Top Flexible Circuit Manufacturers: Choosing the Right Partner for Your Needs

In today's fast-paced technological landscape, flexible circuits have become indispensable in various applications, from consumer electronics to aerospace. Choosing the right flexible circuit manufacturer is critical for product quality and reliability. This article will guide you through the top manufacturers, highlighting their strengths and helping you make an informed decision.

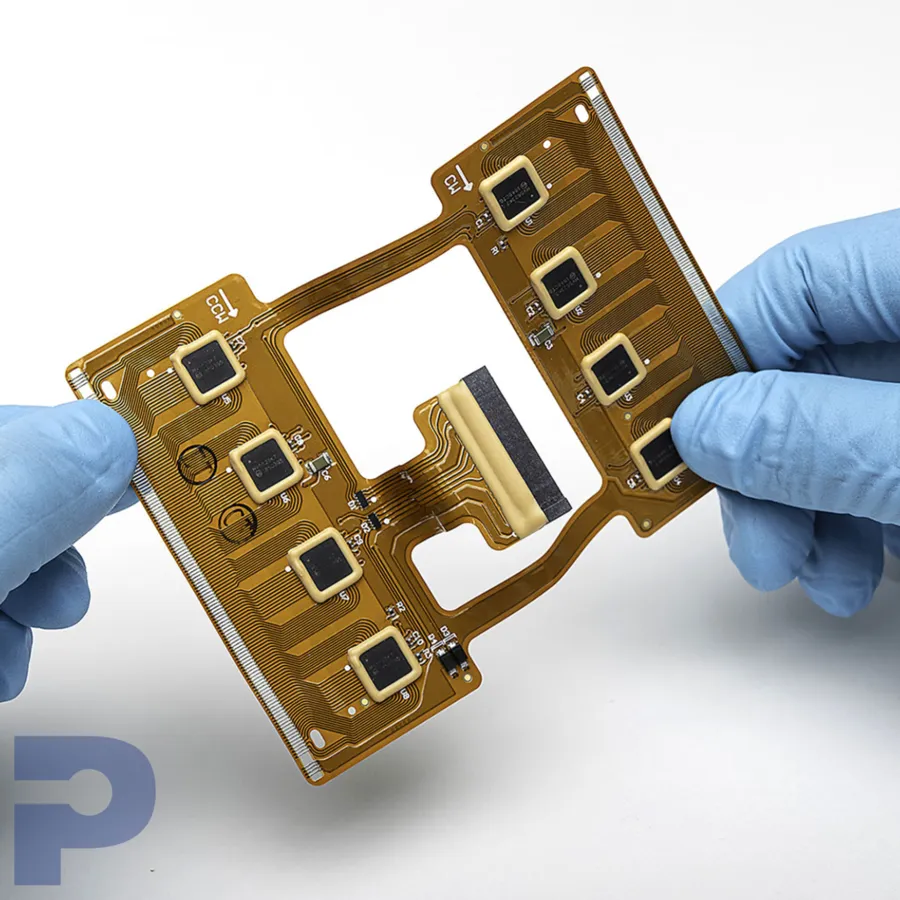

Understanding Flexible Circuits and Their Applications

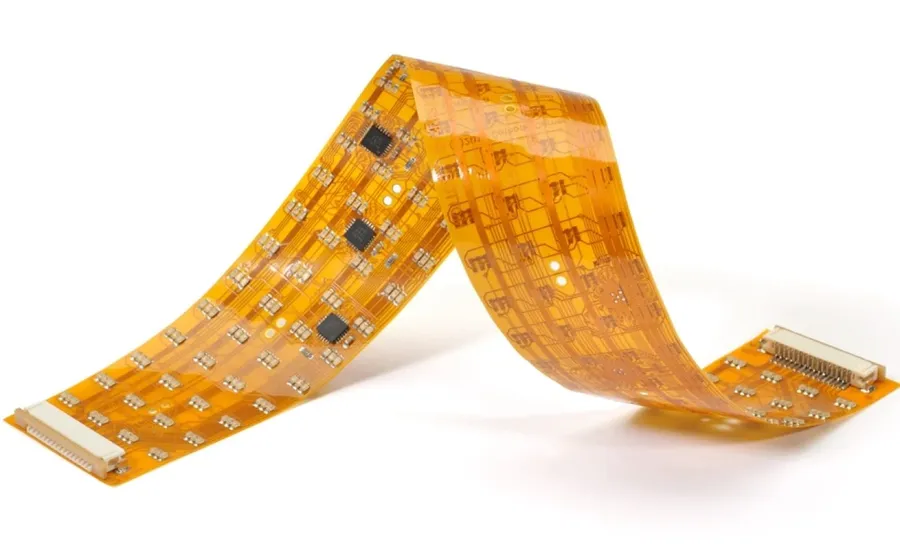

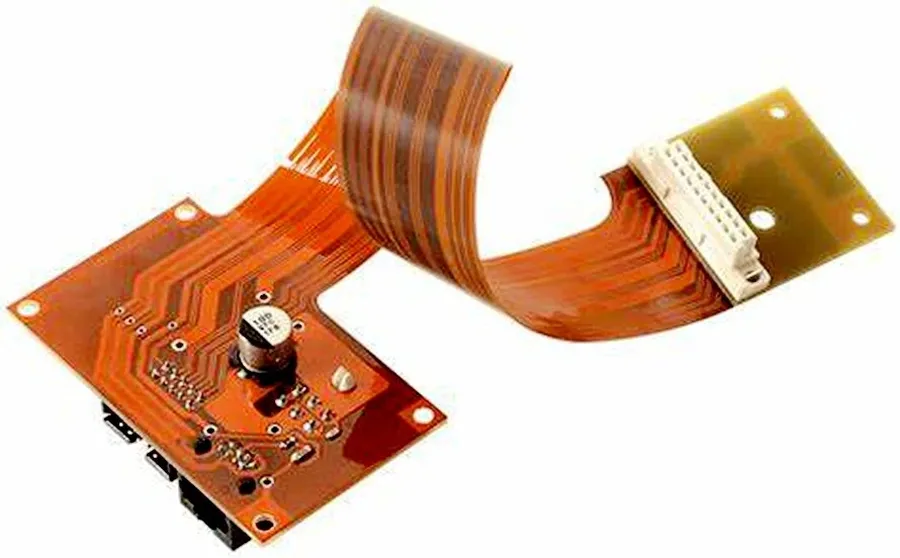

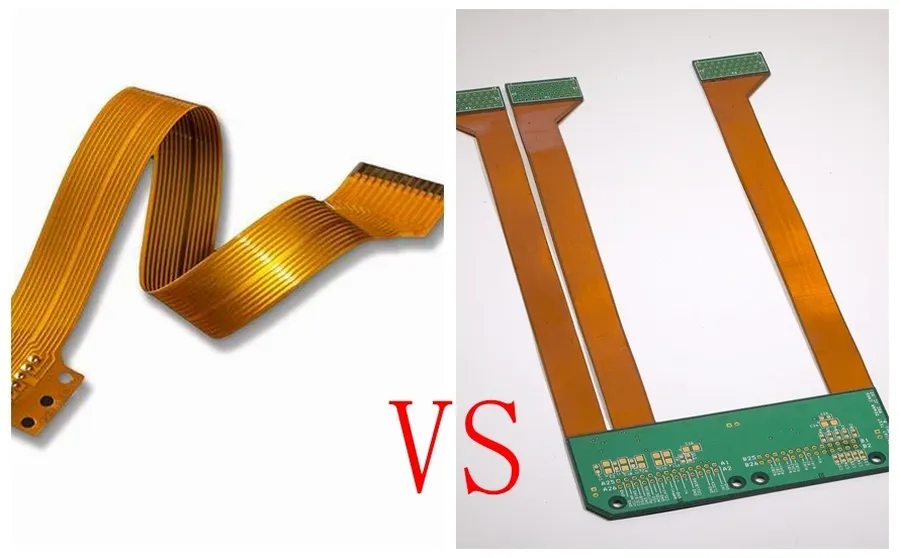

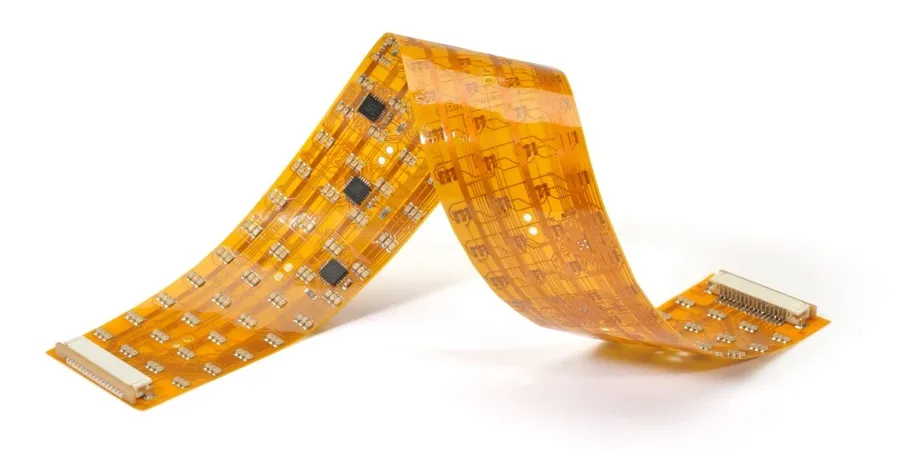

