Electronic Competition Development Board PCB Solution

In the fast-paced world of electronic competitions, having a reliable and high-performance development board is crucial for success. The heart of any development board lies in its PCB (Printed Circuit Board), which serves as the foundation for all electronic components and circuitry. A well-designed PCB can significantly impact the board's performance, stability, and overall functionality. This article delves into the critical aspects of PCB solutions for electronic competition development boards, exploring the design considerations, manufacturing processes, and assembly techniques that ensure a competitive edge. Zero One Solution Limited, with its expertise in rapid prototyping and one-stop PCB services, stands ready to empower your innovative solutions.

Introduction: The Importance of PCB in Electronic Competition Development Boards

In the dynamic realm of electronic competitions, where milliseconds can dictate victory or defeat, the Printed Circuit Board (PCB) serves as the bedrock of every high-performance development board. Beyond merely connecting components, the PCB is the invisible architect dictating signal integrity, power distribution, and thermal management, directly impacting the board's speed, reliability, and ultimately, a competitor's success. A poorly designed PCB can introduce noise, degrade signal quality, and lead to thermal bottlenecks, turning a promising design into a frustrating failure. Conversely, a meticulously engineered PCB ensures that the complex interplay of high-speed processors, memory, and sensors operates seamlessly, unlocking the full potential of a development board in the demanding environment of electronic contests.

- What are electronic competitions?

Electronic competitions encompass a broad spectrum of challenges, from robotics and autonomous vehicles to embedded systems design and high-speed data processing. Participants design, build, and program electronic systems to achieve specific objectives, often under strict time and resource constraints. - What role do development boards play in these competitions?

Development boards are the central platforms for innovation in electronic competitions. They integrate microcontrollers, FPGAs, sensors, and communication interfaces, providing a flexible and powerful environment for prototyping, testing, and deploying complex electronic solutions. They serve as the tangible realization of competitors' designs. - Why is the PCB considered the foundation of a development board?

The PCB is the physical and electrical foundation because it provides the interconnections for all components, manages power delivery, and defines the pathways for signals. Its design dictates how efficiently and reliably the components communicate and operate, directly influencing the board's stability, performance, and longevity. - How does PCB quality impact competition performance?

High-quality PCB design and manufacturing minimize signal loss, crosstalk, electromagnetic interference (EMI), and thermal issues. This leads to stable operation, faster processing, and consistent performance under stress, which are crucial for success in time-sensitive and precision-dependent electronic competitions. Poor PCB quality can lead to unpredictable behavior, system crashes, and reduced accuracy. - What are the critical aspects of PCB design for electronic competition boards?

Critical aspects include signal integrity for high-speed data transmission, robust power delivery networks to ensure stable voltage to all components, efficient thermal management to dissipate heat, and precise component placement to optimize performance and minimize noise. These factors collectively ensure the board's optimal functionality and reliability in competitive scenarios.

Key Design Considerations for Electronic Competition PCBs

Designing PCBs for electronic competition development boards demands meticulous attention to several critical factors, as these directly dictate performance, reliability, and ultimately, success in high-stakes environments. Key considerations like signal integrity, robust power distribution, effective thermal management, and strategic component placement are paramount to achieving optimal functionality and stability. Neglecting any of these can lead to signal degradation, power supply issues, overheating, and unreliable operation, all of which are detrimental in competitive electronics.

| Design Aspect | Description | Impact on Performance | Best Practice |

|---|---|---|---|

| Signal Integrity (SI) | Maintaining signal quality and preventing degradation as signals propagate across the PCB. | Ensures accurate data transmission, prevents errors, and allows for higher operating frequencies. | Minimize trace lengths, use controlled impedance routing, employ proper termination. |

| Power Distribution Network (PDN) | Delivering stable and clean power to all components on the board. | Prevents voltage drops, reduces noise, and ensures consistent operation of sensitive ICs. | Utilize wide power and ground planes, strategic decoupling capacitor placement, low-inductance connections. |

| Thermal Management | Dissipating heat generated by components to maintain optimal operating temperatures. | Prevents component damage, improves reliability, and sustains peak performance over extended periods. | Incorporate thermal vias, large copper pours, heat sinks, and consider airflow within the enclosure. |

| Component Placement | Strategic positioning of components to optimize electrical performance and manufacturability. | Minimizes trace lengths, reduces signal coupling, simplifies routing, and aids thermal dissipation. | Place high-speed components close to connectors, separate analog/digital sections, ensure adequate spacing for cooling and rework. |

- Why is signal integrity so critical in electronic competition PCBs?

