Top 10 Printed Circuit Board Manufacturers: A Global Overview

In today's world, where electronic devices are integral to our daily lives, the printed circuit board (PCB) is an essential component. From smartphones to medical equipment, PCBs form the backbone of modern technology. This article delves into the top 10 printed circuit board manufacturers worldwide, focusing on industry leaders such as TTM Technologies, Sanmina, and Jabil Inc., that are driving innovation and shaping the future of electronics.

Global PCB Manufacturing Landscape

The global printed circuit board (PCB) manufacturing industry is a critical component of the electronics supply chain, characterized by its substantial market size, diverse regional concentrations, and rapidly evolving technological landscape. This industry serves as the foundation for virtually all electronic devices, with a market value reaching hundreds of billions of dollars annually.

Asia Pacific dominates the PCB manufacturing landscape, with China being the single largest producer, followed by other significant contributors such as Taiwan, South Korea, and Japan. North America and Europe also hold key positions, particularly in high-reliability and specialized PCB markets. These regions also house leading research and development facilities that drive innovation within the industry.

Emerging trends in global PCB manufacturing are largely influenced by the demands of modern technology. These include the rise of High-Density Interconnect (HDI) PCBs, flexible circuits, and the incorporation of advanced materials to meet performance requirements in fields like telecommunications, automotive, and aerospace. Moreover, the industry is increasingly focusing on sustainability, seeking more environmentally friendly manufacturing processes and materials.

| Region | Market Share (Approximate) | Key Strengths | Notable Players |

|---|---|---|---|

| Asia Pacific | 70-80% | High volume production, cost competitiveness, broad technology range | China, Taiwan, South Korea, Japan |

| North America | 10-15% | High reliability PCBs, advanced R&D, specialized applications | TTM Technologies, Sanmina, Jabil Inc. |

| Europe | 5-10% | Automotive PCBs, high-quality production, niche markets | AT&S, Schweizer Electronic |

Top 10 PCB Manufacturers: An In-depth Analysis

The global printed circuit board (PCB) manufacturing landscape is dominated by a select group of companies that possess the technological prowess, manufacturing capacity, and global reach to serve a diverse range of industries. This section provides an in-depth analysis of the top 10 PCB manufacturers, examining their market share, technological strengths, and geographical footprint. These companies are pivotal in enabling the technological advancements that underpin modern electronics.

| Rank | Manufacturer | Headquarters | Key Technologies | Market Focus |

|---|---|---|---|---|

| 1 | TTM Technologies | USA | High-density interconnect (HDI), RF/microwave PCBs, aerospace and defense applications | Aerospace, defense, networking, communications |

| 2 | Sanmina | USA | Complex PCB assemblies, backplanes, system integration | Medical, industrial, telecommunications, automotive |

| 3 | Jabil Inc. | USA | High-volume manufacturing, advanced technology PCBs, supply chain solutions | Consumer electronics, automotive, healthcare, industrial |

| 4 | Unimicron | Taiwan | HDI, flexible PCBs, rigid-flex PCBs, IC substrate | Mobile devices, computers, networking equipment, automotive |

| 5 | Compeq | Taiwan | HDI, multilayer PCBs, large-size boards | High-end motherboards, servers, data centers, networking |

| 6 | Zhen Ding Technology | Taiwan | Flexible PCBs, HDI, rigid-flex PCBs | Mobile devices, wearables, automotive electronics |

| 7 | Tripod Technology | Taiwan | Multilayer PCBs, large-size boards, high-volume production | Computers, networking equipment, consumer electronics |

| 8 | Nippon Mektron | Japan | Flexible PCBs, automotive PCBs, specialty materials | Automotive, industrial, medical |

| 9 | Kingboard Chemical | Hong Kong | Multilayer PCBs, laminate materials, comprehensive PCB solutions | Telecommunications, networking, consumer electronics |

| 10 | Sumitomo Electric | Japan | Flexible PCBs, high-speed PCBs, specialty materials | Automotive, telecommunications, industrial equipment |

Leading PCB Manufacturers in the USA

The United States boasts a robust ecosystem of printed circuit board (PCB) manufacturers, catering to diverse industries with varying demands. These companies provide not just manufacturing capabilities but also expertise in design, assembly, and testing, making them vital partners for technology companies across sectors.

