Your Guide to Cheap PCB Printing: Find Affordable Options

In today's rapidly advancing world of electronics, printed circuit boards (PCBs) are the backbone of nearly every electronic device. Whether you're an engineer, hobbyist, or student, getting PCBs printed affordably is a major concern. This article dives into the world of cheap PCB printing, exploring various options and helping you make informed decisions to balance cost and quality without compromising your project's integrity. Let’s explore how to get your circuit boards without breaking the bank.

Understanding Your PCB Needs and Budget

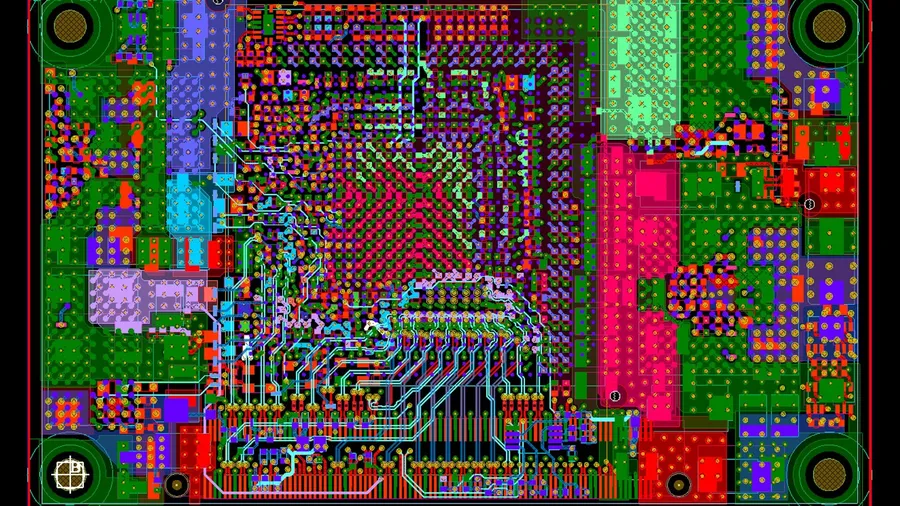

Prior to exploring various vendors for cheap PCB printing, a thorough understanding of your project's specific requirements is crucial. The cost of PCB fabrication is significantly influenced by factors such as board dimensions, the number of layers required, the chosen substrate material, and the quantity of boards needed. Establishing a well-defined budget is essential, as it allows for a more focused approach when evaluating potential PCB printing services, ensuring that you select options that align with your financial and project constraints.

| Factor | Impact on Cost | Considerations |

|---|---|---|

| Board Size | Larger boards increase material usage and production time, raising costs. | Optimize board size to fit within minimum dimensions where possible. |

| Layer Count | More layers require additional processing, resulting in higher cost. | Use the minimum number of layers necessary for the design’s complexity. |

| Material | Advanced materials, e.g., high-temperature laminates, cost more. | Choose standard FR-4 material if high performance is not required. |

| Quantity | Higher quantities usually lower the per-board cost. | Consider small batch production for multiple prototypes. |

| Finishes | Gold, immersion tin or HASL will impact cost. | Select standard finishes for prototyping and basic applications. |