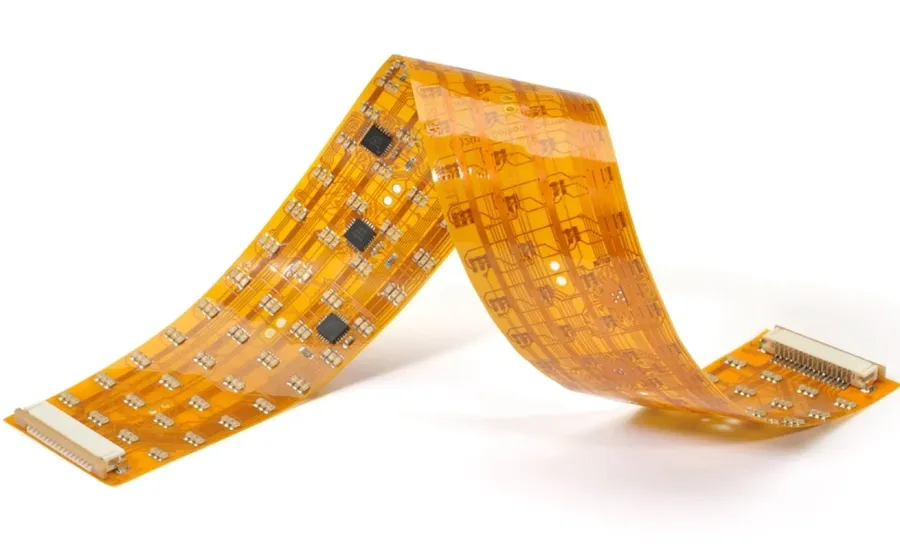

Flexible circuits, also known as flex PCBs, represent a transformative advancement in electronics, offering a departure from traditional rigid circuit boards by utilizing flexible substrates. This characteristic enables them to conform to irregular shapes and dynamic environments, facilitating applications across a multitude of sectors. Their core advantage lies in their ability to provide both electrical interconnection and mechanical flexibility.

- Benefits Over Traditional Rigid PCBs

Flexible circuits provide significant advantages over rigid PCBs, including reduced weight and thickness, increased design freedom, enhanced reliability in dynamic applications, and simplified assembly through integrated wiring harnesses. - Applications in the Medical Industry

In the medical field, flexible circuits are integral to devices like implantable electronics, wearable sensors, and diagnostic equipment, where their flexibility and compact size are critical. - Aerospace Applications

Aerospace applications leverage flex circuits for their vibration resistance, low weight, and ability to fit in confined spaces within aircraft, satellites, and other aerospace vehicles. - Consumer Electronics Applications

In consumer electronics, flexible circuits are essential for compact and durable devices, such as smartphones, wearables, and digital cameras, enabling complex functionalities in small form factors.