While the global PCB market is dominated by Asian manufacturers, the US maintains a strong presence, particularly in high-reliability, advanced technology, and specialized applications. Here's a look at some leading PCB manufacturers in the USA, focusing on their areas of expertise, product ranges, and the specific industries they serve.

- TTM Technologies

A major player globally, TTM Technologies has a significant presence in the US, specializing in high-mix, low-volume manufacturing, and complex PCB designs for aerospace, defense, and telecommunications. They are renowned for their advanced technology capabilities and high reliability PCBs. - Sanmina

Sanmina provides end-to-end manufacturing solutions, including PCB fabrication, assembly, and testing. They have a strong US footprint and serve diverse markets, such as industrial, medical, and automotive industries, with a focus on quality and supply chain management. - Jabil Inc.

Jabil is a global manufacturing services provider, and its operations in the USA includes advanced PCB manufacturing. They focus on providing integrated solutions for various industries, including consumer electronics, healthcare, and industrial sectors. They are known for their scale and capacity to handle large projects. - Advanced Circuits

Advanced Circuits is known for its quick-turn prototyping and production services. They cater to a wide range of industries and are a popular choice for companies needing fast and reliable PCBs with a focus on customer service. - Summit Interconnect

Summit Interconnect specializes in complex PCB manufacturing including rigid, flex, and rigid-flex PCBs. They are a major supplier for defense, aerospace and medical companies requiring high-reliability and advanced material PCBs. - Multek (A Flex Company)

Multek, a subsidiary of Flex, offers a broad range of PCB solutions, including HDI, flex, and rigid-flex PCBs. They offer a worldwide manufacturing footprint, including a strong presence in the US, with a focus on providing tailored PCB solutions for various industries including communications and consumer electronics. - Calumet Electronics

Calumet Electronics is a US-based manufacturer known for producing high-reliability PCBs, particularly for the defense, aerospace and automotive industries. They specialize in advanced technologies including HDI and RF boards.

This list represents a selection of key US-based PCB manufacturers; the landscape is diverse, with many other specialized companies also contributing to the industry. These companies differentiate themselves through their expertise in specific materials, technologies, or industries, enabling them to meet the evolving demands of US based and global technology sectors.