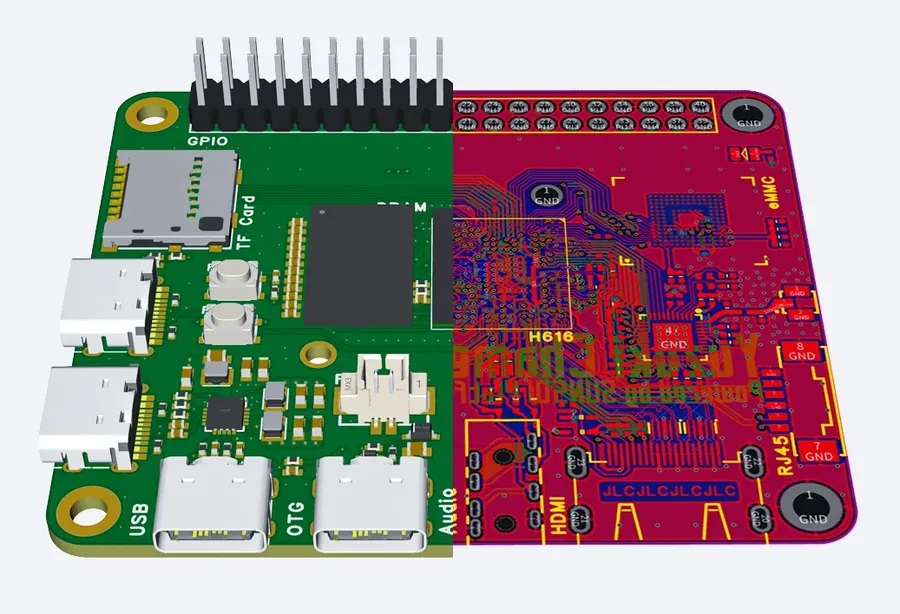

JLCPCB is a prominent online PCB manufacturer renowned for its highly affordable prototyping services, particularly advantageous for smaller board designs. Their specialization in quick-turnaround and low-cost PCB production makes them an ideal choice for rapid prototyping and preliminary project testing. JLCPCB leverages automated production lines and economies of scale to offer competitive pricing, particularly beneficial for hobbyists, students, and small businesses.

- Prototyping Focus

JLCPCB excels in providing cost-effective solutions for prototype PCBs, which makes them a suitable choice for preliminary testing and design iterations. - Small Board Advantage

They offer particularly competitive pricing for smaller boards, catering to designs where the PCB dimensions are compact. - Quick Turnaround Times

The manufacturing process is optimized for speed, allowing for faster turnaround times, which is critical for project timelines. While quick turnarounds are a strength, it's important to consider potential shipping times, which can vary depending on the destination. - Automated Manufacturing

JLCPCB employs highly automated manufacturing processes. This automation not only reduces the cost but also maintains a consistent quality for standard designs. - Price Transparency

They offer a relatively transparent pricing structure, which makes it easier to predict the cost without hidden fees.

While the allure of the lowest price is strong, it's crucial to understand that the cheapest PCB printing option may not always align with your project's quality requirements. Striking the right balance between cost and quality is essential for a successful outcome. Sacrificing quality for the sake of a lower price can lead to unreliable boards, performance issues, and potentially costly rework or redesigns. Therefore a thorough understanding of your project's performance and reliability requirements should take priority over cost.

To evaluate the price versus quality tradeoff effectively, consider the following:

- Project Specifications:

Analyze the critical aspects of your design, such as layer count, minimum trace width and spacing, via requirements, material specifications, and impedance control. These specifications can inform your selection process. - Application Requirements:

Determine the performance expectations of your PCB. Is it for a low-power prototype or high-speed digital circuitry? For projects requiring high precision, more expensive manufacturers will provide better controlled impedance, material quality and manufacturing tolerances. - Review User Feedback:

Seek out reviews from other users to gauge real-world experiences with specific manufacturers. User forums, online reviews, and social media can provide insights into the reliability and quality of PCB manufacturers and the potential issues users have encountered. - Compare Data Sheets and Manufacturing Standards:

Review the datasheets provided by the manufacturers and compare them to industry standards (e.g. IPC). Reputable manufacturers will publish their material specifications, tolerances, testing and quality control standards and will be willing to provide answers to relevant questions. - Request Test Boards (If Needed):

Consider ordering a small batch of test boards from different manufacturers before committing to a large order. Test boards can be used to assess quality and verify manufacturing specifications.

The cost of cheap PCB printing is highly variable, primarily influenced by factors such as board size, complexity (number of layers), and quantity. However, a general cost range can be established to provide a benchmark for different project needs, with the lowest prices typically being for simple prototype boards.

