The Large Screen Display Control Board Solution

In today's world, large screen displays are ubiquitous, from advertising billboards to control rooms and entertainment venues. At the heart of every stunning visual experience lies a sophisticated control board, the unsung hero that dictates performance and reliability. As Zero One Solution Limited, we understand the critical role these control boards play. With our extensive experience in PCB solutions, we offer comprehensive services to meet the demands of modern large screen display technology. This article delves into the intricacies of large screen display control board solutions, exploring design considerations, manufacturing processes, and the advantages of partnering with a rapid prototyping expert like Zero One Solution Limited.

Understanding the Role of Control Boards in Large Screen Displays

At the heart of every visually stunning large screen display lies a sophisticated control board, the unsung hero responsible for orchestrating a seamless and high-performance viewing experience. These control boards are not merely passive components; they are the intelligent core that manages signal processing, resolution control, and overall system stability, ensuring that the displayed content is vibrant, clear, and reliable. They act as the bridge between the input source and the display panel, translating data into a visually coherent output.

- What are the key functions of a control board in large screen displays?

Control boards manage signal processing to optimize image quality, control resolution for clarity, maintain system stability for reliable performance, and ensure compatibility between various input sources and the display panel. - How does a control board contribute to the overall visual experience on a large screen?

By precisely managing color depth, contrast ratios, and brightness levels, the control board ensures vibrant and accurate image reproduction, contributing significantly to an immersive and engaging visual experience. - What happens if the control board malfunctions in a large screen display?

A malfunctioning control board can lead to a variety of display issues, including distorted images, incorrect colors, flickering, or even a complete loss of display, severely impacting the viewing experience and potentially damaging the display panel. - How do control boards manage different input resolutions for large screen displays?

Control boards utilize scaling and interpolation techniques to convert input signals of varying resolutions to match the native resolution of the display panel, ensuring optimal image quality regardless of the input source. - What role does thermal management play in the design of large screen display control boards?

Effective thermal management is crucial to prevent overheating and ensure the reliable operation of the control board. Heat sinks, fans, and strategic component placement are employed to dissipate heat generated by the board's components. - How does Zero One Solution Limited ensure the quality and reliability of its control board solutions for large screen displays?

Zero One Solution Limited employs rigorous testing and quality control procedures throughout the design and manufacturing process, utilizing advanced PCB fabrication techniques and high-quality components to ensure the long-term reliability and performance of its control boards. - What are the key factors to consider when selecting a control board for a specific large screen display application?

Consider factors such as the required resolution, input signal compatibility, processing power, thermal management capabilities, and compliance with relevant industry standards to ensure the selected control board meets the specific demands of the application.

Key Design Considerations for Large Screen Display Control Boards

Designing control boards for large screen displays demands careful attention to several critical factors to ensure optimal performance, reliability, and longevity. These considerations span thermal management to dissipate heat effectively, signal integrity to maintain signal quality, power efficiency to minimize energy consumption, and strategic component selection to meet specific application needs. Balancing these elements is crucial for creating control boards that can drive large, high-resolution displays reliably.

- How does thermal management impact the design of large screen display control boards?

Effective thermal management is crucial because high-resolution displays generate significant heat. Poor thermal design can lead to overheating, reducing performance and lifespan. Key strategies include using heat sinks, optimizing airflow, and selecting components with low thermal resistance to maintain stable operating temperatures. - What role does signal integrity play in the performance of control boards?

Signal integrity is paramount to ensure that signals are transmitted cleanly and accurately across the control board. Reflections, noise, and distortion can degrade signal quality, leading to display issues. Careful PCB layout, controlled impedance routing, and proper termination techniques are essential for preserving signal integrity and achieving optimal display performance. - Why is power efficiency a critical design consideration?

