The Ultimate Guide to UL Certified PCB Manufacturers

In today's interconnected world, printed circuit boards (PCBs) are the backbone of almost every electronic device, from smartphones to industrial machinery. However, not all PCBs are created equal. UL certification serves as a crucial benchmark for quality and safety, ensuring that PCBs meet rigorous standards. This article will serve as your comprehensive guide to understanding the importance of UL certified PCB manufacturers, diving deep into what it means to be UL certified, the benefits it offers, and how to select the best partner for your needs, highlighting the crucial role of UL certified pcb manufacturers.

Understanding UL Certification for PCBs

UL certification for Printed Circuit Boards (PCBs) signifies that these components meet specific safety and performance standards set by Underwriters Laboratories (UL), a globally recognized safety science organization. This certification is crucial for ensuring that electronic products are safe for use and operate reliably. It's not just a mark of compliance, but also a testament to a manufacturer's commitment to quality and safety.

UL’s role is pivotal in the electronics industry, focusing on testing and certifying products, components, and materials. Their standards for PCBs, primarily UL 796, outline the requirements for construction, materials, and manufacturing processes. These rigorous assessments guarantee that certified PCBs will perform as intended and minimize risks to end-users.

The Importance of UL 796 Standard

The UL 796 standard is the cornerstone for ensuring the safety and reliability of printed circuit boards (PCBs). It specifies the rigorous requirements for PCB construction, materials, and manufacturing processes, and adherence to it is essential for producing dependable electronic products.

Specifically, UL 796 outlines crucial aspects including:

- Material Specifications

The standard mandates the use of specific materials that are proven to be flame-retardant, have specific electrical properties, and provide mechanical integrity. This includes base laminates, copper foil, soldermask and other vital components of the PCB. The goal is to minimize fire hazards and ensure long term reliability. - Construction Methods

UL 796 dictates minimum performance requirements for the PCB construction, such as trace spacing, copper thickness, and via integrity. These specifications are key in preventing shorts, arcing, and other electrical failures that could result in safety hazards and product failure. - Manufacturing Process Control

The standard insists on tight control over the manufacturing process, including lamination, drilling, plating, and etching processes. This ensures uniformity and repeatability from batch to batch of the boards, guaranteeing consistent performance and safety standards across all produced boards. - Performance Testing

Rigorous testing protocols are established to examine the boards under different conditions. These tests are essential to simulate real-world stresses that the board may encounter during operation, such as thermal shock, electrical overload, and mechanical stress, verifying its integrity under severe operating parameters.

Complying with the UL 796 standard is not just a regulatory necessity, but a commitment to quality and safety. Using UL 796 certified PCBs can reduce the risks of product defects, failures, and potential hazards, leading to improved product reliability and customer trust. By choosing a manufacturer that adheres to UL 796, companies protect their brand reputation and minimize potential legal liabilities.

| Aspect | UL 796 Requirement | Importance |

|---|---|---|

| Materials | Specific flame-retardant materials with defined electrical and mechanical properties | Ensures safety and reduces fire risks |

| Construction | Precise trace spacing and copper thickness | Prevents electrical shorts and failures |

| Manufacturing | Controlled processes for lamination, drilling, plating, and etching | Guarantees consistent quality and performance |

| Testing | Simulate thermal shock, electrical overload, and mechanical stress. | Verifies the board’s integrity under severe operating conditions. |

Benefits of Using UL Certified PCB Manufacturers

Engaging a UL certified PCB manufacturer offers substantial advantages, primarily centered around enhanced product safety, reduced potential for defects and failures, and elevated customer confidence. These benefits translate directly into tangible financial and reputational gains for businesses. UL certification, specifically adherence to UL 796, signifies a commitment to rigorous standards in PCB design, material selection, and manufacturing processes.

