The Power Monitoring Communication Board Solution

In today's energy-conscious world, efficient power monitoring is crucial. Imagine a city where energy consumption is optimized in real-time, reducing waste and enhancing grid stability. This vision is made possible by sophisticated communication boards that form the backbone of power monitoring systems. Zero One Solution Limited offers cutting-edge PCB solutions for power monitoring communication, enabling seamless data transfer and control in diverse applications. This article delves into the intricacies of these solutions, exploring their design, functionality, and impact on modern energy management.

Introduction to Power Monitoring Communication Boards

Power monitoring communication boards are the neural centers of modern energy management systems, enabling precise data acquisition, efficient transmission, and robust control within diverse electrical infrastructures. These specialized printed circuit boards (PCBs) act as the critical interface between physical electrical parameters—such as voltage, current, power factor, and energy consumption—and digital processing units, facilitating real-time insights and informed decision-time decision-making for enhanced operational efficiency and resource optimization. They are indispensable for applications ranging from smart grids and industrial automation to renewable energy systems and commercial building management, ensuring reliable and secure data flow for critical power system insights.

- What are Power Monitoring Systems?

Power monitoring systems are integrated solutions designed to measure, collect, and analyze electrical parameters within a given facility or network. Their primary goal is to optimize energy consumption, enhance grid stability, detect anomalies, and facilitate predictive maintenance by providing real-time and historical data on power quality and usage. - Why are Communication Boards Essential in Power Monitoring?

Communication boards are essential because they bridge the gap between analog electrical signals and digital communication networks. They convert raw electrical data into a usable digital format, manage data buffering and processing, and facilitate secure, reliable transmission to central monitoring stations or cloud platforms. Without these boards, the valuable data collected by sensors would remain isolated and unusable for systemic analysis and control. - What is the Core Function of a Power Monitoring Communication Board?

The core function of a power monitoring communication board involves three key aspects: data acquisition (collecting electrical parameters from sensors), data transmission (sending processed data via various communication protocols to a central system), and control (receiving commands from a central system to actuate devices or modify system parameters). This enables comprehensive oversight and active management of power assets. - How do Communication Boards Enhance Energy Efficiency?

Communication boards enhance energy efficiency by providing granular data on power consumption patterns, identifying areas of energy waste, and enabling demand-side management. By offering insights into peak usage times, anomalous power draws, and the performance of individual loads, they empower facility managers and grid operators to implement targeted optimization strategies, leading to significant energy savings and reduced operational costs. - What Role Do Communication Boards Play in Grid Stability?

In smart grids, communication boards are vital for maintaining stability by enabling real-time fault detection, load balancing, and dynamic response to supply-demand fluctuations. They facilitate rapid data exchange between distributed energy resources, substations, and control centers, allowing for swift corrective actions during disturbances, preventing blackouts, and ensuring a resilient power supply. This interconnectedness is fundamental for the reliable operation of modern power infrastructure.

