Understanding PCB Transformer Price: Factors, Types & Market Overview

From powering our smartphones to industrial machinery, transformers are crucial components, with PCB transformers being particularly vital in circuit boards. The price of these tiny yet powerful components varies significantly based on several factors. Let's explore what influences the cost of a PCB transformer, where you can find them, and how to choose the right one for your application.

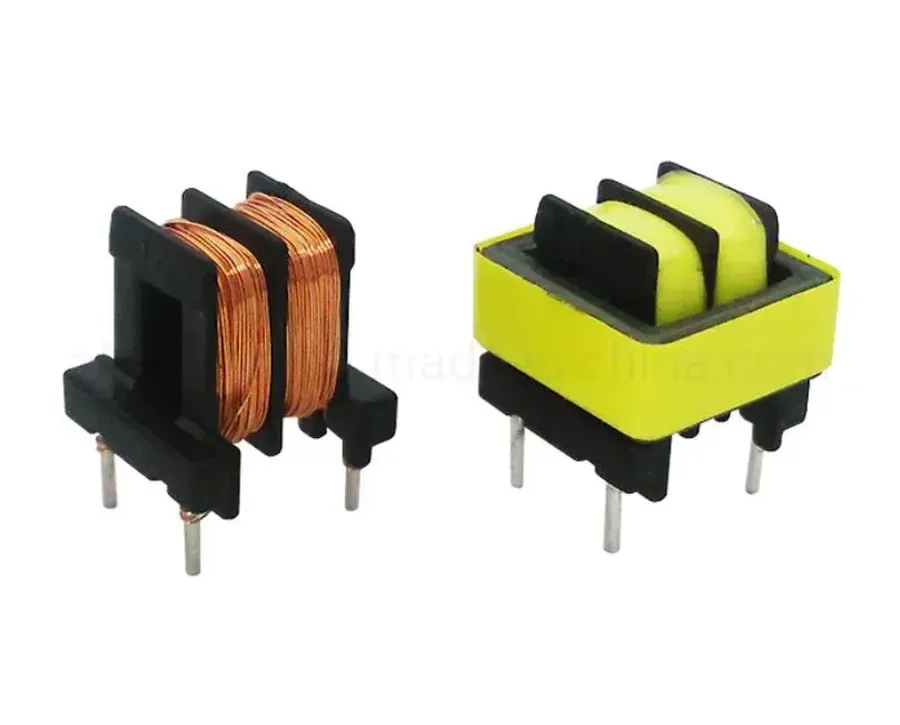

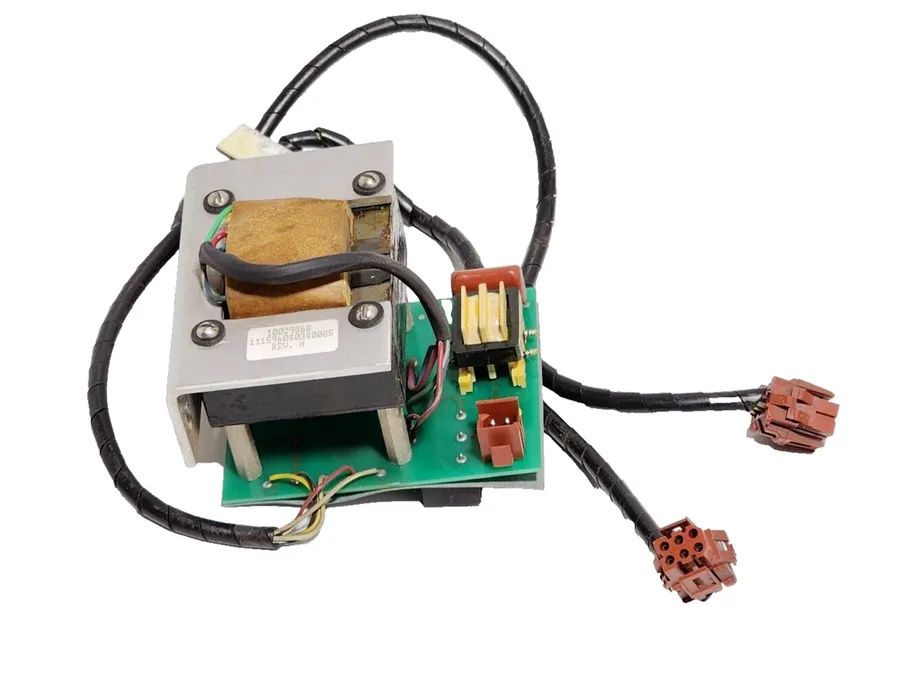

What is a PCB Transformer?

