Top Printed Circuit Board Manufacturers in 2024: A Comprehensive Guide

In our increasingly interconnected world, printed circuit boards (PCBs) are the unseen foundation of nearly every electronic device. From smartphones and computers to industrial machinery and medical equipment, PCBs enable the functionality we rely on daily. This guide explores the landscape of the leading PCB manufacturers, focusing on those who lead the industry with innovation and quality, including industry giants such as TTM Technologies and Sanmina. We'll delve into the key players shaping this essential sector, helping you understand who might be the best partner for your next project and why their role in modern life is so important.

Key Criteria for Choosing a PCB Manufacturer

Selecting the right printed circuit board (PCB) manufacturer is critical for the success of any electronics project. A meticulous evaluation of various factors, including production capabilities, material choices, lead times, cost structures, and quality assurance protocols, is essential to ensure that the manufacturer can meet specific project needs and deliver high-quality boards.

| Criteria | Description | Importance |

|---|---|---|

| Production Capabilities | The manufacturer's ability to handle the required volume, complexity (layer count, trace width, via size), and PCB types (rigid, flex, rigid-flex). | Crucial for meeting project specifications and ensuring scalability. |

| Material Options | The range of materials (FR-4, polyimide, Rogers, metal core) offered and their suitability for different applications and performance requirements. | Affects performance characteristics, reliability, and cost. |

| Lead Times | The typical turnaround time from design submission to delivery of finished PCBs. Including prototyping, production. | Impacts project timelines and can be critical for time-sensitive projects. |

| Pricing | The overall cost of PCB manufacturing, including tooling, materials, and assembly (if applicable). | Must align with the project budget. |

| Quality Control Processes | The manufacturer's testing and inspection methods, certifications (e.g., ISO 9001, IPC standards), and adherence to industry best practices. | Ensures board reliability and performance. |

| Technological Capabilities | The sophistication of equipment and proficiency in handling complex designs, advanced technologies such as HDI, microvias, and impedance control. | Essential for advanced applications requiring precision. |

| Customer Support | The level of assistance and communication provided, especially during the design and manufacturing process. | Facilitates smooth project execution and quick resolution of issues. |

Top Global PCB Manufacturers: A Comparative Analysis

The global PCB manufacturing landscape is dominated by a few key players, each with unique strengths and specializations. This section provides a comparative analysis of these top manufacturers, outlining their global reach and market positioning. Understanding these industry leaders is crucial for selecting the right partner for your specific PCB manufacturing needs.

| Manufacturer | Headquarters | Strengths | Global Reach | Specializations |

|---|---|---|---|---|

| AT&S | Austria | High-end PCBs, advanced packaging | Europe, Asia, Americas | HDI, IC substrates, automotive PCBs |

| Zhen Ding Technology | Taiwan | Large-scale production, flexible PCBs | Asia, Americas | Flexible PCBs, rigid-flex PCBs, mass production |

| Unimicron | Taiwan | Wide range of PCB products, strong R&D | Asia, Europe, Americas | HDI, high layer count, advanced technology |

| TTM Technologies | USA | Aerospace & defense, high-reliability PCBs | North America, Asia | Aerospace, military, high-speed digital PCBs |

| Samsung Electro-Mechanics | South Korea | Advanced packaging, high-density interconnect | Asia, Europe, Americas | IC substrates, high-density PCBs, mobile electronics |

| Nippon Mektron | Japan | Flexible PCBs, automotive applications | Asia, Europe, Americas | Flexible PCBs, automotive, specialty applications |

Leading PCB Manufacturers in the USA

The United States is home to several leading printed circuit board (PCB) manufacturers, known for their advanced technology, high-quality production, and diverse service offerings. These companies play a critical role in supporting the electronics industry across various sectors, from aerospace and defense to telecommunications and medical devices.

| Manufacturer | Headquarters | Key Strengths | Specializations |

|---|---|---|---|

| TTM Technologies | Costa Mesa, CA | High-volume production, Advanced technology | Aerospace, defense, automotive |

| Sanmina | San Jose, CA | Global manufacturing, Supply chain solutions | Networking, communication, cloud |

| Jabil Inc. | St. Petersburg, FL | End-to-end design and manufacturing, large scale | Healthcare, automotive, consumer |

| Viasystems(now part of TTM) | St. Louis, MO | Complex PCBs, high reliability | Industrial, medical, military |

| Benchmark Electronics | Tempe, AZ | Engineering support, Design and Manufacturing | Aerospace, Medical, Industrial controls |

These manufacturers not only provide standard PCB production but also offer specialized services, including design engineering, prototyping, assembly, and testing. This end-to-end capability makes them crucial partners for companies seeking reliable and high-performance PCB solutions in the USA.

