signal integrity, greater routing flexibility, excellent heat dissipation capabilities |

| High-Density Interconnect (HDI) PCBs | Manufacture of boards with finer lines, smaller vias, and higher connection densities. | Smartphones, tablets, portable devices, complex embedded systems | Miniaturization, increased functionality in a smaller area, superior electrical performance, enhanced thermal management |

| Surface Mount Technology (SMT) | Automated assembly of components directly onto the PCB surface, enhancing precision and efficiency. | Consumer electronics, industrial equipment, automotive applications | High-volume production, precise component placement, reduced assembly time, cost-effectiveness |

| Through-Hole Technology (THT) | Assembly of components with leads that are inserted into drilled holes on the PCB. | High-power and robust applications | Strong mechanical connection, suitable for components handling high voltage/current, reliable in harsh environments |

Pioneer PCB Factory also incorporates advanced testing and inspection techniques throughout the manufacturing process to ensure that each board meets stringent quality and performance standards. This commitment to precision and innovation positions them as a leader in the production of specialized and complex circuit boards.

Industries Served by Pioneer PCB Factory

Pioneer PCB Factory's advanced manufacturing capabilities cater to a diverse spectrum of industries that demand high-reliability and performance circuit boards. Their expertise in producing complex PCBs, including rigid-flex designs, makes them a critical supplier for sectors where precision and durability are paramount.

- Avionics

The avionics industry requires PCBs that can withstand extreme temperatures, vibrations, and altitudes. Pioneer PCB Factory provides robust and reliable boards for flight control systems, navigation equipment, and communication devices in both commercial and military aircraft. - Deep Space Exploration

For deep space missions, PCBs must function reliably in the harsh vacuum of space, enduring radiation exposure and extreme temperature fluctuations. Pioneer PCB Factory's expertise in high-reliability manufacturing is essential for spacecraft, satellites, and exploration equipment. - Military and Defense

The military sector requires PCBs that are both rugged and high-performance, supporting battlefield communication systems, radar technologies, and weapons guidance systems. Pioneer PCB Factory delivers PCBs that meet stringent military standards, ensuring reliability under challenging conditions. - Satellite Communications

Satellite communication systems depend on high-frequency, low-loss PCBs for efficient data transmission and reception. Pioneer PCB Factory provides advanced PCB solutions that are critical for satellite payloads, control systems, and ground station equipment. - Medical Devices

The medical device industry utilizes PCBs in life-critical equipment, such as diagnostic and monitoring tools. Pioneer PCB Factory ensures high precision and quality, adhering to strict regulatory requirements to guarantee performance and reliability in the healthcare sector. - Telecommunications

Pioneer PCB Factory supports the telecommunications sector, providing PCBs for network infrastructure, base stations, and handheld devices. These PCBs facilitate high-speed communication and must meet demanding performance and reliability requirements.

| Industry | Application | Key PCB Requirements |

|---|---|---|

| Avionics | Flight control, navigation, communication | High-reliability, temperature resistance, vibration resistance |

| Deep Space Exploration | Spacecraft, satellites, exploration equipment | Radiation resistance, temperature stability, high vacuum operation |

| Military and Defense | Communication, radar, weapons guidance | Ruggedness, high-performance, military standards compliance |

| Satellite Communications | Satellite payloads, control systems, ground stations | High frequency, low loss, signal integrity |

| Medical Devices | Diagnostic equipment, monitoring devices | High precision, quality, regulatory compliance |

| Telecommunications | Network infrastructure, base stations, handheld devices | High speed, performance, reliability |

Pioneer PCB Factory's Global Presence and Reach

Pioneer PCB Factory has established a significant global footprint, extending its reach beyond its primary operational locations to serve a diverse international clientele. This expansion is driven by the increasing demand for advanced printed circuit board solutions across various industries worldwide. The company's strategic locations and partnerships enable them to efficiently meet the needs of customers in key markets, with a notable presence in the Middle East.

