Unlock the Best Advanced Circuits Quote: A Comprehensive Guide

In the world of advanced circuits, precision and efficiency are paramount. Getting the right quote for your Printed Circuit Board (PCB) project is the first step toward success. This guide will demystify the process of obtaining a quote from Advanced Circuits, highlighting key factors influencing cost and offering practical tips to ensure you secure the best possible value. Whether you're prototyping or mass-producing, understanding these intricacies is crucial to bringing your advanced circuits designs to life.

Understanding the Factors Influencing Your Advanced Circuits Quote

The cost of an advanced circuit board is a multifaceted calculation, influenced by several key parameters. Understanding these factors is crucial for obtaining an accurate and competitive quote from Advanced Circuits. This section delves into the primary elements impacting your PCB project's cost, enabling you to make informed decisions and optimize your design for cost-effectiveness.

| Factor | Description | Impact on Cost |

|---|---|---|

| Board Size | The physical dimensions of the PCB. | Larger boards generally require more material and processing, thus increasing cost. |

| Number of Layers | The count of conductive layers within the PCB. | More layers increase complexity and material usage, leading to higher costs. |

| Material Type | The substrate material used, such as FR-4, Rogers, or Polyimide. | Advanced materials with superior electrical or thermal properties command higher prices. |

| PCB Quantity | The number of boards required in the order. | Higher quantities usually result in a lower per-unit cost due to economies of scale. |

| Lead Time | The timeframe within which the boards are required to be manufactured and delivered. | Faster turnaround times often incur premium charges. |

| Surface Finish | The type of plating used for component pads and vias (e.g., HASL, ENIG, immersion silver). | More complex finishes such as ENIG are more expensive than standard finishes. |

| Via Type | The type of vias used for electrical connection between layers (e.g., blind, buried). | Advanced vias such as blind and buried vias require more complex manufacturing processes increasing costs. |

| Trace Width and Spacing | The width and spacing of copper traces. | Very fine traces and spacing can increase manufacturing difficulty and price. |

| Drill Size | The size of drill used for vias and mounting holes. | Very small drill size can increase manufacturing difficulty and price. |

Step-by-Step Guide to Requesting a Quote from Advanced Circuits

Obtaining an accurate quote from Advanced Circuits is a critical first step in your PCB manufacturing process. This section provides a detailed, step-by-step guide to ensure you gather all necessary information and submit a complete request, minimizing delays and ensuring an accurate cost estimate. By following these steps, you'll be well-positioned to receive a prompt and precise quote for your project.

- Prepare Your Design Files

Before requesting a quote, ensure your PCB design files are complete and in the correct format. Advanced Circuits typically accepts Gerber files (RS-274X), but may also support ODB++ or other formats. Include all necessary layers, drill files, and a bill of materials (BOM), if required. Verify that all files are accurate and contain all the necessary design details. This will prevent delays in the quoting process. - Specify Your PCB Requirements

Clearly outline your PCB specifications. This includes dimensions (board size), the number of layers, material type (e.g., FR-4, Rogers), copper thickness, surface finish (e.g., HASL, ENIG), solder mask color, and silkscreen details. Providing precise specifications will greatly improve the accuracy of the quote and avoid additional questions. - Determine Quantity and Lead Time

The number of PCBs you require and your preferred lead time will have a significant impact on the cost. Consider your needs carefully. Higher volumes will generally result in lower per-unit costs, while expedited lead times may incur additional charges. Be realistic about your project timeline and order volume. - Access the Advanced Circuits Quote System

Navigate to the Advanced Circuits website and find their online quote request form. The exact location may vary, but it's usually found in the 'Get a Quote' section, or by searching 'online pcb quote' on their website. This may involve creating an account or logging into your existing one. Familiarize yourself with the online system before initiating the quote request. - Upload Your Design Files and Specifications

Follow the instructions to upload your prepared design files. Carefully input your specified PCB requirements into the quote request form. Ensure all the data matches your actual design requirements. Double check each entry before submission to ensure accuracy. - Review and Submit Your Request

Prior to submission, meticulously review the information you've provided. Ensure that all parameters have been entered correctly and all files have been uploaded. If using their online system, carefully review a summary of the quote before submitting. Once satisfied with the accuracy and completeness of your information, submit the request. - Await Your Quote

After submitting, you will generally receive a quote via email within a specified time frame. The turnaround for a quotation may vary depending on the complexity of your design and their current workload. If you have not received the quote within the expected timeframe, follow up with their customer service. Be aware that more complicated requests will take longer to process.

