Top PCB Manufacturers Globally: Finding the Best Partner for Your Needs

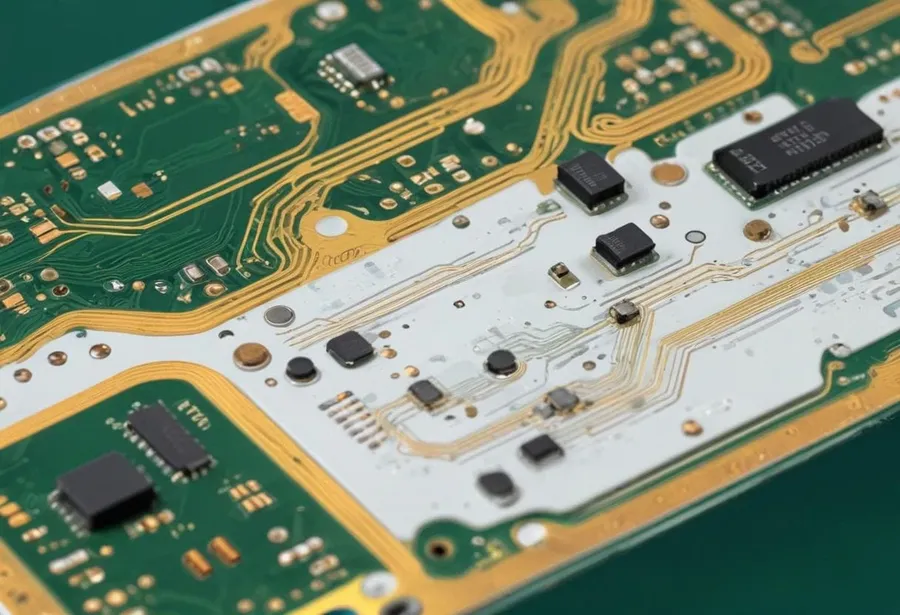

In our increasingly interconnected world, printed circuit boards (PCBs) form the backbone of nearly every electronic device we use. From the smartphones in our pockets to the sophisticated medical equipment in hospitals, PCBs are essential for modern life. Choosing the right PCB manufacturer is crucial for any project, whether you're a hobbyist or a multinational corporation. This article will guide you through the top PCB manufacturers globally, including [best pcb manufacturer in the world], their specialties, and critical factors to consider when selecting a partner.

Understanding the Global PCB Manufacturing Landscape

The global Printed Circuit Board (PCB) manufacturing landscape is a complex ecosystem of companies with varying capabilities, geographic focuses, and technological expertise. This section provides an overview of the major players in this critical industry, their locations, and the types of PCBs they produce. Understanding this landscape is crucial for businesses seeking reliable PCB manufacturing partners.

The PCB manufacturing sector is globally distributed, with a significant concentration of manufacturers in Asia, particularly China, Taiwan, and South Korea. North America and Europe also have a presence, though generally with a focus on specialized or higher-complexity boards. This geographical distribution is driven by factors such as labor costs, infrastructure, and proximity to key electronics markets. Within each region, different manufacturers often specialize in specific PCB types, such as single-sided, double-sided, multilayer, flexible, rigid-flex, or high-density interconnect (HDI) boards. This specialization is a reflection of market demand and manufacturers' unique technological capabilities. The choice of a manufacturer and the location, will affect all aspects of your product development, so a firm understanding of the PCB landscape is critical to success.

| Region | Dominant Manufacturing Countries | Typical PCB Specializations | Key Considerations |

|---|---|---|---|

| Asia | China, Taiwan, South Korea, Japan | Mass-produced PCBs, Flexible PCBs, HDI | Cost-effectiveness, volume capacity, long lead times sometimes an issue, language barrier may occur. |

| North America | USA, Canada | High-complexity PCBs, Military, Aerospace | Advanced technology, higher cost, shorter lead times, high level of communication. |

| Europe | Germany, UK, France | Automotive, Industrial, medical application PCBs | Quality-focused, mid to high-cost, moderate lead time, high level of communication. |

