Top PCB Manufacturers: Finding the Best Fit for Your Project

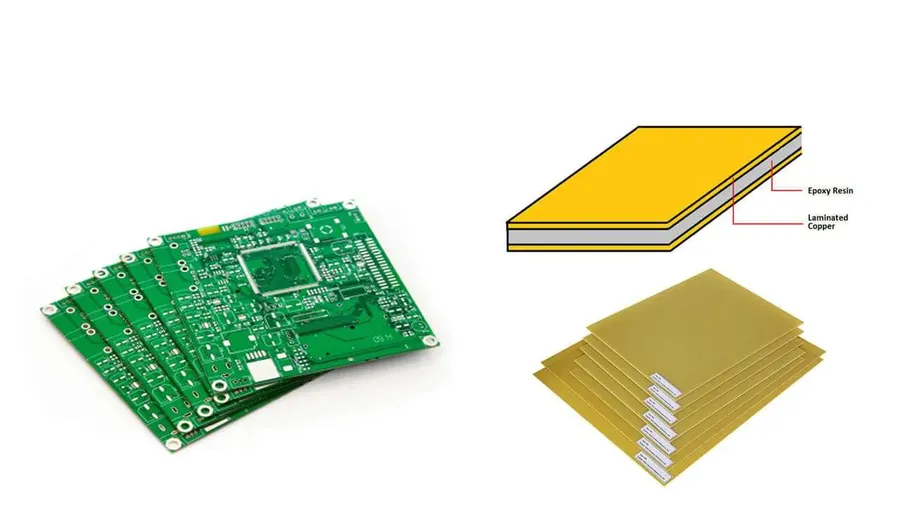

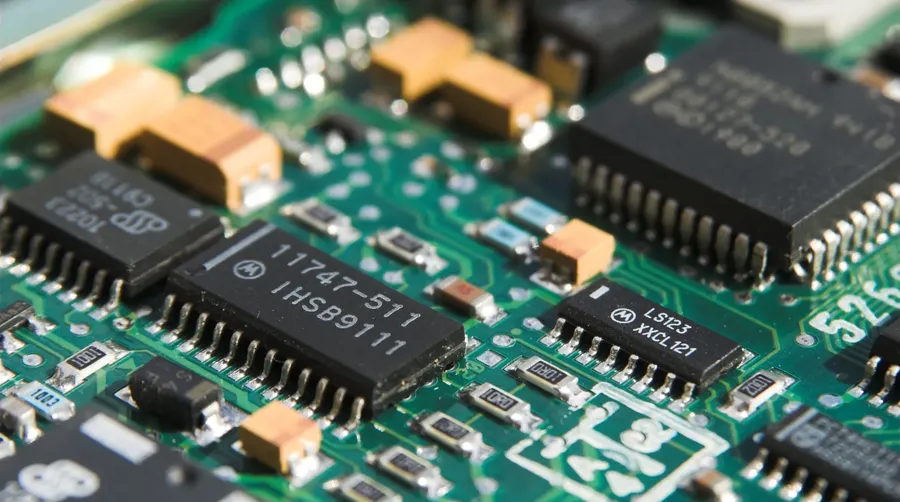

The humble printed circuit board (PCB) is the unsung hero of modern electronics. From smartphones to satellites, PCBs form the backbone of countless devices. Selecting the right PCB manufacturer is crucial for ensuring product reliability and success. This guide will explore the world of PCB manufacturing, highlighting the best PCB manufacturers and helping you navigate the complexities of PCB sourcing.

Understanding Your PCB Needs

Before selecting a PCB manufacturer, a thorough assessment of your project's specific needs is paramount. This involves a detailed analysis of factors such as the complexity of the circuit board, the required production volume, the desired turnaround time, and the budgetary constraints. A clear understanding of these elements will enable a more focused and efficient selection process, ultimately leading to a better match between project requirements and manufacturer capabilities.