PCB Manufacturing Technologies and Innovations

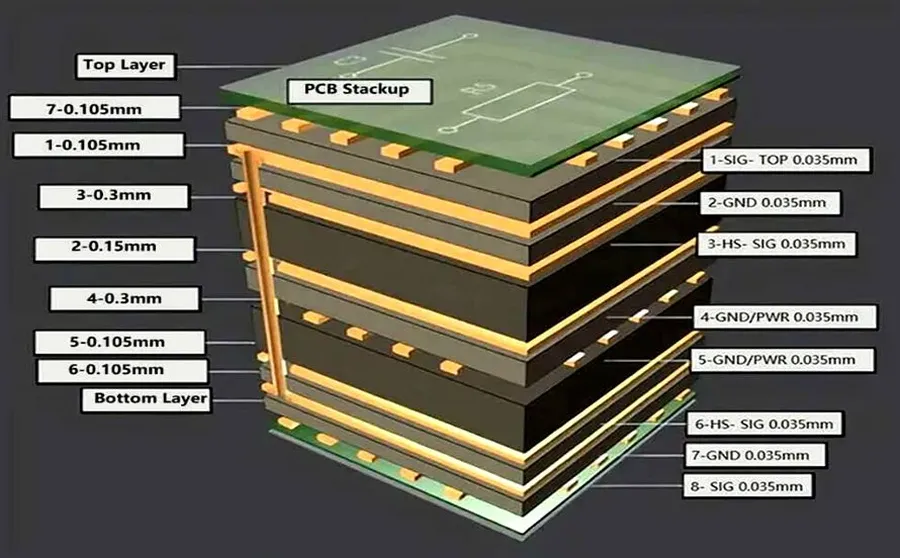

The printed circuit board (PCB) manufacturing sector is characterized by rapid technological advancements, pushing the boundaries of miniaturization, performance, and functionality. This section delves into key innovations shaping the industry, including multilayer PCBs, High-Density Interconnect (HDI) PCBs, and flexible PCBs, alongside their respective manufacturing processes. These advancements are critical to meet the demands of modern electronics across various industries, and are areas where manufacturers like TTM Technologies are at the forefront.

| Technology | Description | Key Features | Applications | Manufacturing Process |

|---|---|---|---|---|

| Multilayer PCBs | PCBs with three or more conductive layers. | Increased circuit density, complex designs, good electrical performance. | High-end electronics, computer motherboards, telecommunications equipment. | Lamination of multiple etched layers using heat and pressure, followed by drilling and plating |

| HDI (High-Density Interconnect) PCBs | PCBs with higher wiring density per unit area. | Fine lines/spaces, microvias, smaller components, increased functionality in less space. | Smartphones, tablets, portable devices, medical equipment. | Sequential build-up process using laser drilling, fine-line etching, and microvia plating. |

| Flex PCBs | PCBs constructed on a flexible substrate. | Flexible, lightweight, capable of fitting into complex shapes, good vibration resistance. | Wearable devices, automotive electronics, aerospace equipment. | Uses flexible base materials, which are often laser cut and have their circuit traces etched using methods similar to rigid boards. |

The evolution of PCB manufacturing is also being driven by the development of new technologies like embedded components, and advanced surface treatments, each aimed at enhancing performance, reducing size, and improving reliability. Leading manufacturers invest significantly in research and development to remain at the technological forefront, driving innovation that benefits various sectors.

Factors to Consider When Choosing a PCB Manufacturer

Selecting the right PCB manufacturer is crucial for ensuring product quality, reliability, and cost-effectiveness. This section provides a detailed guide to the key factors that should be considered when making this critical decision, including production capabilities, turnaround time, cost, and quality control measures.

| Factor | Description | Importance |

|---|---|---|

| Production Capabilities | Range of PCB types (single-layer, multi-layer, flex, HDI), production volume, and panel sizes. Also include the ability to handle advanced technologies. | Ensures the manufacturer can produce the specific PCB type required for the project at the desired scale. |

| Turnaround Time | The time taken from design submission to delivery of finished PCBs, considering rapid prototyping and large batch production. | Impacts project timelines and market entry speed; shorter lead times reduce time-to-market. |

| Cost | The total cost of PCB production, including tooling, materials, and any additional services. Requires a balance between cost and product performance and reliability. | Determines project viability and profitability; significant cost variation exists based on material, volume, and tolerance requirements. |

| Quality Control Measures | The quality control process implemented by the manufacturer, including inspection methods and adherence to industry standards. | Impacts product reliability, long-term performance, and overall product safety. |

| Geographical Location | Whether production is domestic or international, understanding the associated logistical impacts. | Factors in shipping costs, lead times, and communication logistics. Domestic production offers better communication and shorter shipping, while international can be cost-effective but has longer timelines and potential language barriers. |

| Certifications and Standards Compliance | Manufacturer's adherence to relevant industry standards (e.g., ISO, UL, IPC) and any quality certifications they possess. | Ensures high-quality and reliable PCBs while promoting compliance and safety standards. |

| Material Expertise | The manufacturer's experience and proficiency in handling a variety of PCB materials (FR-4, Rogers, ceramics) and different material stack-ups. | Ensures that the selected material meets project requirements for performance and environmental conditions. |

| Technology Expertise | The manufacturer's proficiency with different PCB technologies like high-speed and RF design, buried via, and blind via. | Ensures that the selected technology is suitable for project requirements, improves product performance, and reduces potential manufacturing issues. |

| Communication and Support | The quality and responsiveness of customer support, and effectiveness of communication channels. | Facilitates smooth project progression, with quick resolutions to queries and issues. |