A Printed Circuit Board (PCB) transformer is a specialized type of transformer engineered for direct integration onto a circuit board. Typically smaller and designed for lower power applications compared to traditional transformers, they are available in a variety of shapes, sizes, and core materials, each tailored to meet specific functional requirements. Their integration directly onto PCBs simplifies the design, manufacturing and assembly processes.

Key Factors Influencing PCB Transformer Price

The price of a PCB transformer is determined by a multitude of interconnected factors, spanning material composition, performance specifications, and regulatory requirements. Understanding these elements is crucial for accurately assessing and comparing costs.

| Factor | Description | Impact on Price |

|---|---|---|

| Core Material | Ferrite, laminated steel, amorphous metal, etc. | Ferrite is generally more cost-effective than materials with higher permeability or lower core losses (e.g. amorphous metal), which increase price. |

| Winding Material | Copper or aluminum. | Copper, with higher conductivity, often leads to better efficiency but can be more expensive than aluminum. |

| Turns Ratio | Ratio of primary to secondary windings. | More complex turns ratios that require more precise winding techniques can slightly increase the price. |

| Power Rating | The power handling capability of the transformer. | Higher power transformers necessitate larger cores, more winding material, and higher insulation requirements which increase the cost. |

| Insulation Class | Specifies the temperature rating of the insulation material. | Higher temperature insulation materials are usually more expensive, increasing price for more robust units. |

| Safety Certifications | Compliance with standards like UL, CSA, CE, etc. | Transformers with more stringent safety certifications undergo more testing and quality controls, leading to a higher price. |

| Quantity | Order volume. | Bulk purchases typically result in lower per-unit costs due to economies of scale. |

It's important to note that these factors are not mutually exclusive; they interact to determine the final price. For example, a transformer with a high power rating may also require a more robust core material and higher insulation class, thereby compounding the price increase. Furthermore, market fluctuations in the price of raw materials like copper can also play a role in the final cost of a PCB transformer.