Comparing Advanced Circuits to Other PCB Manufacturers

Choosing the right PCB manufacturer is critical for project success. While Advanced Circuits is a well-established provider known for its high quality and quick turnarounds, understanding how it stacks up against other manufacturers, like JLCPCB, is essential for informed decision-making. This section provides a comparative analysis, highlighting the strengths and weaknesses of each.

| Feature | Advanced Circuits | JLCPCB |

|---|---|---|

| Quality | High, with rigorous testing standards | Good, generally meets industry standards |

| Turnaround Time | Fast, with options for expedited services | Can be slower, especially for complex orders |

| Cost | Generally higher, premium pricing | More affordable, budget-friendly options |

| Complexity Handling | Specializes in advanced PCBs, handles complex designs well | Good for standard PCBs, may have limitations with highly intricate designs |

| Customer Service | Responsive and personalized support | Largely online support, may lack personal touch |

| Minimum Order Quantity | Flexible, accommodates small and large runs | Generally higher minimum order quantities |

| Material Options | Wide range of specialized materials available | Standard material options, fewer specialized options |

While JLCPCB offers cost-effective solutions suitable for standard PCB designs, Advanced Circuits stands out in its ability to produce high-quality, complex PCBs with fast turnaround times and robust customer support. The choice between the two often depends on the specific project requirements, budget, and desired lead time. Projects requiring advanced materials, complex designs, and quick delivery might find Advanced Circuits's premium service worth the cost. Conversely, budget-sensitive projects with less stringent complexity requirements could greatly benefit from JLCPCB's more affordable options.

Optimizing Your PCB Design for Cost-Effectiveness

Optimizing PCB design for cost-effectiveness is crucial in managing the overall expenses of advanced circuits projects. Strategic design choices can significantly reduce manufacturing costs without sacrificing the desired performance characteristics. This section will explore several key considerations.

By carefully considering design parameters such as PCB size, layer count, material selection, and the use of techniques like panelization, designers can directly influence the cost of fabrication. Implementing these strategies requires a balanced understanding of design trade-offs and material properties, enabling the optimization of cost and performance effectively.

| Optimization Technique | Description | Impact on Cost |

|---|---|---|

| Panelization | Combining multiple PCB designs onto a single manufacturing panel, improving production efficiency. | Reduces per-unit cost by maximizing material usage and streamlining the manufacturing process. |

| Layer Reduction | Decreasing the number of conductive layers in a PCB. | Lowers material costs and reduces the complexity of fabrication. |

| Standardized Component Footprints | Using standard component packages and footprints. | Reduces design time and complexity, potentially leading to better pricing due to fewer custom requests. |

| Optimal Board Size | Designing the PCB board size to maximize manufacturing panel utilization. | Reduces material waste, leading to lower unit costs. |

| Material Choice | Selecting cost-effective materials without compromising functional requirements. | Material costs can significantly impact the overall price, and lower cost materials should be considered when suitable. |

Frequently Asked Questions about Advanced Circuits Quotes

This section addresses common queries regarding Advanced Circuits quotes, providing clarity on essential aspects such as data requirements, differences between PCB types, and company information to ensure you have a comprehensive understanding.

- What data is required to obtain an accurate PCB design quote from Advanced Circuits?