In electronic competitions, even minor signal distortions can lead to erroneous data, missed timing, or complete system failures. High-speed signals are particularly susceptible to reflections, crosstalk, and noise, which can degrade signal quality. Ensuring robust signal integrity through controlled impedance traces, proper routing, and termination is vital to maintain the precision and responsiveness required for competitive applications, directly impacting the board's speed and reliability. For instance, a 10Gbps signal running on a poorly designed trace could experience significant data loss within inches, making signal integrity a foundational requirement for high-performance boards used in such contests.

Material Selection: Choosing the Right Substrate for High-Performance PCBs

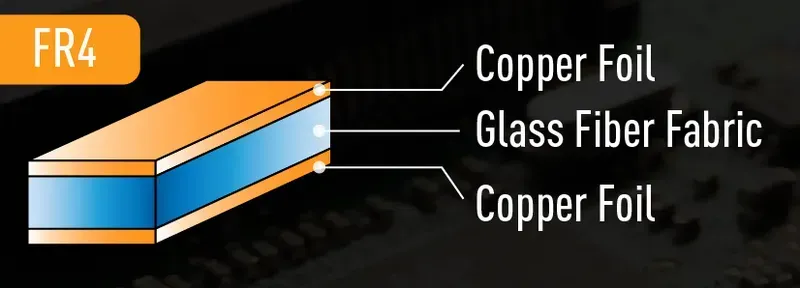

The substrate material forms the backbone of any Printed Circuit Board (PCB), and in high-performance electronic competition development boards, its selection is paramount. The right material dictates crucial electrical and thermal characteristics, directly impacting signal integrity, power efficiency, and the overall reliability of the system under strenuous operational conditions. Choosing an optimal substrate is not merely a design choice; it's a fundamental engineering decision that defines the board's capability to perform at peak levels, especially when dealing with high-speed signals and significant heat dissipation.

| Material Type | Dielectric Constant (Dk) | Dissipation Factor (Df) | Thermal Conductivity | Key Advantages | Typical Applications |

|---|---|---|---|---|---|

| FR-4 | 4.2-4.7 | 0.015-0.025 | 0.2-0.4 W/mK | Cost-effective, widely available, good mechanical strength | General purpose, low-to-moderate frequency boards |

| High-Tg FR-4 | ~4.5 | 0.01-0.015 | 0.3-0.5 W/mK | Improved thermal resistance, better dimensional stability | High-density, moderate-speed digital circuits |

| Rogers (e.g., RO4350B) | 3.48 | 0.0037 | 0.6-0.8 W/mK | Low Dk/Df for high-frequency, excellent thermal stability | RF/Microwave circuits, high-speed data communications, radar |

| PTFE (Teflon) | 2.1-2.3 | 0.0009 | 0.19-0.24 W/mK | Extremely low Dk/Df, excellent high-frequency performance | Ultra-high frequency, aerospace, medical devices |

| Polyimide | 3.0-3.5 | 0.005-0.01 | 0.2-0.3 W/mK | High temperature resistance, good flexibility (for flex PCBs) | Flexible PCBs, high-temperature applications, aerospace |

- Dielectric Constant (Dk) and Signal Speed

The dielectric constant, or permittivity, of a PCB material directly influences the speed at which electrical signals propagate through the traces. Lower Dk values allow signals to travel faster, minimizing propagation delays which are crucial for high-speed digital circuits and RF applications. For instance, Rogers materials with their low Dk are preferred for competition boards where nanosecond delays can mean the difference in performance. - Dissipation Factor (Df) and Signal Loss

