Unlocking PCB Fabrication: A Comprehensive Guide to Gerber Files

In today's world, where technology is rapidly advancing, the humble printed circuit board (PCB) serves as the backbone of countless electronic devices. The process of transforming a design into a physical PCB heavily relies on Gerber files, the lingua franca of PCB manufacturing. These files contain the blueprint needed for fabrication, ensuring that your intricate designs are accurately translated into physical form. This article will dissect Gerber files, exploring their structure, use in PCB production, and how they ensure the fidelity of your designs.

What Exactly are Gerber Files?

Gerber files are the cornerstone of printed circuit board (PCB) manufacturing. They function as an open ASCII vector format, detailing the precise geometric shapes and features of a PCB design. These files are not merely images; they contain crucial information for every layer of the PCB, ensuring that manufacturers can accurately translate the designer's intent into a physical product. They define the copper traces, pads, vias, solder mask, and silkscreen layers.

The Structure and Layers within a Gerber File

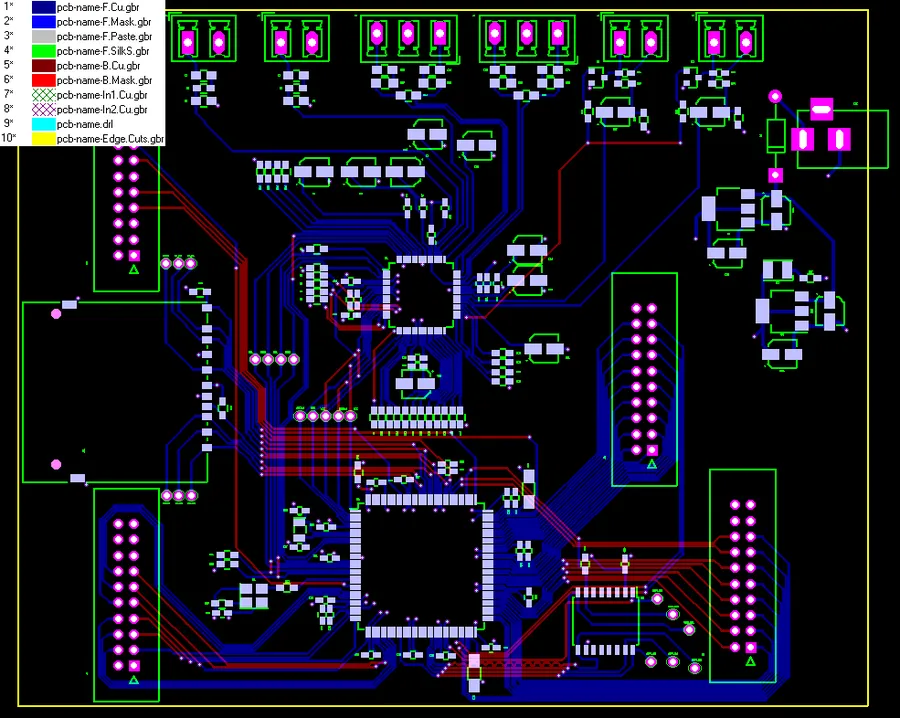

Gerber files, at their core, are meticulously structured to represent the various layers of a Printed Circuit Board (PCB). They utilize a vector-based format, where each layer is described by a series of coordinates and drawing instructions, ensuring accurate reproduction during PCB fabrication. This structure is critical for conveying the precise geometries of copper traces, solder mask openings, silkscreen markings, and other essential board features.