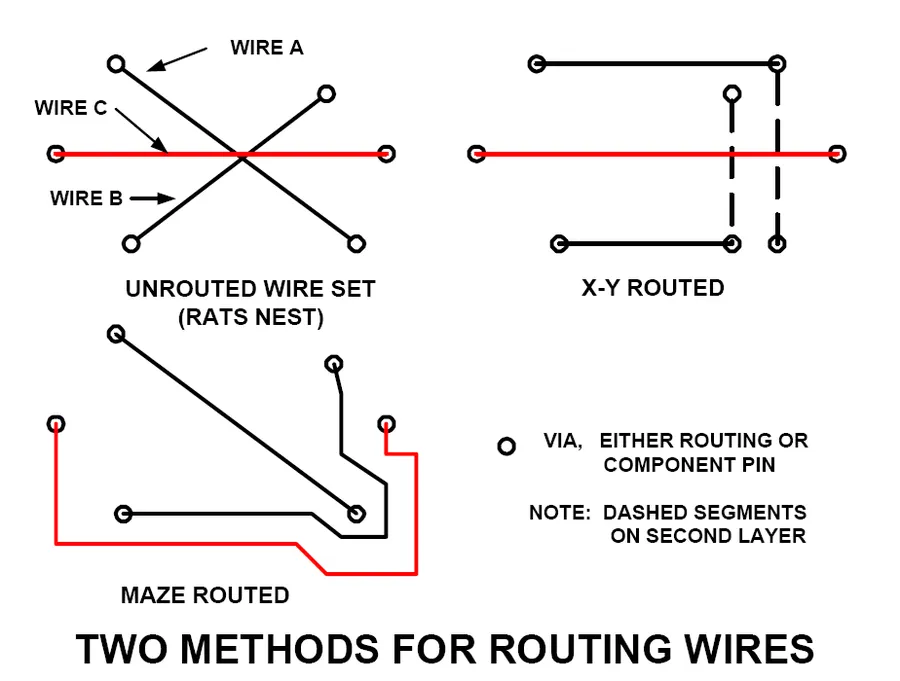

To get an accurate quote, you typically need to provide Gerber files (RS-274X format is preferred), a drill file, a bill of materials (BOM), PCB specifications (layer count, board thickness, material type), and any special instructions or requirements for your project. Ensure the files are complete, correctly formatted, and clearly labeled for a smooth quotation process. - What are the key differences between standard and advanced PCBs when considering a quote?

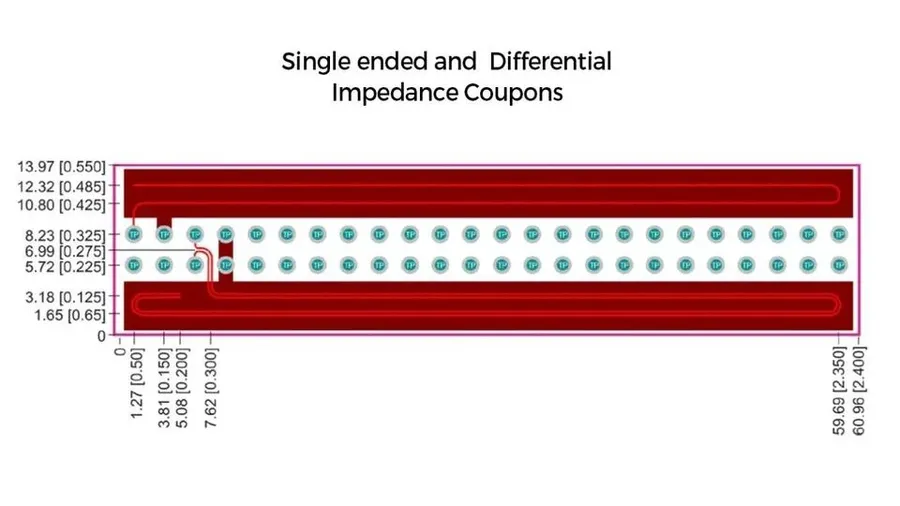

Standard PCBs often involve simpler designs with fewer layers, larger trace widths/spaces and less stringent material requirements compared to advanced PCBs. Advanced PCBs, on the other hand, might feature higher layer counts, tighter tolerances, micro vias, controlled impedance, and use of specialized materials for higher performance applications, these differences will greatly affect the cost and therefore the quote. - Who acquired Advanced Circuits?

Advanced Circuits was acquired by the parent company, APCT. This acquisition has expanded its manufacturing capabilities and resources while retaining the Advanced Circuits brand within the PCB industry. - Where is 4PCB located?

