Top Eltek PCB Manufacturers: A Comprehensive Guide

In today's technology-driven world, printed circuit boards (PCBs) are the unseen backbone of countless devices and systems. Among the prominent players in this critical industry, Eltek PCB manufacturers stand out for their commitment to advanced technology and high-reliability solutions. From rigid to flex-rigid PCBs, their impact spans multiple sectors, and they are an important partner in the world's technological advancement, like the nervous system that supports the entire human body. This article will explore Eltek's position in the global PCB market, providing a detailed look at their offerings and the unique value they bring to the electronic manufacturing industry. Specifically focusing on the role they play and their impact on technology development.

Eltek's Global Presence in PCB Manufacturing

Eltek, a significant player in the PCB manufacturing sector, maintains a robust global presence with strategically located facilities and extensive customer support networks. This international footprint enables Eltek to cater to diverse market needs and provide localized services.

Key to their operations are their manufacturing hubs in Israel and Thailand. These facilities not only serve their respective regions but also contribute to Eltek's global supply chain. The Israeli facility supports advanced technology development and precision manufacturing, while the Thailand site focuses on large-scale production.

Eltek's international presence ensures responsive support and efficient delivery for their global customer base. This decentralized approach allows Eltek to mitigate risks associated with geographical constraints and leverage regional advantages in manufacturing capabilities.

The History of Eltek in PCB Manufacturing

Eltek's journey in the printed circuit board (PCB) manufacturing industry began in 1970, marking the foundation of what would become a globally recognized leader. This history encompasses not just the timeline of its existence but also a narrative of technological advancement and strategic expansion that has led to its current prominence in the PCB manufacturing landscape.

From its inception, Eltek has consistently adapted to the evolving needs of various high-tech industries. This has involved a steady adoption of new technologies, strategic market positioning, and a focus on high quality and reliability. Eltek's growth is a testament to its commitment to these core principles, solidifying its position as a key player in the PCB manufacturing sector.