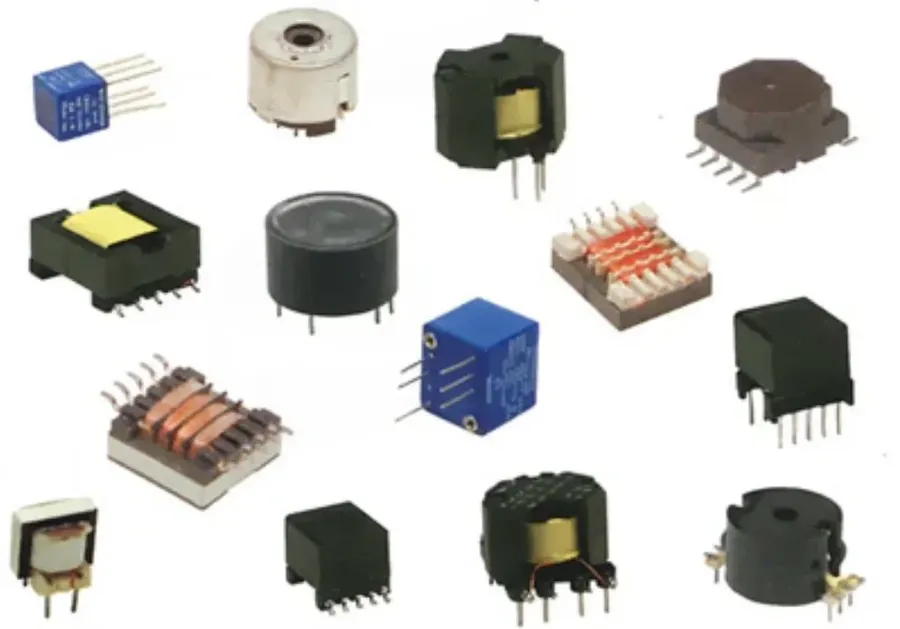

Types of PCB Transformers

PCB transformers are categorized into several types, each engineered for specific applications and exhibiting unique characteristics that influence their pricing. Understanding these types is crucial for selecting the most appropriate component for a given circuit design. The application requirements will dictate the necessary core material, winding style, and insulation class which are the biggest price drivers.

- Standard Power Transformers

These are commonly used for AC/DC conversion and voltage adaptation. They typically operate at mains frequencies (50/60 Hz) and are available in various power ratings and sizes. Their relatively simple design makes them cost effective. - Pulse Transformers

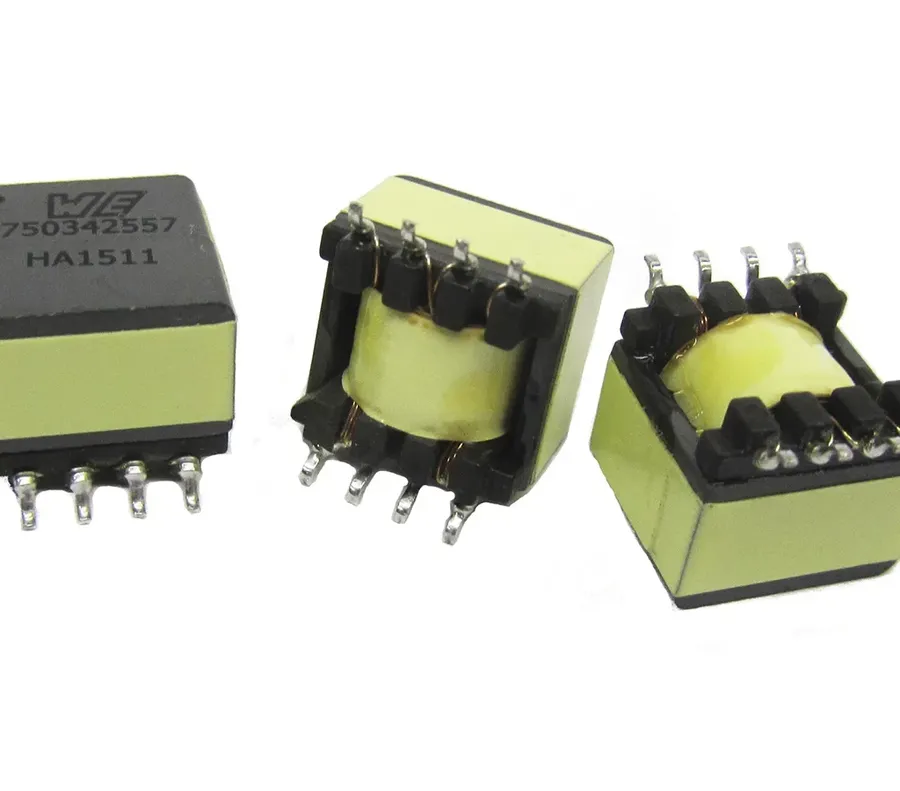

Specifically designed to transmit electrical pulses with minimal distortion, pulse transformers are crucial in applications like gate drivers and digital communication interfaces, such as Ethernet. Their specialized construction leads to moderate cost. - High-Frequency Transformers

Operating at frequencies higher than the standard power transformers, these are used in switched-mode power supplies and inverters. The need for specialized core materials and designs increases their price compared to standard power transformers. - Current Transformers

These transformers measure current in a circuit. They provide galvanic isolation and can be used for protection or feedback in power control applications. Construction of CTs may require specialized materials or turns ratios impacting final cost. - Mounting Styles: PCB Mount vs Surface Mount