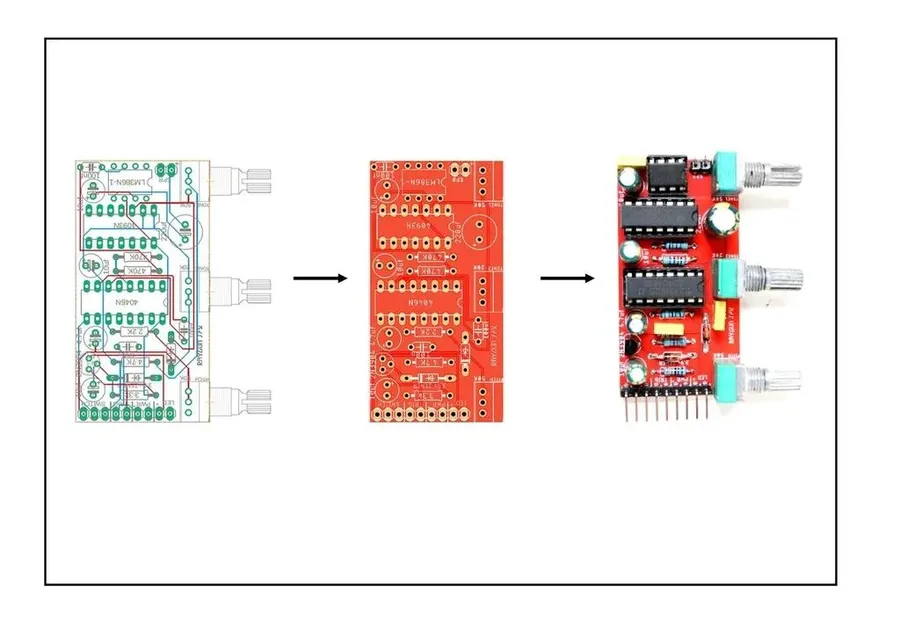

A typical PCB design is composed of multiple layers, each serving a distinct purpose. These layers are individually represented within a set of Gerber files. Understanding these layers is fundamental to interpreting and validating Gerber data.

| Layer Type | Description | Common Gerber Extension |

|---|---|---|

| Copper Layers | Represent conductive paths for electrical signals. PCBs often have multiple copper layers (Top, Bottom, Internal) to facilitate complex routing. | .GTL (Top Copper), .GBL (Bottom Copper), .G1, .G2 (Internal Layers) |

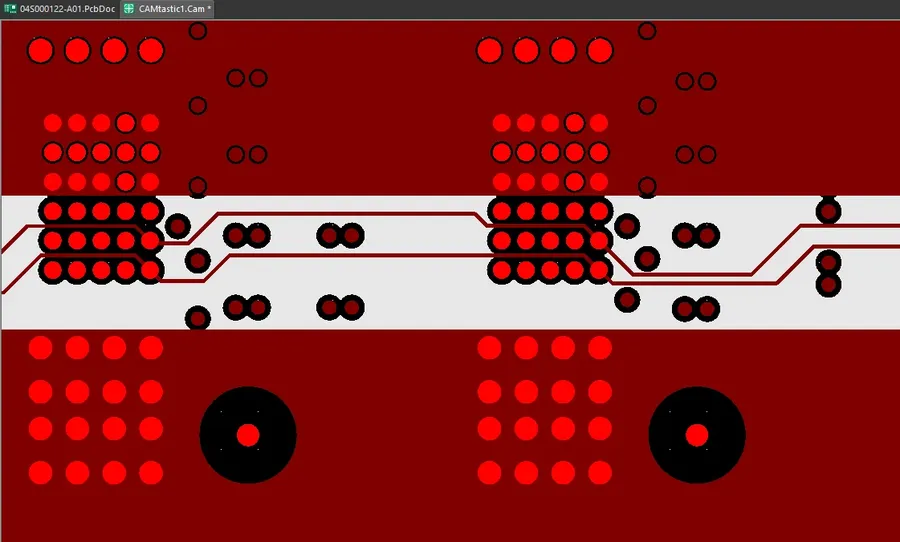

| Solder Mask Layers | Define areas where solder should *not* be applied during assembly, preventing shorts and ensuring reliable connections. Typically a negative image of the copper pads. | .GTS (Top Solder Mask), .GBS (Bottom Solder Mask) |

| Silkscreen Layers | Used for printing component designators, logos, and other informative markings on the PCB. Provides visual aids for assembly and maintenance. | .GTO (Top Silkscreen), .GBO (Bottom Silkscreen) |

| Drill Layer | Specifies the location and size of all holes in the PCB, both plated (vias, component through-holes) and non-plated. | .DRL or .TXT |

| Board Outline | Defines the physical boundaries of the PCB. Often used for panelization and board milling process. | .GKO (Keepout), .GM1 (Mechanical Layer 1) |

The implications of these layers are significant to PCB design. Each layer has its specific requirements and design rules. Incorrect Gerber data for any of these layers can lead to manufacturing errors, functionality issues, or even complete project failure. Therefore, generating and carefully verifying each layer in the Gerber file set is paramount to successful PCB production.