4PCB is a division of Advanced Circuits with locations in multiple states across the U.S., including Colorado and Arizona. These facilities are equipped to handle both prototype and production orders, offering rapid turn times for various PCB requirements. It's important to note that physical location may not be relevant if you are ordering online, but understanding their geographical presence is useful for logistical planning if you require in-person support or faster turn times. - How does the quantity of PCBs affect the quote from Advanced Circuits?

Generally, the per-unit cost of PCBs decreases as the quantity increases due to economies of scale. Initial setup costs, such as tooling and programming, are spread across more units, reducing the overall cost per PCB. Understanding your expected production needs is key for the most accurate cost estimate. - Can I get a quote for a partially assembled PCB?

Yes, Advanced Circuits offers PCB assembly services. You can request a quote for a partially or fully assembled PCB by providing your BOM, pick and place data, and any specific assembly requirements along with the PCB design files, when requesting a quote. This option could save costs for your project compared to obtaining components yourself.

Deciphering Special Offers and Discounts from Advanced Circuits

Advanced Circuits, like many PCB manufacturers, occasionally provides special offers and discounts to attract and retain customers. These promotions can significantly impact the overall cost of your project. Understanding how to identify, evaluate, and leverage these offers is crucial for optimizing your budget.

These offers typically vary, including discounts based on order volume, specific board configurations, or promotional periods. For example, the '$33 Each Special' is a frequently advertised discount.

- Types of Special Offers:

Common special offers include volume discounts (lower per-unit cost for larger orders), new customer promotions (incentives for first-time buyers), seasonal discounts (promotions offered during specific times of the year), and promotions for specific PCB specifications (reduced prices for certain board types). - $33 Each Special:

This specific promotion typically applies to certain board configurations and order quantities, offering a fixed price of $33 per board. Conditions like maximum layers and dimensions may apply; therefore, checking the offer's details is crucial. - How to Find Offers:

These are usually published on their website, newsletters, or through sales representatives. Checking the Advanced Circuits website and signing up for newsletters will help you stay informed of the latest deals. You may also need to contact the sales team directly for some offers.

| Offer Type | Description | Typical Conditions | How to Leverage |

|---|---|---|---|

| Volume Discount | Price reduction based on the quantity of PCBs ordered. | Minimum order quantity required. | Plan your project to reach the threshold for a better rate. |

| New Customer Promotion | Discounts or credits for first-time buyers. | May apply only to the first order. | Ensure to use the required promotional code for your first order. |

| Seasonal Discount | Promotions for specific times of the year. | Limited-time offer. | Time your project to coincide with special holiday and seasonal promotions. |

| $33 Each Special | A fixed price per board for specific configurations. | Specific PCB dimensions, layer count, and other technical specifications. | Design your board to comply with the required specifications. |

Carefully assess the terms and conditions of each offer, such as expiration dates, board requirements, and order quantities. Thoroughly understanding these details will help you accurately determine the final cost and maximize your savings when using these special offers.

Tips for Negotiating Your Advanced Circuits Quote

Negotiating an advanced circuits quote requires a strategic approach that balances cost reduction with the preservation of quality and performance. It's not merely about securing the lowest price, but about achieving the best value for your specific project requirements, necessitating a thorough understanding of the factors influencing the quote.

- Clearly Define Your Requirements

Precise specifications regarding PCB layer count, material, impedance control, and surface finish significantly impact the final price. Providing a detailed and unambiguous set of requirements from the outset minimizes ambiguity and allows for accurate initial quotes, avoiding later price increases due to unforeseen specification issues. The more detailed the information you give, the more accurate the quotes will be. - Explore Alternative Materials

While high-performance materials might be tempting, exploring cost-effective alternatives that still meet your project's requirements can significantly lower the cost. For instance, if a standard FR-4 material meets your needs in terms of thermal and mechanical properties, opting out of premium materials is a good move. - Panelization for Efficiency

If your project allows, strategically panelizing your boards can lead to significant cost reductions. Panelization involves assembling multiple PCBs onto a single manufacturing panel, which maximizes efficiency in the production process. Ask Advanced Circuits about the panelization options they offer. - Be Flexible with Lead Times

If project deadlines allow, being flexible with lead times can give you room for negotiation. Manufacturers often offer discounts for projects that are not time-sensitive, as it allows them to better optimize their production schedules. Understand the trade-off between speed and cost and factor this into your negotiation plan. - Quantities and Batching