Top PCB Manufacturers: A Detailed Comparison

The global PCB manufacturing landscape is dominated by a few key players, each with unique strengths and specializations. This section offers a detailed comparison of these leading manufacturers, focusing on critical factors such as production capacity, technological capabilities, and customer feedback, to help guide your selection process.

| Manufacturer | Headquarters | Key Strengths | Technology Focus | Approximate Market Share | Customer Reviews (General) | Typical Lead Times |

|---|---|---|---|---|---|---|

| Unimicron | Taiwan | High volume production, advanced HDI | HDI, Rigid-Flex, IC Substrates | ~8-10% | Generally Positive, known for high-volume capacity | Varies, typically 2-6 weeks |

| Zhen Ding Technology | Taiwan | Flexible PCBs, strong in consumer electronics | Flexible PCBs, Rigid-Flex | ~7-9% | Positive, especially for flex circuits | Varies, typically 3-8 weeks |

| TTM Technologies | USA | High-reliability PCBs, aerospace and defense focus | High Layer Count, RF/Microwave | ~5-7% | Very Positive, known for reliability and technical support | Often longer, 4-12 weeks |

| Nippon Mektron | Japan | Automotive and industrial applications, advanced materials | Flexible PCBs, Advanced Materials | ~4-6% | Positive, regarded for high-quality materials | Varies, typically 4-10 weeks |

| AT&S | Austria | High-end HDI and IC substrates, medical and industrial focus | HDI, IC Substrates, Embedded Components | ~3-5% | Very Positive, specializing in advanced technology | Typically 6-14 weeks |

Key Factors to Consider When Choosing a PCB Manufacturer

Selecting the right PCB manufacturer is critical to the success of any electronics project. This decision hinges on several key factors that directly impact the final product's quality, performance, and cost. These factors range from material selection to lead times and quality control, each demanding careful evaluation to ensure a successful and efficient manufacturing process.

| Factor | Description | Importance |

|---|---|---|

| Material Selection | Choice of substrates (e.g., FR-4, Rogers), copper thickness, and surface finish. | Impacts electrical performance, thermal properties, and durability of the PCB. |

| Lead Times | The time it takes from order placement to receiving the finished PCBs. | Affects project timelines and ability to meet deadlines. Shorter lead times often mean higher costs. |

| Quality Control | Processes and standards implemented to ensure PCBs meet specifications. | Crucial for reliability and performance; includes inspections and certifications. |

| Cost | Overall price per board, factoring in material costs, manufacturing complexity, and order volume. | Budgetary constraints are always a key consideration and need to be evaluated against quality and other factors. |

| Manufacturing Capabilities | The manufacturer's ability to handle specific PCB types (e.g., HDI, flexible), layer counts, and specialized processes. | Ensure the manufacturer can produce PCBs meeting your complexity requirements. |

| Technology and Innovation | Adoption of latest manufacturing techniques and ability to implement new design features. | Crucial for projects needing leading-edge components and features and helps reduce risks. |

| Customer Reviews and Support | Feedback from other clients on the manufacturer's performance and the availability of technical assistance. | Can indicate reliability and responsiveness of the manufacturer. |