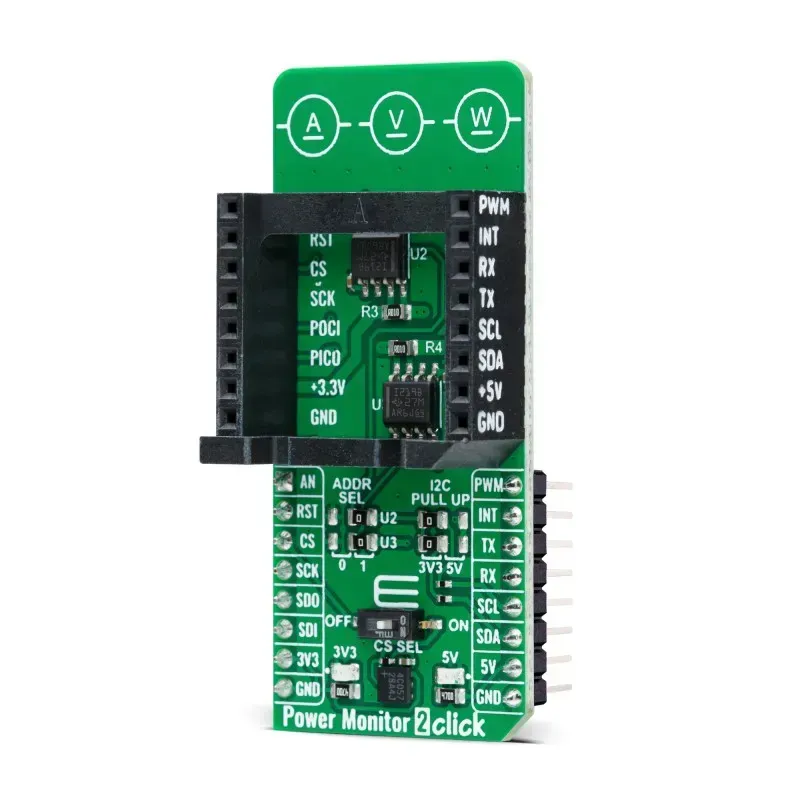

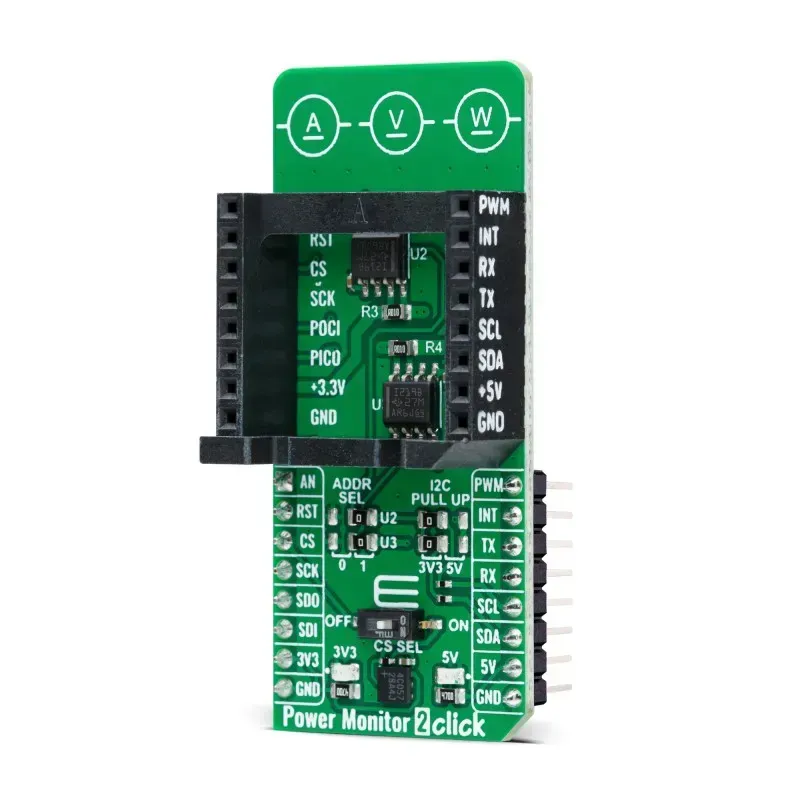

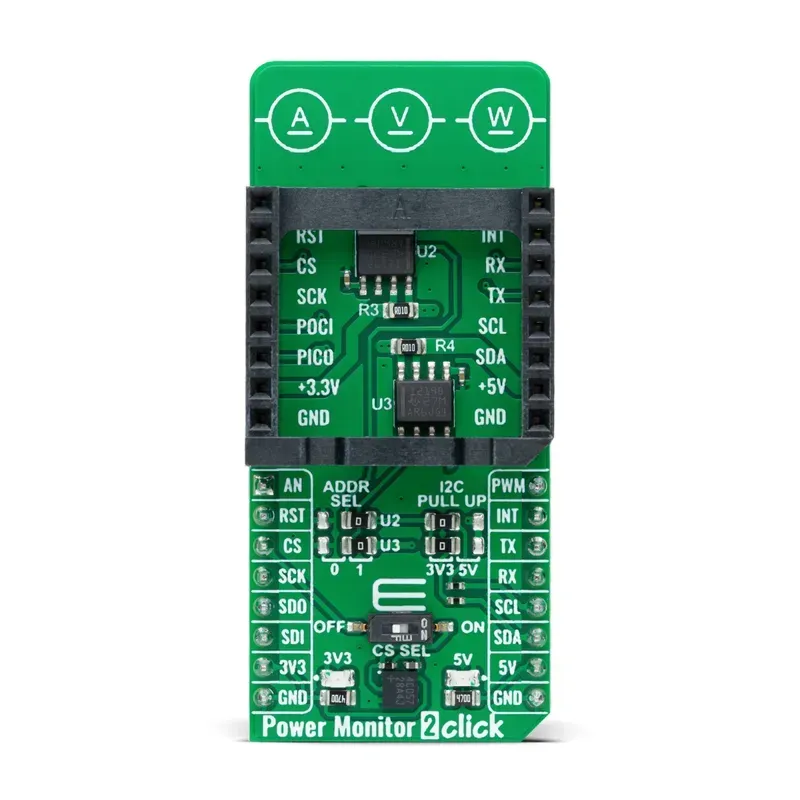

Key Components of a Power Monitoring Communication Board

A robust power monitoring communication board is engineered with a precise selection of components, each playing a critical role in data acquisition, processing, and reliable transmission. Understanding these core elements is fundamental to appreciating the board's functionality and its ability to deliver accurate and actionable insights into power consumption and quality.

| Component Type | Primary Function | Key Specification Considerations | Impact on Performance | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Microcontroller (MCU) | The brain of the board, processing data from sensors, managing communication protocols, and controlling peripheral operations. | Processing speed (MHz), Flash/RAM size, Peripherals (SPI, I2C, UART), Power consumption. | Determines data processing capability and response time. A powerful MCU can handle complex algorithms and multiple communication tasks simultaneously, crucial for real-time monitoring and advanced analytics. Zero One Solution recommends high-performance, low-power MCUs like ARM Cortex-M series for optimal balance. | Responsible for converting analog sensor signals (voltage, current) into digital data for the MCU. The resolution (bits) and sampling rate (samples/second) are crucial. | Resolution (e.g., 16-bit, 24-bit), Sampling rate, Number of channels, Input voltage range, Noise performance. | Directly impacts the accuracy and precision of measured power parameters. Higher resolution ADCs provide finer detail in readings, essential for detecting subtle anomalies