The dissipation factor, also known as loss tangent, quantifies the amount of electrical energy absorbed by the material. A lower Df indicates less signal loss, which is vital for maintaining signal integrity, especially at higher frequencies. Materials like PTFE exhibit exceptionally low Df, making them ideal for sensitive RF and microwave designs where signal attenuation must be minimized. - Thermal Conductivity and Management

Electronic competition development boards often generate significant heat due to high-power components and rapid switching. A substrate with higher thermal conductivity can more effectively dissipate this heat away from critical components, preventing overheating and ensuring stable operation. Materials like Rogers exhibit superior thermal management properties compared to standard FR-4, which is essential for sustained high-performance in competitive environments. - Impedance Control and Trace Geometry

Maintaining precise impedance control is critical for high-speed signals to prevent reflections and signal distortion. The dielectric constant of the material, combined with trace width, thickness, and distance to ground planes, determines the characteristic impedance. Advanced materials offer more stable Dk across frequencies, making impedance matching more predictable and reliable, a non-negotiable for competitive electronics. - Moisture Absorption and Environmental Stability

PCB materials vary in their ability to absorb moisture. High moisture absorption can lead to changes in Dk and Df, affecting the board's electrical performance and long-term reliability. For competition boards exposed to varying environmental conditions, selecting materials with low moisture absorption is important to maintain consistent performance.

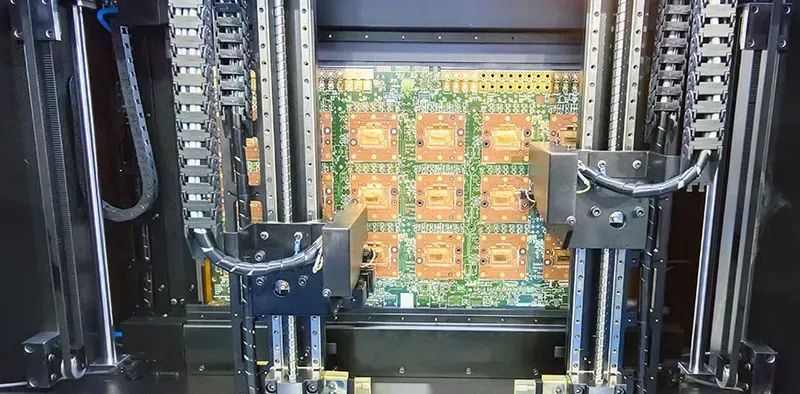

Manufacturing Processes: Ensuring Precision and Reliability

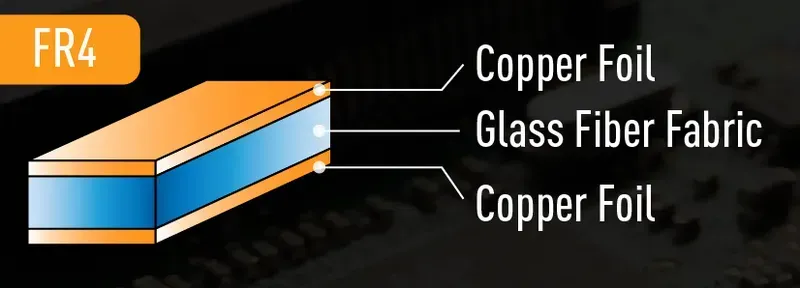

The manufacturing process of Printed Circuit Boards (PCBs) is a highly intricate and critical phase that directly dictates the performance and reliability of electronic competition development boards. Precision and stringent quality control at every stage are paramount to transforming a theoretical design into a functional, robust physical product, capable of withstanding the demanding environments of competitive electronics. From initial material preparation to final surface finishing, each step must adhere to rigorous standards to ensure the longevity and optimal operation of the board.