How Gerber Files Are Used in PCB Manufacturing

Gerber files are the cornerstone of printed circuit board (PCB) manufacturing, serving as the precise blueprint that guides the fabrication process. These files detail every aspect of the board's design, from the conductive traces to the placement of components, and are crucial for ensuring the accurate and efficient production of PCBs.

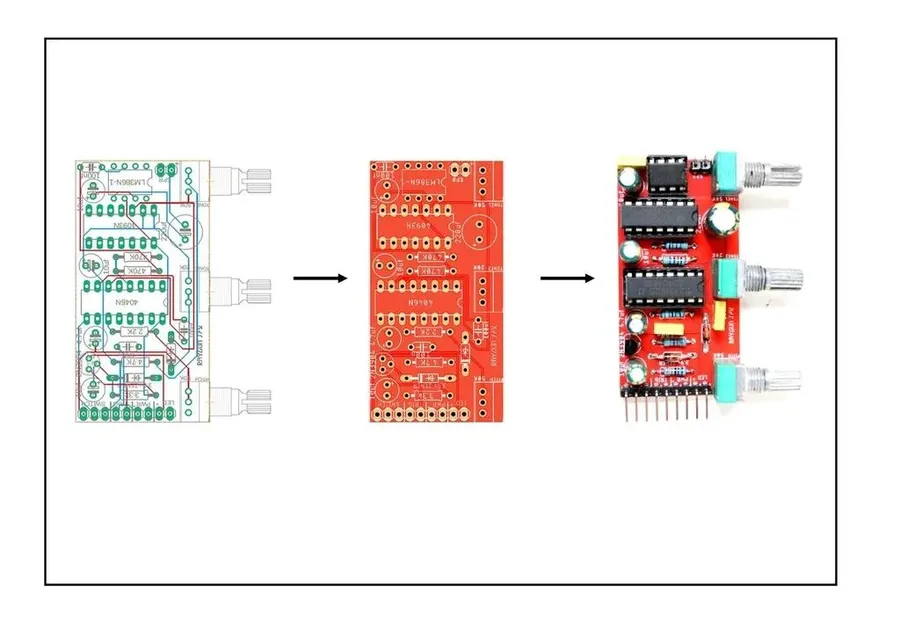

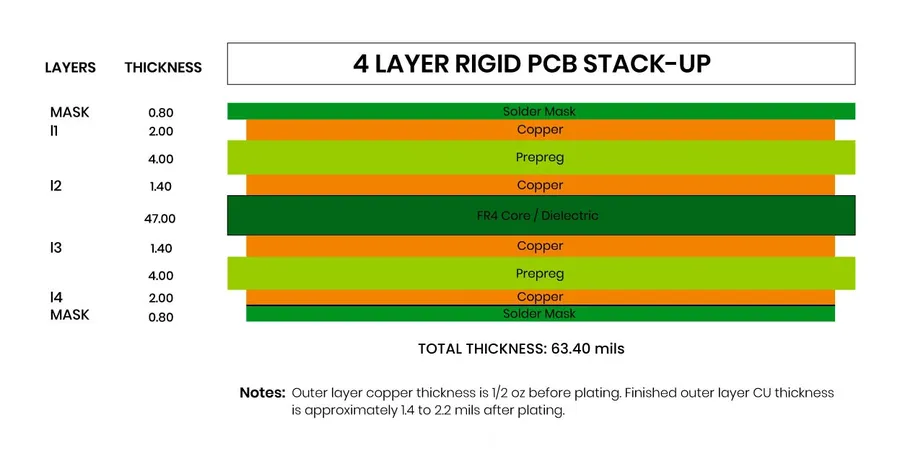

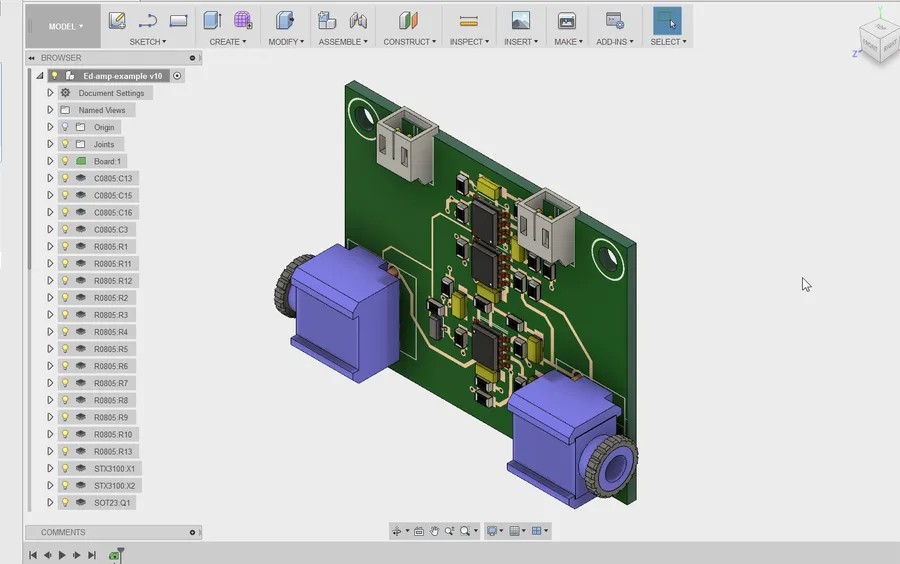

The PCB manufacturing process using Gerber files involves a series of critical steps, each requiring precise data interpretation. The process initiates with loading the Gerber data into Computer-Aided Manufacturing (CAM) software at the fabrication facility. This software meticulously interprets the Gerber files, extracting data pertaining to various layers, such as copper traces, solder mask, and silkscreen. Each layer is individually processed and then carefully aligned to form a complete PCB structure. The CAM system generates machine-readable instructions that guide the precision equipment used in PCB fabrication. This includes photoplotters for creating film masks of each layer, drilling machines to create vias and component holes, and etching and plating equipment to develop the conductive patterns on the substrate. Once these individual layers are etched or plated, they are laminated together to form the final structure.

| Manufacturing Step | Description | Gerber File Usage |

|---|---|---|

| Data Loading | Gerber files are imported into CAM software. | File parsing to extract layer data. |

| Panelization | Multiple PCBs are arranged on a single panel for efficient manufacturing. | Gerber data used to generate panel layout. |

| Film Plotting | Photoplots for each layer are created using the Gerber data. | Film is used to transfer patterns onto the PCB material. |

| Drilling | Holes for vias and component leads are drilled. | Drill file information is used to control drill depth and size. |