- Board Complexity

Consider the number of layers, trace widths, via types, and component density. Highly complex designs may necessitate manufacturers with advanced fabrication capabilities. - Production Volume

Prototype quantities, small batch production, or high-volume runs will influence the choice of manufacturer, as some specialize in specific production scales. - Turnaround Time

Project timelines impact manufacturer selection, as some offer faster lead times but potentially at a higher cost. - Budget

Cost considerations are vital, and understanding your budget will help you identify manufacturers that align with your financial constraints without compromising necessary quality.

Key Factors in Evaluating PCB Manufacturers

Selecting the right PCB manufacturer is crucial for ensuring the quality and performance of your electronic product. This process requires a thorough evaluation of various factors that directly influence the final outcome. These key factors range from material quality and manufacturing capabilities to certifications and customer support.

Careful consideration of each of these elements is essential when choosing a PCB manufacturer to minimize risks and costs while maximizing the likelihood of a successful project. This section provides a detailed look at what you should be evaluating.

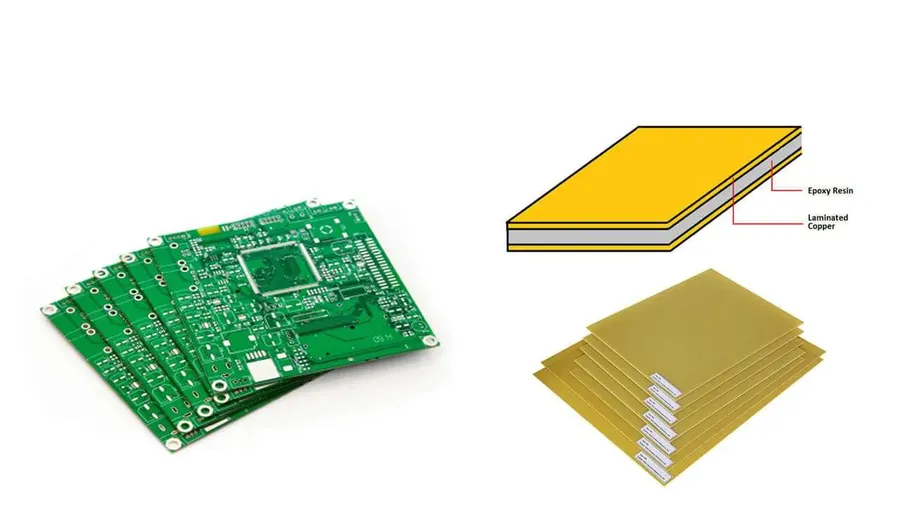

- Material Quality

The quality of materials like FR-4, Rogers, or metal core laminates directly affects the PCB's reliability, thermal performance, and signal integrity. Check for manufacturers that use certified materials from reputable suppliers to ensure long-term durability and functionality. - Manufacturing Capabilities

Evaluate a manufacturer's ability to meet your design specifications, including the number of layers (single, double, or multi-layer), minimum trace width and spacing, via size, and board size. Advanced capabilities like impedance control and blind/buried vias are necessary for complex designs. - Certifications and Standards Compliance

Verify that the manufacturer complies with industry standards such as ISO 9001 for quality management and IPC standards for PCB manufacturing. Certifications validate the quality system in place and adherence to manufacturing best practices. - Production Volume Capacity

Ensure that the manufacturer can handle your current and future volume requirements. Whether you need a few prototypes or large-scale production, verify that they have the capacity and resources to meet your needs without compromising quality or lead times. - Turnaround Time

Consider your project timelines and evaluate the manufacturer’s lead times for fabrication and assembly. Faster turnaround times may be crucial for prototypes and time-sensitive projects, but be aware that express services may come at a higher cost. - Customer Support and Communication

Responsive and helpful customer support is vital for addressing any issues that may arise during the manufacturing process. Choose a manufacturer that offers good communication channels, technical assistance, and prompt responses to your queries and concerns. - Cost and Pricing Transparency

Compare pricing from multiple manufacturers and ensure that pricing is transparent without hidden fees or unexpected charges. Consider factors like setup fees, unit costs, and shipping costs when making your decision.