| Process Step | Description | Precision Criticality | Key Quality Control Focus |

|---|---|---|---|

| Imaging & Etching | Transferring the circuit design onto the copper layers and selectively removing unwanted copper to form traces. | High (Trace width, spacing accuracy) | Uniform etching, no short circuits or open circuits |

| Drilling | Creating precise holes for component leads (through-hole) and vias (interlayer connections). | Very High (Hole diameter, positional accuracy) | Correct hole size, accurate alignment, no burrs |

| Plating (Electroless & Electro) | Depositing copper within the drilled holes and on the surface to create conductive pathways. | High (Copper thickness, uniformity) | Consistent copper thickness, strong adhesion, no voids |

| Solder Mask Application | Applying a protective polymer layer over the copper traces, exposing only component pads for soldering. | Medium (Alignment, coverage) | Even coverage, no mask on pads, no air bubbles |

| Surface Finish Application | Applying a protective metallic coating to exposed copper pads to prevent oxidation and ensure solderability. | High (Thickness, uniformity) | Consistent thickness, good flatness, excellent solderability |

| Profiling/Routing | Cutting the large PCB panel into individual boards according to the specified dimensions. | High (Dimensional accuracy) | Accurate board dimensions, smooth edges, no delamination |

| Electrical Testing (E-Test) | Verifying the continuity of all traces and isolating any short or open circuits. | Very High (Fault detection) | 100% circuit integrity, no electrical defects |

- Why is precision drilling so critical for multi-layer PCBs in electronic competitions?

Precision drilling is paramount for multi-layer PCBs because it ensures accurate alignment of vias (vertical interconnect access) that connect different layers. Misaligned holes can lead to signal integrity issues, impedance mismatches, and even complete circuit failures, which are unacceptable in high-performance electronic competition scenarios where every millisecond and every signal matters. Advanced drilling technologies, such as laser drilling for micro-vias, are often employed to achieve the necessary accuracy for high-density interconnect (HDI) boards.

void setup() {

// Initialize competition board components

pinMode(LED_BUILTIN, OUTPUT);

Serial.begin(115200);

}

void loop() {

// Simulate a competitive task

digitalWrite(LED_BUILTIN, HIGH);

delay(100);

digitalWrite(LED_BUILTIN, LOW);

delay(100);

Serial.println("Board operating...");

}High-Speed PCB Layout Techniques for Optimal Signal Integrity

In the realm of electronic competition development boards, achieving optimal signal integrity is paramount for reliable and high-performance operation. High-speed PCB layout techniques are not merely best practices; they are critical engineering disciplines that directly impact the board's ability to transmit data accurately and efficiently. Without meticulous attention to these techniques, even the most sophisticated designs can succumb to signal degradation, leading to unreliable performance and competitive disadvantages. This section delves into the fundamental strategies employed to preserve signal integrity in high-speed PCB designs.

- Impedance Matching

Impedance matching is crucial for high-speed signals to prevent reflections that can distort waveforms and cause data errors. By matching the impedance of the trace to the source and load impedances (typically 50 ohms for single-ended signals and 100 ohms for differential pairs), maximum power transfer is ensured, and signal reflections are minimized. This involves careful calculation of trace width, dielectric constant, and trace-to-plane spacing, often requiring specialized software tools and iterative design adjustments to achieve precise impedance control. Without proper impedance matching, signals can bounce back and forth, creating standing waves that severely degrade signal quality and reliability, especially at higher frequencies where wavelength becomes comparable to trace length. Techniques include using controlled impedance traces, series termination, or parallel termination depending on the specific signal characteristics and requirements.