| Imaging | Copper traces, pads, and other patterns are imaged onto the PCB. | Gerber files guide the exposure process. |

| Etching | Unwanted copper is chemically removed. | Patterns defined in the Gerber data guide the etching process. |

| Solder Mask Application | Solder mask is applied, leaving pads exposed for soldering. | Solder mask layer in Gerber data is used to control solder mask coverage. |

| Silkscreen Printing | Component designators and other text are printed onto the PCB. | Silkscreen layer in Gerber data is used to control text placement. |

| Final Inspection | Completed PCBs are inspected for defects. | Gerber files serve as the reference for the final product. |

Generating Gerber Files: A Practical Guide

Generating Gerber files is a critical step in the PCB fabrication process, translating your design into a format that manufacturing equipment can understand. This section provides a practical guide on how to generate these files from popular PCB design software, along with essential validation tips to ensure a smooth manufacturing process.

The process generally involves selecting the appropriate output settings within your PCB design software, choosing which layers to export, and verifying the generated files with a Gerber viewer. While the specific steps may vary slightly between different software packages, the underlying principles remain consistent.

- Generating Gerber Files in Altium Designer

In Altium, navigate to 'File' > 'Fabrication Outputs' > 'Gerber Files'. Configure the layers, units, and format, then generate the files. Ensure all critical layers like copper, solder mask, and silkscreen are included. - Generating Gerber Files in Eagle

In Eagle, use the 'CAM Processor' to create a new CAM job. Add the necessary layers, select the output directory, and run the job to generate Gerber files. Verify the output settings match your manufacturer's requirements. - Generating Gerber Files in KiCad

In KiCad, from the PCB editor, go to 'File' > 'Plot'. Choose the layers to plot, select 'Gerber' as the plot format, and then plot the files. Always double-check the export settings.