Eltek's Specialization in Rigid and Flex-Rigid PCBs

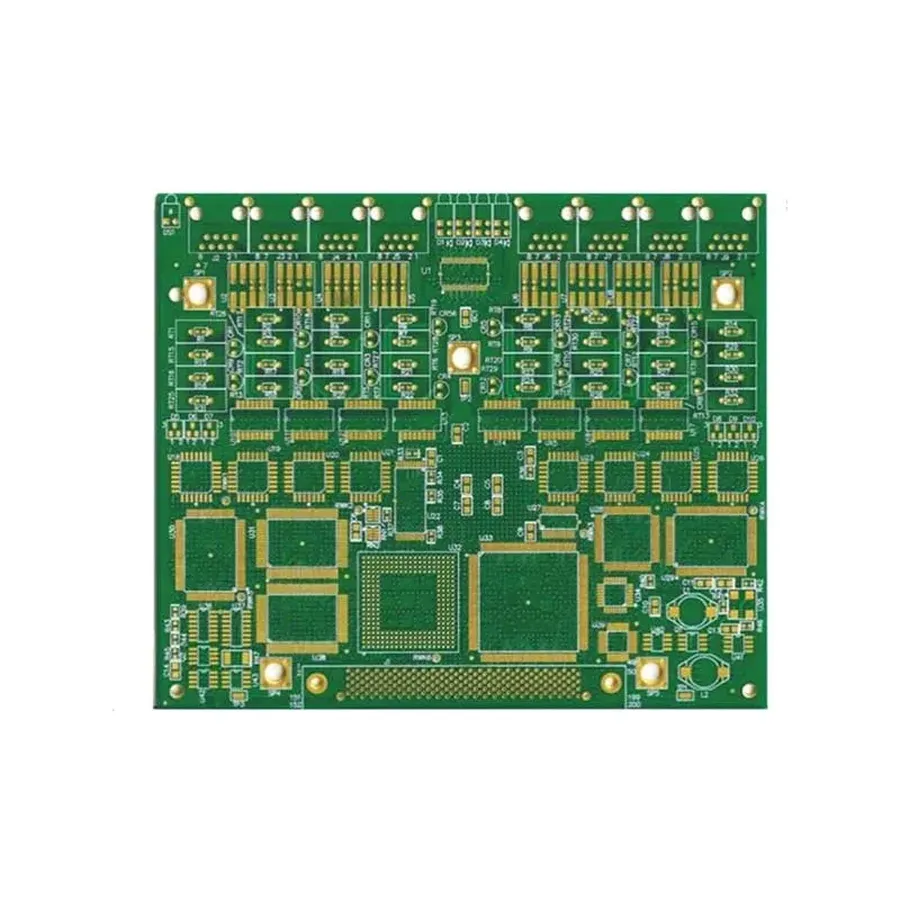

Eltek distinguishes itself in the PCB manufacturing landscape through its specialized capabilities in producing both rigid and flex-rigid printed circuit boards. This expertise allows Eltek to cater to the demanding requirements of high-performance electronic applications, where board integrity and flexibility are critical. Their proficiency extends to intricate designs, high layer counts, and stringent quality standards, making them a preferred partner for industries where reliability is paramount.