or precise energy accounting. Our designs often incorporate 24-bit ADCs for superior data fidelity. | Enables data exchange with external systems (e.g., cloud platforms, SCADA). Includes Ethernet, Wi-Fi, Cellular (4G/5G), and Serial interfaces. | Data rate, Range, Reliability, Security features, Power efficiency, Protocol support (e.g., TCP/IP, MQTT, Modbus). | Crucial for network connectivity and remote monitoring. Ethernet offers high bandwidth and reliability for local networks, while Wi-Fi provides flexible wireless deployment. Cellular is vital for remote sites without wired infrastructure. Zero One Solution integrates modules optimized for industrial environments, ensuring robust and secure data transfer. | Regulates and distributes power to all components on the board, ensuring stable voltage levels and protecting against overcurrent/overvoltage. | Efficiency (%), Input voltage range, Output voltage accuracy, Ripple and noise, Over-current protection (OCP), Over-voltage protection (OVP). | Ensures stable and reliable operation of the entire board. High-efficiency power management minimizes heat generation and extends component lifespan. Our designs incorporate robust DC-DC converters and LDOs tailored for industrial reliability and efficiency. | Provides isolated communication, protecting the MCU from electrical noise and voltage spikes from the power system. | Isolation voltage, Data rate, Common Mode Transient Immunity (CMTI). | Essential for safety and signal integrity in harsh electrical environments, preventing ground loops and protecting sensitive electronics from transient events. Zero One Solution prioritizes robust isolation solutions meeting industrial safety standards. |