While precise details about all of Pioneer PCB's global locations are proprietary, it's evident through their industry engagements that they maintain a strong operational and distribution presence in several key regions. This includes:

- Middle East

With a firm presence in Saudi Arabia and the broader Middle East, this region serves as a primary market for Pioneer PCB Factory, catering to diverse sectors from telecommunications to defense. - North America

Pioneer PCB Factory maintains a presence in North America to serve the needs of key clients in aerospace, high tech, and medical industries. This presence includes sales, distribution, and potentially some manufacturing or research partnerships. - Europe

While specific locations may vary, the European market is strategically important for Pioneer PCB Factory, given the demand for high-quality PCB solutions in sectors such as automotive and industrial electronics. - Asia

Asia is a critical manufacturing and consumer hub, and Pioneer PCB Factory is involved in supply chains and sales throughout the region. This includes strategic partnerships to address both manufacturing and distribution.

Pioneer PCB Factory's ability to deliver advanced PCB solutions globally is facilitated by its robust supply chain and logistical network, ensuring timely delivery and consistent quality. Their approach is tailored to meet the specific needs of various regions while maintaining consistent high standards of quality.

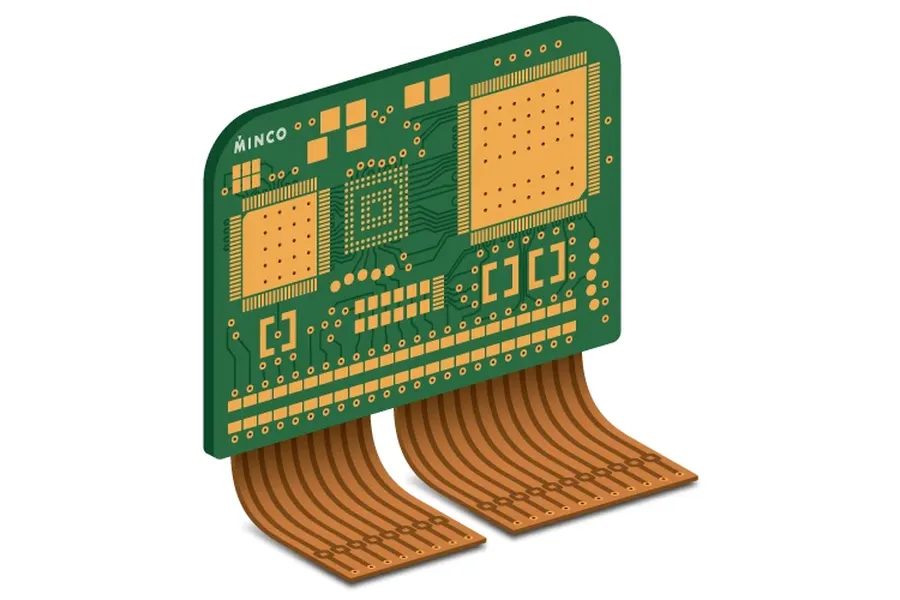

Rigid Flex PCB Manufacturing at Pioneer PCB Factory

Pioneer PCB Factory excels in the manufacturing of rigid-flex PCBs, a technology that combines the advantages of both rigid and flexible circuit boards. This capability allows for the creation of complex electronic assemblies that offer superior performance and space efficiency.

The manufacturing process for rigid-flex PCBs involves several key steps, each demanding precision and expertise. This process begins with the design phase, where engineers carefully layout both the rigid and flexible layers. Following the design, the flexible substrate is created, typically using materials like polyimide, known for their flexibility and thermal stability. This flexible layer then undergoes a precise etching process to define the circuitry. For rigid sections, traditional PCB materials such as FR-4 are utilized and processed with standard PCB manufacturing techniques. Finally, these rigid and flex layers are laminated together with specialized adhesives to form the final integrated structure. Pioneer PCB Factory utilizes state-of-the-art equipment and techniques to ensure the precise alignment and bonding of all layers, delivering reliable and high-performance rigid-flex PCBs.