- Enhanced Product Safety

UL certification ensures that PCBs meet stringent safety standards, reducing the risk of electrical fires, shorts, and other hazards. This is critical for safeguarding end-users and preventing product recalls. - Reduced Risk of Defects and Failures

Manufacturers adhering to UL standards employ robust quality control processes, leading to a lower incidence of manufacturing defects and premature failures in PCBs. This translates to increased reliability and longer product lifecycles. - Increased Customer Confidence

The UL mark is a globally recognized symbol of safety and quality. Products featuring PCBs from a UL-certified manufacturer instill confidence in customers, enhancing brand reputation and driving sales. - Reduced Liability

Using UL certified components can limit legal liability in the event of product failures, demonstrating due diligence in safety and quality control. - Access to International Markets

Many international markets require UL certification or recognition for electronic products. Using UL-certified PCBs facilitates market access and compliance with global standards. - Financial Gains through Reduced Costs

Though there is an upfront investment, the long-term cost savings derived from decreased defects, lower failure rates and fewer product returns can greatly contribute to profitability and efficiency. - Reputational Gains through Enhanced Reliability

Reliable products lead to satisfied customers and positive word-of-mouth which boosts the brand value, positioning companies ahead of competitors.

The UL Certification Process for PCB Manufacturers

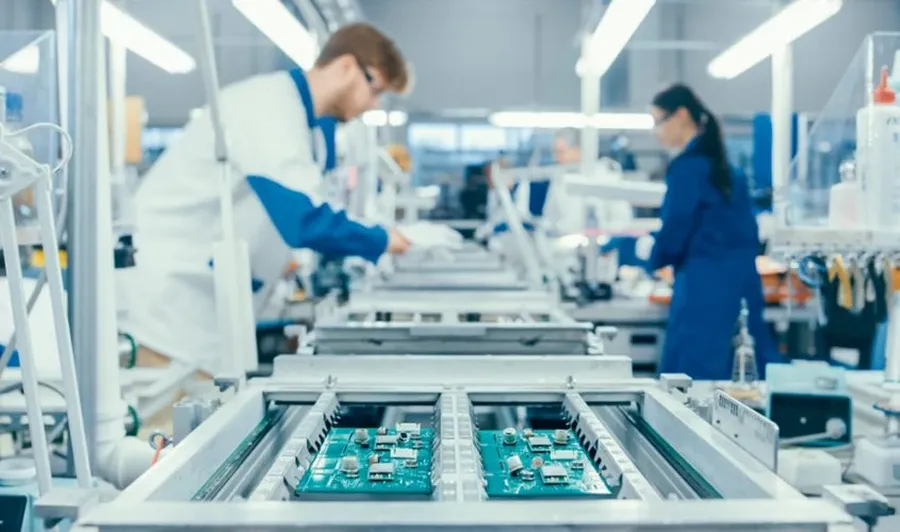

The journey to becoming a UL certified PCB manufacturer is a rigorous, multi-stage process designed to ensure that the manufacturer consistently meets high safety and performance standards. This process involves a thorough evaluation of the manufacturer's facilities, processes, and quality control systems.

- Initial Application and Documentation

The process begins with the PCB manufacturer submitting a formal application to Underwriters Laboratories (UL). This application must include detailed documentation about the manufacturer's facilities, PCB manufacturing processes, materials used, and quality control procedures. The manufacturer must demonstrate an understanding of and commitment to UL 796 standards. - Preliminary Evaluation and Testing

Following the application, UL conducts a preliminary evaluation of the documentation. If the documentation meets the initial requirements, UL will proceed to schedule on-site audits of the manufacturing facility. This audit ensures that the facility and production processes align with the documentation and UL 796 standards. Samples of PCBs from the manufacturer may also be selected for initial testing. - On-Site Audit and Assessment

UL auditors conduct a comprehensive on-site assessment of the PCB manufacturing facility. This involves observing the production line, inspecting equipment, verifying material handling and storage, and reviewing quality control systems. The goal is to verify compliance with UL 796 in real-world conditions. - Product Testing and Compliance

PCB samples are subjected to a series of rigorous tests to ensure they meet the performance and safety requirements specified in UL 796. These tests can cover a range of parameters such as flammability, electrical insulation, mechanical strength, and environmental resistance. This phase is critical to confirm that the end product meets safety requirements. - Certification Granting

If the audit and product testing are successful, UL will grant the manufacturer UL certification. This certification allows the manufacturer to use the UL mark on their PCBs, indicating that they comply with UL 796. The certificate will also include details such as the specific materials and processes approved. - Ongoing Compliance Audits and Surveillance

UL certification is not a one-time event. UL conducts ongoing surveillance audits of the certified PCB manufacturer's facilities and processes to ensure continuous compliance with UL standards. These audits help to identify any deviations and ensure that certified manufacturers maintain high standards of quality and safety. This may include testing of samples from current production batches.