Regardless of the software used, ensure that your chosen units (inches or millimeters), the format (RS-274-X is preferred), and layer mapping are configured correctly. Most PCB manufacturers have specific requirements for Gerber files, so refer to their guidelines before exporting.

Following the Gerber file generation process, validation is crucial. This step helps in identifying errors before they make it to the manufacturing stage, preventing costly errors. Here's what to consider:

- Layer Alignment

Use a Gerber viewer to check if all layers align correctly. Misalignment can lead to manufacturing defects. Ensure the drill layer is properly aligned with the copper layers. - Aperture List Verification

Ensure that the aperture list is complete, and that all defined shapes and sizes match the design. Inaccurate apertures can result in missing features on the final board. - File Completeness

Confirm that all necessary Gerber files have been generated, including copper layers (top and bottom), solder mask (top and bottom), silkscreen (top and bottom), and drill files. Missing layers will cause manufacturing to fail. - Design Rule Check (DRC)

Before generating the Gerber files, ensure that your design passes the Design Rule Check (DRC) of your PCB design software. A DRC violation could cause issues during manufacturing, even if the Gerber file looks correct.

Understanding the Common Gerber File Extensions

Gerber files, the cornerstone of PCB manufacturing, utilize a variety of file extensions, each denoting a specific layer or aspect of the printed circuit board design. Understanding these extensions is crucial for effective communication between designers and manufacturers.

| File Extension | Description | Common Usage |

|---|---|---|

| .GBR | General Gerber file extension. Often used when the file type is not explicitly defined by another extension. It contains graphical data. | General layer data, may include multiple layers if not specified |

| .GTL | Gerber Top Layer. Represents the top copper layer of the PCB. | Top copper traces, pads and vias |

| .GBL | Gerber Bottom Layer. Corresponds to the bottom copper layer of the PCB. | Bottom copper traces, pads and vias |

| .GTO | Gerber Top Overlay (or Silkscreen). Shows the markings on the top of the PCB. | Component designators, logos, and other silkscreen elements on top layer |

| .GBO | Gerber Bottom Overlay (or Silkscreen). Shows the markings on the bottom of the PCB. | Component designators, logos, and other silkscreen elements on bottom layer |

| .GTS | Gerber Top Solder Mask. Defines the areas where solder should not be applied on the top layer. | Solder mask for top side, protects from solder bridging |

| .GBS | Gerber Bottom Solder Mask. Defines the areas where solder should not be applied on the bottom layer. | Solder mask for bottom side, protects from solder bridging |

| .GKO | Gerber Keep Out Layer. Specifies areas where no components or traces should be placed. | Defines forbidden areas for components, traces, and other conductive parts |

| .DRL | Drill file. Contains the locations and sizes of all drilled holes on the PCB. | Drill hole locations for components, vias and mounting holes |

Gerber File Compatibility and Versioning

Ensuring Gerber file compatibility and understanding versioning are crucial for successful PCB fabrication. This section explores the different Gerber formats, the importance of compatibility between design software and manufacturing equipment, and the best practices for managing these aspects.

| Feature | RS-274-D | RS-274-X |

|---|---|---|

| Data Format | Basic vector data, requires separate aperture file | Extended Gerber, includes aperture information within the file |

| Aperture Definition | Stored in a separate aperture file (e.g., .APT) | Embedded within the Gerber file |

| Complexity | Simpler format, but requires additional files | More complex, self-contained format |

| Usage | Older format, less common in modern workflows | Modern format, widely adopted for its convenience |

| File Management | Requires managing multiple files, which can lead to errors | Simplifies file management and reduces chances of errors |

The RS-274-X format, also known as Extended Gerber, has largely replaced the older RS-274-D due to its self-contained nature. While RS-274-D requires separate aperture files, the RS-274-X format integrates this data, streamlining the fabrication process. It's important to note that while most modern PCB design software supports both formats, RS-274-X is the generally recommended format for its ease of use and reduced risk of errors.

When working with Gerber files, compatibility between design tools and manufacturing equipment is paramount. Differences in interpretation or software versions can lead to significant issues in the final product. It is vital to generate Gerber files that match the specifications of the PCB manufacturer's equipment and that the manufacturer has a process in place for dealing with version changes to avoid errors and delays. Regularly consult the manufacturer's guidelines to ensure that compatibility requirements are met.