The Rise of Asia in PCB Manufacturing

Asia has become a dominant force in the global PCB manufacturing landscape, significantly shaping the supply chain with its vast production capabilities and competitive pricing. This section delves into the key Asian regions and manufacturers that have become indispensable to the industry, highlighting their pivotal role in meeting global demand.

The ascent of Asian PCB manufacturers is underpinned by several factors, including substantial investments in manufacturing infrastructure, a skilled workforce, and supportive government policies. These elements have propelled the region to the forefront of PCB production, catering to a wide array of industries, from consumer electronics to automotive and aerospace.

| Region | Key Manufacturing Hubs | Dominant Manufacturers | Impact on Supply Chain |

|---|---|---|---|

| China | Shenzhen, Shanghai, Suzhou | Shenzhen Fastprint Circuit Tech, Kinwong Electronic, Founder PCB | Largest PCB producer globally; high volume production capability |

| Taiwan | Taoyuan, Hsinchu | Zhen Ding Technology, Unimicron Technology, Compeq Manufacturing | Strong focus on high-tech and advanced PCB manufacturing; key supplier for high-end electronics |

| South Korea | Ansan, Incheon | Korea Circuit, Samsung Electro-Mechanics | Technologically advanced PCBs, strong domestic demand from tech giants |

| Other Regions (Japan, Southeast Asia) | Japan, Malaysia, Thailand, Vietnam | Nippon Mektron, various regional players | Emerging manufacturing bases; contributing to supply chain resilience |

The impact of Asian PCB manufacturers is far-reaching, affecting lead times, cost structures, and overall supply chain strategies. The concentration of manufacturing in these regions provides both advantages and challenges, particularly in terms of supply chain vulnerability and geopolitical considerations.

In conclusion, understanding the dynamics of Asian PCB manufacturing is crucial for any business involved in the electronics industry. The region's dominance is set to continue, making it vital to establish strong partnerships with these manufacturers to ensure a reliable and cost-effective supply of printed circuit boards.

PCB Manufacturing for Different Applications

The selection of a PCB manufacturer is critically dependent on the specific application, as the requirements for printed circuit boards vary dramatically across industries. This section explores the diverse needs of sectors ranging from consumer electronics to high-reliability aerospace and medical applications, guiding users to the most suitable manufacturers for their particular needs.

| Industry | Typical PCB Requirements | Recommended Manufacturers (Examples) | Key Considerations |

|---|---|---|---|

| Consumer Electronics | High-volume, low-cost, compact designs, moderate reliability | Shenzhen Sunsoar Circuit Technology, Kingboard Chemical Holdings | Cost-effectiveness, rapid production, miniaturization capabilities |

| Automotive | High reliability, temperature resistance, vibration tolerance, often rigid-flex | TTM Technologies, AT&S | Stringent quality standards, durability, environmental robustness |

| Aerospace | Extremely high reliability, thermal performance, radiation resistance, high-layer count | TTM Technologies, Sanmina | Advanced materials, rigorous testing, certifications like AS9100 |

| Medical Devices | High precision, biocompatibility, low electromagnetic interference, often small batch | Advanced Circuits, Jabil | Compliance with medical standards (ISO 13485), material safety, precision manufacturing |

| Telecommunications | High-frequency performance, signal integrity, impedance control | Zhen Ding Technology, Unimicron | Advanced materials for high-speed data transfer, RF expertise, signal analysis capabilities |

| Industrial Control | Robustness, long-term reliability, resistance to harsh environments | Multek, Cirexx | Durability, wide operating temperature range, resistance to vibration and chemicals |

Frequently Asked Questions About PCB Manufacturers

This section addresses common questions about PCB manufacturers, providing clear and concise answers to help you navigate the selection process. We've compiled a list of frequently asked questions to clarify key aspects of PCB manufacturing.