Transformers are also classified by their mounting style. PCB mount transformers utilize through-hole pins for soldering, while surface mount transformers are designed for reflow soldering onto pads on the PCB surface. Surface mount types often allow for more automated manufacturing, but design and part cost can be impacted.

| Transformer Type | Typical Application | Relative Cost | Key Characteristics |

|---|---|---|---|

| Standard Power Transformer | AC/DC conversion, Voltage adaption | Low to Moderate | Operates at Mains Frequency, Basic Design |

| Pulse Transformer | Gate drivers, Ethernet | Moderate | Transmits Pulses, Minimizes Distortion |

| High-Frequency Transformer | Switch-mode power supplies, Inverters | Moderate to High | High Operating Frequency, Specialized Core |

| Current Transformer | Current sensing, Feedback | Moderate to High | Measures Current, Galvanic Isolation |

| PCB Mount | Various, depending on transformer type | Varies | Through-hole pin mounting |

| Surface Mount | Various, depending on transformer type | Varies | Reflow solder pad mounting |

PCB Mount Transformer Options and Pricing

PCB mount transformers are engineered for direct integration onto printed circuit boards, facilitating efficient power conversion and signal isolation within electronic devices. These transformers come in a variety of mounting styles, including through-hole configurations with pin leads and surface-mount designs with pads for reflow soldering. The price of these transformers is highly dependent on factors such as power rating and specific functional requirements. Understanding these options and their associated costs is critical for effective design and cost management.

| Transformer Type | Mounting Style | Typical Power Range | Price Range (USD) | Typical Applications |

|---|---|---|---|---|

| Low Power Split Bobbin | Through-hole | < 5VA | $1 - $5 | Small power supplies, signal isolation |

| Standard Power Transformer | Through-hole | 5VA - 50VA | $5 - $20 | AC/DC power conversion |

| High Power Transformer | Through-hole | > 50VA | $20 - $50+ | High current power supplies |

| Surface Mount Transformer | Surface Mount | < 10VA | $2 - $10 | Compact designs, automated assembly |

| Specialized Transformer (e.g. pulse, current) | Surface or Through-hole | Variable | $5 - $50+ | Specific signal processing, current measurement |

Note: Prices are approximate and can fluctuate based on order volume, specific performance parameters, and vendor.

Where to Buy PCB Transformers?

The procurement of PCB transformers involves navigating a diverse landscape of suppliers, each with unique strengths and weaknesses. Understanding these trade-offs is critical for optimizing cost, lead time, and overall project efficiency. This section will guide you through the various options available.

- Electronic Component Distributors

Major distributors like Mouser, Newark, and RS Components offer a vast selection of PCB transformers from various manufacturers. These distributors are known for their reliability and extensive product catalogs. They are often a good starting point for sourcing a wide variety of components. Typically these have good search tools to help you identify the exact part you need. - Online Marketplaces

Platforms such as eBay and Alibaba provide a broader spectrum of sourcing options, including direct manufacturers and smaller suppliers. While prices may be competitive, it's crucial to scrutinize seller ratings and product specifications. Quality control and traceability can vary widely, so due diligence is essential. - Direct from Manufacturers

Engaging directly with manufacturers can be advantageous for custom designs or large-volume orders. Direct communication with the manufacturer can help facilitate custom designs and allow for a direct negotiation of pricing. However, this may require larger minimum order quantities and longer lead times.

| Source | Pros | Cons |

|---|---|---|

| Electronic Component Distributors (Mouser, Newark, RS Components) | Reliable, broad selection, strong search tools | Potentially higher prices, less flexibility |

| Online Marketplaces (eBay, Alibaba) | Competitive pricing, wide range of suppliers | Variable quality and reliability, potential for counterfeit products |

| Direct from Manufacturers | Custom design capabilities, competitive pricing for high volumes | Larger minimum order quantities, potentially longer lead times |

When evaluating sourcing options, consider the balance between price, lead time, minimum order quantities, and the required quality standards for your PCB transformer application. Always prioritize verifying the datasheets and specifications of the transformer with your project requirements. Lead times can significantly affect project schedules, and the time it takes to order components must be considered early on in your project planning.