| Characteristic | Rigid PCBs | Flexible PCBs |

|---|---|---|

| Flexibility | Inflexible | Highly Flexible |

| Weight | Heavier | Lighter |

| Form Factor | Fixed Shape | Adaptable Shape |

| Application | Static Environments | Dynamic Environments |

Key Factors to Consider When Choosing a Flexible Circuit Manufacturer

Selecting the right flexible circuit manufacturer is critical for the success of any project involving flexible printed circuits (FPCs). This decision should be guided by a thorough evaluation of several key factors, including manufacturing capabilities, material expertise, quality assurance, and prototyping support. A careful assessment ensures that the chosen manufacturer is equipped to meet specific project requirements and deliver reliable, high-performance FPCs.

| Factor | Description | Importance |

|---|---|---|

| Manufacturing Capabilities | Range of circuit types they can produce (single-sided, double-sided, multilayer, rigid-flex) and the complexity of designs they can handle. | Directly impacts their ability to produce your specific circuit requirements. |

| Material Selection Expertise | Their knowledge of different materials (polyimide, polyester, LCP) and their application-specific suitability. | Ensures your circuit uses the best material for performance and environment. |

| Quality Control | Compliance with standards like ISO 9001, AS9100, and robust testing processes during manufacturing. | Crucial for reliability and longevity of your flexible circuits. |

| Prototyping Speed | Ability to quickly produce prototypes for design validation and testing. | Essential for rapid development cycles and minimizing time to market. |

| Certifications | Possession of industry specific certifications such as ISO 9001, AS9100, ISO 13485, etc. | Signifies adherence to international quality standards, especially important for safety and regulatory requirements in aerospace, medical devices and industrial applications. |

| Specialized Processes | Capabilities in laser ablation, fine-line etching, and other advanced techniques. | Needed for complex designs, higher density circuits, and special applications. |

| Geographical Location | Manufacturing location relative to your engineering team and manufacturing facility | Can affect communication and speed of product development and production. |

Leading Flexible Circuit Manufacturers Globally

The global flexible circuit manufacturing landscape is dominated by a few key players, each with unique strengths and specializations. These manufacturers serve diverse markets and offer varying capabilities, impacting the design and production strategies of countless electronics products. Understanding these leaders is crucial for selecting the right partner for your specific flexible circuit needs.

| Manufacturer | Market Position | Capabilities | Geographical Focus | Specializations |

|---|---|---|---|---|

| Nippon Mektron | Global Leader, strong presence in Asia | High-volume production, multi-layer flex, rigid-flex | Primarily Asia, expanding globally | Automotive, consumer electronics, high-density interconnect |

| Zhen Ding Technology (ZDT) | Leading manufacturer from China | Mass production, diverse material offerings | Asia, with a growing global reach | Mobile devices, consumer electronics, high-volume applications |

| Interflex | Major player, known for innovation | Advanced flex circuit technologies, fine-line etching | Global, with facilities in Asia and Europe | Automotive, medical devices, high-reliability applications |

| Sumitomo Electric | Established brand with diverse products | Advanced material science, integrated solutions | Global, with strong presence in Japan | Automotive, telecommunications, industrial applications |

Top Flexible Circuit Manufacturers in the USA

The United States is home to several leading flexible circuit manufacturers, renowned for their technological prowess and specialization in high-reliability applications, rapid prototyping, and quick-turn manufacturing. These manufacturers are crucial partners for industries requiring advanced flexible circuit solutions.

- Flexible Circuits, Inc.

Flexible Circuits, Inc. is known for its focus on high-reliability applications and offers a broad range of flexible circuit technologies, including single-sided, double-sided, and multilayer flex circuits. They have extensive experience in serving the aerospace, medical, and industrial sectors. - Minco

Minco stands out for its expertise in manufacturing flexible circuits for demanding environments, particularly in medical and aerospace industries. They offer a wide range of flexible heater and sensor integration, showcasing their specialization in integrated solutions. - Sierra Circuits

Sierra Circuits is well-regarded for its rapid prototyping and quick-turn manufacturing services. Their capabilities include advanced processes for fine-line etching and complex circuit designs. They cater to a broad spectrum of industries, emphasizing speed and precision.