To ensure a smooth manufacturing process, adopt best practices for Gerber file management. Use the latest version of your PCB design software and avoid outdated versions to minimize the risk of compatibility issues. Always perform a thorough validation using Gerber viewers or manufacturer-provided tools before submitting the design. Furthermore, maintain a well-organized file structure to easily track and manage different versions and revisions of Gerber files.

Troubleshooting Common Gerber File Issues

Successfully fabricating a printed circuit board (PCB) hinges on the integrity of the Gerber files. Common issues such as errors and missing data in these files can disrupt the manufacturing process. This section provides troubleshooting guidance to help ensure a smooth transition from design to production.

- Missing Layers

A frequent problem is the omission of necessary layers, like the solder mask or silkscreen. Validate that all required layers are exported during the Gerber file generation. Cross-reference your design with the generated Gerber files to confirm layer completeness. - Incorrect Units

Gerber files can be generated using either inches or millimeters. Inconsistency between the units specified in the Gerber files and the manufacturing equipment can lead to significant errors. Confirm that the unit settings are consistent across your design and manufacturing specifications, the most common unit is millimeter. - Aperture Issues

Incorrectly defined or missing aperture lists can lead to errors. Ensure that the aperture list is included and is correct to render the shapes as expected. Check for overlapping or incorrectly sized apertures. - Overlapping Copper Features

Copper features that overlap in the design can cause shorts on the manufactured PCB. Verify that all copper traces and pads have sufficient spacing to ensure that design rules are followed and do not violate the specified tolerance. - Drill File Inconsistencies

Drill files, often in Excellon format, need to match the corresponding Gerber layers for accurate drill hole placement. Double-check the drill file against the board layout to make sure all the holes are correctly located and that their sizes are correctly described. - File Format Compatibility

Different PCB manufacturers might have preferences or requirements for Gerber file formats (RS-274-D or RS-274-X). Ensure you are using the correct format that will be compatible with the manufacturer's equipment to avoid any misinterpretation of the data. RS-274-X is generally preferred, due to its self-contained nature. - Data Corruption

During the transfer process, data corruption can occur. This can affect the design which will be reflected in the manufactured PCB. Verify your Gerber files using multiple Gerber viewers to ensure the data has not been corrupted. In cases where data corruption occurs during transmission, it can be resolved by resending your files.

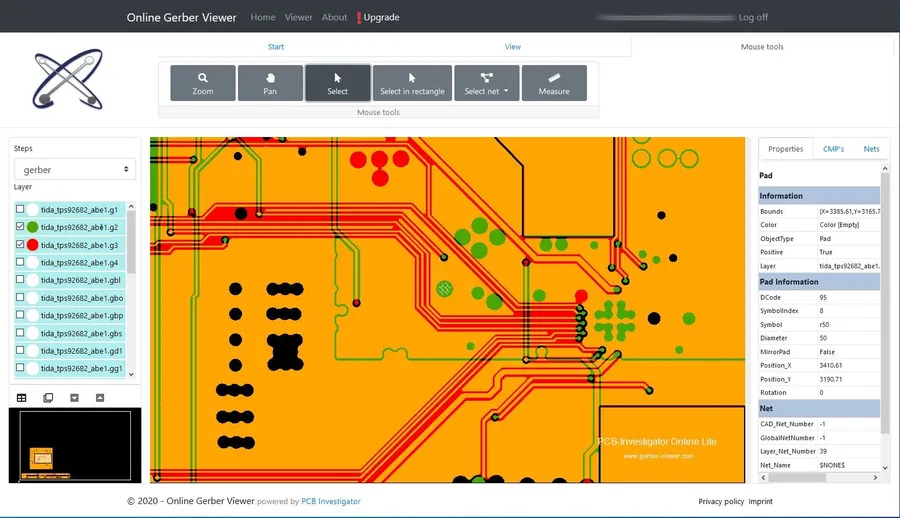

Online Gerber Viewers: Validating Your Design

Online Gerber viewers are indispensable tools for PCB designers, offering a convenient way to visually inspect Gerber files before submitting them for manufacturing. These viewers allow for quick validation of the design, ensuring that all layers are correctly aligned and that no critical design elements are missing or misplaced.