Power efficiency is vital for reducing energy consumption, minimizing heat generation, and extending the lifespan of the control board. Efficient power delivery circuits, low-power components, and intelligent power management techniques can significantly reduce energy waste and improve overall system reliability, making it a key factor in sustainable and cost-effective large screen display solutions. - What are the key components to consider when designing a display control board?

Selecting the right components is essential for the reliability and performance of large screen display control boards. Processors, memory, display drivers, and power management ICs must be carefully chosen based on performance, power efficiency, and compatibility. High-quality, reliable components ensure long-term stability and optimal display performance. - How does component placement affect control board performance?

Component placement significantly impacts signal integrity, thermal management, and EMC performance. Strategic placement minimizes signal path lengths, reduces thermal hotspots, and optimizes EMI shielding. Proper component placement is crucial for achieving reliable and high-performance large screen display control boards. - What design choices improve EMC compliance for display control boards?

To ensure EMC compliance, control boards must minimize electromagnetic interference. Shielding, proper grounding techniques, and careful signal routing are critical design choices. Compliance with regulatory standards ensures the control board can operate reliably without causing interference to other electronic devices.

Advanced PCB Manufacturing Techniques for High-Performance Control Boards

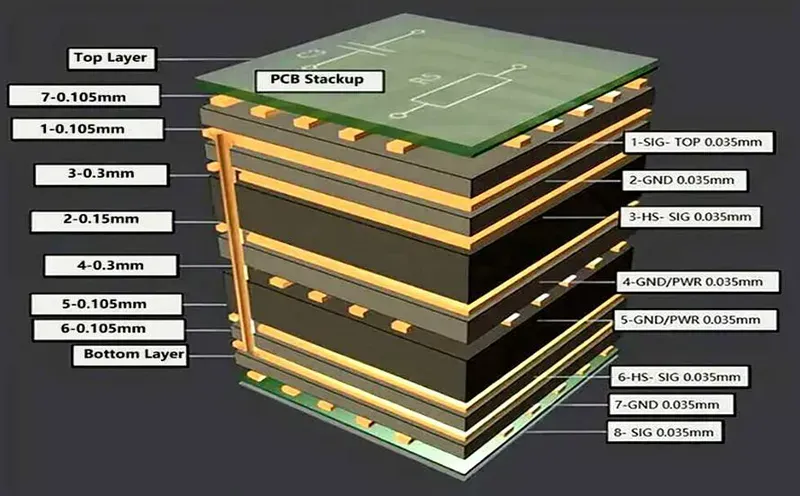

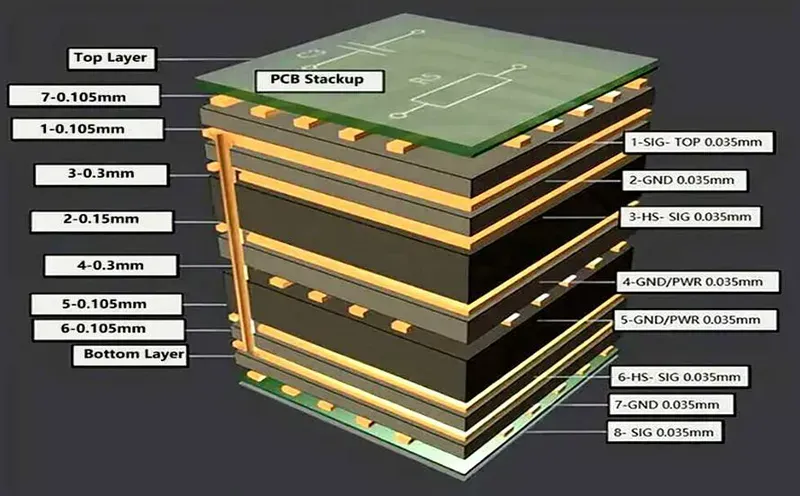

The creation of high-performance control boards for large screen displays relies heavily on advanced PCB manufacturing techniques. These techniques ensure the reliability, efficiency, and signal integrity necessary for driving large, high-resolution displays. Key processes include multilayer PCB fabrication for increased circuit density, Surface Mount Technology (SMT) for precise component placement, and Automated Optical Inspection (AOI) for quality control. By leveraging these advanced methods, manufacturers can produce control boards capable of meeting the demanding requirements of modern display technology.

