Top 10 PCB Suppliers: Global Leaders & How to Choose the Right One

Printed Circuit Boards (PCBs) are the backbone of modern electronics, enabling everything from smartphones to satellites. Choosing the right PCB supplier is crucial for quality, cost, and reliability. This article delves into the top 10 PCB suppliers globally and in the USA, examining their strengths and guiding you on how to select the ideal partner for your projects. Just like the arteries in our body, a quality PCB from top suppliers, such as the ones mentioned here, enables the flawless operation of devices that support our daily lives, from the simplest remote controls to the most sophisticated medical equipment. Understanding the landscape of [top 10 pcb suppliers] is paramount to ensuring your electronic designs come to life effectively.

Global Leaders in PCB Manufacturing

The global printed circuit board (PCB) manufacturing landscape is dominated by a handful of key players, each possessing distinct geographical strengths and substantial market share. These companies are pivotal in supplying the complex circuitry that forms the backbone of modern electronics. Understanding their positions and capabilities is critical for any organization involved in electronic product development.

The leading PCB manufacturers are not just production facilities; they are innovation hubs that constantly push the boundaries of what's possible in circuit board technology. Their contributions range from high-density interconnect PCBs used in consumer electronics to specialized boards for aerospace and medical equipment.

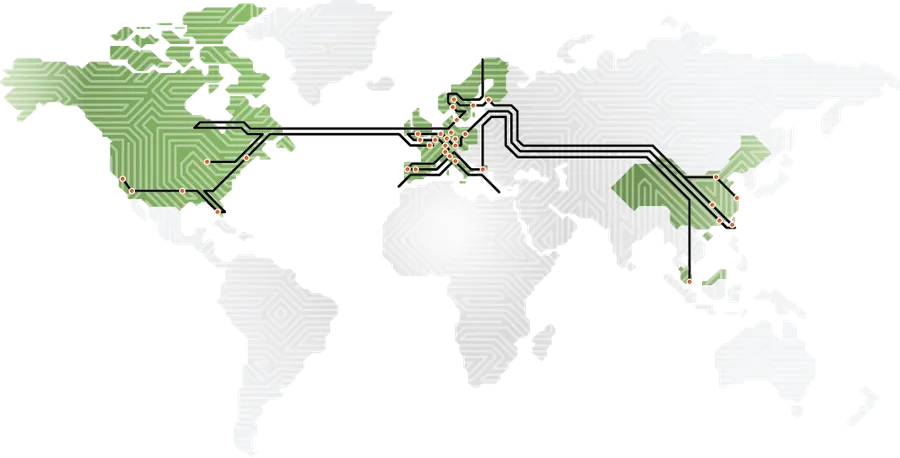

Key global PCB manufacturing leaders include companies like AT&S, a European powerhouse known for its high-end PCB technology, TTM Technologies, an American giant with a global footprint, and Zhen Ding Technology, a major player in the Asian market. These companies, along with others, are critical for global electronics supply chains and their performance impacts the availability and price of electronic products globally.

Geographical location plays a crucial role in the supply chain dynamics. For example, companies based in Asia often offer high-volume production capabilities, while European and North American companies might focus more on high-reliability, technologically advanced PCBs. This differentiation influences project management, lead times, and ultimately the project's overall success. Therefore, understanding the geographical advantages of various [top 10 pcb suppliers] helps in choosing the right partner.

Top PCB Suppliers in the USA

The United States is home to several leading printed circuit board (PCB) manufacturers, renowned for their technological innovation, quality, and diverse capabilities. These companies consistently rank among the top PCB suppliers globally, serving critical sectors such as aerospace, defense, medical, and telecommunications. This section provides an in-depth look at some of the key players in the US PCB market, their strengths, and specializations.

Key players in the US market, such as TTM Technologies, Sanmina, and Jabil Inc., demonstrate exceptional expertise in advanced PCB manufacturing techniques, including HDI (High-Density Interconnect), rigid-flex, and RF/microwave PCBs. These manufacturers are distinguished by their ability to handle complex projects, deliver high reliability, and adhere to rigorous industry standards. Their consistent high ranking among top PCB suppliers reflects their continuous investment in research and development, enabling them to provide cutting-edge solutions to their customers.