- Prototype Boards

Many manufacturers offer small, basic prototype boards for under $5 USD. These are generally single or double-layer boards, with limited size and minimal complexity. - Standard Boards

For slightly larger, or more complex boards the costs will range from $10-$50 for small batch runs. This pricing variation reflects the increase in materials, fabrication, and handling of more complex PCB designs. - Factors Affecting Pricing

The final cost of the boards will depend on many factors. These will include but are not limited to: the number of board layers, the board area, the number of through hole components, and the desired copper weight. Special PCB finishes, unique board thicknesses and unusual material selection will also add costs to the final order price.

Exploring Online PCB Manufacturers Offering Cheap Printing

The proliferation of online PCB manufacturers has significantly lowered the barrier to entry for electronics prototyping and production. Several companies now offer competitive pricing, making it easier and more affordable than ever to bring your circuit designs to life. This section highlights key players in the cheap PCB printing space.

JLCPCB

JLCPCB stands out for its remarkably affordable prototyping services, particularly for smaller circuit boards. They are a popular choice for individuals and small businesses seeking rapid and budget-friendly PCB prototypes. Their strength lies in low-cost, high-turnaround manufacturing, making them ideal for initial design iterations.

PCBWay

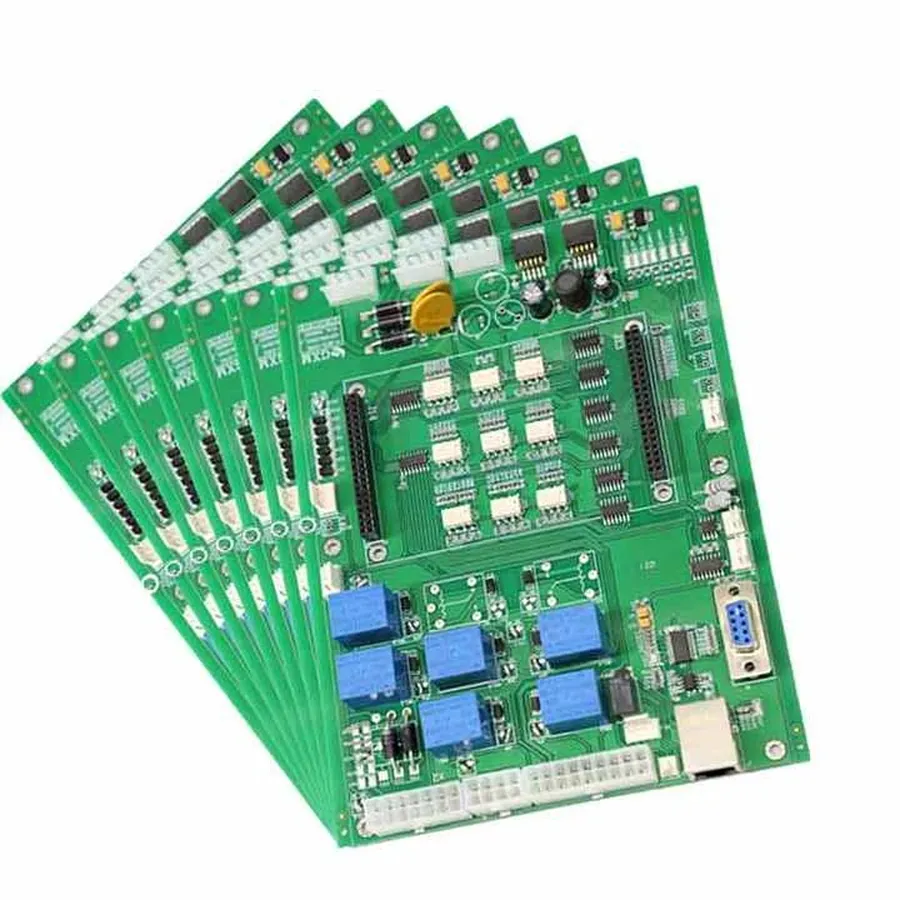

PCBWay is another well-regarded online PCB manufacturer known for offering a diverse range of services. From basic PCBs to more complex multilayer designs, PCBWay provides a good balance between cost, quality, and customer support. This makes them a suitable option for a wide variety of projects and user requirements, including those requiring a more comprehensive set of features.