| Aspect | Rigid PCBs | Flexible PCBs | Rigid-Flex PCBs |

|---|---|---|---|

| Material | FR-4, CEM-1 | Polyimide, Polyester | Combination of Rigid and Flexible Materials |

| Flexibility | Inflexible | Highly Flexible | Flexibility in designated areas |

| Application | General Electronics, Mounting Components | Dynamic and Static Flexing | High-Density Interconnects, Space-Constrained Applications |

| Complexity | Relatively Simple | Complex in assembly | Highly Complex Manufacturing Process |

| Cost | Lower Cost | Moderate Cost | Higher cost due to complex manufacturing |

The primary advantage of using rigid-flex PCBs over traditional rigid or flexible boards lies in their ability to integrate multiple circuit boards into a single structure, significantly reducing the need for connectors and cables. This not only simplifies the assembly process but also enhances the reliability of the final product by minimizing potential points of failure. The reduction in interconnects leads to improved signal integrity and lower impedance, which are crucial in high-speed applications. Furthermore, rigid-flex PCBs provide a highly customizable solution, allowing engineers to tailor the shape and functionality of the circuit to the specific demands of the application. This makes rigid-flex boards an ideal choice for compact, high-performance devices.

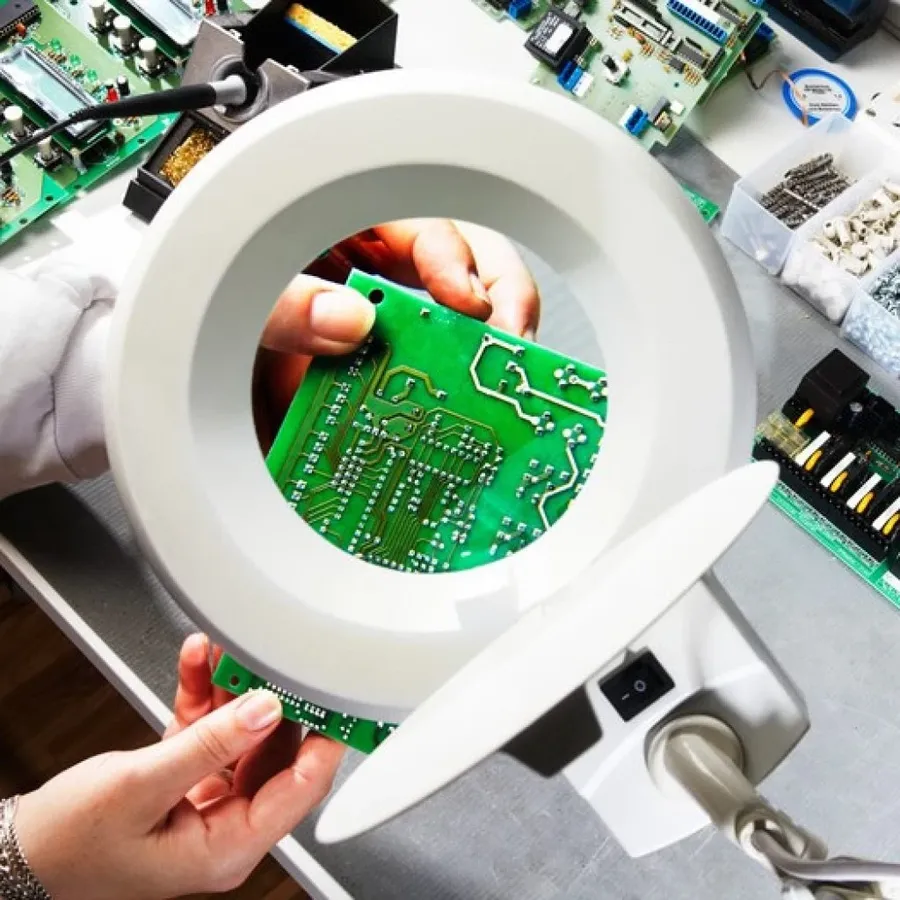

Quality Assurance and Certification at Pioneer PCB Factory

Pioneer PCB Factory upholds stringent quality assurance protocols to guarantee the reliability and performance of their circuit boards. These measures encompass rigorous testing, meticulous material selection, and adherence to industry best practices, ensuring that every product meets the highest standards of quality and durability.