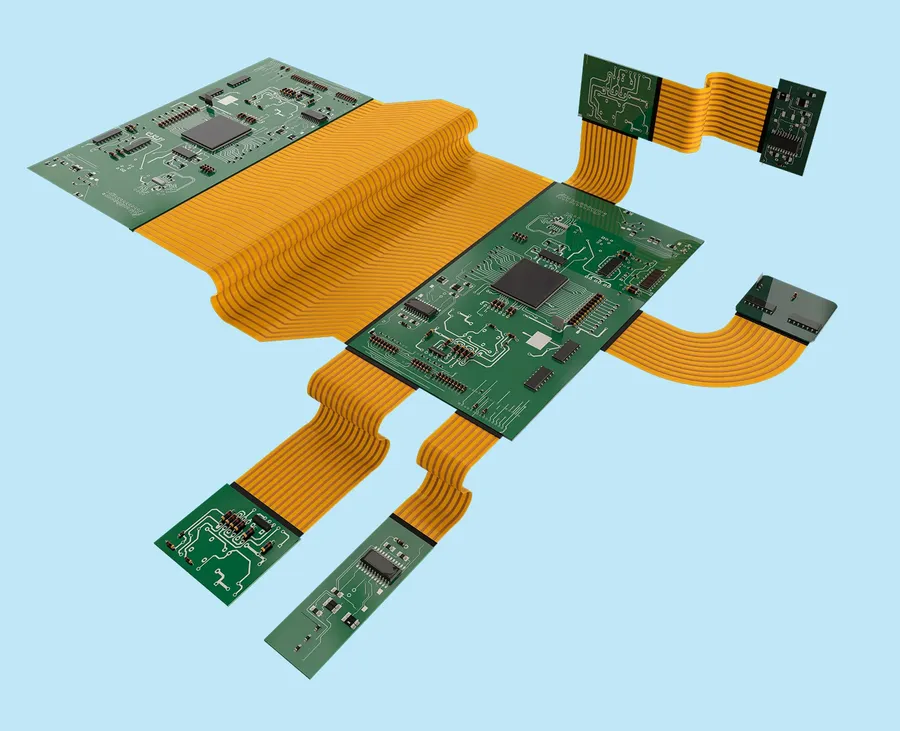

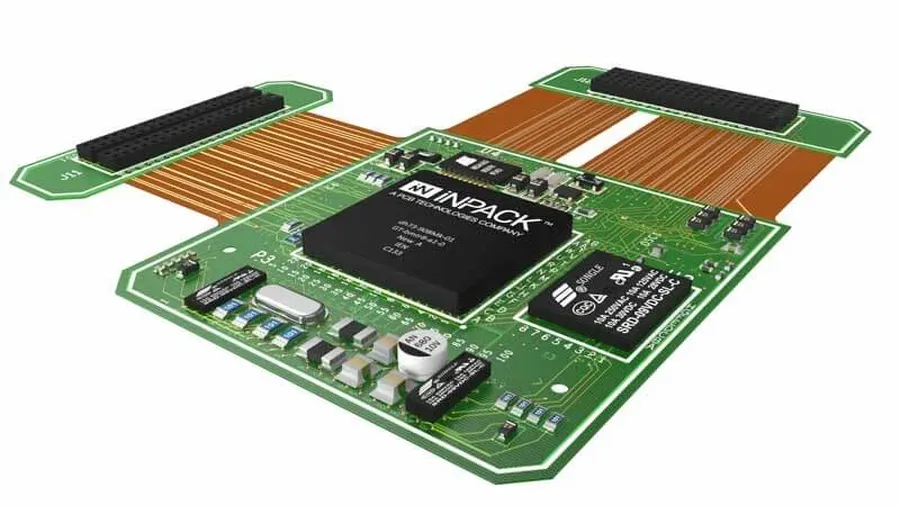

Rigid PCBs form the backbone of most electronic devices due to their robust nature and cost-effectiveness. However, flex-rigid PCBs combine the advantages of both rigid and flexible boards, allowing designers to create compact devices with complex interconnections, reducing the need for connectors and enhancing reliability. This blend of rigid and flexible materials provides optimal mechanical stability with the versatility of complex 3D electronic packaging. Eltek's advanced manufacturing technologies enable them to produce these complex boards with precision.

- Key Technologies Employed

Eltek utilizes advanced technologies such as laser direct imaging (LDI), automated optical inspection (AOI), and sophisticated drilling and plating processes to ensure high accuracy and quality in rigid and flex-rigid PCB manufacturing. These processes allow for the production of high-density interconnect (HDI) PCBs with fine lines and spacing. - Material Expertise

Eltek works with a variety of high-performance materials, including FR-4, polyimide, and PTFE, catering to specific performance needs like thermal management, high-frequency operations, and mechanical resilience. - Custom Design and Engineering Support

Beyond manufacturing, Eltek offers design and engineering support, guiding clients through the selection of appropriate materials, layer stack-ups, and other critical factors that impact PCB performance and reliability. This collaborative approach helps optimize designs for manufacturability.

Eltek's Focus on High-Tech Industries

Eltek strategically concentrates its PCB manufacturing expertise on high-tech industries that demand exceptional performance, reliability, and stringent quality control. This focus allows Eltek to develop specialized solutions tailored to the unique needs of sectors such as aerospace, medical, and telecommunications, where PCB failures can have catastrophic consequences.

Within these demanding fields, Eltek's PCBs are engineered to meet rigorous standards and certifications, often surpassing those of consumer-grade electronics. The company's commitment to precision and reliability is especially evident in its use of advanced materials, intricate design capabilities, and meticulous manufacturing processes.

- Aerospace

In aerospace, Eltek's PCBs are vital for mission-critical applications, including avionics, satellite systems, and guidance control. These PCBs must withstand extreme temperatures, vibrations, and electromagnetic interference while maintaining peak functionality. - Medical

The medical field requires PCBs for devices such as diagnostic equipment, surgical instruments, and patient monitoring systems. Eltek provides PCBs that meet stringent health and safety regulations, offering precise and reliable operation. - Telecommunications

In telecommunications, Eltek's PCBs are used in networking infrastructure, base stations, and high-speed data transmission systems. These PCBs must support high-frequency signals and maintain signal integrity, essential for reliable communication networks.

Cybersecurity in Eltek's Operations

Eltek prioritizes cybersecurity, acknowledging the vital need to safeguard critical infrastructure components in today's interconnected world. This commitment extends to its PCB manufacturing processes, ensuring the integrity and confidentiality of designs and production data.

In the context of PCB manufacturing, robust cybersecurity measures are essential to prevent tampering, counterfeiting, and intellectual property theft. Eltek implements comprehensive security protocols to protect its manufacturing facilities and digital assets from cyber threats.