How to Verify a PCB Manufacturer's UL Certification

Verifying a PCB manufacturer's UL certification is crucial to ensure the safety and reliability of your electronic products. This process involves several key steps, from utilizing the UL iQ database to identifying specific markings on the PCBs themselves, and understanding potential pitfalls in the selection process.

- Utilize the UL iQ Database

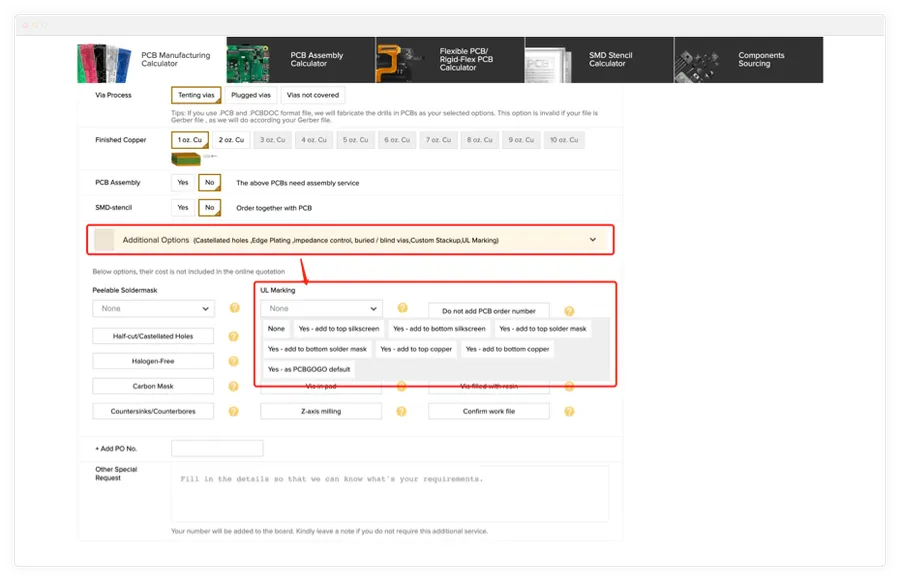

The UL iQ database is the primary resource for verifying a manufacturer's UL certification status. This online tool allows you to search for certified companies using their file number or company name. Ensure that the manufacturer is listed and that their certification covers the specific type of PCBs you require, such as UL 796. - Inspect UL Markings on PCBs

A genuine UL certified PCB will typically bear specific UL markings. These markings include the UL logo, the manufacturer’s file number, a control number, and a date code, which identifies the date and location of manufacture. These should be clearly and permanently marked on the PCB, according to UL standards. - Confirm UL File Number

The UL file number is a unique identifier assigned to each certified manufacturer. You can verify the validity of a manufacturer’s UL file number in the UL iQ database. Make sure the file number on the PCB matches the one listed in the database for the manufacturer you are using. - Verify Certification Scope

Confirm that the scope of the UL certification covers the specific PCB technology and material you are procuring. For example, a manufacturer may be certified for single-layer PCBs, but not for multilayer boards, or vice-versa. Check the fine print within the certification documentation to ensure the scope matches your needs. - Beware of Counterfeit Markings

Counterfeit UL markings are a serious concern. If the markings appear to be of low quality, inconsistent, or not in line with UL standards, this should raise a red flag. Inconsistencies, blurred printing, misspellings, or poor materials are usually the main culprits of fake UL markings. - Conduct Independent Audits

Consider conducting independent audits to verify that the manufacturer's processes and quality control systems align with UL requirements. This is especially important for critical applications or when working with a new supplier. - Request Certification Documentation

Request a copy of the manufacturer's UL certification documentation directly. Examine it closely to verify the validity of their UL certification, the specific standards covered (e.g., UL 796), and the expiration date. The documentation should come directly from the manufacturer and not a third party.