- Who is the best PCB manufacturer?

The 'best' PCB manufacturer is subjective and depends heavily on your specific project needs. Factors to consider include the complexity of your design, required materials, volume, and budget. There is no single best manufacturer universally, but rather one best suited for your specific requirements. Evaluate manufacturers based on their demonstrated capabilities and experience in producing similar PCBs. - Which company's PCB is best for high-performance applications?

For high-performance applications, it is crucial to select a manufacturer with a proven track record in producing PCBs that meet stringent requirements. Manufacturers specializing in advanced materials and high-density interconnect (HDI) technologies are often preferred. For example, companies like TTM Technologies and AT&S are known for their expertise in high-performance PCBs for industries like aerospace, defense, and telecommunications. Evaluate their capabilities to handle precision manufacturing, advanced materials, and rigorous testing. - Who is the largest PCB manufacturer in the world?

Zhen Ding Technology is often cited as one of the largest PCB manufacturers globally, based on revenue and production volume. The company has a significant market share in the flexible printed circuit (FPC) and rigid-flex PCB sectors. However, size alone does not guarantee the best fit for a particular project. Consider their specialization and ensure that it aligns with the requirements of your PCB needs. - Who is the largest manufacturer of PCB in North America?

TTM Technologies is a prominent PCB manufacturer in North America, recognized for its significant manufacturing capacity and diverse range of PCB products. Their expertise covers high-end technologies for various sectors. When choosing a manufacturer in North America, consider their proximity to your operations, their certifications, and their experience with similar projects. - What factors should I consider when selecting a PCB manufacturer?

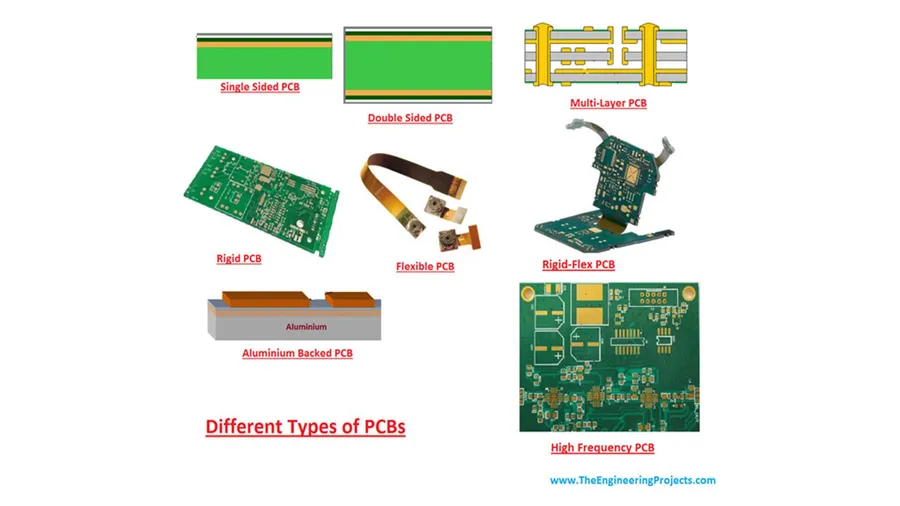

When selecting a PCB manufacturer, consider several factors: their manufacturing capabilities (including the types of PCBs they can produce, such as single-sided, double-sided, multilayer, flexible, or rigid-flex), material options, lead times, pricing structure, quality control processes, certifications (like ISO 9001), customer reviews, and communication efficiency. Always ensure that the manufacturer can meet your specific technical and logistical needs. - How do I verify the quality of a PCB manufacturer?

To verify the quality of a PCB manufacturer, check if they have ISO 9001 certification, review their past performance and customer feedback, request samples, conduct thorough audits of their production facilities, and ensure they perform strict quality checks throughout the manufacturing process. Transparency and willingness to share detailed technical specifications are also good indicators of quality. - What is the impact of lead time on the selection of a PCB manufacturer?