The number of PCBs you order can have a significant impact on price. Ordering in larger batches tends to drive down per-unit costs due to economies of scale. When asking for a quote, see if you can order multiple batches to help reduce the overall cost. This approach allows manufacturers to reduce setup costs, which are often passed on to customers. - Demonstrate Long-Term Potential

If you have the ability, show that your projects have potential for repeat business, this is a powerful negotiation tool, as they know this is not a one off project. By presenting a clear plan for future orders, you can position yourself for more favorable pricing terms. Establish long term relationships if you are able. - Get Multiple Quotes and Compare

To make sure you are getting a fair price, seek multiple quotes from different suppliers to compare cost breakdowns from the different vendors. This also allows you to leverage your negotiating power. Ensure that you are comparing the same specs to ensure a truly fair comparison.

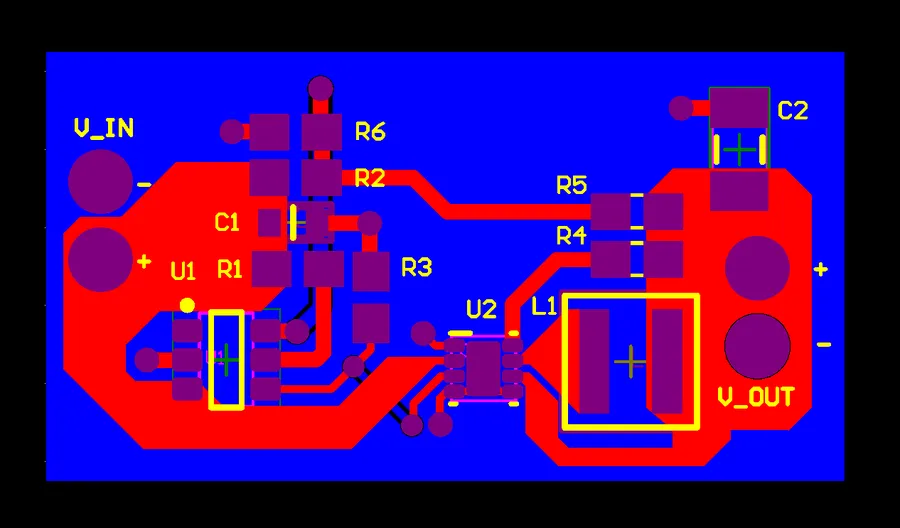

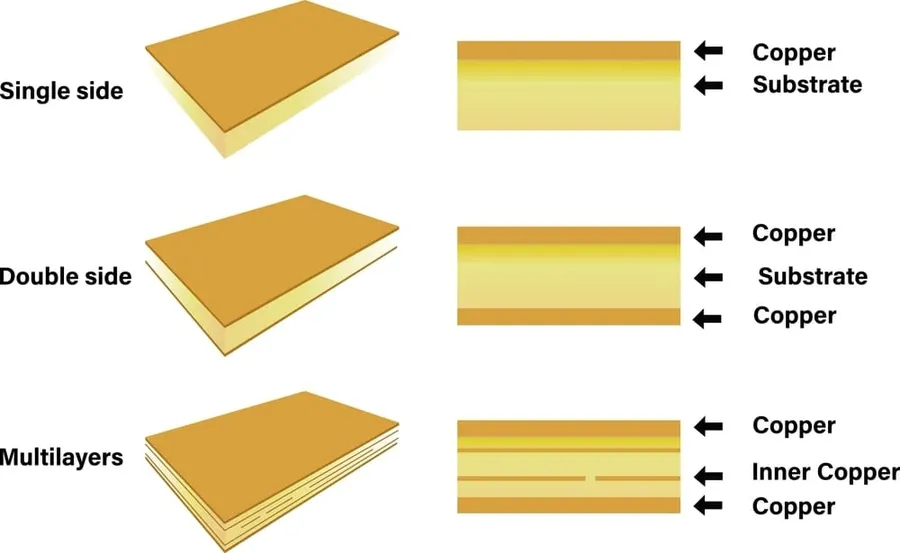

Understanding Different PCB Types and Their Impact on Quoting

The type of printed circuit board (PCB) significantly influences the quoting process and overall cost due to variations in materials, manufacturing processes, and design complexity. Understanding these differences is crucial for obtaining an accurate quote from manufacturers like Advanced Circuits and ensuring that project budgets are well-managed.