- TTM Technologies

A major global manufacturer with a significant presence in the USA, TTM excels in high-technology PCBs, offering a wide range of solutions from standard to highly complex boards, particularly in the aerospace and defense sectors. Their expertise also covers HDI, RF/microwave, and rigid-flex technologies. - Sanmina

Sanmina provides end-to-end manufacturing solutions, including PCB fabrication, assembly, and system integration. They are recognized for their ability to handle large-scale projects and their expertise in high-mix, low-volume PCB production, primarily serving the industrial, medical, and communications industries. - Jabil Inc.

Jabil is a prominent contract manufacturer that offers a broad spectrum of services, including PCB manufacturing, with facilities across the USA and worldwide. Jabil's strengths are in its extensive global footprint and supply chain management capabilities, allowing for flexibility and cost-effectiveness for its clients. They are known for manufacturing PCBs used in consumer electronics and automotive industries. - Other Key U.S. PCB Suppliers

Beyond these giants, there are numerous other notable PCB suppliers in the USA, such as Advanced Circuits, a company known for its quick turnaround and prototyping services and Multek, a part of the Flex company, which specializes in flexible and rigid-flex PCB technology. These companies also contribute significantly to the US's PCB manufacturing capacity and technological prowess.

Key Factors in Choosing a PCB Supplier

Selecting the right PCB supplier is crucial for the success of any electronic product. This decision hinges on several key factors that directly impact the quality, cost, and timeliness of PCB production. A thorough evaluation of these aspects is essential to ensure a smooth manufacturing process and a reliable end product.

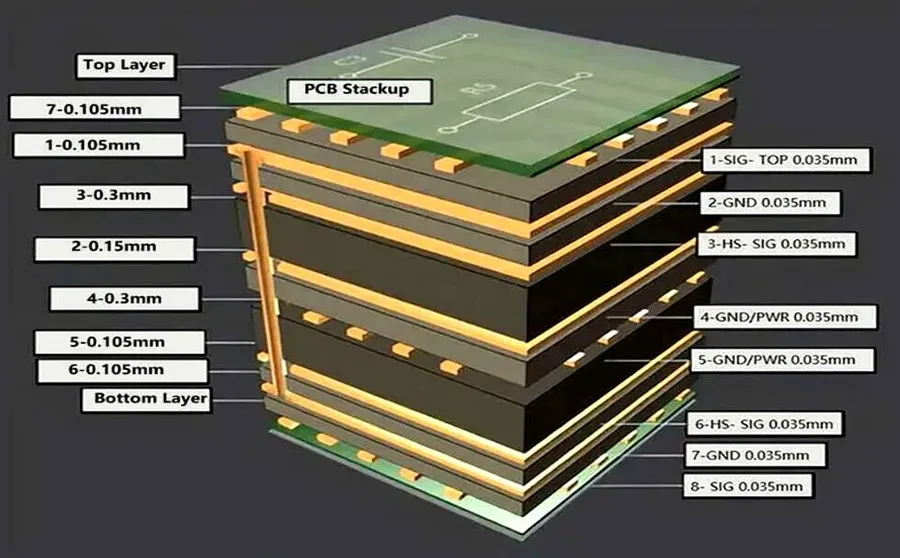

- Manufacturing Capabilities

Assess the supplier's technology, equipment, and experience in producing the type of PCBs needed (e.g., single-sided, double-sided, multilayer, flexible, rigid-flex). Look for capabilities in advanced technologies such as HDI (High-Density Interconnect), and microvia formation if your design requires it. A supplier's capabilities should align with your project's technical demands. For example, if your board requires a controlled impedance, the supplier should have the equipment and expertise to measure and maintain it. - Turnaround Time

Evaluate the supplier’s typical lead times, especially for prototype runs and production quantities. Inquire about their process for expediting orders if necessary. A key factor here is the time from design submission to having finished PCBs ready for assembly. Consider whether the supplier can meet your project deadlines without compromising quality. Ideally, they should have robust processes for all the stages of PCB manufacturing, from CAM data review to quality inspection. - Cost