The factory's commitment to quality is further substantiated by its certifications, which demonstrate adherence to internationally recognized standards.

| Quality Assurance Aspect | Description |

|---|---|

| Incoming Material Inspection | Thorough checks of all raw materials and components to ensure they meet specifications prior to manufacturing. |

| In-Process Quality Control | Continuous monitoring and testing of PCBs throughout the manufacturing process to detect and correct any deviations early on. |

| Automated Optical Inspection (AOI) | Use of advanced optical equipment to automatically inspect circuit boards for defects such as shorts, opens, and improper component placement. |

| Electrical Testing | Comprehensive electrical testing, including continuity and impedance tests, to verify the functionality of each circuit board. |

| Final Quality Check | A final, detailed inspection before packaging and shipping, to ensure only compliant products reach the customer. |

While specific certifications can vary based on industry needs and standards, Pioneer PCB Factory is typically compliant with globally recognized certifications such as:

- ISO 9001

A globally recognized standard for quality management systems, demonstrating the factory's commitment to consistent quality and customer satisfaction. - IPC Standards

Adherence to IPC standards, which are the industry benchmark for PCB manufacturing and assembly, ensuring products meet specified performance criteria. - Specific Industry Certifications

Depending on the industry served, Pioneer PCB Factory may also hold other specific certifications such as AS9100 for aerospace applications or medical device certifications for relevant products.

Frequently Asked Questions about Pioneer PCB Factory

This section addresses common questions about Pioneer PCB Factory, providing a comprehensive overview of its operations, capabilities, and reach. By answering these queries, we aim to clarify key aspects for potential clients, partners, and stakeholders.

- Where is Pioneer PCB Factory located?

While the specific address may vary, Pioneer PCB Factory has a significant presence in Saudi Arabia, often with facilities strategically positioned to serve the Middle East market effectively. For precise location details, it's best to consult their official website or contact them directly. - What types of PCBs does Pioneer PCB Factory specialize in?

Pioneer PCB Factory is highly regarded for its expertise in manufacturing rigid-flex PCBs, which integrate both rigid and flexible circuit board sections. These are particularly suited for complex and demanding applications. Additionally, they produce a range of other specialized boards based on client needs and technological advancements. - How many employees does Pioneer PCB Factory have?

As a major player in the PCB manufacturing industry, Pioneer PCB Factory employs a substantial number of skilled professionals, including engineers, technicians, and production staff. This number can vary based on project volume and expansion. Exact figures are generally not publicly disclosed. - Does Pioneer PCB Factory offer prototyping services?

Yes, Pioneer PCB Factory typically offers prototyping services to clients to test and refine their designs before full-scale production. This is a crucial step to ensure the quality and functionality of the final product. - What are the key industries that Pioneer PCB Factory serves?

Pioneer PCB Factory caters to a diverse range of sectors, including avionics, military, deep space exploration, and satellite communications. Their highly specialized PCBs are designed to meet the stringent requirements of these demanding industries. - Is Pioneer PCB Factory certified to any international quality standards?

Pioneer PCB Factory adheres to stringent quality standards, and is often certified under industry standards, including ISO certifications. These standards are important for ensuring the reliability and quality of their products. - How can I request a quote from Pioneer PCB Factory?

To request a quote, it is advisable to contact Pioneer PCB Factory directly through their website or official channels. Provide them with your specific requirements, including PCB type, quantities, and desired specifications. This will allow them to provide the most accurate pricing and lead time estimates.