Choosing the Right UL Certified PCB Manufacturer

Selecting a UL certified PCB manufacturer requires careful consideration of several key factors to ensure the production of reliable, safe, and high-quality printed circuit boards. This section outlines the essential criteria and provides a framework for evaluating potential partners.

The following table provides a structured approach for assessing and comparing UL certified PCB manufacturers based on critical parameters:

| Factor | Description | Importance |

|---|---|---|

| Manufacturing Capabilities | Range of PCB technologies, complexity, layer count, and volume capabilities. | High: Aligns with project requirements and future scalability. |

| Materials Expertise | Knowledge and experience with various PCB materials (e.g., FR-4, high-speed laminates, specialized substrates). | High: Ensures proper material selection for performance and reliability. |

| UL Certification Scope | Verify the specific UL standard and PCB types the manufacturer is certified for (e.g., UL 796, specific material categories). | High: Direct correlation to compliance and safety. |

| Lead Times | Time from order placement to delivery of PCBs. | Medium: Impacts project timelines and time to market. |

| Cost-Effectiveness | Balance between price and quality, including tooling, material, and fabrication costs. | Medium: Critical for budget management and ROI. |

| Quality Control | Adherence to quality standards, including testing procedures and inspection processes, and IPC standards. | High: Minimizes defects and ensures PCB performance. |

| Technical Support and Communication | Availability of technical staff for design assistance, communication clarity and responsiveness to inquiries. | Medium: Facilitates smooth project execution and problem solving. |

| References and Reputation | Positive testimonials, a track record of successful projects and reliability. | Medium: Provides assurance of quality and service. |

By systematically evaluating these factors, businesses can make well-informed decisions when selecting a UL certified PCB manufacturer. Prioritizing alignment between project needs and a manufacturer's capabilities is crucial for success.

Frequently Asked Questions About UL Certified PCB Manufacturers

This section addresses common inquiries about UL certification for Printed Circuit Boards (PCBs) and the manufacturers that produce them. Understanding UL standards is crucial for ensuring the safety and reliability of electronic products. This FAQ aims to provide clarity on various aspects of UL certification, from its meaning to verification processes.

- What does UL certification for PCBs mean?

UL certification for PCBs signifies that a printed circuit board has been tested and meets specific safety and performance standards set by Underwriters Laboratories (UL). These standards, particularly UL 796, cover material flammability, electrical safety, and mechanical integrity. This certification assures that the PCB is designed and manufactured to minimize the risk of fire, electric shock, and other hazards. - How can I verify if a PCB manufacturer is UL certified?

To verify a PCB manufacturer's UL certification, you should first check their official website for their UL certification number. You can then confirm the validity of the certification using the UL iQ database (available on the UL website), which lists all certified manufacturers. In addition, look for the UL mark on the PCBs themselves or their packaging. Always cross-reference this information to confirm the authenticity of the certification. - What is the difference between UL 796 and UL 94 standards?

UL 796 is the specific standard for printed wiring boards. It covers the requirements for the design, materials, manufacturing processes, and performance characteristics of PCBs. UL 94, on the other hand, is a standard for flammability of plastic materials. While UL 796 includes flammability requirements specific to PCBs, it references UL 94 test methods for assessing material flammability ratings. Therefore, a UL 796 certified PCB incorporates UL 94 criteria as part of its flammability safety standard but is a much broader certification. - What steps should I take if I suspect a counterfeit UL mark on a PCB?

If you suspect a counterfeit UL mark on a PCB, immediately stop using the product. Report the issue to the supplier and request documented proof of certification. Also, you should report the matter to Underwriters Laboratories, providing as much detail as possible, including photos of the markings and the supplier's information. UL takes cases of counterfeiting very seriously. Counterfeit UL marks are unsafe, and reporting this ensures the safety of the market and consumers. - What are the key requirements of UL 796 standard that PCB manufacturers must adhere to?