Frequently Asked Questions About PCB Transformers

This section addresses common inquiries regarding PCB transformers, providing concise answers to key questions about their cost, applications, and characteristics.

- What is the typical cost of a PCB transformer?

The price of a PCB transformer varies significantly based on factors such as power rating, core material, and safety certifications. Simple, low-power transformers may cost under $2, while high-power or specialized transformers can range from $10 to over $50. Bulk purchases may reduce the unit cost. Always consider all technical requirements before making a price comparison. - Are PCB transformers still a relevant technology?

Yes, PCB transformers remain a relevant and widely used technology in numerous electronic devices. They provide efficient voltage conversion and isolation in a compact, board-mountable form factor and are preferred for their ease of integration. Despite advances in other technologies, their benefits make them a staple in many designs. - What does 'PCB' refer to in the context of a transformer?

In the context of a transformer, 'PCB' refers to a Printed Circuit Board. A PCB transformer is specifically designed to be mounted directly onto a circuit board, often using through-hole pins or surface-mount pads, facilitating efficient and space-saving integration within electronic circuits. - What is the purpose of a current transformer on a PCB?

A current transformer (CT) on a PCB is used to measure the current flowing through a conductor without making direct electrical contact. It provides isolation between the measured current and the measuring circuitry. CTs are typically used in power supplies, motor drives, and energy metering applications, allowing for accurate and safe current monitoring. - Can PCB transformers be used in high-frequency applications?

Yes, specialized PCB transformers can be designed for high-frequency applications, often using ferrite core materials and specific winding techniques to minimize losses at higher frequencies. These transformers are commonly found in switch-mode power supplies and communication systems, but require careful design considerations. - How do I choose the right PCB transformer for my project?

Selecting the correct PCB transformer involves specifying the input and output voltages, required power rating, isolation needs, safety certification requirements, core material and mounting style and considering ambient operating temperature. Ensure the chosen transformer matches or exceeds your application's requirements to guarantee efficient and reliable operation. Always refer to the transformer datasheet for accurate information. - What are the key factors that affect PCB transformer price?

Key factors influencing PCB transformer price include the core material, winding material, turns ratio, power rating, insulation class, safety certifications, and purchase quantity. Higher power ratings and stringent specifications will typically lead to increased prices. Material costs, like copper, can fluctuate based on market conditions which will also impact price.

PCB Transformer Price Comparison: Key Factors & Tips

Effective PCB transformer price comparison necessitates a thorough evaluation of multiple variables beyond just the initial cost. This includes a detailed understanding of transformer specifications, purchase volume, shipping options, and delivery timelines. Strategic sourcing from reliable distributors or manufacturers is crucial, alongside rigorous verification of datasheet specifications to ensure compatibility with your specific PCB application requirements.

It is also essential to recognize that PCB transformer pricing is not static; it is subject to market dynamics, most notably fluctuations in raw material costs, such as copper. Therefore, being attentive to price changes over time is key to optimizing procurement costs.

| Factor | Description | Impact on Price |

|---|---|---|

| Transformer Specifications | Power rating, voltage, current, turns ratio, isolation | Higher specifications typically increase price. |

| Core Material | Ferrite, laminated steel, amorphous metal | Advanced materials increase cost. |

| Winding Material | Copper, aluminum, litz wire | High conductivity materials increase cost. |

| Quantity | Order volume | Bulk orders usually lower the unit price. |

| Delivery Options | Shipping speed, carrier | Faster delivery methods cost more. |

| Lead Time | Time from order to delivery | Shorter lead times can increase costs. |

| Certifications | Safety and quality certifications | Certified transformers often have a higher price. |

| Manufacturer Reputation | Supplier credibility and expertise | Reputable manufacturers may command premium pricing. |

| Raw Material Costs | Copper and other key components | Price fluctuations impact overall transformer cost. |

When comparing prices, ensure you consider the total cost of ownership. This includes not just the unit price but also shipping costs, potential tooling charges, and the cost of any rework needed due to non-conformance.