AllPCB

AllPCB positions itself as one of the cheapest PCB manufacturers, especially for basic designs. While their pricing can be attractive for simple PCB printing, it is important to thoroughly verify the quality of their boards. AllPCB may be suitable for less demanding projects or where cost is the primary concern. However, users are advised to exercise due diligence in quality checks, particularly for intricate designs.

PCBWay stands out as a popular online PCB manufacturer, offering a comprehensive suite of services that cater to both basic and advanced PCB designs. They are recognized for striking a balance between cost-effectiveness, quality, and customer service, making them a strong contender for various PCB printing needs.

PCBWay's services extend beyond simple prototyping, encompassing capabilities for more complex multilayer boards, various materials, and finishes. This versatility is a key advantage, positioning them as a potentially suitable partner for a diverse range of projects. Their online platform facilitates the ordering process, and they offer various shipping options and customer support channels.

- Services Offered

They provide a wide array of services, including basic single-layer PCBs, multilayer PCBs, flexible PCBs, and metal core PCBs. - Quality and Reliability

While focusing on cost-effectiveness, PCBWay maintains a reasonable level of quality control, utilizing automated manufacturing processes to ensure consistent output. - Customer Support

PCBWay offers multiple channels for customer support, including online chat, email, and support forums. This can be an important consideration for those requiring assistance through the manufacturing process. - Cost Considerations

While not always the absolute cheapest, PCBWay provides very competitive pricing, especially when considering the wide variety of their services. Users can benefit from transparent pricing and different shipping options.

Turnaround time is a critical factor when selecting a PCB manufacturer. While some vendors offer expedited services, these typically come at a higher cost. It's essential to plan your lead time meticulously, accounting for not just the manufacturing process itself but also shipping durations and potential customs delays.

| Factor | Description | Impact on Turnaround Time |

|---|---|---|

| Manufacturing Time | The time required to fabricate the PCB boards themselves. | Varies based on board complexity, layer count and vendor workload. Can range from a few days to several weeks. |

| Shipping Time | The time it takes to transport the finished PCBs to your location. | Dependent on shipping method and destination. Can range from a few days to several weeks, including customs clearance |

| Vendor Location | The location of the manufacturer, affecting both manufacturing and shipping time. | Domestic manufacturers typically have faster shipping than international ones. Overseas manufacturing requires additional time for customs and international transport |

| Expedited Services | Options for quicker manufacturing and shipping, usually available at a premium. | Can significantly reduce turnaround time, but this comes at an additional cost. |

| Order Size | The quantity of PCBs ordered | Large order quantities may require additional manufacturing time. |

| Board Complexity | The number of layers, board dimensions, design rules, and special feature requirements | Boards with higher layers and design complexity will increase manufacturing time. |