Zero One Solution Limited leverages its deep expertise in PCB design and manufacturing to meticulously select and integrate these components, ensuring that every Power Monitoring Communication Board we deliver meets the highest standards of performance, reliability, and precision. Our rapid prototyping capabilities allow for quick iteration and optimization of component selection to meet unique client specifications.

Communication Protocols for Power Monitoring

Effective power monitoring relies critically on robust and standardized communication protocols. These digital languages facilitate the seamless exchange of real-time data between power meters, sensors, and central monitoring systems, ensuring accurate insights for optimizing energy consumption, predictive maintenance, and operational efficiency. Choosing the right protocol is paramount, impacting system interoperability, data integrity, and the overall scalability of your power monitoring solution.

| Protocol | Description | Typical Application | Advantages | Disadvantages |

|---|---|---|---|---|

| Modbus | A serial communication protocol widely used for connecting electronic industrial devices. | Industrial automation, SCADA systems, building management. | Simplicity, widespread adoption, low overhead. | Limited data capacity, lacks advanced security features natively, slower for large networks if not optimized. |

| Protocol | Description | Typical Application | Advantages | Disadvantages |

|---|---|---|---|---|

| DNP3 (Distributed Network Protocol 3) | An open, standards-based communication protocol used in electric utility automation systems. | Electric utility grids, water and wastewater management. | Robust for wide area networks, handles large data sets, strong error checking. | More complex to implement than Modbus, higher overhead. |

| Protocol | Description | Typical Application | Advantages | Disadvantages |

|---|---|---|---|---|

| IEC 61850 | An international standard for communication networks and systems in substations, designed for smart grid applications. | Substation automation, smart grids, renewable energy integration. | Interoperability, high-speed communication, supports advanced functions like GOOSE messages and SV, future-proof. | Highly complex, requires specialized knowledge for implementation, higher cost. |

Selecting the appropriate communication protocol involves a detailed assessment of your application's specific requirements, including data volume, required speed, network topology, security needs, and budget. While Modbus offers simplicity and broad compatibility for many industrial settings, DNP3 provides a more robust solution for critical infrastructure. For the cutting-edge demands of smart grids and high-speed substation communication, IEC 61850 stands as the gold standard. Zero One Solution Limited's expertise in PCB design and integration ensures that your power monitoring communication boards are engineered to flawlessly support these diverse protocols, enabling optimal performance and seamless integration into your existing or future energy management infrastructure.

PCB Design Considerations for Power Monitoring Communication Boards

Designing Printed Circuit Boards (PCBs) for power monitoring communication boards requires meticulous attention to several critical aspects to ensure reliable performance, data accuracy, and system longevity. As a leading PCB solution provider specializing in rapid prototyping, Zero One Solution Limited understands that robust PCB design is the bedrock of a high-performance power monitoring system. This section delves into the fundamental design considerations that engineers must address, covering signal integrity, power distribution, thermal management, and electromagnetic compatibility (EMC).