Selecting the Right PCB Transformer for your Application

Selecting the correct PCB transformer is crucial for ensuring optimal performance and safety in your electronic application. This process involves a careful evaluation of several key electrical and mechanical parameters to match the transformer's specifications with the application's needs. An unsuitable transformer can lead to decreased efficiency, system malfunction, or potentially hazardous operating conditions.

Here is a structured approach to aid in making the right selection:

- Determine Input and Output Voltages:

Precisely define the required input voltage (e.g., 120VAC, 240VAC) and output voltage(s) (e.g., 5VDC, 12VDC). Consider voltage tolerances and variations in the application. - Calculate Power Rating:

Determine the required power output of the transformer (in Watts) based on the load it will drive. The power rating should account for expected peak demands and losses within the transformer itself. Choose a transformer with a power rating that meets or exceeds the load requirements, with a safety margin built in. - Assess Isolation Requirements:

Isolation between the primary and secondary windings is essential for safety. Choose an appropriate isolation voltage level for the intended application, in accordance with applicable safety standards (e.g., UL, IEC). Reinforced or double isolation may be necessary for certain applications. - Choose Core Material Type:

Select a suitable core material (e.g., ferrite, amorphous metal, laminated steel) based on the operating frequency and application. Ferrite cores are suitable for high-frequency switching power supplies, while laminated steel cores are more appropriate for line frequency applications. The core material affects performance, efficiency and size. - Certifications:

Ensure that the transformer has the required safety certifications and meets all standards applicable to your application (e.g., UL, IEC, VDE). These certifications ensure the transformer has been tested for safe operation under specified conditions. - Mounting Style:

Select the mounting style: through-hole (pin leads) or surface mount (SMT). Mounting style affects the PCB layout and assembly process and also impacts the physical form factor of the transformer. - Verify Datasheet Specifications:

Confirm that all transformer parameters (e.g., voltage, current, power, temperature rating, pinout) match the application needs by thoroughly inspecting the manufacturer's datasheet.

Future Trends in PCB Transformer Technology

The evolution of PCB transformer technology is characterized by a relentless pursuit of miniaturization, enhanced efficiency, and superior thermal management. These advancements are driven by the demand for smaller, more powerful electronic devices and a commitment to environmental sustainability.

- Miniaturization

The trend towards smaller form factors continues, pushing manufacturers to develop PCB transformers that occupy less space on circuit boards. This involves optimizing core designs, winding techniques, and insulation materials. - Increased Efficiency

Higher efficiency translates to reduced energy consumption and heat dissipation. Future trends focus on minimizing losses through core material improvements, winding optimization, and innovative switching techniques. - Enhanced Thermal Management

Effective thermal management is critical for maintaining the performance and reliability of PCB transformers, especially at higher power densities. Advancements include improved heat sink designs, novel thermal interface materials, and core materials with better thermal conductivity. - Advanced Core Materials

Ongoing research is exploring new core materials with higher permeability, lower losses, and improved thermal properties. These materials enable the design of more efficient and compact transformers. - Integrated Magnetics

Integrating magnetic components directly onto the PCB is a key trend, reducing overall component count, and improving performance. This approach involves advanced fabrication techniques and precise control of material properties. - Winding Technology Improvements

Improvements in winding techniques aim to reduce parasitic capacitance and resistance, leading to higher efficiencies and better frequency response. Innovations include advanced multi-layer winding approaches, and novel litz wire structures.

These future trends are not only impacting the performance and size of PCB transformers but also their long-term price and availability. The adoption of new materials and processes will likely influence the cost structure, while increased demand for more efficient and compact components will encourage further innovation.

Understanding the factors influencing PCB transformer price, from material choices to vendor selection, is vital for making informed purchasing decisions. The price ranges significantly based on specifications and quantity, but taking the time to match your application requirements will pay off by ensuring efficient and safe performance. Keeping an eye on industry trends will be helpful in long-term planning and future PCB transformer price predictions.

AnyPCBA

AnyPCBA