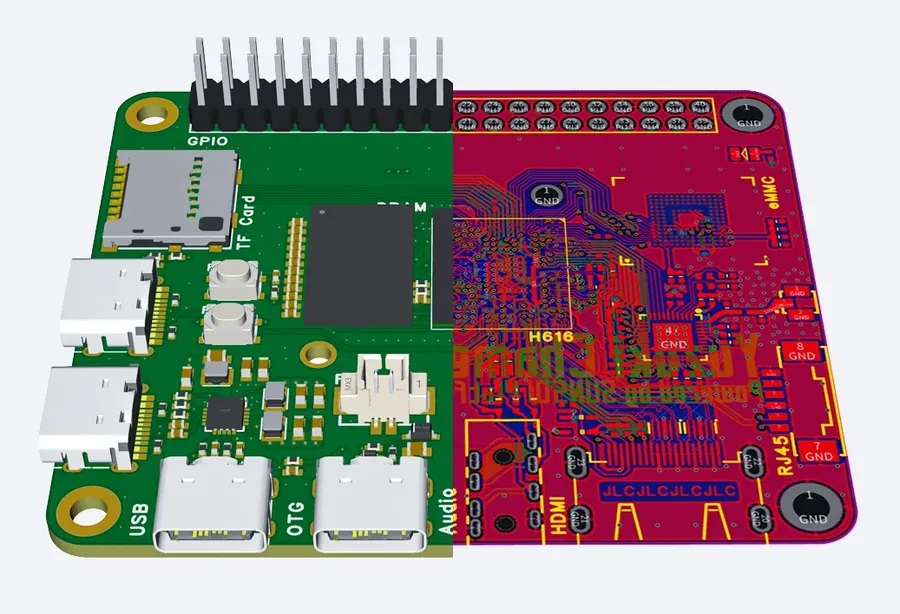

The reliability of cheap PCBs is a common concern, but many manufacturers utilize streamlined production processes and automated assembly lines to maintain consistent quality even at lower price points. While costs are reduced, it’s essential to understand the trade-offs and how to ensure you receive reliable boards.

- Automated Manufacturing

Automated production lines minimize human error, ensuring greater consistency in manufacturing, thus improving reliability. - Standard Materials

Most budget manufacturers use standard FR-4 material, which offers acceptable performance for a majority of applications and is well understood in terms of reliability characteristics. - Quality Control Checks

Reputable manufacturers will perform basic quality control checks such as continuity testing to ensure your board is functional as designed. Check with the supplier if more comprehensive testing is required. - User Feedback Is Key

A key factor when assessing PCB reliability is to review the experience of other users. Check online forums and reviews to get an impression of the reliability of a given supplier.

AllPCB positions itself as a budget-friendly option in the PCB manufacturing market, frequently cited as potentially the cheapest, particularly for basic designs. While their pricing can be attractive for straightforward PCB printing, it's essential to approach AllPCB with an understanding of their strengths and limitations, especially regarding quality control for more complex designs.

Here's a breakdown of what you should know about AllPCB:

- Strengths:

Competitive pricing for simple PCB designs makes it attractive for basic projects where cost is a primary concern. - Weaknesses:

Quality control for complex designs may not be as rigorous as some other manufacturers, and thus, requires careful consideration and potentially increased scrutiny on the part of the customer. - Suitable for:

Ideal for basic, single or double sided PCBs where high precision and quality assurance is not critical for the project's success. - Not recommended for:

Complex multilayer PCBs or designs with very fine pitch components where the risk of defects may be greater given its production quality.

Before committing to AllPCB, it's prudent to review independent user feedback and thoroughly assess your project requirements to determine if it aligns with their capabilities.

Comparing Cheap PCB Manufacturers: Key Factors

Selecting a PCB manufacturer for low-cost printing requires a careful evaluation of several key factors beyond just the initial price quote. This section details critical considerations to help you choose a vendor that balances cost-effectiveness with the specific needs of your project.

- Price vs. Quality

While a low price is attractive, it should not compromise the quality required for your specific application. Thoroughly examine user reviews and sample boards when available to confirm quality meets your requirements. A very cheap manufacturer may not be best if your project needs high reliability. It may be better to use a manufacturer with a reputation for quality even if they cost a little more. - Turnaround Time

The time taken from placing an order to receiving the finished PCBs can vary significantly. Factor in manufacturing, shipping, and potential customs delays. While faster turnaround options exist, these usually come at a premium cost. Plan your projects carefully and consider lead times to avoid delays. - Shipping Costs

The cost of shipping can substantially increase the overall expense of an order, especially for smaller quantities. Compare shipping options to find vendors with reasonable rates or suppliers who offer free or discounted shipping if order sizes are appropriate. Factor this into your final decision. - Manufacturing Capabilities

Ensure that the manufacturer has the technical capabilities to manufacture your specific design, including layer counts, board thickness, material type and other factors. Some vendors are more suited to simple, low-layer count designs, while others can handle more complex projects. Make sure the vendor meets your specific design requirements. - Customer Support

Good customer support is vital for addressing issues and resolving questions. Look for manufacturers who offer responsive support channels, including email and/or online chat. Check user reviews for insights on how the manufacturer handles technical issues and order problems. - Minimum Order Quantity

Many PCB manufacturers have minimum order quantities, which can be an important factor if you need small quantities or prototypes. A high minimum order quantity might make a vendor unsuitable for small projects. Check these before starting your order.