| Manufacturer | Strengths | Specializations |

|---|---|---|

| Flexible Circuits, Inc. | High-reliability applications | Aerospace, medical, and industrial sectors |

| Minco | Demanding Environments, integrated solutions | Medical and aerospace industries |

| Sierra Circuits | Rapid prototyping and quick-turn manufacturing | Fine-line etching and complex circuit designs |

Comparing Flexible Circuit Manufacturers: Capabilities and Specializations

Selecting the appropriate flexible circuit manufacturer hinges on a thorough comparison of their capabilities and specializations. This involves scrutinizing their material offerings, proficiency in advanced manufacturing processes, and the specific types of flexible circuits they are adept at producing. A nuanced understanding of these factors is crucial for ensuring that the chosen manufacturer aligns with the precise requirements of your project.

| Manufacturer | Material Options | Special Processes | Specializations |

|---|---|---|---|

| Manufacturer A | Polyimide (Kapton), Polyester (PET) | Laser Ablation, Fine-Line Etching | High-Density Interconnects, Multilayer Flex Circuits |

| Manufacturer B | Polyimide (Kapton), Liquid Crystal Polymer (LCP) | Laser Direct Structuring, Microvias | High-Frequency Flex Circuits, Rigid-Flex PCBs |

| Manufacturer C | Polyester (PET), PEN | Chemical Etching, Roll-to-Roll Processing | Large-area Flexible Displays, Low-Cost Flex Circuits |

| Manufacturer D | Polyimide (Kapton), Modified Acrylic | Automated Assembly, Component Embedding | Medical Device Flex Circuits, High Reliability Flex Circuits |

The selection of a flexible circuit manufacturer is dependent on the specific demands of the application. Manufacturers who specialize in processes such as laser ablation, and fine-line etching are often better suited to products that require high precision and complex geometries. On the other hand, if the requirement is for very large volume products, then roll-to-roll processing may be more suitable. The base material also greatly impacts the final application of the flexible circuit. Polyimide is an ideal material when the flex circuit must operate in a high-temperature environment, while polyester may be more appropriate in lower temperature, less demanding applications.

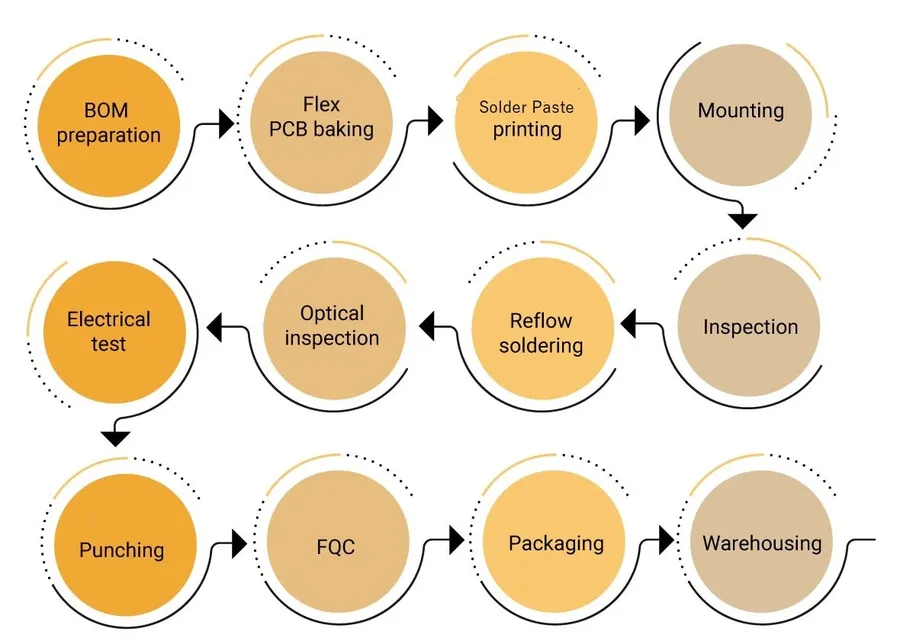

Prototyping and Quick-Turn Flexible PCB Services

Rapid prototyping and quick-turn manufacturing are vital for validating flexible circuit designs efficiently. These services allow for swift design iterations, reducing time-to-market and enabling rapid validation of the design and functionality. Selecting a manufacturer specializing in these services is crucial for projects requiring agility and fast turnaround.