While the price is a critical factor, focus on the total cost of ownership, which includes shipping, tooling, and potential rework. Seek transparent pricing structures and avoid suppliers with hidden costs. Request quotes from multiple suppliers and analyze them in detail. Consider not just the price per board, but also the cost per unit when factoring in scrap rate and rework. A thorough cost analysis should reveal the true financial commitment to a particular supplier. - Quality Control

Inquire about the supplier's quality certifications (e.g., ISO 9001, ISO 13485, IPC standards) and their quality assurance processes. Ask about their inspection methods, statistical process control (SPC), and any quality control data. Look for evidence of their commitment to quality, such as documentation of procedures, equipment calibration records, and staff training. PCB quality is directly linked to product performance and reliability. - Customer Support

Evaluate the supplier's responsiveness, technical expertise, and problem-solving capabilities. Look for a supplier who offers good communication, technical assistance, and design-for-manufacturability (DFM) feedback. A good supplier partner will be responsive and proactive in addressing issues and may be able to identify and fix design flaws before production, which can save costs and delays. Check reviews of customer support as this is an important component of a successful partnership.

Specialization of PCB Manufacturers: Beyond General Production

While many PCB manufacturers offer general production capabilities, the leading suppliers often distinguish themselves through specialized expertise. This section delves into the unique strengths of top PCB manufacturers, focusing on their ability to produce advanced and specialized circuit boards, such as flexible PCBs and high-frequency boards. Understanding these specializations is crucial for selecting the right partner for projects requiring more than just standard PCB production.

- Flexible PCBs

Flexible PCBs (FPCBs) are designed to bend and flex, making them suitable for applications where space is limited or dynamic movement is required. Manufacturers specializing in FPCBs possess the technology and expertise in materials handling and circuit design to create reliable flex circuits. These PCBs are commonly found in devices like smartphones, cameras, and wearable technology. - High-Frequency PCBs

High-frequency PCBs are designed to handle signals operating at very high frequencies, typically in the GHz range. These PCBs require specialized materials, precise manufacturing techniques, and careful signal integrity management. Applications include radar systems, 5G communication equipment, and high-speed data transmission. - Metal Core PCBs

Metal core PCBs, also known as MCPCBs, feature a metal base, usually aluminum or copper, as the core material, offering superior heat dissipation compared to standard FR-4 PCBs. MCPCBs are critical in high-power applications like LED lighting, power converters, and automotive electronics. - HDI PCBs

High-Density Interconnect (HDI) PCBs feature finer lines, vias, and higher connection pad densities per unit area. HDI PCBs are employed in applications requiring miniaturization and high-performance like handheld devices, medical devices, and high-speed networking hardware. - RF and Microwave PCBs

RF and Microwave PCBs are designed for radio frequency and microwave applications. These boards require precise impedance control, low-loss dielectric materials, and specialized surface finishes to ensure optimal performance, crucial for telecommunications, satellite, and radar systems. - Rigid-Flex PCBs

Rigid-flex PCBs combine the properties of both rigid and flexible PCBs in one integrated circuit board. These structures allow for complex electronic designs with increased reliability, design flexibility, and component density. Typical uses include aerospace, military, medical, and consumer electronics. - Specialized Material PCBs

Some PCB manufacturers specialize in using high-performance materials beyond standard FR-4. These may include polyimide, PTFE (Teflon), ceramic, or other specialized substrates that are chosen for their unique dielectric properties, thermal performance, and chemical resistance. These materials are used in high-reliability, high-temperature, and high-frequency applications.

Geographical Considerations When Choosing a Supplier

The geographical location of a PCB supplier significantly impacts lead times, shipping costs, and communication efficiency. Choosing between local, national, or international suppliers involves weighing these factors against specific project requirements and supply chain dynamics.