Lead time is a critical factor in selecting a PCB manufacturer, especially when tight project schedules must be met. Evaluate manufacturers based on their ability to consistently meet promised deadlines, as well as their flexibility for accelerated timelines when needed. A reliable manufacturer will also provide clear communication about any potential delays or adjustments to the schedule.

Future Trends in PCB Manufacturing

The printed circuit board (PCB) industry is rapidly evolving, driven by technological advancements and increasing demands for smaller, faster, and more efficient electronic devices. This section explores key emerging trends shaping the future of PCB manufacturing, including the rise of flexible PCBs, the adoption of advanced materials, and the critical move toward sustainable practices. Understanding these trends is crucial for anticipating future industry shifts and maintaining a competitive edge.

- Flexible PCBs

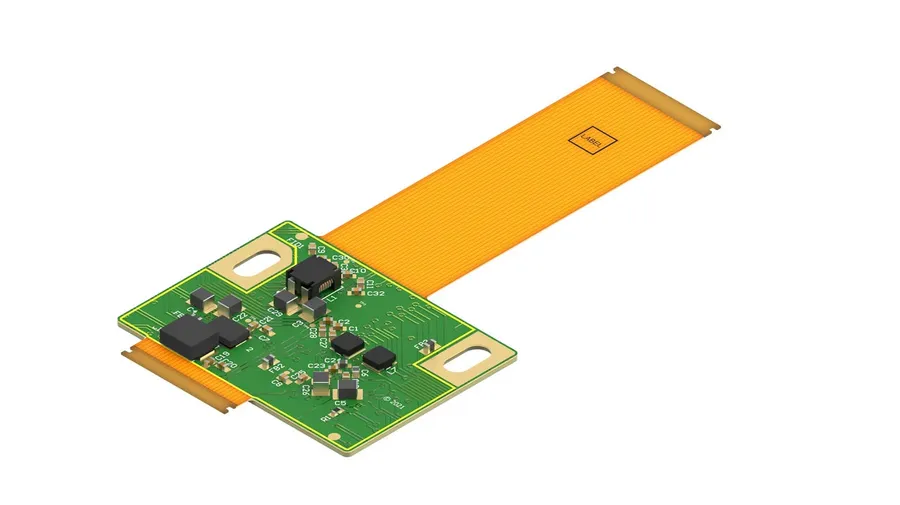

Flexible PCBs, constructed from materials like polyimide, enable circuits to conform to complex shapes and bend without losing functionality. This is vital for applications in wearable electronics, automotive components, and medical devices, where traditional rigid PCBs are unsuitable. The demand for more flexible and compact devices is accelerating the adoption of this technology. This flexibility opens up possibilities for innovative product designs and functionalities. - Advanced Materials

The quest for higher performance has led to exploration of advanced materials for PCBs. These include: - Low-loss dielectrics: Minimize signal loss in high-frequency applications, crucial for 5G and beyond. - Thermally conductive materials: Improve heat dissipation to prevent component failure, particularly important in high-power electronics. - Nanomaterials: Enhance mechanical strength and electrical performance with reduced material consumption. These materials are essential for overcoming the limitations of traditional PCB materials and improving the reliability and efficiency of electronic devices. - Sustainable Manufacturing

Growing environmental consciousness is driving the industry toward more sustainable practices. This includes: - Eco-friendly materials: Replacing hazardous materials with biodegradable or recyclable alternatives. - Water and energy conservation: Optimizing production processes to reduce consumption. - Waste reduction: Implementing efficient recycling programs and reducing material waste. The transition to sustainable manufacturing practices is not only an ethical responsibility but also a necessity for long-term industry viability and compliance with increasingly stringent environmental regulations. - Additive Manufacturing

Additive manufacturing, also known as 3D printing for PCBs, allows for rapid prototyping, custom designs, and production of complex geometries. It offers significant advantages for low-volume production and design iterations, minimizing the time and cost associated with traditional processes. This trend is expected to gain more importance as demand for highly customized PCBs increases. - Miniaturization and High-Density Interconnects (HDI)

The relentless drive for smaller and more powerful devices is fueling the miniaturization trend. High-Density Interconnect (HDI) technology enables the creation of very fine traces, microvias, and higher layer counts, thus allowing for denser component placement and greater functionality within a smaller footprint. This is essential for modern portable electronics and other compact devices.