Pioneer PCB Factory vs. Other PCB Manufacturers: A Comparative Analysis

Pioneer PCB Factory distinguishes itself in the competitive PCB manufacturing landscape through its specialization in complex, high-reliability circuit boards, particularly rigid-flex PCBs. A comparative analysis reveals key differentiators from other manufacturers, extending beyond basic production capabilities to encompass technological expertise, industry focus, and quality assurance practices.

| Feature | Pioneer PCB Factory | Typical PCB Manufacturers |

|---|---|---|

| Core Competency | High-reliability rigid-flex PCB manufacturing, specialized for aerospace, defense, and satellite applications. | General PCB manufacturing, often focusing on high-volume, standard designs. |

| Technology Focus | Advanced materials, precision assembly, and tight tolerance control. Extensive R&D in high-density interconnect (HDI) and advanced packaging. | Standard materials, volume assembly, and adherence to standard specifications. |

| Industry Specialization | Extensive experience in avionics, deep space exploration, military, and satellite communications where high reliability is paramount. | Broader industry base, including consumer electronics, automotive, and industrial sectors. |

| Quality Standards | Stringent quality control, AS9100 and other high-reliability industry certifications, emphasizing long-term performance. | Variable, ranging from ISO to industry-specific, but may not always meet the rigorous demands of aerospace or defense. |

| Supply Chain Management | Robust and secure supply chain management focusing on traceability and reliability, which can be more demanding for specialized materials. | Supply chain management that is geared towards the most common materials, with less focus on secure sourcing. |

| R&D Investment | Significant investment in research and development to meet the evolving needs of cutting-edge technology industries. | Typically lower investment in R&D, which tends to follow market demands more than lead innovative development. |

Future Trends and Innovations at Pioneer PCB Factory

Pioneer PCB Factory is strategically positioned to lead in the next wave of PCB technology, focusing on research and development initiatives that anticipate future demands. This forward-thinking approach is essential for maintaining a competitive edge and meeting the evolving needs of industries requiring advanced circuit board solutions.

The company's future direction is marked by several key areas of innovation. These include:

- Advanced Materials Research

Exploring new substrate materials with improved thermal, electrical, and mechanical properties. This includes the development of composite materials and advanced polymers that can withstand extreme operating environments and enable higher performance circuit boards. - Miniaturization and High-Density Interconnect (HDI) Technologies

Investing in technologies that allow for the production of smaller, more densely packed circuit boards. This involves fine-line lithography and advanced via drilling techniques to increase component density and improve electrical performance while reducing footprint. - Embedded Systems and Integration

Expanding capabilities in embedding passive components directly into the PCB layers, which reduces overall board size and cost, while enhancing reliability and functionality, creating more compact and integrated solutions for advanced electronic devices. - Sustainable Manufacturing Processes

Implementing more environmentally friendly PCB manufacturing methods, this includes reducing waste, using recyclable materials, and adopting processes that minimize the use of hazardous chemicals. This aligns with growing environmental concerns and promotes long-term sustainability. - Automation and Artificial Intelligence

Incorporating automation and AI to optimize the production process. This includes automated inspection systems, predictive maintenance, and AI-driven design tools to improve efficiency, reduce defects, and accelerate time-to-market. - Advanced Testing and Reliability Protocols

Developing more robust and precise testing methodologies to ensure the highest quality and reliability of circuit boards. This includes non-destructive testing methods and predictive reliability analysis to guarantee product performance in diverse applications.

These innovations will enable Pioneer PCB Factory to provide solutions for emerging applications in areas such as 5G communications, artificial intelligence, advanced automotive electronics, and space exploration. The commitment to research and development underscores Pioneer's dedication to leading the industry in quality, performance, and innovation.

Pioneer PCB Factory stands as a prominent example of how dedication to innovation and quality can lead to global influence in the specialized field of PCB manufacturing. Their work not only impacts industries like aerospace and military but also continues to push the boundaries of what's possible with circuit board technology. As the demand for advanced electronics grows, Pioneer PCB Factory remains at the forefront, ready to meet the challenges of the future, cementing its position as a key player in the electronic component manufacturing landscape. Pioneer PCB Factory’s commitment to excellence positions them as a critical resource for advanced electronic solutions globally.

AnyPCBA

AnyPCBA