- Importance of Quick-Turn Prototyping:

Quick-turn prototyping enables rapid design validation, allowing for iterative improvements and faster time-to-market. It also allows designers to test concepts before committing to large-scale production, minimizing risk and potential costs associated with design flaws. - Benefits of Rapid Prototyping:

The benefits are lower initial costs, identification of design problems early, increased flexibility in the design process, and the ability to test new materials or processes quickly. This is essential for complex flex circuit applications. - Key considerations for prototyping:

Considerations include material selection, technology limits, layer count requirements and production volume. Choosing the right manufacturing partner who can meet these demands is crucial. - Typical services for rapid prototyping:

These include fast turnaround times, small batch production capabilities, and design for manufacturing (DFM) feedback.

Flexible Circuit Material Options and Considerations

Selecting the appropriate base material is paramount in flexible circuit design, as it directly impacts performance, reliability, and cost. This section explores common materials like polyimide, polyester, and liquid crystal polymer, detailing their properties and suitability for various applications and thermal demands. Material selection is a critical step in the design process, as it must align with the functional requirements of the final product, and the manufacturing capabilities of the chosen flexible circuit manufacturer.

| Material | Properties | Advantages | Disadvantages | Typical Applications | Manufacturer Example |

|---|---|---|---|---|---|

| Polyimide (Kapton) | High temperature resistance, excellent chemical resistance, good mechanical strength | High reliability, durable, suitable for harsh environments | Higher cost than polyester, can be more difficult to process | Aerospace, medical, automotive, high-temperature electronics | DuPont |

| Polyester (PET) | Good tensile strength, cost-effective, flexible | Lower cost, good for lower-temperature applications | Lower temperature resistance, susceptible to chemical damage | Consumer electronics, keyboards, membrane switches, low-cost applications | Toray |

| Liquid Crystal Polymer (LCP) | Excellent electrical properties, low moisture absorption, high temperature stability | High-frequency applications, dimensionally stable, good for fine-line circuitry | Higher cost, more challenging processing | High-speed data transmission, antennas, high-frequency applications | Kuraray |

Material selection often involves trade-offs between performance, cost, and processability. Polyimide, such as DuPont's Kapton, offers superior thermal and chemical resistance, making it ideal for demanding applications. Conversely, polyester is a cost-effective choice for less rigorous environments. Liquid Crystal Polymer is an excellent choice where high electrical performance is critical. Understanding these differences is critical for proper design and manufacturing process.

Flexible Circuit Design Best Practices

Effective flexible circuit design necessitates a meticulous approach, balancing electrical performance with mechanical flexibility. Adhering to best practices from the outset ensures the final product meets functional and reliability requirements while minimizing manufacturing challenges and costs.

- Trace Routing Guidelines

Route traces with smooth, gradual curves rather than sharp 90-degree angles. This reduces stress concentration and minimizes the risk of trace cracking during flexing. Maintain consistent trace widths and spacing to ensure uniform impedance and signal integrity. Avoid routing traces across the bend area. Place traces perpendicular to bend lines or within the neutral axis of the bend to minimize stress during flexing. - Bend Radius Considerations

Adhere to the manufacturer's recommended minimum bend radius for the chosen material and thickness. Exceeding this limit can result in material fatigue, trace cracking, and overall failure. Consider the number of flex cycles the circuit will endure during operation when determining minimum bend radius. Design for a relaxed bend, whenever possible. - Component Placement

Avoid placing components within the bending region. Rigid components or connectors, when necessary in flexed regions, require robust anchoring and strain relief. Orient components such that stresses during flexing are minimized. Consider the implications of heat generated by components and provide a suitable heat management system, when necessary. - Material Selection

Select the appropriate base material (e.g., polyimide, polyester, or LCP) based on the application requirements, including flexibility needs, operating temperatures, and chemical exposure. The chosen material must meet the needs of thermal conductivity, flexibility, and mechanical strength. - Early Engagement with Manufacturer

Collaborate with the chosen flexible circuit manufacturer early in the design process. Their expertise in material capabilities, manufacturing limitations, and design for manufacturability (DFM) can significantly impact the success of the final product. Leverage their knowledge to optimize design and minimize potential costly revisions. Early communication is critical to ensure material and performance targets are achieved.