Price vs. Quality

The trade-off between price and quality is crucial when selecting a cheap PCB manufacturer. Opting for the absolute lowest price might result in boards that are unreliable or do not meet your specifications. It is vital to review user feedback and, if possible, request samples to gauge the real-world quality before committing to a large order. Balancing your budget with the required quality ensures the project's success and minimizes potential issues down the line.

Turnaround Time

Turnaround time refers to the period from order placement to the moment you receive your PCBs. While some manufacturers advertise rapid services, it's important to understand that faster turnaround times can increase production costs. Planning your project timelines carefully, accounting for both manufacturing and potential shipping delays (including any customs processing), will lead to a smoother workflow and help you stay within your schedule.

Shipping Costs

Shipping costs can represent a significant part of the overall expenses, particularly for small orders. It is essential to compare shipping prices across vendors, considering both the shipping method and delivery time. Some manufacturers offer free shipping when order values reach a certain threshold or are located within specific regions. Taking shipping costs into account helps to more accurately assess the total price, ensuring you don’t exceed your budget.

The cost of shipping printed circuit boards can often be a surprisingly large part of the total expense, particularly for smaller, prototype-level orders. Therefore, a careful evaluation of shipping options is essential when sourcing cheap PCB printing services. Understanding these costs and how to mitigate them can lead to substantial savings.

- Shipping Cost Factors

Shipping costs are influenced by several factors, such as the weight and dimensions of the package, the distance to the destination, and the chosen shipping speed. Express options will increase costs substantially. Bulk orders may qualify for discounted shipping rates. Some suppliers also offer bundled shipping to further reduce costs, especially if combined with other orders or services. - Shipping Speed and Cost

Faster shipping options come at a higher price. Consider whether the speed of delivery is critical for your project, or whether slower, more economical shipping is acceptable. Also consider potential customs clearance delays and costs, particularly for international shipments. Plan for this additional time and potential fees. - Comparing Shipping Options

When evaluating different manufacturers, always compare the available shipping options and their associated costs. Some manufacturers may offer discounted or even free shipping when an order reaches a specific threshold. This is frequently a combination of cost and volume. Ensure that you fully understand all the shipping terms. - Free Shipping

Some PCB manufacturers offer free shipping, but this often comes with minimum order quantities or specific conditions, so be sure to review the details carefully. Consider these options to help bring down costs, however, be mindful that free shipping may be slower. Consider also the overall cost; if free shipping results in the boards being substantially more expensive, this may not be the ideal choice. - Packaging

Some suppliers offer basic packaging while others will package individual PCBs which can increase shipping costs. Consider whether you need additional packaging to protect your PCB or whether standard packaging will suffice. If the manufacturer provides no packaging or limited packaging options, you may need to source packaging elsewhere, which will add further cost.

When sourcing cheap PCBs, being aware of potential hidden fees is crucial to avoid unexpected costs. While the base price might seem low, additional charges for testing, tooling, expedited shipping, and specific material requirements can significantly increase the total expenses.

- Testing Fees

Some manufacturers may charge extra for electrical testing or other quality control measures. While essential, these costs can add up, especially for complex designs. Always clarify what level of testing is included in the base price. - Tooling Costs

Tooling fees, sometimes referred to as setup fees, can be applied to your order. These fees are associated with the initial processes to prepare a PCB for manufacturing. Ask for a detailed breakdown to understand all associated costs. - Expedited Shipping

While vendors may offer standard shipping as the default, faster delivery options can incur substantial fees. Carefully consider whether you need expedited shipping, and compare costs from different carriers. - Material Specific Requirements

Requests for specific materials ( e.g. higher grade FR-4, specific metal cladding, controlled impedance laminates ) can significantly increase the overall cost. Standard materials are often much cheaper, so choose them unless a higher specification is absolutely necessary. - Panelization Charges

If your design requires multiple boards to be panelized (grouped together on one larger board for manufacturing), there might be additional panelization charges. In some instances, you may be able to provide your own panelised gerber data. - Minimum Order Quantities

Some vendors have a minimum order quantity. If your needs are less than this quantity, the vendor might still charge you the price associated with that minimum. This means your per-board cost will be higher, and you may end up with surplus boards.