The implications of cybersecurity within Eltek's PCB operations include safeguarding sensitive design files, maintaining the integrity of manufacturing processes, and protecting customer data. These measures ensure the reliability and trustworthiness of the PCBs produced, particularly for high-tech industries where security breaches can have significant consequences.

Eltek's Commitment to Innovation and Advanced Technology

Eltek's dedication to innovation and advanced technology is central to its position as a leading PCB manufacturer. This commitment is evident in their significant investments in research and development (R&D), the implementation of cutting-edge automation, and the adoption of advanced manufacturing techniques, all of which ensure they stay at the forefront of the industry.

By consistently incorporating the latest technological advancements, Eltek enhances the quality, reliability, and precision of their PCBs, which are critical for high-tech sectors. This approach not only improves product performance, but also allows Eltek to handle increasingly complex design and manufacturing challenges, meeting the evolving needs of their diverse customer base.

- R&D Investments

Eltek allocates substantial resources to R&D, fostering a culture of continuous improvement and innovation. This includes exploring new materials, refining manufacturing processes, and developing advanced PCB designs to meet emerging industry demands. - Automation and Efficiency

The company employs advanced automation technologies to streamline production, minimize errors, and enhance efficiency. This includes robotics, automated inspection systems, and data-driven process optimization, ensuring consistent quality and scalability. - Advanced Manufacturing Techniques

Eltek incorporates advanced manufacturing techniques such as laser direct imaging (LDI), microvia technology, and advanced surface finishes. These methods allow for greater precision and complexity in PCB fabrication, meeting the stringent requirements of high-tech industries. - Data-Driven Manufacturing

Eltek leverages data analytics to monitor and improve production processes, identifying areas for optimization and ensuring consistent product quality. This includes the implementation of Industry 4.0 principles for a smart factory approach.

Comparing Eltek with Other PCB Manufacturers

Understanding how Eltek stands relative to its competitors is crucial for stakeholders evaluating PCB manufacturing options. This section provides a comparative analysis of Eltek against major players, considering aspects like technological capabilities, service offerings, and cost-effectiveness, to provide a clear market position assessment.

| Feature | Eltek | Competitor A | Competitor B |

|---|---|---|---|

| Specialization | Rigid & Flex-Rigid | Rigid | Flexible |

| Global Reach | Yes | Limited | Yes |

| Cybersecurity Focus | Strong | Moderate | Low |

| Technology Focus | Advanced | Moderate | Moderate |

| Industry focus | High-tech industries | Consumer electronics | Consumer and some medical |

Frequently Asked Questions About Eltek PCB Manufacturing

This section addresses common inquiries regarding Eltek's PCB manufacturing capabilities, reputation, and competitive advantages, drawing on a synthesis of user questions and industry knowledge to offer comprehensive insights into the company's position in the market.

- What is Eltek's reputation as a PCB manufacturer?

Eltek is globally recognized for its high-quality, reliable, and complex PCBs, especially in the rigid and flex-rigid categories. The company serves high-tech industries such as aerospace, medical, and telecommunications, which further establishes its credibility as a leading PCB manufacturer. Their reputation is built on a foundation of technological innovation, stringent quality control, and strong cybersecurity measures. - Where are Eltek PCBs typically used?

Eltek's PCBs are predominantly utilized in high-reliability applications. Key sectors include aerospace (avionics, satellites), medical devices (diagnostic equipment, implants), telecommunications infrastructure (base stations, networking equipment), and other industrial and military applications where robust performance and longevity are critical. The focus is on areas where performance, quality, and reliability are paramount. - How does Eltek compare to other PCB manufacturers in terms of technology and services?

Eltek distinguishes itself by focusing on complex, high-reliability rigid and flex-rigid PCBs. Their emphasis on cybersecurity in operations, coupled with advanced manufacturing technology and a significant commitment to R&D, sets them apart from manufacturers that may focus on more general or consumer-grade PCBs. While other manufacturers might offer lower costs, Eltek provides higher quality for demanding applications. - Who is the best PCB manufacturer?