Top Global PCB Manufacturers: A Comparative Overview

The global PCB manufacturing landscape is dominated by a mix of large corporations and specialized regional players. This section provides an overview of leading manufacturers, highlighting their core competencies and geographic focus. Understanding these nuances is crucial for selecting the best partner for your project, impacting cost, lead time, and technological capabilities.

| Manufacturer | Headquarters | Strengths | Specializations | Considerations |

|---|---|---|---|---|

| TTM Technologies | USA | Large-scale production, diverse capabilities, global presence | Aerospace, defense, medical, automotive | May have longer lead times for small orders; premium pricing |

| AT&S | Austria | High-end technology, strong in HDI and advanced interconnect solutions | Automotive, industrial, medical, mobile devices | Potentially higher costs for standard PCBs, specialized capabilities |

| PCBONLINE | China | Cost-effective solutions, quick turnaround, wide range of services | Prototyping, small to medium volume production, general electronics | Quality can vary; due diligence needed for complex projects |

| Unimicron | Taiwan | High-volume manufacturing, advanced technologies | Consumer electronics, computing, communications | Primarily focused on large-scale production |

| Nippon Mektron | Japan | High-quality, complex PCBs, strong material science expertise | Automotive, industrial, medical | Can be more expensive; best suited for high-performance applications |

| Kingboard Holdings | Hong Kong | Vertically integrated manufacturer with a wide range of product offerings | General electronics, consumer products | Potentially variable quality control |

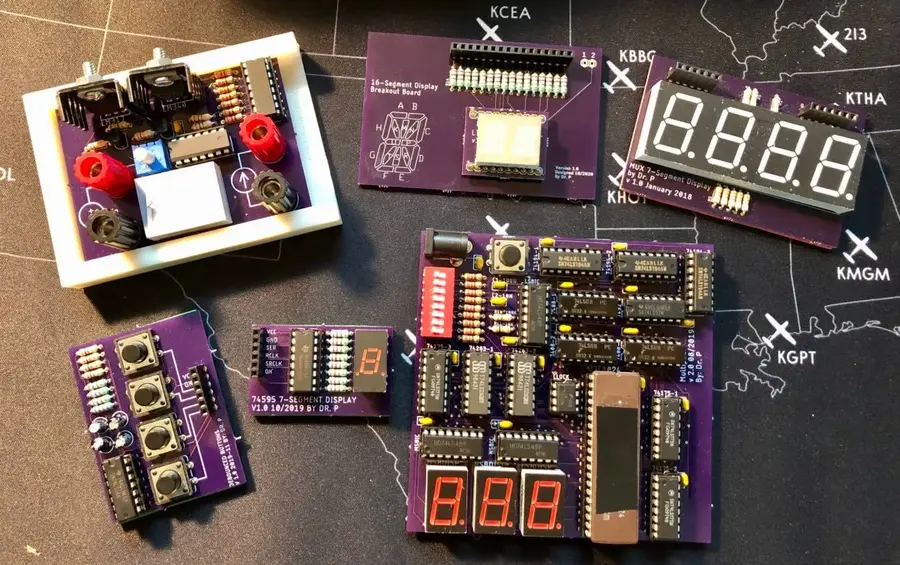

Best PCB Manufacturers for Hobbyists and Small Projects

For hobbyists and small-scale ventures, the ideal PCB manufacturer offers a blend of affordability, reliability, and user-friendliness. These manufacturers prioritize accessibility, enabling rapid prototyping and production of small batch orders without compromising on quality. The cost-effectiveness and quick turnaround times are key factors for users working within constrained budgets and timelines.