Frequently Asked Questions about Cheap PCB Printing

This section addresses common questions regarding affordable PCB manufacturing, providing clarity and practical insights for users seeking cost-effective solutions. Understanding these frequently asked questions can help you navigate the landscape of cheap PCB printing more effectively.

- What is the typical cost for cheap PCB printing?

The cost of cheap PCB printing varies based on factors such as board size, complexity, layer count, and quantity. For small, simple prototype boards, some manufacturers offer services for under $5. However, more complex designs, higher layer counts, and larger quantities will increase the price. It is crucial to obtain quotes based on your specific needs. - Can cheap PCBs still be reliable?

Yes, many low-cost PCB manufacturers achieve reliability through streamlined, automated production processes and quality control measures. While the price may be lower, this does not necessarily mean a compromise in essential functionality. It's advisable to review user feedback and consider purchasing a small batch to verify the quality before larger production runs. The reliability of a PCB is fundamentally linked to adherence to design rules and manufacturing tolerances, which are independent of the cost. - Are there any hidden fees to watch out for in cheap PCB printing?

Yes, be cautious of hidden fees such as those related to testing, tooling, and expedited shipping. Some manufacturers have charges for electrical testing, creating custom tooling or for faster turnaround times. Look for vendors that offer transparent pricing structures and review the fine print carefully before committing to a service, clarifying all potential costs before finalizing an order. - How does board size and complexity impact the cost of cheap PCB printing?

Board size and complexity are primary drivers of PCB printing cost. Larger boards require more material and processing, increasing costs. More complex designs involving multiple layers, fine traces, and vias will also raise the price due to increased manufacturing difficulty and material usage. Simpler, smaller boards are significantly cheaper to manufacture, therefore it's important to optimize your design to minimize both board size and complexity for lower cost. - What are the benefits of ordering PCBs in larger quantities for reducing the cost?

Ordering PCBs in larger quantities often leads to a significant reduction in per-board cost, due to economies of scale. Manufacturers amortize their setup and tooling costs across a larger batch, and bulk material purchasing reduces material cost per board. Therefore, if your budget permits, ordering in larger quantities of PCBs can substantially lower the price per board, even if it means having some excess boards in your stock. - What turnaround time can I expect for cheap PCB printing?

Turnaround time for cheap PCB printing can vary based on the manufacturer and complexity of the PCB. Standard turnaround times can range from a few days to a couple of weeks. Some manufacturers offer faster, expedited options that come with a premium cost. Consider your project timeline when selecting a vendor, factoring in manufacturing time, shipping, and potential customs delays. Planning ahead and anticipating delays in lead time is crucial for project success. - What are some tips for reducing PCB printing costs?

To reduce PCB printing costs, aim to minimize board size and complexity, use standard components that are readily available, optimize your PCB layout for manufacturability, and order in slightly larger quantities when possible to take advantage of economies of scale. Avoid complex geometries and non-standard processes in your PCB design, these increase the complexity of manufacturing and add cost. These strategies contribute to lowering per-unit cost and improving manufacturing efficiency.

Tips for Reducing PCB Printing Costs

Optimizing your PCB design and ordering strategy can significantly lower manufacturing expenses. By implementing strategic choices in design, component selection, and order volume, you can achieve considerable savings in your PCB printing costs, without compromising the functionality of the final product.