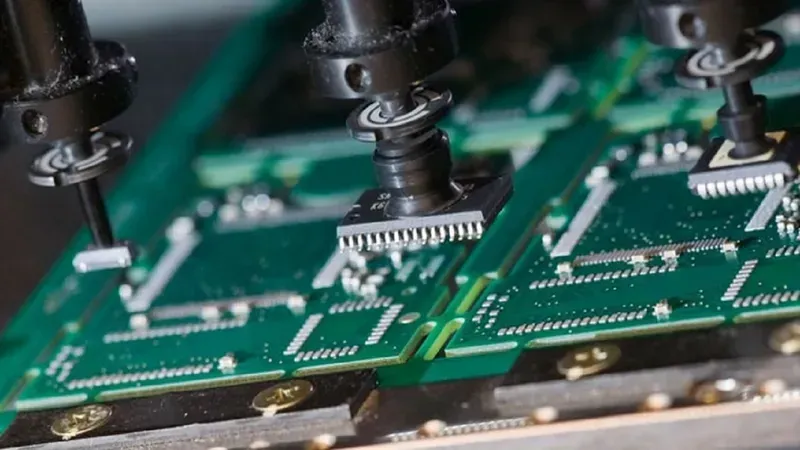

Component Assembly: SMT and Through-Hole Technologies

Precise and reliable component assembly is paramount for the functionality and longevity of Electronic Competition Development Boards. The choice between Surface Mount Technology (SMT) and Through-Hole Technology (THT) significantly impacts board density, performance, and manufacturing efficiency. As veteran engineers, we understand that selecting the appropriate assembly method, or a hybrid approach, is critical for achieving optimal circuit performance, especially in high-frequency and high-density electronic competition applications. This decision directly influences the board's form factor, cost-effectiveness, and overall robustness, ensuring it can withstand the rigors of competitive environments.

| Feature | Surface Mount Technology (SMT) | Through-Hole Technology (THT) |

|---|---|---|

| Component Size | Smaller, lighter components | Larger, bulkier components |

| Mounting Method | Components soldered directly onto the PCB surface | Component leads inserted through holes and soldered on the opposite side |

| Board Density | Higher component density, allowing for more compact designs | Lower component density, requires more PCB real estate |

| Automation | Highly automatable, suitable for high-volume production | Often requires manual insertion, less automatable |

| Performance (High Freq.) | Reduced lead inductance/capacitance, better for high-frequency signals | Longer leads introduce more parasitic effects, less ideal for high-frequency |

| Mechanical Strength | Less mechanical strength against vibrations and impacts without additional reinforcement | Higher mechanical strength, more robust connections |

| Cost | Lower cost per component in high volume; higher initial setup costs | Higher cost per component; lower initial setup costs |

| Repairability | More challenging to repair/rework due to smaller components and higher density | Easier to inspect, repair, and replace components |

At Zero One Solution Limited, our state-of-the-art facilities are equipped to handle both SMT and THT assembly with exceptional precision. Our automated SMT lines ensure rapid, high-volume assembly of miniature components, crucial for compact and high-performance electronic competition boards. Concurrently, our expert technicians adeptly handle THT assembly for components requiring superior mechanical stability or for specific power applications. We meticulously manage solder paste application, component placement accuracy, reflow soldering profiles, and wave soldering processes to guarantee robust and reliable connections, meeting the demanding specifications of competitive electronic systems.

Testing and Validation: Ensuring Functionality and Performance

For Electronic Competition Development Boards, rigorous testing and validation are not merely a final step but a crucial continuum ensuring that every PCB functions as intended, withstands operational demands, and delivers peak performance under competitive pressure. This meticulous process safeguards signal integrity, power delivery, and thermal stability, transforming theoretical designs into reliable, high-performing hardware platforms ready for the intense demands of electronic competitions.

- Why is comprehensive testing critical for competition PCBs?

Comprehensive testing is paramount for competition PCBs because it identifies and rectifies potential flaws early in the development cycle, preventing catastrophic failures during critical competition moments. It verifies adherence to design specifications, ensures optimal signal integrity at high frequencies, validates power delivery stability under varying loads, and confirms thermal dissipation effectiveness, all of which directly impact performance and reliability in demanding competitive environments. Without robust testing, even minor defects can lead to intermittent glitches, performance degradation, or complete system failure, undermining a competitor's efforts.