Local PCB Suppliers often provide faster turnaround times and easier communication due to closer proximity and similar time zones. However, they may have limited capabilities or higher costs compared to larger national or international suppliers. National suppliers offer a wider range of manufacturing capabilities and competitive pricing while still maintaining some degree of geographical proximity. International PCB suppliers, frequently based in Asia, can offer significant cost advantages and high-volume production capabilities, but might involve longer lead times, potential logistical challenges, and communication barriers. The best choice depends on a balance of these considerations with project specific requirements.

- Local Suppliers Advantages

Faster lead times, quicker communication, potential for in-person meetings, ease of visiting facilities, and alignment with local business practices. - Local Suppliers Disadvantages

Potentially higher costs, more limited manufacturing capabilities, less capacity for large volume production. - National Suppliers Advantages

Wider range of manufacturing options, competitive pricing, some level of geographical proximity, and generally more mature supply chains. - National Suppliers Disadvantages

Longer lead times compared to local, increased shipping costs and potential customs delays. - International Suppliers Advantages

Significant cost savings, ability to produce large volumes, and access to advanced technologies. - International Suppliers Disadvantages

Longer lead times, potential logistical complexities, communication challenges due to time zones and language, difficulties in auditing facilities.

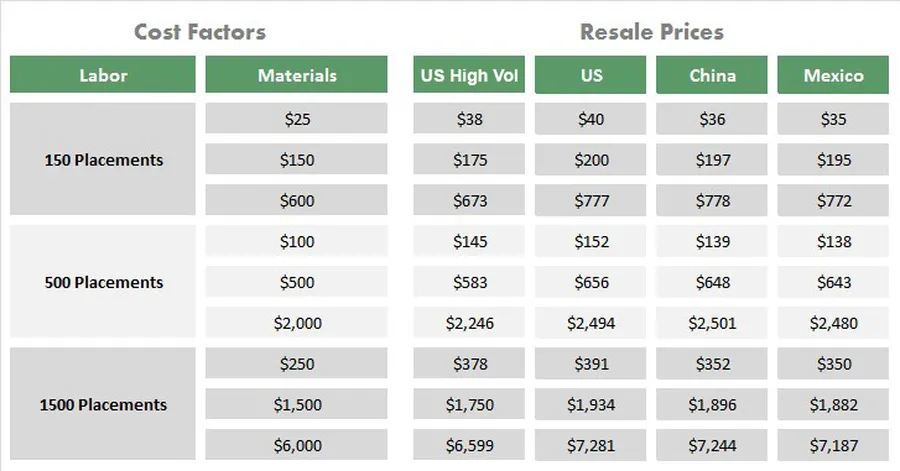

Cost Analysis: Finding the Best Value

Understanding the nuances of PCB manufacturing costs is crucial for securing the best value without compromising quality. This section provides a breakdown of key cost drivers and offers strategies for evaluating quotes from various PCB suppliers, ensuring you select a partner that aligns with your budget and performance requirements.

Several factors influence the final cost of PCBs, making it essential to consider them carefully when evaluating potential suppliers. These include:

- Material Costs

The base materials, such as FR-4, polyimide, or metal substrates, significantly impact the price. Material choice often depends on the specific application and performance requirements. - Complexity of Design

The number of layers, via types, trace widths and spacing, and the complexity of the circuit design all affect the cost. Intricate designs require more advanced manufacturing processes. - Production Volume

Larger production runs typically result in lower per-unit costs due to economies of scale. Prototype runs, conversely, are generally more expensive. - Surface Finish

Different surface finishes, such as ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling), or OSP (Organic Solderability Preservative) affect both cost and performance. - Manufacturing Tolerances

Tighter tolerances demand more precise manufacturing techniques, which typically increase production costs. Standard tolerances are usually more cost-effective. - Turnaround Time

Rush or expedited manufacturing typically comes with a premium price. Balancing lead times with project needs can help control costs. - Testing and Quality Assurance

Rigorous testing procedures, such as electrical testing, flying probe tests, or impedance control tests, add to the overall cost but are essential for ensuring reliability.