The geographical location of the manufacturer is also a significant consideration. Domestic manufacturers often provide quicker turnaround times and better communication, while international manufacturers may offer more cost-effective solutions. However, international options may involve longer lead times and potential communication barriers. Ultimately, the choice depends on a careful balance of these factors, with project needs as the highest priority.

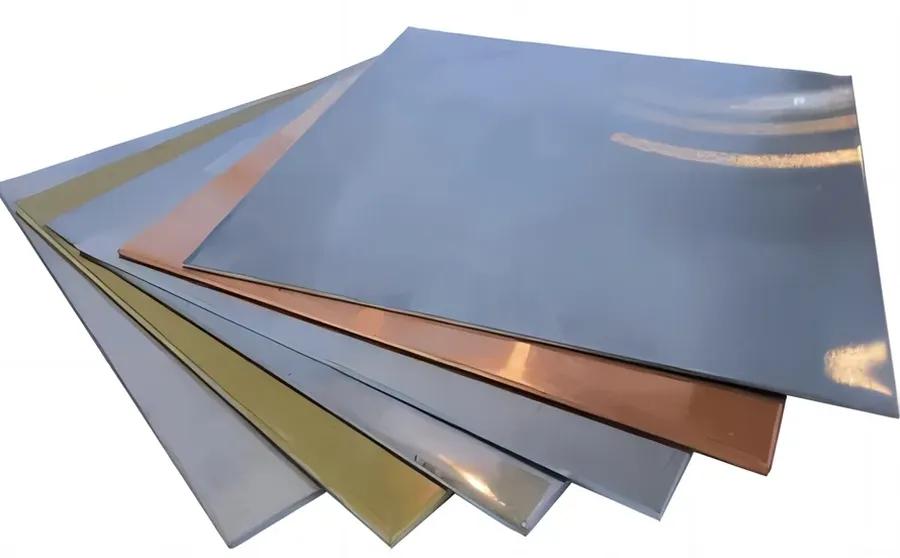

Material Science in PCB Manufacturing

The performance and reliability of a printed circuit board (PCB) are intrinsically linked to the materials used in its construction. Material selection significantly impacts the electrical, thermal, and mechanical properties of the final product. This section explores the diverse range of materials employed in PCB manufacturing, emphasizing their specific roles and performance attributes.

| Material Type | Composition | Key Characteristics | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|---|

| FR-4 | Woven fiberglass cloth with epoxy resin | Good mechanical strength, flame retardant, low cost | General-purpose PCBs, consumer electronics | Widely available, cost-effective, good dielectric properties | Limited thermal performance, susceptible to moisture absorption |

| Rogers Materials | Proprietary composite materials (e.g., PTFE based) | Superior electrical performance, low loss tangent, high-frequency applications | High-frequency RF circuits, aerospace applications | Excellent high-frequency performance, low signal loss, stable dielectric constant | Higher cost, more complex processing |

| Polyimide | Polyimide resin | High thermal stability, good chemical resistance, flexible | Flexible circuits, high-temperature applications | Excellent high temperature performance, lightweight, flexible | Higher cost, more complex processing than FR-4 |

| Metal Core PCBs (MCPCB) | Metal core (typically aluminum or copper) with dielectric layer | Excellent heat dissipation, high power applications | LED lighting, power electronics | Superior heat dissipation, high reliability | Heavier, more expensive |

| Ceramic Substrates | Ceramic materials (e.g., alumina, aluminum nitride) | High thermal conductivity, excellent electrical insulation, high-temperature performance | High-power electronics, aerospace, medical devices | Exceptional thermal management, high insulation performance, chemically inert | High cost, brittle |

Frequently Asked Questions About PCB Manufacturers

This section addresses common inquiries regarding printed circuit board (PCB) manufacturers and the PCB manufacturing process. We aim to provide clear, concise answers to help you navigate this complex industry.