| Testing Type | Purpose | Key Parameters Evaluated | Industry Relevance | |

|---|---|---|---|---|

| Electrical Testing (e.g., Flying Probe, Bed of Nails) | Verify circuit continuity, shorts, opens, and component presence. | Resistance, capacitance, inductance, open circuits, short circuits. | IPC-9252 (Electrical Test Guidelines for Bare Boards), IPC-A-600 (Acceptability of PCBs). Essential for validating basic circuit integrity before assembly. | This ensures the fundamental electrical pathways are correct, preventing immediate failures upon power-up. |

| Testing Type | Purpose | Key Parameters Evaluated | Industry Relevance | |

|---|---|---|---|---|

| Signal Integrity (SI) Testing | Assess signal quality at high speeds, minimizing distortion and crosstalk. | Eye diagrams, rise/fall times, overshoot/undershoot, impedance matching, crosstalk noise. | IEEE 802.3 standards for Ethernet, JEDEC standards for memory interfaces. Crucial for high-speed data transmission in competitive electronics. | Critical for boards with DDR, PCIe, or high-speed communication interfaces to ensure data reliability and speed. |

| Testing Type | Purpose | Key Parameters Evaluated | Industry Relevance | |

|---|---|---|---|---|

| Thermal Testing (e.g., Thermal Imaging, Environmental Chambers) | Evaluate heat dissipation efficiency and component temperature under operational loads. | Component temperatures, thermal hotspots, temperature gradients, cooling effectiveness. | JEDEC JESD51 (Thermal Characterization of Integrated Circuits), MIL-STD-810 (Environmental Engineering Considerations). Vital for long-term reliability and preventing performance degradation due to overheating. | Ensures the board remains within safe operating temperatures, preventing thermal throttling and component damage during intense use. |

Zero One Solution Limited: Your Partner for Electronic Competition PCB Solutions

In the fast-paced realm of electronic competitions, where every millisecond and every micron of precision counts, the underlying PCB is not merely a component but a critical enabler of victory. Zero One Solution Limited stands as a premier partner, offering unparalleled rapid prototyping and comprehensive one-stop PCB services specifically tailored for the demanding requirements of electronic competition development boards. Our expertise ensures that your innovative designs are translated into robust, high-performance hardware, giving you the competitive edge.

- Rapid Prototyping for Competitive Agility

Zero One Solution Limited excels in rapid-response R&D prototype manufacturing. This capability is paramount in electronic competitions where iterative design improvements and quick turnarounds are essential to stay ahead. We drastically cut down development cycles, allowing teams to test, refine, and deploy new iterations of their development boards with exceptional efficiency. Our streamlined processes mean your conceptual designs quickly become tangible, testable prototypes, accelerating your path to market or competition readiness. From initial schematic to final assembly, our integrated approach ensures a seamless and expedited experience, critical for time-sensitive projects in electronic sports engineering.

FAQ: Common Questions About Electronic Competition PCB Design and Manufacturing

Navigating the complexities of PCB design and manufacturing for electronic competition development boards can raise numerous questions for engineers and developers alike. This FAQ section addresses the most common inquiries, providing authoritative answers to clarify critical aspects of ensuring optimal performance, reliability, and competitive advantage through superior PCB solutions.

- What are the primary factors that differentiate Electronic Competition PCBs from standard PCBs?

Electronic Competition PCBs demand superior performance, reliability, and speed compared to standard PCBs. Key differentiators include an emphasis on stringent signal integrity (minimizing crosstalk and impedance mismatch), robust power delivery networks (handling high current transients without significant voltage drop), advanced thermal management (dissipating heat from high-performance components), and often a compact form factor. These boards frequently integrate high-speed interfaces, requiring precise impedance control and advanced routing techniques to ensure data integrity and prevent signal degradation critical for competitive advantage where milliseconds matter. - How does material selection impact the performance of an Electronic Competition Development Board PCB?