- What is Multilayer PCB Fabrication and Why is it Important?

Multilayer PCB fabrication involves creating PCBs with more than two layers of conductive material, separated by insulating layers. This is crucial for high-performance control boards because it allows for increased circuit density and complexity within a smaller area. More layers mean more space for routing signals, improved signal integrity, and better power distribution, all essential for driving large screen displays effectively. - How Does Surface Mount Technology (SMT) Enhance Control Board Performance?

SMT involves mounting components directly onto the surface of the PCB, rather than inserting them through holes. This technology enables smaller component sizes, higher component density, and improved electrical performance due to shorter lead lengths. For large screen display control boards, SMT allows for the precise placement of components, minimizing signal interference and maximizing performance. - What Role Does Automated Optical Inspection (AOI) Play in Ensuring Control Board Quality?

AOI is an automated visual inspection technique that uses cameras to scan the PCB and identify defects such as missing components, incorrect placement, or solder joint issues. AOI is critical for ensuring the quality and reliability of control boards, as it can detect errors early in the manufacturing process, preventing costly failures and ensuring optimal performance of the large screen display. - Why is thermal management important in advanced PCB manufacturing for large screen displays?

Large screen displays often generate significant heat. Advanced PCB manufacturing incorporates techniques like thermal vias and heat sinks to dissipate heat effectively, preventing component overheating and ensuring long-term reliability. - What considerations are important for selecting materials in advanced PCB manufacturing?

Material selection is critical for signal integrity, thermal performance, and overall reliability. High-performance materials with low dielectric loss and high thermal conductivity are often chosen for large screen display control boards. - How does impedance control contribute to signal integrity in high-performance control boards?

Impedance control ensures that the signal impedance remains consistent throughout the signal path, minimizing reflections and signal loss. This is achieved through careful PCB layout and material selection, which are critical for maintaining signal integrity in large screen displays.

Rapid Prototyping: Accelerating Your Product Development with Zero One Solution Limited

In the fast-paced world of large screen display technology, time is of the essence. Rapid prototyping is not just a luxury; it's a necessity for accelerating product development cycles. Zero One Solution Limited understands this imperative, offering quick-turn services that significantly expedite the design and testing phases of your large screen display control boards, ensuring you stay ahead of the competition.

Here’s how rapid prototyping with Zero One Solution Limited can revolutionize your product development:

- Accelerated Time-to-Market

Rapid prototyping slashes development time, allowing you to introduce your large screen display products to the market faster. This speed advantage can be crucial in capturing market share and establishing your brand. - Early Design Validation

Identify and rectify design flaws early in the process. By creating functional prototypes, you can test your control board's performance under real-world conditions, preventing costly revisions later on. - Cost-Effective Iteration

Experiment with different design options without incurring massive costs. Rapid prototyping enables you to iterate quickly and efficiently, optimizing your design for performance and manufacturability. - Risk Mitigation

Minimize the risk of unforeseen issues during mass production. By thoroughly testing your prototype, you can identify and address potential problems before they escalate into major setbacks. - Enhanced Collaboration

Facilitate better communication and collaboration between design, engineering, and manufacturing teams. A tangible prototype serves as a common reference point, ensuring everyone is on the same page. - Access to Cutting-Edge Technologies

Zero One Solution Limited provides access to the latest PCB manufacturing technologies, allowing you to incorporate advanced features and functionalities into your large screen display control boards.

With Zero One Solution Limited's rapid prototyping services, you can transform your concepts into tangible prototypes in record time, accelerating your product development and gaining a competitive edge in the large screen display market.