- Who is the best PCB manufacturer?

The 'best' PCB manufacturer is subjective and depends heavily on specific project requirements. Factors include the complexity of the design, volume requirements, material specifications, and budget. There isn't one universal 'best' choice, but rather the optimal partner for a given set of needs. It's crucial to evaluate manufacturers based on their capabilities and alignment with your project. - Which company's PCBs are considered superior?

Several companies are known for producing high-quality PCBs, often specializing in particular niches like high-reliability or high-density applications. Companies such as TTM Technologies, Sanmina, and Jabil are often cited for their advanced capabilities, especially in complex designs. However, the superiority of a PCB depends less on the manufacturer alone and more on the quality control processes, advanced technology utilization, and materials employed for specific performance parameters. - Who is the largest PCB manufacturer in the world?

The title of 'largest' can fluctuate based on revenue and production volume. However, companies like TTM Technologies and other major global players consistently rank highly in terms of their global footprint and market share in the PCB manufacturing industry. - Who is the largest manufacturer of PCBs in North America?

TTM Technologies is often recognized as one of the largest PCB manufacturers in North America, having a significant presence and production capacity within the region, with a focus on a diverse range of PCB technologies. - What is the typical turnaround time for PCB manufacturing?

Turnaround time varies greatly depending on the complexity of the board, the manufacturer's capabilities, and the order size. Simple, standard PCBs may have a turnaround time of a few days, while more complex boards can take several weeks. It is essential to discuss lead times with the manufacturer before placing an order. - What factors affect the cost of PCB manufacturing?

Several factors influence the cost of PCB manufacturing, including the number of layers, materials used, size, complexity of the design, surface finish requirements, and order volume. Additionally, expedited manufacturing services will incur extra costs. - What are the critical aspects to check for quality control in PCB manufacturing?

Quality control in PCB manufacturing involves multiple checkpoints: design review (DRC) to identify errors, automated optical inspection (AOI) to check for defects, electrical testing to verify functionality and adherence to impedance specifications, cross-section analysis to check internal structures and dimensions, and reliability testing to ensure PCBs endure thermal stress and mechanical stress.

Future of PCB Manufacturing

The future of printed circuit board (PCB) manufacturing is being shaped by rapid technological advancements, driven by the need for greater efficiency, higher performance, and increased sustainability. Industry 4.0, automation, and material innovation are pivotal forces that are fundamentally changing how PCBs are designed, manufactured, and utilized.

- Industry 4.0 and Smart Manufacturing

The integration of IoT (Internet of Things) devices, AI (Artificial Intelligence), and machine learning into PCB manufacturing processes is leading to smart factories. These technologies enable real-time data analysis, predictive maintenance, and improved quality control, optimizing production efficiency and reducing waste. - Automation and Robotics

Increased automation through robotics is enhancing manufacturing precision and speed. Automated assembly lines and robotic handling of materials are reducing human error, leading to higher yields and more consistent product quality, while also improving workplace safety. - Advanced Materials

The development and adoption of new materials with enhanced electrical and thermal properties are crucial. This includes advanced polymers, ceramics, and composites that can withstand higher temperatures, improve signal integrity, and enable more complex PCB designs to meet demands of emerging high-speed and high-frequency applications. - Miniaturization and High-Density Interconnect (HDI)

The trend toward smaller electronic devices with increased functionality is driving demand for HDI PCBs with finer lines, smaller vias, and tighter spacing. This pushes for constant development in manufacturing techniques such as microvia drilling, laser ablation, and fine-line etching. - Sustainable Manufacturing Practices

Sustainability is becoming increasingly important. PCB manufacturers are adopting eco-friendly materials, optimizing water usage, and implementing recycling programs. This includes efforts to reduce the use of hazardous substances and promote the circular economy in electronics manufacturing. - Additive Manufacturing

Additive manufacturing, or 3D printing, holds great potential for custom PCB production, enabling rapid prototyping and the creation of complex geometries and unique PCB designs. These technologies enable rapid prototyping, reduce lead time, and allow for customized PCB solutions, potentially revolutionizing the PCB manufacturing landscape.