Frequently Asked Questions about Flexible Circuit Manufacturers

Navigating the world of flexible circuit manufacturing can be complex. This section addresses common queries to help you make informed decisions when selecting a manufacturer and planning your flexible circuit projects, covering aspects from cost considerations to design best practices.

- What are the primary cost factors when sourcing flexible circuits?

The cost of flexible circuits is influenced by several factors, including the base material used (e.g., polyimide, polyester), the number of layers, circuit complexity, feature size, and required tolerances. Additional costs may arise from special processes like laser ablation or fine-line etching, as well as the order volume and any required certifications. Prototyping and quick-turn services can also impact pricing. - What are typical lead times for flexible circuit fabrication?

Lead times for flexible circuits vary depending on the manufacturer's capacity and the complexity of the design. Simple single or double-sided flex circuits may have shorter lead times, while complex multilayer or rigid-flex designs typically require longer production times. Expect a range from a few days for quick-turn prototypes to several weeks for high-volume production. It's critical to discuss lead times with the manufacturer early in the design process. - What are the minimum order quantities (MOQs) for flexible circuits?

Minimum order quantities (MOQs) differ significantly between manufacturers. Some may specialize in small-batch prototyping with lower MOQs, while others cater to high-volume production with higher minimums. Negotiating MOQs is possible based on project requirements. Consider your project's long-term needs when discussing MOQs to avoid future production delays or unnecessary costs. It's also beneficial to explore options for panelization if smaller quantities are needed to reduce cost. - How do I choose the right flexible circuit manufacturer for my specific project requirements?

Choosing the right manufacturer involves evaluating several key criteria, including manufacturing capabilities (single-sided, double-sided, multilayer, rigid-flex), material expertise, certification compliance (ISO 9001, AS9100), quality control, prototyping speed, and customer support. It's essential to discuss specific project requirements with potential manufacturers, requesting samples and quotes to evaluate their suitability and fit with your needs. Also, review case studies and customer testimonials to get a better understanding of each manufacturer. - Which certifications should I expect from a reputable flexible circuit manufacturer?

Reputable flexible circuit manufacturers should possess certifications such as ISO 9001 for quality management and AS9100 for aerospace applications, demonstrating adherence to industry standards and quality control processes. These certifications provide assurance regarding product reliability and consistent manufacturing processes. Manufacturers should provide certificates of conformity to customer requirements, which can be tracked for audits and assurance. - What material selection criteria are critical for flexible circuit applications?

Material selection depends on the specific application environment and operational requirements. Polyimide (Kapton) offers excellent thermal and chemical resistance, making it suitable for high-temperature environments and demanding applications. Polyester (PET) is a cost-effective alternative for less harsh conditions. Liquid Crystal Polymer (LCP) is chosen for high frequency applications and fine-line features. Consider factors such as flexibility, thermal stability, dielectric properties, and chemical resistance when choosing materials. - How early should I involve a manufacturer in the flexible circuit design process?

Early involvement of the manufacturer in the design process is crucial for ensuring manufacturability and avoiding costly design iterations. Engaging the manufacturer early allows for design for manufacturing (DFM) feedback, identifying potential issues with trace routing, component placement, and material selection. This collaborative approach optimizes designs, reduces lead times, and lowers overall costs. Discuss design constraints and required capabilities with the manufacturer during the early design phase.

Choosing the right flexible circuit manufacturer is paramount to the success of your projects. By understanding their capabilities, specializations, and material options, you can ensure high-quality flexible circuits that meet your specific needs. Flexible circuit manufacturers play a crucial role in developing cutting-edge products, and a knowledgeable choice is key to achieving optimal results and pushing the boundaries of technology.

AnyPCBA

AnyPCBA