Several manufacturers have carved a niche in this segment. Below is an overview of prominent players, each with their own strengths.

| Manufacturer | Key Strengths | Typical User | Considerations |

|---|---|---|---|

| JLCPCB | Highly cost-effective, fast turnaround, wide range of options | Hobbyists, small businesses, prototypes | High volume orders may have longer lead times; some limitations in very complex designs |

| PCBWay | Good balance of cost, speed and quality, offers assembly services | Hobbyists, makers, small to medium-sized projects | Slightly higher cost than JLCPCB, but with more service options |

| OSH Park | Focus on quality and open-source hardware community, purple solder mask | Hobbyists, educational projects, open-source enthusiasts | Limited options in layer counts and materials, longer turnaround times, but high quality |

PCB Manufacturers in the USA: Local Options and Their Advantages

Choosing a domestic PCB manufacturer within the USA offers significant advantages, particularly for projects requiring rapid turnaround, stringent quality control, and adherence to specific regulatory standards. American-based manufacturers like Advanced Circuits and Sunstone Circuits provide reliable solutions with added benefits of faster shipping, enhanced communication, and compliance with US regulations.

| Advantage | Description |

|---|---|

| Faster Shipping | Domestic manufacturing significantly reduces shipping times compared to overseas options, crucial for time-sensitive projects. |

| Enhanced Communication | Real-time communication and direct interaction with the manufacturer's team simplifies project management and issue resolution. This minimizes potential delays and misunderstandings. |

| Compliance with US Regulations | U.S.-based manufacturers adhere to strict environmental and quality standards, ensuring high levels of product consistency and regulatory compliance. This is especially important for projects with regulatory or certification requirements, offering peace of mind. |

| Intellectual Property Protection | Domestic production reduces the risks associated with IP theft or unauthorized replication of your PCB designs, which can be a major concern with international manufacturers. The legal framework within the USA provides greater IP protection. |

| Support for Local Economy | Choosing domestic manufacturers contributes to the local economy, creating jobs and supporting the growth of domestic technology sectors. It promotes American manufacturing, fostering economic development and innovation within the USA. |

While potentially more expensive upfront compared to overseas manufacturers, the long-term benefits, such as reduced lead times, consistent quality, and strong communication channels, frequently outweigh the initial cost difference for businesses that prioritize reliability and quality in their supply chain.

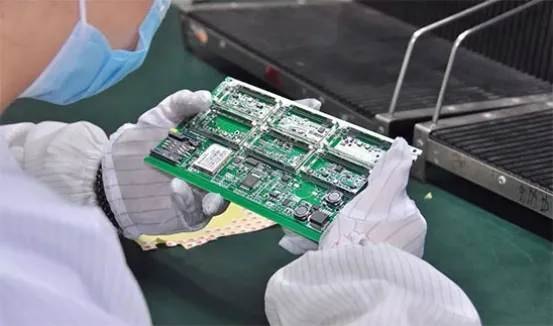

Navigating PCB Assembly Services

The process of assembling a Printed Circuit Board (PCB) involves mounting electronic components onto the fabricated board, and it is a critical step in transforming a bare PCB into a functional electronic device. PCB assembly services provide a crucial bridge between PCB fabrication and the final product, which can streamline the manufacturing process and ensure the reliable functionality of the electronic device. Manufacturers offering turnkey solutions, encompassing both PCB fabrication and component assembly, present significant advantages in terms of efficiency, quality control and cost.

A unified process, often referred to as a 'turnkey' service, eliminates the need to coordinate between separate fabrication and assembly vendors, reducing the risk of compatibility issues, delays, and errors. Additionally, it streamlines communication, which can improve the efficiency of the whole process. By consolidating these processes, manufacturers can exert greater control over the quality and integrity of the final product, from board design through to final assembly. Choosing the right vendor with comprehensive services ensures better outcomes. This not only simplifies the project management but also enables more effective cost controls and faster turnaround times.