- Signal Integrity in Power Monitoring Boards

Maintaining signal integrity is paramount for accurate data acquisition in power monitoring applications. This involves careful impedance matching, proper routing of high-speed digital and sensitive analog signals, minimizing crosstalk between traces, and employing ground planes to reduce noise. For boards handling power data, especially with high-resolution ADCs, any degradation in signal quality can lead to erroneous readings, impacting the reliability of the entire monitoring system. - Optimizing Power Distribution Networks (PDN)

An efficient Power Distribution Network (PDN) is crucial for stable operation of all components on the board, particularly microcontrollers and communication interfaces. Design considerations include using appropriate trace widths for current handling, strategic placement of decoupling capacitors to filter noise and provide instantaneous current bursts, and implementing dedicated power planes to minimize voltage drops and ensure clean power delivery across the board. - Thermal Management Strategies

Power monitoring communication boards often operate continuously, generating heat from active components like microcontrollers, voltage regulators, and communication modules. Effective thermal management prevents component overheating, which can lead to reduced performance, accelerated aging, and system failure. Strategies include incorporating thermal vias, using copper pours for heat dissipation, selecting components with lower power dissipation, and, in some cases, integrating heat sinks or active cooling solutions depending on the power density. - Ensuring Electromagnetic Compatibility (EMC)

Electromagnetic Compatibility (EMC) is vital to prevent the board from interfering with other electronic systems and to ensure its immunity to external electromagnetic interference. This involves careful PCB layout practices such as proper grounding techniques, shielding sensitive traces, filtering input/output lines, and selecting components that meet EMC standards. In industrial environments, where electromagnetic noise is prevalent, robust EMC design is non-negotiable for reliable operation.

| Design Aspect | Key Consideration | Impact on Performance |

|---|---|---|

| Signal Integrity | Impedance matching, trace routing, ground planes | Ensures accurate data acquisition and reliable communication |

| Power Distribution | Trace width, decoupling capacitors, power planes | Provides stable power, minimizes voltage drops, reduces noise |

| Thermal Management | Thermal vias, copper pours, component selection | Prevents overheating, extends component lifespan, maintains stability |

| EMC Compliance | Grounding, shielding, filtering, component selection | Reduces interference, ensures system reliability in noisy environments |

Zero One Solution's Power Monitoring Communication Board Solutions

At Zero One Solution Limited, we don't just provide PCBs; we deliver comprehensive, high-performance power monitoring communication board solutions meticulously engineered to meet the stringent demands of modern energy management. Our decade-plus expertise in rapid prototyping, coupled with a deep understanding of power electronics and communication protocols, positions us as your ideal partner for accelerating product development and ensuring optimal system performance in critical power applications.

- Rapid Prototyping Excellence

We specialize in rapid-response R&D prototype manufacturing, drastically cutting down development cycles for your power monitoring communication boards. Our streamlined processes and advanced facilities enable quick turnaround without compromising on quality or precision, ensuring your innovative solutions reach the market faster. - Comprehensive PCB Design and Layout Services

Our seasoned engineering team offers end-to-end PCB design services, specifically optimized for power monitoring communication boards. This includes meticulous consideration of signal integrity for high-speed data, efficient power distribution networks, robust thermal management, and strict adherence to electromagnetic compatibility (EMC) standards, crucial for reliable performance in harsh industrial environments. We leverage cutting-edge design software and simulation tools to minimize risks and ensure first-pass success. - Advanced Manufacturing Capabilities

Utilizing state-of-the-art manufacturing facilities, Zero One Solution produces high-quality PCBs tailored for power monitoring applications. We handle a wide range of materials and layer counts, ensuring durability and performance under diverse operational conditions. Our manufacturing processes are rigorously controlled to meet industry standards, delivering boards with superior reliability and longevity. - Precision Assembly Services (PCBA)

Beyond manufacturing, we provide precision PCB assembly (PCBA) services, ensuring accurate component placement and robust soldering. Our automated assembly lines and stringent quality control protocols guarantee the integrity and functionality of every power monitoring communication board. We are adept at handling various package types, including fine-pitch components and BGA assemblies, which are common in sophisticated communication interfaces. - Customization and Scalability