The UL 796 standard mandates rigorous compliance in various aspects of PCB manufacturing. This encompasses the precise specifications for base materials, ensuring they meet stringent flammability ratings and possess the required electrical and mechanical properties. It also dictates the allowable tolerances for trace width and spacing, guaranteeing signal integrity and preventing shorts. Crucially, it covers the construction and assembly processes, ensuring each step adheres to UL standards for reliability and safety. Additionally, manufacturers must implement robust quality control programs, from raw material inspection to final product testing, to ensure consistent adherence to these standards. - What are the advantages of choosing UL certified PCB manufacturers over non-certified ones?

Opting for UL certified PCB manufacturers provides several crucial benefits. It ensures the PCBs are manufactured under strict quality control and safety standards, significantly reducing the risk of defects, failures, and potential safety hazards. This enhanced reliability translates into safer and more dependable end products, minimizing costly recalls and repairs. Furthermore, using UL certified PCBs instills greater confidence in end-users, boosting your brand's reputation for quality and safety and providing a clear marketing advantage in a competitive market. - How does UL certification impact the liability of a product?

While UL certification does not absolve a manufacturer of all liability, it demonstrates a commitment to product safety and compliance. In the event of a product failure or incident, having UL-certified components like PCBs can serve as evidence of due diligence, potentially mitigating legal and financial risks. It indicates that the components have been tested and meet industry safety standards, which can be a critical factor in liability assessments. This can be very useful in proving a responsible approach to manufacturing and distribution, but it does not replace the responsibility of quality control and manufacturing best practices.

The Future of UL Certified PCB Manufacturing

The landscape of UL certified PCB manufacturing is continually evolving, driven by advancements in materials science, fabrication technologies, and increasingly stringent regulatory demands. Manufacturers are adapting to these changes, focusing on sustainability, miniaturization, and enhanced performance.

Emerging trends are pushing the boundaries of what's possible in PCB design and production, with a greater emphasis on high-reliability applications and integration of advanced components. These trends are impacting not only the technical aspects of manufacturing but also the very definition of what it means to be a UL certified pcb manufacturer.

- Advanced Materials

The use of novel materials with improved thermal, electrical, and mechanical properties is gaining momentum. These materials enable the production of PCBs that are more durable, efficient, and capable of withstanding extreme operating conditions. For instance, high-performance polymers and ceramics are being explored as alternatives to traditional materials. - Miniaturization and High-Density Interconnect (HDI)

The demand for smaller, more compact electronic devices is driving the need for miniaturized PCBs with higher circuit densities. HDI technology, with its fine lines and microvias, is crucial for achieving these designs. This requires advanced manufacturing techniques and precise quality control, posing new challenges for UL certification. - Flexible and Stretchable PCBs

Flexible and stretchable PCBs are becoming increasingly popular for wearable electronics, medical devices, and automotive applications. These PCBs require specialized materials and manufacturing processes. UL certification standards are evolving to address the unique challenges associated with these types of PCBs. - Smart Manufacturing and Automation

The integration of automation, artificial intelligence (AI), and machine learning (ML) into PCB manufacturing is streamlining production, improving efficiency, and reducing defects. These technologies enable real-time monitoring of production parameters and predictive maintenance, contributing to higher-quality and more reliable PCBs. UL certification will likely incorporate metrics related to these processes. - Sustainability and Environmental Compliance

Growing environmental awareness is driving the adoption of sustainable manufacturing practices in the PCB industry. This includes the use of eco-friendly materials, reduced waste, and responsible disposal methods. UL certification standards may evolve to incorporate environmental compliance requirements, encouraging manufacturers to prioritize sustainability. - Evolving Regulatory Landscape

Regulatory requirements for electronic products are becoming more stringent, necessitating a proactive approach to compliance. UL certified pcb manufacturers must stay abreast of changes in standards and regulations to ensure their products continue to meet safety and performance requirements. This includes global standards for specific markets.

Choosing a UL certified PCB manufacturer is not just about compliance; it's about ensuring the safety, reliability, and longevity of your electronic products. By understanding the UL certification process and carefully selecting a partner that meets your specific needs, you can significantly enhance the quality of your products and increase customer confidence. The future of PCB manufacturing is continually advancing, and staying informed about the latest trends and standards, especially from ul certified pcb manufacturers, will provide a competitive edge in the ever-evolving electronics industry.

AnyPCBA

AnyPCBA