- Turnkey PCB Assembly

A comprehensive solution where the manufacturer handles all aspects of the PCB process, including fabrication, component procurement, and assembly. - Consolidated Process

A single vendor manages both PCB fabrication and component assembly, thereby reducing logistical complexities and potential communication errors between two separate vendors. - Advantages of a Unified Process

Streamlined communication, simplified project management, and better quality control, resulting in faster turnaround and better overall cost efficiency.

| Aspect | Separate Vendors | Turnkey Solution |

|---|---|---|

| Vendor Coordination | Requires meticulous management and synchronization between multiple vendors. | Managed by a single source, simplifying coordination. |

| Quality Control | Quality control can be challenging to manage across multiple vendors. | Better quality control, as the process is managed by a single entity. |

| Communication | Increased risk of miscommunication, leading to errors and delays. | Communication is streamlined, reducing risk of errors. |

| Logistics | More complex logistics and longer lead times due to coordination. | Simplified logistics, shorter lead times, and increased efficiency. |

| Cost | Cost may be difficult to estimate upfront, and costs can increase due to logistical complexities. | Potentially lower cost due to economies of scale and simplified processes. |

| Compatibility Issues | Higher risk of incompatibility issues between fabricated boards and assembly process. | Ensures compatibility between the fabricated board and assembly components. |

Frequently Asked Questions About Choosing the Best PCB Manufacturers

Selecting the right PCB manufacturer is crucial for project success. This section addresses common questions to guide you in making an informed decision.

- Who are the best PCB manufacturers?

The 'best' PCB manufacturer depends heavily on specific project needs. For high-volume, complex boards, manufacturers like TTM Technologies and AT&S are often cited for their advanced capabilities and reliability. For prototyping and smaller projects, JLCPCB, PCBWay, and OSH Park offer cost-effective solutions with reasonable turnaround times. Regional manufacturers like Advanced Circuits and Sunstone Circuits in the USA are excellent for domestic projects due to reduced lead times and better communication. The best manufacturer is not a single company but the one that best matches project requirements. Therefore, no single entity can be labeled the definitive 'best'. - Which company's PCBs are considered the highest quality?

High-quality PCBs result from a combination of superior materials, precise manufacturing processes, and stringent quality control. Companies such as TTM Technologies and AT&S are known for their high-quality boards, often serving sectors that require utmost reliability such as aerospace, defense, and medical applications. High quality also comes with rigorous adherence to certifications such as ISO 9001, and IPC standards. The specific quality requirements need to be considered on a project basis when choosing a manufacturer, where material selection and production process are key considerations. Therefore, there is no single PCB manufacturer with universally accepted highest-quality across all parameters. This determination is usually a project specific engineering consideration. - Who is the largest PCB manufacturer in the world?

Based on revenue and production volume, TTM Technologies is frequently cited as one of the largest PCB manufacturers globally. AT&S is another major player, especially in the high-end sector, while other large Asian manufacturers like Unimicron and China-based companies have significant capacity, contributing greatly to the global supply chain. The ranking can vary based on the source, but these are among the dominant players. These manufacturers have huge production capabilities to cater to large-volume needs. - Who is the largest PCB manufacturer in North America?

TTM Technologies is also one of the largest PCB manufacturers based in North America, with a vast production network. Other significant manufacturers include companies like Advanced Circuits and Sunstone Circuits, although their production volume may be lower than TTM Technologies. However, companies like Advanced Circuits and Sunstone Circuits have a significant market presence in the US due to their customer service and speed of delivery. The specific ranking of companies can change with market dynamics, with no single constant leader. Therefore, the title of largest manufacturer may not have a single clear and constant answer depending on a specific analysis. - How do I find the best PCB manufacturer for my small project?