To find the best value from top PCB suppliers, consider these key steps:

- Obtain Multiple Quotes

Contact several suppliers and request detailed quotations, specifying your exact requirements. - Compare Pricing and Inclusions

Compare not just the price, but also what's included, such as testing, shipping, or special services. - Evaluate the Value Proposition

Consider the overall value, balancing cost with the supplier's reputation, quality, and support. - Negotiate and Optimize

Explore options for design adjustments that could lower costs without affecting performance and negotiate favorable payment terms or volume discounts where possible.

By considering these cost factors and following a strategic evaluation process, you can confidently select a PCB supplier that offers the optimal balance of quality, cost, and service for your project.

Frequently Asked Questions About PCB Suppliers

Navigating the world of PCB suppliers can be complex, this section addresses key questions to help you make informed decisions when selecting a PCB supplier.

- Who is the largest PCB supplier globally?

Determining the absolute 'largest' can depend on metrics like revenue, production volume, or market share. However, companies like AT&S, TTM Technologies, and Zhen Ding Technology are consistently recognized as some of the largest PCB suppliers worldwide based on these metrics. Their substantial production capabilities and global reach make them significant players in the PCB market. Detailed analysis of annual reports and market research can provide further insights. - Which PCB manufacturer is considered the best?

The concept of 'best' varies significantly depending on specific project requirements. Some manufacturers excel in high-volume, cost-effective production, while others specialize in high-complexity boards or niche technologies. For example, TTM Technologies is known for its advanced technology and high-performance PCBs. The 'best' PCB supplier will be the one that best aligns with a project's requirements for quality, cost, turnaround time and technology needs. Rigorous qualification processes should be conducted before selection. - What types of companies manufacture PCBs?

PCB manufacturing is undertaken by a diverse range of companies, including large global corporations, medium-sized businesses specializing in specific PCB types, and smaller, specialized shops that focus on prototyping or low-volume production. These companies range from vertically integrated manufacturers, who also produce the core materials for PCBs, to those that focus on manufacturing based on designs provided by the customer. Furthermore, contract manufacturers and electronic manufacturing service providers also often handle PCB manufacturing. The scale and specialization of these companies differ greatly. - How should I choose the right PCB manufacturer for my project?

Selecting a PCB manufacturer requires a careful evaluation of several factors. These include the manufacturer's production capabilities (e.g., minimum feature sizes, layer counts, material options), quality certifications (ISO, IPC), turnaround time for orders, cost structure, and their demonstrated ability to handle your specific technology requirements. The manufacturer's customer support and communication channels should also be considered. It’s essential to obtain quotes from multiple potential suppliers and ask for samples or references to assess quality before finalizing a decision. Proper due diligence is key to a successful partnership. - How do PCB suppliers ensure quality and reliability?

Reputable PCB suppliers use a variety of measures to guarantee quality and reliability, starting from stringent material selection and continuing through each phase of the manufacturing process. They adhere to industry standards such as IPC-A-600, utilizing quality management systems certified to ISO 9001, and often employ advanced inspection techniques including automated optical inspection (AOI) and electrical testing. Detailed documentation and traceability procedures are important as well. Furthermore, continuous process improvements and statistical process control methods are regularly deployed. Regular audits by third parties or customers are sometimes employed. Transparency in these procedures is a sign of reliable vendor. - What is the impact of lead time on choosing a PCB manufacturer?

Lead time has a significant impact on project timelines and costs. PCB suppliers offer different lead times depending on the complexity of the board, their production capacity, and any special material or process requirements. Faster turnaround times often command higher costs. Therefore, lead time must be balanced against the project schedule and budget. Communication with your chosen supplier about realistic lead times is necessary. Some manufacturers provide express services for prototypes or urgent orders. - Are there regional differences in PCB supplier pricing?

Yes, pricing can differ across regions. Factors influencing price include labor costs, material costs, energy costs, and governmental regulations. Regions with lower labor costs may offer competitive pricing, but this may be balanced with longer shipping times and potential communication or logistical challenges. It’s necessary to consider all aspects of cost, including potential shipping costs and import/export fees, in your cost calculations. It is best practice to compare several suppliers from various regions.