Top PCB manufacturers are actively adapting to these trends. For instance, companies like TTM Technologies are investing heavily in advanced manufacturing equipment and research to drive next-generation PCB design and production capabilities. Moreover, their ability to integrate smart manufacturing principles and focus on sustainability will differentiate leaders in this field.

Case Studies of Top PCB Applications

The versatility of Printed Circuit Boards (PCBs) is demonstrated by their widespread use across diverse industries. This section examines real-world applications of PCBs from leading manufacturers, showcasing how specific requirements are met in various sectors, from everyday consumer electronics to highly demanding aerospace applications. By exploring these examples, we gain insight into the critical role PCBs play in modern technology and manufacturing.

Below are a few examples of case studies.

- Consumer Electronics: Smartphones and Tablets

High-Density Interconnect (HDI) PCBs are integral to smartphones and tablets, enabling complex functionalities within compact designs. Manufacturers like TTM Technologies provide PCBs with fine-line traces and microvias, facilitating the integration of multiple ICs and features. These PCBs manage high-speed data transfer and power distribution within the devices while keeping the form factor as small and light as possible. - Automotive Industry: Advanced Driver-Assistance Systems (ADAS)

In the automotive sector, PCBs are crucial for ADAS, powering sensors like radar, lidar, and cameras. Sanmina is among the top manufacturers delivering high-reliability PCBs that operate under harsh conditions including extreme temperature variations and vibrations. These PCBs support the real-time processing required for safety features such as lane departure warnings, adaptive cruise control, and emergency braking systems. - Aerospace: Satellite and Communication Systems

Aerospace applications demand PCBs that are extremely robust and reliable due to the harsh operating conditions. Jabil Inc. produces PCBs using advanced materials like polyimide and PTFE to withstand extreme temperatures and vibrations, while offering exceptional signal integrity. These PCBs are used in satellite communication equipment, flight control systems, and onboard diagnostics, ensuring optimal performance under rigorous conditions. Multilayer boards are required to manage the complex array of functions while ensuring optimal signal integrity. - Medical Devices: Diagnostic Equipment

Medical devices like diagnostic imaging equipment, monitoring systems, and pacemakers rely on high-precision PCBs. These PCBs often incorporate advanced materials to meet stringent bio-compatibility and performance standards. Leading manufacturers ensure that these boards comply with strict quality control and regulatory requirements. Specific PCB features, such as impedance control, are critical to delivering accurate and reliable performance. - Industrial Automation: Robotics and Control Systems

In industrial settings, PCBs are a fundamental component in robotic systems, motor controllers, and programmable logic controllers (PLCs). These PCBs are designed to withstand challenging conditions such as high temperatures, dust, and vibrations. They must also be highly reliable to avoid costly downtime in manufacturing processes. Manufacturers often prioritize robust designs and high-quality materials to ensure dependable operation in these demanding applications.

The printed circuit board industry is a cornerstone of modern electronics, with the top 10 printed circuit board manufacturers such as TTM Technologies, Sanmina, and Jabil Inc. playing pivotal roles. These companies not only manufacture but also innovate, pushing the boundaries of technology. As we move forward, the PCB industry is expected to continue its rapid evolution, driven by demand for smaller, more powerful devices and increasingly complex electronic systems. The future will likely bring even more advanced manufacturing techniques and materials, ensuring that PCB technology remains at the heart of technological progress.

AnyPCBA

AnyPCBA