How to Vet a New PCB Manufacturer

Selecting the right PCB manufacturer is crucial for ensuring the quality and reliability of your electronic products. A thorough vetting process is essential to mitigate risks and establish a successful partnership. This section provides a step-by-step guide on how to conduct due diligence when evaluating a potential PCB manufacturing partner, focusing on certifications, reviews, and site visits.

- Initial Assessment: Define Your Needs

Begin by clearly outlining your project's requirements, including the types of PCBs needed (single-layer, multi-layer, flexible, etc.), required quantities, material specifications, tolerances, and any special design considerations. Understanding these needs upfront will help you identify manufacturers that are capable of meeting your specific demands. - Verify Certifications and Compliance

Confirm that the manufacturer has the necessary certifications. ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System) are critical indicators of commitment to quality and sustainable practices. Other industry-specific certifications, such as IATF 16949 for automotive applications or AS9100 for aerospace, may also be necessary depending on your industry. - Check Manufacturing Capabilities and Technology

Evaluate the manufacturer's technological capabilities. This includes the types of equipment they use (e.g., drilling, etching, plating), their production capacity, and their ability to handle your specific PCB requirements. Assess their experience with the complexity of your designs and their capability to produce high-quality, high-precision PCBs. - Review Quality Control Processes

Inquire about the manufacturer's quality control procedures. A robust system should include inspections at various stages of production, testing, and clear protocols for addressing any non-conformances. Confirm they use industry-standard testing methods, such as electrical testing, impedance testing, and solderability testing. - Review Online Reviews and Testimonials

Research online customer reviews and testimonials about the potential partner. Look for consistency in positive feedback, and pay close attention to any recurring complaints or issues. It's beneficial to check multiple sources to form a comprehensive opinion. Platforms for reviews can be found on websites like Google Reviews and industry-specific forums. - Conduct a Site Visit or Virtual Audit

When possible, conduct an on-site visit to the manufacturer’s facilities. This provides a first-hand look at their operations, equipment, and work environment. If a physical visit is not feasible, request a virtual audit that includes a video tour. Ensure that the manufacturer has a well-organized and clean production area and that their staff are knowledgeable and trained in proper manufacturing procedures. - Evaluate Communication and Support

Assess the communication and support from the manufacturer's sales and engineering teams. A responsive and communicative partner is crucial for seamless project management. Evaluate how quickly they respond to your requests, whether they provide adequate technical support, and if they are transparent with their manufacturing processes. - Request Samples and Conduct Testing

Request sample boards and have them tested. This gives you a tangible way to evaluate the quality and accuracy of the manufacturing process. Testing should cover dimensional accuracy, electrical performance, and material quality. - Compare Pricing and Payment Terms

Obtain detailed quotes from multiple manufacturers, considering the total cost and not just the per-unit price. Understand all pricing factors involved (e.g., tooling, setup fees) and evaluate the manufacturer’s payment terms. - Establish Contractual Agreements and Ongoing Monitoring

Once you've selected a manufacturer, establish a clear contractual agreement that outlines all expectations, including production timelines, quality standards, and warranty provisions. Regularly monitor their performance through periodic inspections or audits to ensure continuous compliance with agreed terms and conditions.

Choosing the right PCB manufacturer is vital for ensuring the success and reliability of your electronic products. This guide has highlighted some of the top players in the industry, including TTM Technologies, Sanmina, and other globally recognized leaders. By understanding their capabilities, specializations, and geographic reach, you can make informed decisions that align with your project needs and goals. As technology advances, PCB manufacturing will continue to evolve, driving further innovation across all sectors. Staying informed about the latest trends and developments will be critical for navigating this dynamic landscape and ensuring your products remain competitive and cutting-edge.

AnyPCBA

AnyPCBA