Specialized PCB Manufacturing Capabilities

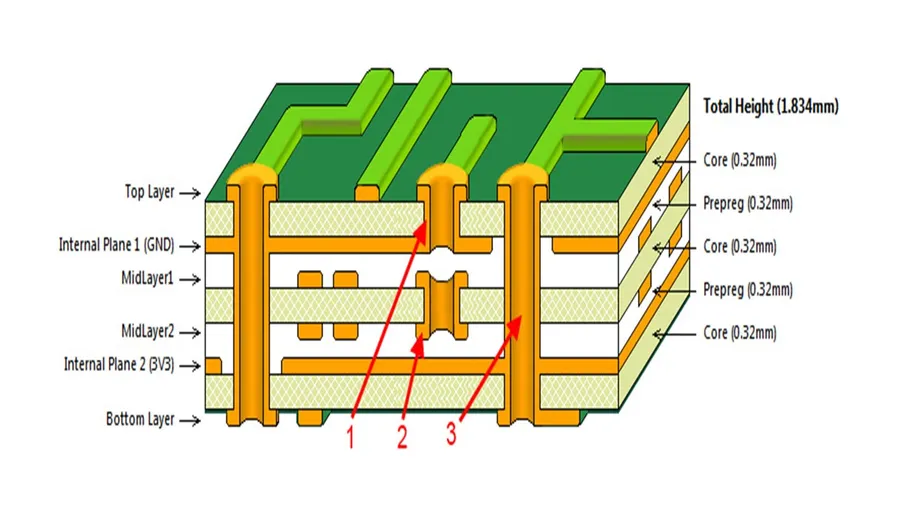

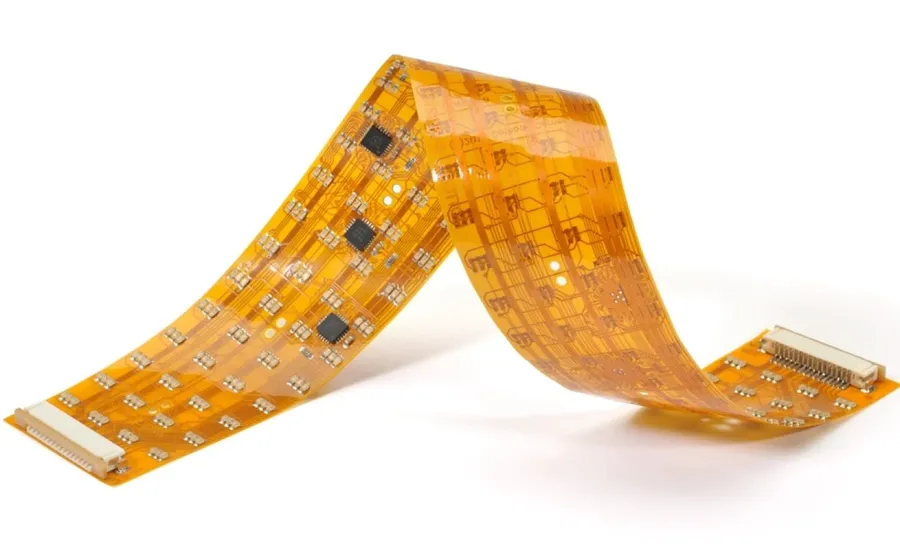

The PCB manufacturing landscape is not monolithic; certain manufacturers distinguish themselves through specialized capabilities, catering to niche applications with advanced PCB designs. These specialized services encompass technologies like High-Density Interconnect (HDI), flexible PCBs, and Radio Frequency (RF) PCBs, each requiring unique expertise and equipment.

Understanding the nuances of these specialized PCB types is critical for selecting a manufacturer that can meet the demands of your specific project. The ability to produce these boards is not just a matter of equipment, but also of a deep understanding of material science, fabrication processes, and quality control at very precise tolerances.

| PCB Type | Description | Typical Applications | Manufacturing Considerations |

|---|---|---|---|

| High-Density Interconnect (HDI) | PCBs with higher wiring density per unit area, achieved through finer lines, microvias, and advanced materials. | Smartphones, wearables, and other compact electronic devices requiring high functionality in small form factors. | Requires advanced laser drilling, precision lamination, and specialized material handling. |

| Flexible PCBs | PCBs built on flexible substrates, allowing them to conform to various shapes and bend or flex during operation. | Automotive, medical, and aerospace applications where dynamic bending or unusual shapes are necessary. | Needs careful material selection, controlled bending radiuses, and precise layering techniques. |

| Radio Frequency (RF) PCBs | PCBs designed to transmit high-frequency signals with minimal loss or interference. They require very tight impedance control and specific materials. | Telecommunications, radar, and other high-frequency signal applications. | Requires very low dielectric loss materials, tight impedance control, and precise fabrication techniques. |