For smaller projects, focusing on cost-effectiveness and ease of use is critical. Manufacturers like JLCPCB, PCBWay, and OSH Park are excellent choices, providing online platforms for easy ordering and often lower minimum order quantities. These manufacturers are tailored for rapid prototyping and small production runs, catering to hobbyists and small businesses that may not have large budgets or require specialized high-end boards. Choosing from these manufacturers offer a fast turnaround and affordable options for most small-scale projects, with ease of use as a key consideration. - What is the importance of certifications when choosing PCB manufacturers?

Certifications, such as ISO 9001 and IPC standards, are crucial indicators of a PCB manufacturer’s commitment to quality and process control. ISO 9001 certification demonstrates that a manufacturer has established a quality management system, while IPC standards ensure PCBs are manufactured to industry-accepted standards. Choosing certified manufacturers can reduce the risk of defective boards and ensures compliance. Compliance to these standards means reduced defects, consistent quality and reliability, hence certifications are key when evaluating manufacturers. Therefore, choosing certified manufacturers are important due to the reduced risk and increase reliability they offer. - Are there any differences between PCB manufacturers in Asia and the USA?

Yes, there are several key differences. Asian manufacturers, particularly in China, often offer lower prices and high-volume production capabilities, making them attractive for cost-sensitive projects with large order quantities. USA-based manufacturers often provide faster turnaround times, easier communication, and may be better suited for projects requiring compliance with US regulations and defense related applications. Regional differences in lead times, customer service, and compliance requirements need to be considered. Therefore the choice of Asian vs US manufacturer depends on the specific project needs.

Cost and Pricing Considerations when choosing your PCB Manufacturers

Selecting a PCB manufacturer involves a careful evaluation of cost factors to balance project budget with desired quality. Understanding the various cost components and strategies for optimization is crucial for effective project management. Transparent pricing policies from your chosen manufacturer are paramount to avoiding unexpected expenses.

| Cost Factor | Description | Impact on Overall Cost | Optimization Strategies |

|---|---|---|---|

| Setup Fees | One-time charge for preparing manufacturing tools, such as stencils and programming equipment. | Significant for small batches; can be amortized over larger volumes. | Batch similar boards together, choose manufacturers with low setup costs for prototypes. |

| Unit Costs | Cost of manufacturing each individual PCB, based on materials, complexity, and manufacturing processes. | Varies with board size, layers, and technology. Lower costs can result in compromised quality. | Compare costs per board, optimize designs for lower material costs, evaluate bulk pricing options. |

| Shipping | Expenses to transport PCBs from the manufacturer to the desired location. | Dependent on location, shipping speed, and order weight/volume. | Consider local manufacturers to reduce shipping costs, plan orders to optimize packaging and shipment method. |

| Bulk Discounts | Reductions in unit costs for larger production volumes. | Significant for larger projects, lower average cost. | Forecast accurately for projected volumes, plan for higher volume orders if feasible to leverage discounts. |

| NRE (Non-Recurring Engineering) costs | These are one-time costs for the engineering work required, often for complex or customized PCBs. | Can significantly increase initial project cost; often associated with first time builds or highly custom designs. | Ensure your designs are optimized and well documented, aim to minimize revisions and iterations, choose manufacturers who offer design consultation early. |

| Tooling Costs | Costs associated with creating necessary tools like stencils for assembly. | Can be substantial for complex boards or large batch sizes. | Reuse tools where possible, choose manufacturers who offer tool reuse policies or minimal tooling fees. |

To ensure you are getting the best deal for your project, always request detailed quotations from multiple manufacturers listed as the best PCB manufacturers, understanding that price should be a factor but not the sole determinant of a final choice. Prioritize providers who offer transparent pricing breakdowns, ensuring that you can identify the source of each cost component. When comparing quotes, make sure you are considering all cost components, not just the quoted unit price. This practice allows you to assess the full expenditure and facilitates making a cost-effective decision without compromising on the final product's overall quality or performance.