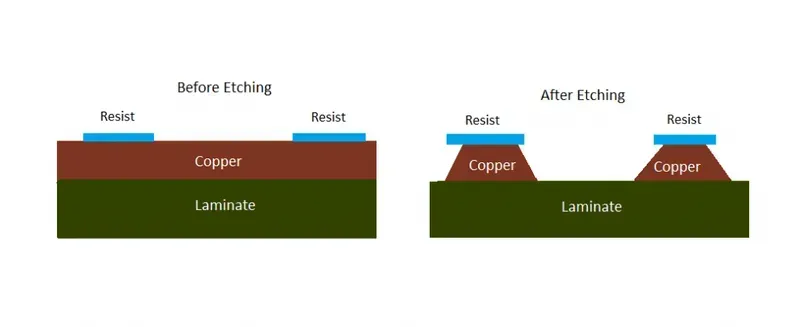

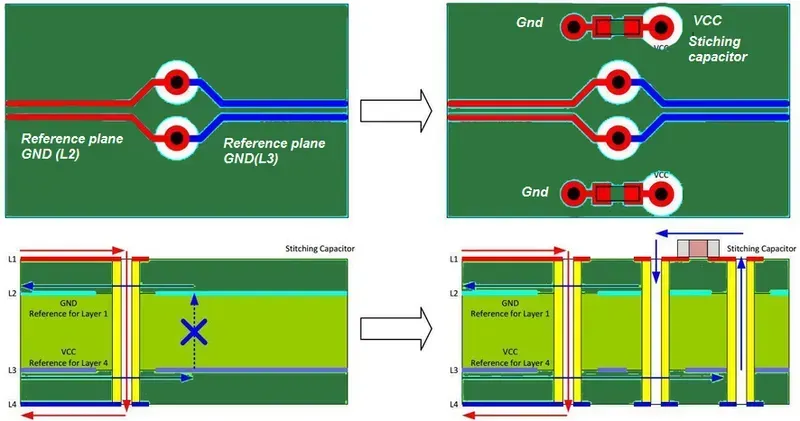

Material selection profoundly influences the performance of high-speed Electronic Competition PCBs. Substrates like standard FR-4 are often insufficient due to higher dielectric loss (Df) and dielectric constant (Dk) variations, which can lead to signal attenuation and timing skew at high frequencies. High-performance laminates such as Rogers, Isola, or Panasonic materials offer lower Df and stable Dk across frequency and temperature, improving signal integrity, reducing insertion loss, and enabling tighter impedance control. This directly translates to faster signal propagation, reduced noise, and enhanced overall system stability, crucial for demanding competitive applications. - What are the common pitfalls in power delivery network (PDN) design for high-performance Electronic Competition PCBs?

Common pitfalls in PDN design for Electronic Competition PCBs include inadequate plane capacitance, insufficient copper weight, and poor power/ground plane stitching. These issues can lead to significant voltage droop during peak current demands, increased ground bounce, and electromagnetic interference (EMI). A robust PDN requires careful consideration of distributed capacitance (using multiple decoupling capacitors of varying values), wide power and ground planes with minimal splits, and optimal via stitching to minimize inductance. Simulation tools are essential to validate PDN performance, ensuring stable and clean power delivery to all components, especially high-speed processors and FPGAs. - Why is thermal management critical in Electronic Competition Development Board PCB design?

Thermal management is critical in Electronic Competition PCB design because high-performance components generate significant heat, which can lead to reduced lifespan, performance degradation (e.g., increased propagation delays, reduced clock speeds), and even component failure. Effective thermal management involves designing efficient heat dissipation paths, such as using larger copper planes for heat spreading, integrating thermal vias under hot components, and potentially incorporating external heatsinks or active cooling solutions. Proper thermal design ensures components operate within their specified temperature ranges, maintaining optimal performance and reliability during intense, prolonged competitive use.

In conclusion, a robust PCB solution is paramount for creating a successful electronic competition development board. From careful design considerations to precise manufacturing and assembly, every step plays a crucial role in optimizing performance and reliability. Zero One Solution Limited is dedicated to providing comprehensive PCB solutions, enabling you to push the boundaries of innovation and achieve excellence in electronic competitions. Contact us today to discover how our expertise can elevate your next project and bring your winning ideas to life. Visit our website or reach out to our team to learn more about our services and how we can help you succeed.

AnyPCBA

AnyPCBA