Geographic Considerations When Selecting a PCB Manufacturer

The geographic location of a PCB manufacturer significantly impacts factors such as cost, lead times, and communication. Selecting a manufacturer involves careful consideration of regional advantages and disadvantages to optimize your supply chain.

| Region | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| Asia (China, Taiwan, South Korea) | Lower manufacturing costs, large capacity, established supply chains, wide range of capabilities. | Potentially longer lead times for overseas shipping, time zone differences can complicate communication, quality control concerns can vary, intellectual property risks. | High-volume production, consumer electronics, cost-sensitive projects |

| North America (USA, Canada) | Strong intellectual property protection, easier communication, faster lead times for North American customers, higher quality standards, advanced technical capabilities. | Higher manufacturing costs, potentially less flexibility in large volume production. | Aerospace, military, medical devices, high-reliability applications, rapid prototyping. |

| Europe | High quality standards, strong regulatory compliance, advanced technical capabilities, focus on sustainable practices, good communication. | Higher manufacturing costs than Asia, moderate lead times compared to North America, may have less capacity for very high-volume orders. | Automotive, industrial automation, high-precision engineering, projects requiring specific certifications. |

Frequently Asked Questions About Choosing the Best PCB Manufacturer

Navigating the selection of a PCB manufacturer can be complex. Here, we address common questions to guide your decision, offering clarity on critical aspects of this process.

- Who is generally considered the best PCB manufacturer?

Identifying a single 'best' PCB manufacturer is challenging as it depends greatly on specific project needs. However, companies like Unimicron and Zhen Ding Technology are consistently recognized for their large scale, technological capabilities, and quality. The 'best' choice should align with your volume requirements, complexity needs, and geographical preferences. - Which company's PCBs are considered to be the highest quality?

Quality is a multifaceted attribute influenced by materials, manufacturing processes, and quality control. While several manufacturers uphold high standards, companies that are certified with ISO 9001 and have a proven track record of producing intricate, high-reliability PCBs are generally favored for superior quality. Always check specific certifications and quality reports. - Who is the largest PCB manufacturer in the world by production volume?

Unimicron is often cited as one of the largest PCB manufacturers globally, based on sheer production volume and revenue. However, market positions can shift, so it's crucial to refer to the most recent industry reports for the latest rankings. Their size often translates to diverse capabilities and potential economies of scale. - Who is the largest manufacturer of PCBs in North America?

While the global PCB manufacturing scene is dominated by Asian manufacturers, there are significant players in North America as well. Companies like TTM Technologies are generally recognized as a large-scale manufacturer in the region. The specific 'largest' position can vary by metrics like revenue or units produced, requiring reference to industry-specific data. - How do I determine the best PCB manufacturer for a prototype project?

For prototypes, flexibility, quick turnaround times, and lower minimum order quantities are critical. Manufacturers specializing in rapid prototyping services or those with dedicated prototype lines are often better choices than very large-scale producers. Evaluate their responsiveness and communication capabilities for iterative development. - What should I look for in a PCB manufacturer for high-volume production?

For high-volume production, the key factors shift towards cost-effectiveness, consistent quality, robust supply chains, and scalable manufacturing processes. Look for manufacturers with extensive automation, established supplier relationships, and documented quality management systems to maintain high throughput. - Is it better to choose a local PCB manufacturer or an overseas one?

This choice depends on several factors. Local manufacturers can offer quicker turnaround, easier communication, and potentially better compliance with local regulations, but often at higher costs. Overseas manufacturers may provide lower prices but may have longer lead times, more complex logistics, and potential cultural barriers. Analyze your specific requirements related to timelines, budgets, and communication capabilities to determine the most appropriate choice.