- What is the typical turnaround time for rapid prototyping of large screen display control boards?

Zero One Solution Limited offers a rapid turnaround, often delivering prototypes within days. The exact timeframe depends on the complexity of the design and the availability of components, but we prioritize speed without compromising quality. - What design considerations are crucial for rapid prototyping of display control boards?

Key considerations include component selection, thermal management, signal integrity, and power efficiency. Selecting readily available components and designing for manufacturability can significantly accelerate the prototyping process. - Can rapid prototyping help in identifying potential EMC issues early in the design phase?

Yes, absolutely. Rapid prototyping allows for early EMC testing, helping to identify and mitigate potential electromagnetic interference issues before mass production, saving time and resources. - What types of testing are typically performed on rapid prototypes of display control boards?

Testing typically includes functional testing, signal integrity analysis, thermal testing, and EMC compliance testing. These tests ensure the prototype meets the required performance and regulatory standards. - How does Zero One Solution Limited ensure the quality of rapid prototypes?

We adhere to strict quality control procedures throughout the prototyping process. This includes using high-quality materials, employing advanced manufacturing techniques, and conducting thorough testing and inspection at every stage. - What file formats are accepted for rapid prototyping orders?

We accept a variety of file formats, including Gerber files, ODB++, and IPC-2581. Providing comprehensive and accurate design files ensures a smooth and efficient prototyping process.

Component Selection: Ensuring Reliability and Performance

Selecting the right components for large screen display control boards is paramount for achieving optimal reliability and sustained performance. This involves a meticulous evaluation of processors, memory modules, display drivers, and other critical parts, ensuring they meet stringent performance benchmarks and longevity requirements. Thoughtful component selection directly impacts the display's visual quality, lifespan, and overall operational stability.

- What are the key factors to consider when selecting processors for large screen display control boards?

When selecting processors, consider processing power (CPU and GPU capabilities), power consumption, thermal management requirements, support for relevant display interfaces (HDMI, DisplayPort), and the processor's lifecycle and availability. The processor should be capable of handling the display's resolution and refresh rate without bottlenecks. - How does memory module selection impact the performance of large screen displays?

Memory modules (RAM) are crucial for storing and quickly retrieving data needed for display operations. Key considerations include memory capacity, speed (MHz), latency (CAS latency), and memory type (DDR4, DDR5). Insufficient memory or slow memory speeds can lead to performance issues such as lag, stuttering, and reduced frame rates. - What role do display drivers play in ensuring high-quality visuals on large screens?

Display drivers are responsible for converting data into a format that the display panel can understand and for controlling various display parameters such as brightness, contrast, and color accuracy. Selecting drivers that offer robust features, excellent color reproduction, and support for the display panel's native resolution is essential for achieving high-quality visuals. - Why is thermal management an important consideration in component selection?

High-performance components generate heat, which can negatively impact their reliability and lifespan. Selecting components with low power consumption and efficient thermal dissipation characteristics is important. Heatsinks, fans, and other cooling solutions may also be necessary to maintain optimal operating temperatures. - How can component lifecycle management affect the long-term viability of large screen display products?

Component lifecycles vary, and some components may become obsolete or unavailable over time. Selecting components with long lifecycles and ensuring a reliable supply chain are critical for long-term product support and to avoid costly redesigns due to component obsolescence. - What certifications or standards should be considered when choosing components for large screen displays?

Depending on the application and target market, certain certifications or standards may be required. These can include safety certifications (UL, CE), EMC compliance (FCC, CE), and environmental standards (RoHS, REACH). Ensuring components meet these standards is essential for regulatory compliance and product safety. - How does Zero One Solution Limited assist in component selection for large screen display control boards?

Zero One Solution Limited leverages its extensive experience and partnerships with leading component manufacturers to guide clients in selecting the optimal components for their specific needs. We consider performance requirements, budget constraints, and long-term reliability to ensure the best possible outcome for your large screen display project. Our expertise in rapid prototyping also allows for quick validation of component choices in real-world scenarios.