Comparing Different PCB Manufacturing Technologies

Selecting the appropriate PCB manufacturing technology is crucial for project success. Different techniques offer varied capabilities in terms of complexity, cost, and application suitability. Understanding the nuances of single-sided, double-sided, multi-layer, and flexible PCBs will guide you towards the best pcb manufacturer for your specific needs.

| PCB Type | Description | Typical Applications | Cost | Typical Manufacturers |

|---|---|---|---|---|

| Single-Sided PCB | Components are mounted on one side of the board; simple to design and manufacture. | Simple electronic devices, LED lighting, basic sensor circuits. | Lowest cost; ideal for high-volume, low-complexity applications. | JLCPCB, PCBWay, OSH Park |

| Double-Sided PCB | Components can be mounted on both sides; allows for more complex circuits. | Consumer electronics, power supplies, simple control systems. | Moderate cost; good for medium-complexity applications. | Advanced Circuits, Sunstone Circuits, TTM Technologies |

| Multi-Layer PCB | Consists of three or more layers of conductive material; allows for high-density and complex routing. | Advanced electronics, computers, aerospace equipment, high-speed communication systems. | Higher cost; essential for high-density and complex routing demands. | AT&S, TTM Technologies, PCBONLINE |

| Flex PCB | Flexible substrate material, can bend and conform to various shapes, often used in dynamic applications. | Wearable technology, automotive electronics, medical devices, foldable electronics. | Higher cost; specialized material and manufacturing process. | Nippon Mektron, Flexium Interconnect, Multek |

Future Trends in PCB Manufacturing

The PCB manufacturing landscape is constantly evolving, driven by the demand for smaller, more efficient, and environmentally friendly electronics. These emerging trends not only shape the capabilities of printed circuit boards but also influence the selection criteria for the best PCB manufacturers. Understanding these trends is crucial for engineers and businesses looking to stay ahead in the electronics industry.

Key trends that are currently shaping the industry include miniaturization, flexible circuits, and sustainable manufacturing.

- Miniaturization

The push for smaller and more compact electronic devices requires PCBs with higher density and finer features. This includes smaller trace widths and spacing, increased layer counts, and the use of microvias and blind/buried vias. Manufacturers investing in advanced equipment and processes to support miniaturization are becoming leaders in the market. The [best pcb manufacturers] need to continually invest in new technologies to support these needs. - Flexible Circuits

Flexible PCBs (FPCs) are gaining popularity due to their ability to conform to complex shapes and their reduced weight and size compared to rigid PCBs. They are used extensively in wearables, automotive, and medical applications. Manufacturers focusing on FPC technology are well-positioned for future growth. For projects that require flexible circuits, carefully select [best pcb manufacturers] based on their specific experience. - Sustainable Manufacturing

Environmental consciousness is driving the adoption of sustainable manufacturing practices. This includes using eco-friendly materials, reducing water and energy consumption, and improving waste management. The [best pcb manufacturers] are increasingly focused on green manufacturing and should be preferred for projects seeking environmentally friendly solutions. Furthermore, they must comply with standards such as RoHS to reduce the environmental impact.

These trends impact manufacturer selection by necessitating careful evaluation of their technological capabilities and commitments to innovation. When selecting a manufacturer, evaluate their capacity for high-density interconnect (HDI) PCBs, flexible circuit fabrication, and their adherence to sustainable manufacturing standards.

The adoption of these future trends will differentiate leading-edge manufacturers and is crucial for future-proofing any long-term project. Therefore, when choosing [best pcb manufacturers], consider those that have embraced, or are proactively adopting, these innovative approaches.

Selecting the right PCB manufacturer is a strategic decision that impacts your product's performance, reliability, and cost. By carefully considering your needs, evaluating manufacturers based on the factors discussed in this article, and staying informed about industry trends, you can find the perfect partner for your project. Regardless of whether you need complex multi-layer boards, or a simple prototype, always consider cost-effective, quality solutions from the [best pcb manufacturers]. The future of electronic devices lies in advanced PCB designs and meticulous manufacturing.

AnyPCBA

AnyPCBA