Comparison of Top PCB Suppliers

Selecting the right PCB supplier involves a detailed evaluation of various factors, including their technological capabilities, geographical reach, and specific industry expertise. This section provides a comparative analysis of several leading PCB suppliers, offering a structured overview to facilitate informed decision-making. This comparison focuses on the suppliers' core competencies, geographic advantages, and distinctive strengths, empowering users to quickly assess options and streamline their selection process.

| Supplier | Specialties | Geographic Reach | Key Strengths |

|---|---|---|---|

| AT&S | High-end PCBs, HDI, Substrates | Global (Europe, Asia, America) | Advanced technology, strong R&D, large-scale production. |

| TTM Technologies | Complex PCBs, RF, Aerospace & Defense | Global (North America, Asia) | Broad portfolio, excellent customer service, leading-edge technology. |

| Zhen Ding Technology | Flexible PCBs, Rigid-Flex PCBs | Asia-Pacific (primarily China) | High-volume production, focus on mobile devices, competitive pricing. |

| Sanmina | High-complexity PCBs, Backplanes, System Assembly | Global (North America, Europe, Asia) | Integrated manufacturing solutions, robust supply chain, strong industry experience. |

| Jabil Inc. | Wide range of PCBs, EMS, Supply Chain Solutions | Global (North America, Europe, Asia) | Comprehensive services, scalable solutions, experienced in various industries. |

| Unimicron | HDI, High-layer count, Rigid PCBs | Asia (primarily Taiwan) | Leading-edge technology, high-volume capacity, established industry presence. |

| Compeq Manufacturing | Rigid PCBs, HDI, High-frequency PCBs | Asia (primarily Taiwan, China) | Strong in mobile and computing, competitive costs, rapid prototyping capabilities. |

Future Trends in PCB Manufacturing

The PCB manufacturing landscape is undergoing rapid transformation, driven by technological advancements and evolving market demands. Understanding these future trends is crucial for selecting a PCB supplier that is not only capable today but also prepared for tomorrow's challenges.

- Miniaturization and High-Density Interconnect (HDI)

The demand for smaller, more compact electronic devices is driving the need for PCBs with higher circuit densities. This trend involves advanced manufacturing techniques like microvias, laser drilling, and fine-line etching, allowing for more functionality in less space. - Flexible and Stretchable PCBs

Beyond traditional rigid boards, flexible PCBs are gaining traction, particularly in wearable technology, automotive applications, and medical devices. Further advancements are pushing towards stretchable electronics, enabling even more innovative design possibilities. - Advanced Materials

The use of advanced materials, such as low-loss dielectrics, high-thermal conductivity substrates, and novel conductive inks, is increasingly important for improving performance and reliability of PCBs, particularly in high-speed and high-frequency applications. - Sustainability and Eco-Friendly Manufacturing

Concerns about the environmental impact of PCB manufacturing are driving demand for more sustainable materials and processes. This includes the reduction of hazardous chemicals, recycling of materials, and use of energy-efficient manufacturing methods. - Integration of AI and Automation

Artificial Intelligence (AI) and automation are being adopted to optimize manufacturing processes, improve quality control, reduce errors, and streamline supply chain management. This results in faster turnaround times, reduced costs, and higher overall efficiency. - Embedded Components

Embedding components within the PCB layers offers advantages like improved electrical performance, reduced size and weight, and increased reliability, thus becoming a pivotal element in modern PCB design. - Increased Focus on Signal Integrity

As electronic devices operate at higher frequencies, maintaining signal integrity in PCBs becomes crucial. This involves the need for controlled impedance, low-loss materials, and advanced design techniques.

Choosing the right PCB supplier is critical for ensuring the success of any electronics project. By examining the [top 10 pcb suppliers], both globally and within the USA, this guide has equipped you with the information needed to make an informed decision. Considering factors like cost, capability, location, and future trends will help you select the ideal partner to meet your manufacturing demands, whether it’s one of the global giants or a specialized provider. Keep in mind, the best supplier is one that aligns with your specific needs, ensuring a reliable, high-quality product that will power the future of technology. Always double check the capabilities and specializations of each of the [top 10 pcb suppliers] before making a commitment.

AnyPCBA

AnyPCBA