Signal Integrity and EMC Compliance in Control Board Design

In large screen display control board design, signal integrity (SI) and electromagnetic compatibility (EMC) are paramount. These considerations ensure minimal interference, high signal quality, and adherence to regulatory standards, ultimately leading to reliable and stable display performance. Addressing SI and EMC early in the design process mitigates risks associated with signal degradation and electromagnetic emissions, which can compromise functionality and compliance.

- Why is signal integrity crucial in large screen display control boards?

Signal integrity ensures that signals are transmitted without distortion or loss, which is critical for maintaining image quality and preventing errors in large screen displays. Poor signal integrity can lead to flickering, incorrect colors, or complete display failure. High-speed data transmission requirements in modern displays demand careful management of impedance, reflections, and crosstalk. - What are the primary sources of electromagnetic interference (EMI) in control boards?

EMI can originate from various sources, including high-frequency switching components, clock signals, and data lines. These sources can radiate unwanted energy, affecting nearby components or even external devices. Identifying and mitigating these sources through proper shielding, filtering, and PCB layout techniques is essential for EMC compliance. - How does PCB layout affect signal integrity and EMC?

PCB layout plays a significant role in both signal integrity and EMC performance. Careful routing of high-speed signals, minimizing trace lengths, using ground planes, and implementing proper impedance control can significantly improve signal integrity. For EMC, strategic placement of components, using shielding techniques, and incorporating filters can reduce electromagnetic emissions and susceptibility. - What EMC compliance standards are relevant for large screen display control boards?

Depending on the target market, various EMC standards may apply. Common standards include FCC Part 15 (for the United States), CISPR 32 (international standard), and EN 55032 (European standard). These standards specify limits for radiated and conducted emissions and define testing procedures to ensure compliance. Meeting these standards is crucial for legal sale and operation of the display system. - What design techniques can improve signal integrity in control boards?

Several techniques can enhance signal integrity, including impedance matching, differential signaling, proper termination, and minimizing stubs. Impedance matching ensures that the signal's energy is efficiently transferred from source to load, reducing reflections. Differential signaling provides better noise immunity. Proper termination absorbs signal energy at the end of the transmission line, preventing reflections. Shorter stubs minimize signal degradation. - How can simulation tools aid in addressing signal integrity and EMC challenges?

Simulation tools, such as SPICE simulators and electromagnetic field solvers, allow engineers to model and analyze signal behavior and electromagnetic emissions before physical prototypes are built. These tools can identify potential SI/EMC issues early in the design process, enabling corrective actions to be taken, saving time and cost. - What role do components play in achieving EMC compliance?

Careful selection of components, particularly those involved in high-speed signal processing and power management, is vital for EMC. Using components with integrated shielding, low EMI characteristics, and proper filtering can significantly reduce emissions. Additionally, choosing components from reputable manufacturers ensures that they meet specified performance and compliance standards.

The Advantages of Partnering with Zero One Solution Limited for PCB Solutions

Choosing the right PCB solution provider is critical for the success of your large screen display projects. Zero One Solution Limited offers a unique combination of expertise, rapid prototyping capabilities, a robust global supply chain, and an unwavering commitment to quality, making us an ideal partner for businesses seeking cutting-edge PCB solutions. Our dedication to innovation and customer satisfaction ensures that your project receives the attention and resources it deserves, from initial design to final production.