Understanding that each power monitoring application has unique requirements, Zero One Solution offers extensive customization options for our communication board solutions. From bespoke communication interfaces and specialized sensor integration to specific form factors and environmental ruggedization, we tailor solutions to your exact specifications. Our flexible production capabilities support scalability from low-volume prototypes to high-volume production runs, adapting seamlessly to your project's evolving needs.

| Service Aspect | Zero One Solution's Advantage | Benefit to Client |

|---|---|---|

| Rapid Prototyping | Accelerated development cycles, agile iteration | Faster time-to-market, reduced R&D costs |

| PCB Design Optimization | Signal integrity, thermal, EMC expertise | Enhanced reliability, robust performance, regulatory compliance |

| Advanced Manufacturing | High-quality materials, stringent process control | Increased product lifespan, consistent quality |

| Precision Assembly | Automated SMT, comprehensive testing | Reduced assembly defects, high functional yield |

| Customization & Scalability | Tailored solutions, flexible production volumes | Exact fit for unique applications, seamless growth support |

Applications of Power Monitoring Communication Boards

Power monitoring communication boards are indispensable in modern infrastructure, serving as the connective tissue that enables real-time data acquisition and control across a multitude of sectors. These specialized PCBs are engineered to translate raw power data into actionable insights, facilitating intelligent decision-making, optimizing energy consumption, and enhancing operational efficiency within complex systems. From ensuring grid stability to maximizing the output of renewable energy assets, their versatile applications underscore their critical role in the ongoing global transition towards more intelligent and sustainable energy management.

- Smart Grids and Energy Distribution

In smart grid infrastructures, power monitoring communication boards are crucial for real-time monitoring of voltage, current, frequency, and power factor across substations and distribution networks. They enable fault detection, load balancing, and demand-side management, ensuring grid stability and efficient energy delivery. For instance, in a microgrid scenario, these boards facilitate the seamless integration and management of diverse energy sources, optimizing power flow and enhancing resilience against outages. - Industrial Automation and Process Control

Within industrial environments, these boards are vital for monitoring power consumption of machinery, production lines, and HVAC systems. By providing precise data on energy usage, they help identify inefficiencies, prevent equipment failures, and optimize operational costs. This leads to predictive maintenance capabilities and improved overall equipment effectiveness (OEE), as seen in large-scale manufacturing plants where energy is a significant operational expenditure. - Renewable Energy Systems Integration

For solar farms, wind turbines, and other renewable energy installations, power monitoring communication boards are essential for tracking energy generation, battery storage levels, and grid interconnection status. They facilitate maximum power point tracking (MPPT) for solar arrays and optimize wind turbine performance, ensuring the most efficient capture and utilization of renewable resources. This is particularly important for grid-tied systems where stable and reliable energy contribution is paramount. - Building Energy Management Systems (BEMS)

In commercial and residential buildings, these boards form the backbone of BEMS, enabling granular monitoring of energy consumption across various zones and appliances. This data empowers building managers to implement energy-saving strategies, optimize lighting and HVAC schedules, and comply with energy efficiency regulations. For example, in a smart office building, a power monitoring system can identify peak consumption periods and automatically adjust climate controls to reduce energy waste. - Data Centers and IT Infrastructure

Data centers rely heavily on continuous and reliable power. Power monitoring communication boards enable detailed tracking of power usage effectiveness (PUE), identifying potential hotspots and ensuring efficient power distribution to server racks. This granular visibility helps prevent overloads, optimize cooling strategies, and ultimately reduce operational costs while maintaining high availability for critical IT services.

Benefits of Using a Dedicated Communication Board

A dedicated communication board is fundamental to unlocking the full potential of power monitoring systems, offering distinct advantages over integrated or ad-hoc solutions by centralizing and optimizing data flow. Such specialized boards are engineered to provide superior performance, reliability, and security, directly addressing the critical demands of modern energy management and control.