Choosing a PCB Manufacturer for Specific Project Types

Selecting the right PCB manufacturer hinges significantly on the specific nature of your project, with key considerations varying drastically between prototypes, small-batch runs, and high-volume production. Understanding these differences ensures that the chosen manufacturer can meet your unique demands for quality, cost-effectiveness, and scalability.

| Project Type | Key Considerations | Recommended Manufacturer Focus |

|---|---|---|

| Prototypes | Quick turnaround time, low setup costs, flexibility in design changes | Manufacturers with rapid prototyping services and good communication channels for design iteration. |

| Small Batches | Moderate cost, consistent quality, ability to handle design variations. | Manufacturers offering flexible production runs and good control over material and process quality. |

| High-Volume Production | Lowest cost per unit, reliable supply chain, stringent quality control | Manufacturers with advanced automated production lines, robust supply chain management, and comprehensive quality assurance systems. |

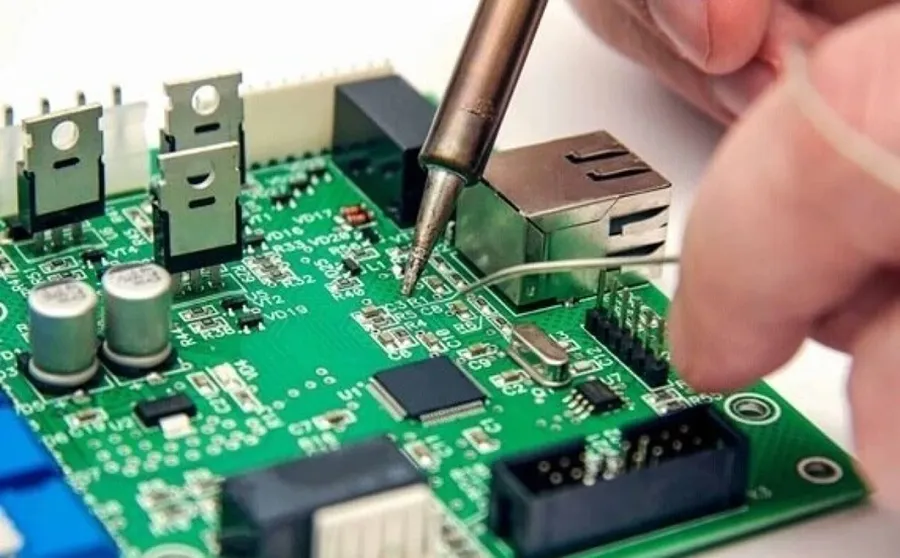

- Prototype PCB Manufacturing

For prototypes, prioritize manufacturers that offer rapid prototyping services, flexible design changes, and have low setup costs. Look for manufacturers that are willing to work with you through iterative design processes, which may include small-volume runs at varying specifications. It's crucial that the manufacturer provides good communication and technical support. Data from industry reports highlights that agile manufacturing and prototyping services contribute significantly to faster product development cycles. - Small-Batch PCB Production

Small-batch production requires a balance between cost and quality. Manufacturers should have the capability to handle design variations and provide consistent quality across runs. It is essential for these manufacturers to provide clear communications, and be willing to adjust processes if needed. They should also be able to work within a budget while maintaining quality standards, so choosing manufacturers with good reputations is important. - High-Volume PCB Production

When producing PCBs in large quantities, the primary focus shifts to cost-effectiveness, reliability, and the supply chain. High-volume PCB manufacturers must have advanced automation systems and stringent quality control measures in place. Look for manufacturers that have robust supply chains to maintain a high yield. It is also important to choose a manufacturer that has certifications and compliance that meet your needs.

Case Studies: Success Stories with Top PCB Manufacturers

Examining real-world case studies illuminates the profound impact of selecting the right PCB manufacturer. These examples demonstrate how strategic partnerships with leading manufacturers, such as Unimicron or Zhen Ding Technology, can translate into significant project success, highlighting the crucial role these partnerships play in product development and market competitiveness.

The following case studies demonstrate the tangible benefits realized through successful collaborations between businesses and top-tier PCB manufacturers. While specific company names may be anonymized for confidentiality, the impact of strategic partnerships in achieving desired outcomes is evident.