| PCB Type | Material | Complexity | Cost Impact | Typical Applications |

|---|---|---|---|---|

| Single-Sided PCB | FR-4 (common), CEM-1 | Low | Lowest | Simple electronics, basic LED circuits |

| Double-Sided PCB | FR-4 (common), CEM-1 | Medium | Low-Medium | Consumer electronics, basic industrial control |

| Multilayer PCB | FR-4 (common), High-Tg FR-4, Polyimide | High | Medium-High | Complex circuits, high-speed applications |

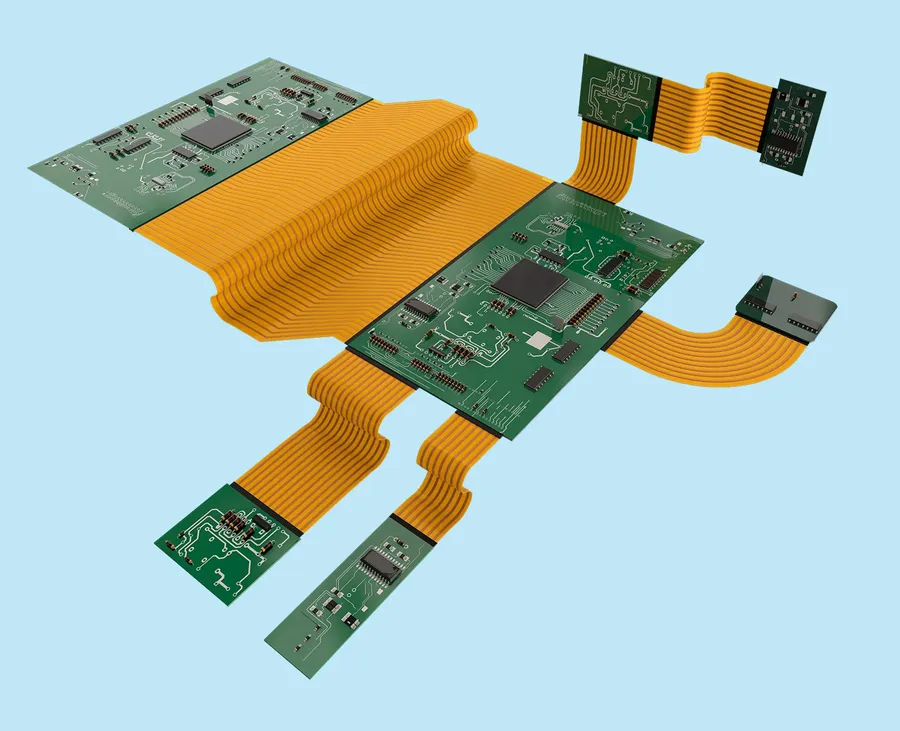

| Rigid-Flex PCB | Polyimide (flexible), FR-4 (rigid) | High | High | Space-constrained electronics, automotive |

| Flex PCB | Polyimide, Polyester | High | High | Wearable devices, medical equipment |

| Metal Core PCB | Aluminum, Copper | Medium-High | High | High-power applications, LED lighting |

Each PCB type is associated with distinct fabrication methods and material requirements. For instance, rigid-flex PCBs, which combine rigid and flexible substrates, incur higher costs due to their sophisticated construction. Similarly, flex PCBs often require more intricate manufacturing processes because of their thin and delicate material composition.

Understanding the specific requirements of your project and the corresponding PCB type is key to obtaining a precise quote. This allows you to accurately plan your budget and timeline while ensuring the product meets desired functional and performance standards.

Securing the best quote for your advanced circuits project requires a thorough understanding of the various influencing factors and a strategic approach to both design and communication with manufacturers like Advanced Circuits. By applying the knowledge and tips shared in this guide, you will be able to get the best value for your PCB needs, ensuring the success of your advanced circuits projects. Remember, the right quote is not just about price, but about the overall value and quality of the final product.

AnyPCBA

AnyPCBA