The 'best' PCB manufacturer varies depending on the specific needs of a project. While Eltek excels in high-reliability sectors, other manufacturers may be better suited for different applications. Factors such as cost, volume, complexity, and specific industry requirements all play a critical role in determining the most suitable PCB manufacturer. 'Best' is therefore a relative term dependent on the specific context. - Who is the largest PCB manufacturer in the world?

The title of largest PCB manufacturer often rotates between companies based on revenue, but it's generally held by a few key players in Asia. While Eltek is a significant player globally, they are not typically in the discussion for the title of 'largest,' as they focus on niche markets with higher value rather than the highest production volume. - Which company's PCB is best?

The selection of the ‘best’ PCB company depends on the user's specific requirements. For high-tech and high-reliability projects Eltek is often considered to be the 'best' due to their focus on complex rigid and flex-rigid PCBs, as well as their strong emphasis on cybersecurity. However, for projects with different requirements there are other ‘best’ options. The choice needs to be evaluated based on the necessary trade-offs. - Who is the manufacturer of PCB assembly in China?

PCB assembly in China is dominated by a large number of companies, ranging from smaller local factories to large multinational corporations. Many of these companies provide a high volume of consumer electronics and lower cost PCBs. Eltek is not primarily focused on PCB assembly in China, as it has its own global manufacturing sites, and does not compete in this market.

The future of Eltek and PCB technologies

The printed circuit board (PCB) industry is undergoing rapid transformation driven by advancements in technology, increasing demand for miniaturization, and a growing emphasis on sustainability. Eltek, as a key player in this sector, is strategically positioning itself to address these future demands. This section explores emerging trends and how Eltek is adapting to ensure its continued relevance and success.

The evolution of PCB technology is accelerating, driven by the need for higher performance, greater functionality, and smaller form factors. Eltek's strategic focus on advanced research and development is critical in this dynamic environment. Specifically, Eltek is investing in areas such as:

- High-Density Interconnect (HDI) PCBs

The demand for smaller, more complex devices requires HDI technology, which enables denser component placement and finer traces, crucial for miniaturized electronics. Eltek is enhancing its capabilities in this area to support advanced applications. - Advanced Materials

New materials with improved thermal, electrical, and mechanical properties are critical for performance improvements in extreme conditions. Eltek is exploring and implementing these advanced materials in its PCB production. - Embedded Technologies

Integrating components directly into the PCB substrate reduces size and improves reliability. Eltek is incorporating embedded technologies to enhance its PCB offerings for sophisticated electronic devices. - Automation and AI

The adoption of automation and artificial intelligence in PCB manufacturing processes is crucial for improving production efficiency, reducing errors, and enabling faster turnaround times. Eltek's investments in smart factory technology support these goals.

Sustainability and environmental responsibility are becoming increasingly important. Eltek is committed to environmentally sound practices by focusing on:

- Reduced Waste

Implementation of manufacturing processes that minimize material waste is a key focus for Eltek to reduce its ecological footprint. - Energy Efficiency

Eltek is focused on adopting technologies and practices that minimize energy consumption throughout the PCB manufacturing process. - Sustainable Materials

Exploring alternatives to traditional materials that are eco-friendlier is an ongoing objective for Eltek to support environmental goals and reduce the environmental impact of its operations.

Looking ahead, Eltek is well-positioned to adapt to the challenges and opportunities that the evolving PCB landscape presents. By focusing on innovation, advanced technology, and sustainability, Eltek is poised to continue as a leader in the industry, meeting the demands of future generations of electronics.

Eltek PCB manufacturers represent a pivotal force in the global electronics industry, distinguished by their expertise in both rigid and flex-rigid PCB production. Their deep-rooted history, commitment to innovation, and stringent focus on cybersecurity make them a preferred choice for high-tech applications. As technology continues to advance, Eltek will likely continue to be a critical enabler of countless devices and systems, maintaining its significance in the future of PCB manufacturing. For companies seeking cutting-edge PCB solutions, Eltek stands as a reliable and innovative partner for their technological advancements.

AnyPCBA

AnyPCBA