- Case Study 1: High-Performance Computing Application

A technology firm required a complex, multi-layer PCB with stringent impedance control for a high-performance computing application. By partnering with a manufacturer known for its advanced technology and precision engineering, the company successfully developed a product that met demanding performance specifications, significantly reduced signal loss, and minimized thermal issues. This collaboration ensured the product's reliability and market launch within the tight schedule. - Case Study 2: Medical Device Manufacturing

A medical device manufacturer needed a PCB with high reliability and strict quality control for a critical life-saving device. By choosing a manufacturer with robust quality assurance processes and certifications, the company produced a PCB that adhered to medical device standards and provided consistent performance, demonstrating the crucial need for compliance and high manufacturing standards. - Case Study 3: Automotive Electronics

An automotive company required a durable and reliable PCB capable of withstanding extreme environmental conditions for a vehicle control system. By collaborating with a manufacturer experienced in automotive standards, the company created a PCB that met stringent thermal, vibration, and shock requirements. This successful partnership enabled the company to deliver a reliable product that increased the vehicle's safety and longevity. - Case Study 4: Aerospace Application

An aerospace company needed a lightweight, high-density PCB for a satellite component, with extremely tight tolerances and high reliability requirements. Through collaboration with a manufacturer specializing in aerospace-grade PCBs, they achieved a PCB that met the necessary specifications, ensuring optimal performance in the harsh environment of space. This case underscores the importance of a strategic partnership with specialist manufacturing capabilities. - Case Study 5: IoT Device Development

A startup developing IoT devices required a cost-effective and scalable PCB solution with integrated wireless capabilities. By working with a manufacturer offering flexible design services and efficient production processes, they rapidly scaled production and met the market demands. This demonstrates how the right manufacturer can be critical for agile product development and fast time to market.

Future Trends in PCB Manufacturing

The PCB manufacturing industry is in constant evolution, driven by the relentless demand for smaller, faster, and more efficient electronic devices. Several key trends are shaping the future of PCB design and production, influencing material choices, fabrication techniques, and the overall approach to electronics manufacturing. These trends are critical for businesses to understand as they plan future product development and supply chain strategies.

- Advanced Materials

The push for higher performance and reliability is driving research into advanced PCB materials. These include low-loss dielectrics for high-frequency applications, thermally conductive substrates for improved heat dissipation, and flexible materials for innovative designs. These advancements address the limitations of traditional FR-4 materials and enable new possibilities in electronic device design. - Miniaturization and High-Density Interconnect (HDI)

As devices become smaller and more feature-rich, the demand for miniaturization in PCBs is increasing. HDI technology allows for more circuits to be packed into a smaller area, using techniques like microvias, fine-line traces, and multilayer designs. This is crucial for applications in smartphones, wearables, and other compact electronic devices. - Sustainable Manufacturing Practices

Environmental concerns are leading to a greater focus on sustainable PCB manufacturing processes. This includes using more environmentally friendly materials, implementing water and energy conservation methods, and developing recycling programs for end-of-life PCBs. The goal is to reduce the carbon footprint of the electronics industry and comply with stricter environmental regulations. - Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, is emerging as a viable method for creating PCBs, especially for prototyping and small-batch production. 3D printing offers advantages such as faster turnaround times, customizable designs, and the ability to create complex shapes and structures. As the technology matures, it is expected to play an increasingly significant role in PCB manufacturing. - Automation and AI

The integration of automation and artificial intelligence (AI) is transforming PCB manufacturing, leading to increased efficiency, precision, and quality control. AI algorithms are being used for tasks such as design optimization, process monitoring, and defect detection. These technologies minimize human error, reduce manufacturing costs, and improve the overall production process.

Selecting the right PCB manufacturer, including [best pcb manufacturer in the world], is a critical step towards success for any electronics project. By understanding the global landscape, assessing your specific needs, and considering key factors like quality, cost, and lead times, you can establish a partnership that propels your projects forward. As technology continues to advance, keeping abreast of future trends in PCB manufacturing will be essential for maintaining a competitive edge in the ever-evolving electronics industry. The right PCB partner is a cornerstone for successful product development and innovation.

AnyPCBA

AnyPCBA