By using an online viewer, designers can identify potential issues early in the design process, which can save time and reduce the costs associated with design revisions and manufacturing errors.

These tools typically support standard Gerber formats (RS-274X being most common), allowing a designer to verify the accuracy of their board designs as they will appear to the manufacturer. This capability reduces misunderstandings and improves communication between designers and PCB manufacturers, ultimately leading to a smoother fabrication process.

- Key Features of Online Gerber Viewers

Typical features include layer selection, zoom and pan functionalities, measurement tools, and the ability to overlay multiple layers to check alignment. Some viewers may also offer advanced analysis tools such as netlist comparison, allowing a comprehensive review of the PCB design. - Benefits of Using an Online Gerber Viewer

The advantages include cost savings by preventing errors early, increased efficiency through quick visual checks, and improved communication with manufacturers through clear, visual design representation. - Workflow Integration

Online viewers can be easily integrated into a designer's workflow, enabling verification of the design data at different stages and before releasing the final Gerber files for PCB fabrication. The convenience of these viewers eliminates the need for specialized, proprietary software for basic verification purposes.

Frequently Asked Questions About Gerber Files

This section addresses common inquiries regarding Gerber files, providing clear and concise answers to assist with your PCB design and manufacturing process. These questions are derived from common user queries, ensuring they directly address practical concerns.

- What exactly is a Gerber file in the context of PCB fabrication?

A Gerber file is an open ASCII vector format standard used to convey printed circuit board (PCB) design specifications to manufacturing equipment. It contains crucial information about each layer of the PCB, such as copper traces, pads, vias, solder mask, and silkscreen, defining precisely where these features should be placed on the board. - How do I generate Gerber files for PCB manufacturing?

Gerber files are generated from your PCB design software (such as Altium, Eagle, KiCad, etc.) after your design is complete. The process involves selecting the appropriate output option in your software, choosing the necessary layers for output (copper layers, solder mask, silkscreen, drill files), and configuring the output settings to match your manufacturer’s requirements. This usually involves specifying units, format, and precision. - How can I order PCBs using Gerber files?

To order PCBs, you'll need to package the generated Gerber files along with the drill file(s) and a README file containing any manufacturing specifications into a compressed archive (e.g. a .zip file). Then, you will upload this archive to the PCB manufacturer's website. The manufacturer uses these files to understand the design and fabricate your boards. - What is a Gerber job file, and how is it different from other Gerber files?

A 'Gerber job file' is not a standard type but is sometimes mentioned by manufacturers. It usually refers to a single archive (.zip) or a collection of files containing all necessary Gerber files, along with the drill file and any additional instructions for manufacturing. It does not have a specific extension. This collection provides a comprehensive package for the PCB manufacturer. - Which software tools are best for viewing and validating Gerber files?

Several online and desktop applications are available for viewing and verifying Gerber files. These tools allow you to inspect individual layers and the overall PCB design, thus helping you catch errors or discrepancies prior to fabrication. Some popular options include online Gerber viewers, as well as software like GerbView, and the viewers that are often included with the design tools themselves. - What are the key considerations for ensuring Gerber file compatibility?

To ensure compatibility, pay attention to the Gerber format, either RS-274-D or RS-274-X. RS-274-X includes aperture information within the file, which simplifies the manufacturing process. Consult your manufacturer's specific requirements regarding Gerber format, file extensions, and any other specific guidelines. Consistent units and precision are also critical for avoiding manufacturing errors. - What are some common errors to watch out for when generating Gerber files?

Common issues include incorrect scaling, missing layers, misaligned layers, incorrectly specified units, or missing drill files. Thoroughly review your generated files using a Gerber viewer and compare them to your original design to catch these errors. Always consult your manufacturer's specifications to avoid delays or manufacturing issues due to file errors.

Gerber files are more than just digital data; they're the bridge connecting PCB design to physical reality. Mastering their intricacies allows designers to ensure precision, quality, and efficiency in PCB fabrication. As technology advances, Gerber files will remain an indispensable part of electronics, guiding the production of the technology we rely on every day. Understanding their nuances empowers you to confidently transform your innovative PCB designs into tangible products.

AnyPCBA

AnyPCBA