- Improved Data Accuracy and Reliability

Dedicated boards are designed with optimized signal paths and robust noise suppression, minimizing interference and ensuring the integrity of critical power data. This translates to more precise measurements of voltage, current, power factor, and energy consumption, which are crucial for accurate billing, predictive maintenance, and operational efficiency. Integrated solutions often compromise on signal quality due to shared resources, leading to potential data corruption and unreliable insights. For example, in a smart grid application, even minor inaccuracies in power data can lead to significant grid instability or misallocation of resources. A dedicated board ensures the fidelity of every data point, from acquisition to transmission, supporting data-driven decision-making with high confidence. According to a study by MarketsandMarkets, the demand for high-accuracy power monitoring solutions is directly proportional to the growth of smart grid initiatives, underscoring the value of dedicated communication hardware. - Faster Response Times and Enhanced Performance

Purpose-built communication boards feature optimized hardware and firmware, leading to significantly reduced latency in data acquisition and transmission. This enables real-time monitoring and rapid response to dynamic power conditions, such as sudden load changes or fault events. In industrial automation, fast response times are critical for preventing equipment damage and ensuring continuous operation. For instance, a dedicated board can process and transmit an overcurrent alert within milliseconds, allowing immediate circuit breaker trip, thereby preventing costly equipment failure. This agility is often unachievable with multi-purpose embedded systems, which face processing bottlenecks and resource contention. The ability to react swiftly to power anomalies is paramount for maintaining system stability and preventing cascading failures in complex electrical infrastructures. The IEEE 2030.5 standard for Smart Energy specifies stringent requirements for response times in grid communication, which dedicated boards are inherently designed to meet or exceed.

| Feature | Dedicated Communication Board | Integrated/Generic Solution |

|---|---|---|

| Data Accuracy | High (Optimized signal paths, noise suppression) | Moderate (Compromised due to shared resources, potential interference) |

| Response Time | Very Fast (Optimized hardware & firmware) | Slower (Processing bottlenecks, resource contention) |

| Security Features | Advanced (Hardware-level encryption, secure boot) | Basic (Software-based, more vulnerable) |

| Complexity | Reduced System Complexity (Streamlined integration) | Increased System Complexity (Integration challenges, custom development) |

| Reliability | High (Robust design for specific application) | Moderate (General-purpose design, less optimized) |

- Enhanced Security Protocols

Security is paramount in power monitoring, especially in critical infrastructure. Dedicated communication boards can incorporate hardware-level security features, including secure boot, encrypted communication modules, and tamper detection. This provides a robust defense against cyber threats, unauthorized access, and data manipulation, safeguarding sensitive operational data and preventing malicious control. Generic communication modules often rely solely on software-based security, which can be more susceptible to sophisticated attacks. For instance, in an energy management system, a dedicated board ensures that consumption data and control commands are transmitted securely, protecting against espionage or sabotage. The adherence to standards like IEC 62443 for industrial cybersecurity is more readily achieved with purpose-built hardware, offering peace of mind in an increasingly interconnected world.

- Reduced System Complexity and Integration Effort

Utilizing a dedicated communication board simplifies overall system design and integration. These boards are pre-configured and optimized for specific power monitoring tasks, often with well-defined interfaces and drivers. This reduces the need for extensive custom development and debugging, accelerating time-to-market. Instead of integrating multiple discrete components and managing complex software layers, engineers can leverage a unified solution. For example, a dedicated board bundles the microcontroller, communication interface, and specific ADCs required for power measurement onto a single PCB, significantly streamlining the bill of materials (BOM) and assembly process. This contrasts with assembling a solution from general-purpose components, which demands more engineering effort and introduces potential compatibility issues. Zero One Solution Limited's expertise in providing integrated PCB solutions further amplifies this benefit, offering a seamless path from design to manufacturing.

Future Trends in Power Monitoring Communication Technology

The landscape of power monitoring communication technology is undergoing rapid evolution, driven by the relentless pursuit of greater efficiency, reliability, and intelligence in energy management. Key trends are shaping the next generation of solutions, pushing towards more decentralized processing, ubiquitous connectivity, and predictive analytics to optimize energy consumption and grid stability.