- Minimize Board Size

Smaller PCBs require less material and processing time, directly translating to lower production costs. Ensure your design is as compact as possible, focusing on efficient use of board space. Avoid excessively large or irregular board shapes. - Use Standard Components

Opt for commonly available components instead of specialty or hard-to-find parts. Standard components are generally less expensive and readily accessible, and will likely result in cost savings. - Optimize Your Layout

A well-optimized layout reduces the complexity of the manufacturing process, which in turn reduces costs. Keep trace lengths short, avoid unnecessary vias, and ensure proper spacing between components. This can help prevent errors and delays in production. - Panelization

When ordering multiple small boards, consider panelizing them before placing your order. This means combining multiple copies of the same board into a single larger panel which can improve the efficiency of the production process. This can result in lower per-board costs. Check with the PCB vendor to ensure this is done correctly and avoid additional handling charges. - Order in Optimized Quantities

While very small quantity orders can be costly, ordering in slightly larger batches can significantly reduce the per-board cost due to manufacturing economies of scale. Determine the minimum order that gives the best unit price. - Avoid Complex Designs

Simpler PCB designs are cheaper to manufacture. Avoid unnecessary layers, complicated routing and exotic materials. If your design is complex, consider if it could be broken down into smaller, less expensive boards. - Double Check Your Design Files

Thoroughly check all design files before submitting them for fabrication. Reworking designs and remanufacturing PCBs can be very costly. Double check footprints, layer stackup, and gerber files to help avoid costly errors.

Alternatives to Traditional PCB Printing for Prototyping

While PCB printing is the standard for producing final circuit boards, several alternatives exist for prototyping, especially in the initial stages of design. These methods allow for quick testing and iteration without the commitment and cost of a professionally printed PCB. They are particularly useful for simpler circuits or for verifying the functionality of a design before investing in a more permanent solution.

- Perfboards and Stripboards

These are boards with a grid of holes (perfboard) or strips of copper (stripboard) where components can be soldered. They offer a flexible, solderable platform for building circuits by hand. Components are connected with solder bridges and wires, making them ideal for testing circuit ideas quickly, they are cheap and readily available but are not suitable for high density or high-frequency circuits. - Breadboards

Breadboards are solderless prototyping tools that allow for easy connection of components using jumper wires. Components can be inserted into the board and interconnections can be made using wires. This makes breadboards ideal for prototyping and experimentation when you need to make frequent changes or try out different circuit configurations. Breadboards are not suitable for production because they are not designed to be permanent. - Chemical Etching

Chemical etching of copper-clad boards is a method where the desired copper traces are exposed and etched away using chemicals and a resist. This method allows for the creation of custom PCB layouts on single or double sided boards without the cost of a PCB service. This option is suitable for hobbyists with some experience in chemical handling who desire a more custom solution than perfboard.

Future Trends in Affordable PCB Printing

The landscape of affordable PCB printing is constantly evolving, driven by advancements in manufacturing technologies and material science. These innovations promise to further reduce costs, improve quality, and expand the possibilities for both hobbyists and professionals.

- Enhanced Automation in PCB Manufacturing

Increased automation and robotics in PCB production lines are streamlining processes, minimizing errors, and reducing labor costs, all contributing to lower overall prices. - Advanced Material Development

Research into new, cost-effective materials with improved electrical and thermal properties is paving the way for cheaper and more efficient PCB fabrication. This includes exploration of alternatives to traditional FR-4. - Direct Digital Fabrication Techniques

Emerging technologies like inkjet printing of conductive inks and laser direct structuring are enabling more efficient and precise PCB fabrication, reducing material waste and production time. - Improved Supply Chain Efficiencies

Optimizing the supply chain through better logistics and inventory management leads to further cost reductions as companies become more efficient at managing the material flows of pcb manufacturing. - Integration of AI in PCB Design

Artificial intelligence algorithms can optimize PCB layouts, minimize material usage, and automate the design process leading to faster prototyping and cost savings. This type of AI is also being used to identify design issues, improve quality and speed up production.

Finding cheap PCB printing is achievable by carefully assessing your project needs, comparing the costs and services provided by different vendors, and opting for the best value instead of just the lowest price. Understanding the available options empowers you to confidently embark on your electronics projects without breaking the bank. With the right planning, cheap PCB printing can be a game-changer for your prototyping process and large-scale projects.

AnyPCBA

AnyPCBA