- Expertise and Experience

With over a decade of experience in the PCB industry, Zero One Solution Limited brings a wealth of knowledge and technical skills to every project. Our team of experienced engineers and designers understands the intricacies of large screen display control boards and can provide valuable insights and recommendations to optimize your design for performance, reliability, and cost-effectiveness. - Rapid Prototyping Capabilities

Our rapid prototyping services enable you to quickly test and refine your designs, reducing time-to-market and minimizing development costs. We offer quick-turn PCB fabrication and assembly, allowing you to iterate on your designs and validate your concepts in a matter of days. - Global Supply Chain Network

Headquartered in Shenzhen, China, and with a branch office in Dubai, we operate within a global PCBA supply chain network, ensuring seamless access to worldwide resources and support. This strategic positioning allows us to source high-quality components at competitive prices and manage the entire supply chain efficiently. - Commitment to Quality

We are committed to providing our customers with the highest quality PCB solutions. Our manufacturing processes are rigorously controlled, and we use advanced inspection techniques, such as automated optical inspection (AOI), to ensure that every board meets our strict quality standards. We are also ISO 9001 certified, demonstrating our commitment to quality management. - Comprehensive Services

From PCB design and layout to manufacturing and assembly, we offer a comprehensive suite of services to meet all of your PCB needs. We can handle projects of any size and complexity, and we are committed to providing our customers with personalized attention and support throughout the entire process. - Cost-Effective Solutions

We understand the importance of cost-effectiveness, and we are committed to providing our customers with competitive pricing without compromising on quality. Our efficient manufacturing processes and global supply chain network enable us to minimize costs and pass the savings on to our customers.

Case Studies: Successful Large Screen Display Projects with Zero One Solution Limited

Zero One Solution Limited has a proven track record of delivering high-quality PCB solutions for large screen display projects. Our expertise in rapid prototyping, component selection, and signal integrity ensures that our clients receive reliable and high-performance control boards. The following case studies illustrate our ability to meet diverse customer needs and deliver exceptional results.

- Case Study 1: Large Format LED Display for Outdoor Advertising

A client specializing in outdoor advertising required a robust and reliable control board for their large format LED display. Zero One Solution Limited provided a rapid prototype solution that met their specific requirements for signal processing, thermal management, and EMC compliance. The result was a high-performance display that delivered exceptional visual quality and reliability in harsh outdoor environments. - Case Study 2: High-Resolution Video Wall for Control Room Applications

A government client needed a high-resolution video wall for their control room. Zero One Solution Limited designed and manufactured a control board that supported multiple video inputs, high refresh rates, and low latency. Our expertise in signal integrity and component selection ensured that the video wall delivered crystal-clear images and reliable performance, enhancing the client's situational awareness and decision-making capabilities. - Case Study 3: Interactive Touch Screen Display for Retail Applications

A retail client sought to enhance customer engagement with an interactive touch screen display. Zero One Solution Limited provided a custom control board solution that integrated touch screen functionality, high-resolution graphics, and seamless connectivity. The resulting display offered an engaging and intuitive user experience, driving sales and enhancing brand loyalty. - Case Study 4: LCD Control Board for Medical Imaging Display

For a company specializing in medical imaging displays, Zero One Solution Limited provided a control board that met stringent requirements for image quality and reliability. The board supported high-resolution LCD panels and provided accurate color reproduction, ensuring precise and detailed medical images for diagnostics. This solution showcased our ability to meet the critical demands of the medical industry. - Case Study 5: LED Matrix Display Control Board for Industrial Application

An industrial client required a robust LED matrix display for real-time data visualization on the factory floor. Zero One Solution Limited engineered a control board capable of withstanding harsh environmental conditions, ensuring continuous operation and clear data presentation, which significantly improved operational efficiency.

In conclusion, the large screen display control board solution is a crucial element in delivering high-quality visual experiences. Zero One Solution Limited's expertise in PCB design, manufacturing, and assembly ensures that your display systems operate flawlessly. By choosing Zero One Solution Limited, you gain a partner dedicated to innovation, quality, and rapid prototyping. Contact us today to discuss your large screen display control board needs and discover how we can accelerate your product development and bring your innovative solutions to market efficiently. Visit our website or contact our Shenzhen or Dubai offices to learn more.

AnyPCBA

AnyPCBA