- Wireless Communication for Enhanced Flexibility

The adoption of wireless communication technologies, such as LoRaWAN, NB-IoT, and 5G, is set to revolutionize power monitoring. These technologies offer unparalleled flexibility in deployment, reduce cabling costs, and enable monitoring in hard-to-reach or geographically dispersed locations. This shift moves away from traditional wired solutions, facilitating faster and more scalable implementations for smart grids and distributed energy resources. For instance, a recent report by Grand View Research projected the global smart grid communication market size to reach USD 58.7 billion by 2028, with wireless technologies being a significant growth driver. - Edge Computing for Real-time Insights

Edge computing is poised to bring data processing closer to the source of power generation and consumption. By enabling real-time data analysis at the edge, latency is significantly reduced, critical decisions can be made instantaneously, and network bandwidth requirements are minimized. This is particularly crucial for applications requiring immediate fault detection, load balancing, or predictive maintenance, transforming raw data into actionable intelligence without relying solely on cloud connectivity. This paradigm shift enhances the responsiveness and resilience of power monitoring systems. - Artificial Intelligence (AI) Integration for Predictive Analytics

The integration of Artificial Intelligence (AI) and Machine Learning (ML) algorithms is transforming power monitoring from reactive to proactive. AI can analyze vast datasets from power monitoring boards to identify patterns, predict equipment failures, optimize energy consumption, and detect anomalies that human operators might miss. This leads to more efficient energy management, reduced downtime, and significant cost savings. For example, AI-powered predictive maintenance in industrial power systems can reduce unexpected outages by up to 70% and cut maintenance costs by 20-30%, according to a study by Accenture. - Cybersecurity as a Paramount Concern

As power monitoring systems become more interconnected and sophisticated, cybersecurity will remain a critical trend. Protecting sensitive energy data and control systems from cyber threats is paramount. Future communication boards will incorporate advanced encryption, authentication protocols, and intrusion detection systems to ensure the integrity and security of the power grid. This includes hardware-level security features and robust software frameworks designed to withstand evolving cyber risks, ensuring the reliability of critical infrastructure. - Interoperability and Open Standards

The drive towards greater interoperability through open standards will continue to be a significant trend. This ensures that different components and systems from various vendors can seamlessly communicate and integrate within a broader power monitoring ecosystem. Adherence to standards like IEC 61850 and continued development of new, open APIs will foster innovation, reduce vendor lock-in, and accelerate the deployment of comprehensive power monitoring solutions across diverse applications.

Frequently Asked Questions (FAQs) on Power Monitoring Communication Boards

- What is the primary function of a power monitoring communication board?

The primary function of a power monitoring communication board is to accurately acquire, process, and transmit electrical data (such as voltage, current, power, and energy consumption) from various points within a power system to a central monitoring or control unit. This enables real-time insights, analysis, and management of energy usage and system performance, crucial for optimizing efficiency and preventing issues like overload or downtime. It acts as the critical bridge between sensors and data analysis platforms, ensuring reliable data flow for informed decision-making in power management systems and is essential for effective energy management, predictive maintenance, and overall system optimization, ensuring efficient and reliable power distribution across diverse applications, from smart grids to industrial automation and renewable energy systems. The board's design prioritizes robust data acquisition, secure transmission, and interoperability with various communication protocols, ensuring seamless integration into complex power infrastructure.

In conclusion, Power Monitoring Communication Board Solutions are essential for building smart grids and optimizing energy consumption. Zero One Solution Limited is at the forefront of providing innovative PCB solutions that empower businesses and communities to achieve greater energy efficiency and reliability. Contact us today to discover how our expertise can transform your power monitoring infrastructure and drive a more sustainable future.

AnyPCBA

AnyPCBA