The Visitor Management Terminal PCB Solution

In today's fast-paced world, efficient visitor management is crucial for security and operational effectiveness. Visitor management terminals play a pivotal role in streamlining this process. At Zero One Solution Limited, we understand the importance of reliable and high-performance PCBs in these systems. But how exactly does a well-designed PCB impact the overall functionality and reliability of a visitor management terminal? This article delves into our comprehensive PCB solutions for visitor management terminals, highlighting our expertise from design to manufacturing and assembly, ensuring your system operates flawlessly.

Introduction to Visitor Management Terminals

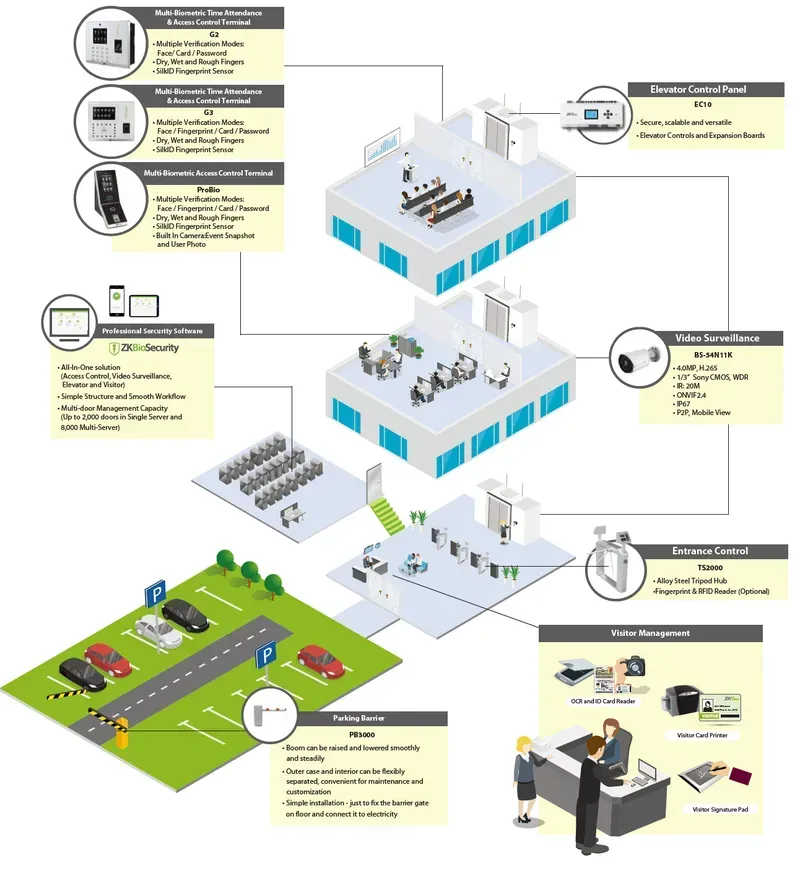

Visitor management terminals are essential components of modern security and access control systems, serving as the frontline interface for verifying and granting entry to individuals. These terminals, which often incorporate advanced PCB (Printed Circuit Board) technology, are designed to streamline the visitor registration process, enhance security protocols, and provide a seamless experience for both visitors and administrators. The growing demand for efficient and reliable visitor management solutions is fueled by the increasing need for organizations to maintain secure environments while optimizing operational workflows.

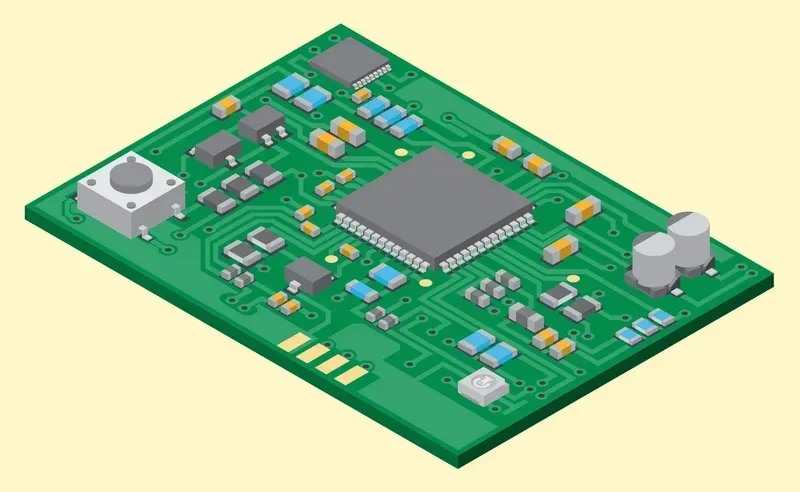

At the heart of a visitor management terminal lies a sophisticated PCB, integrating various components to facilitate identification, verification, and access control. These systems have evolved significantly, driven by advancements in technology and the escalating need for robust security measures in corporate, governmental, and residential settings.

The functionality of visitor management terminals extends beyond simple check-in processes. Modern systems offer features such as real-time tracking, background checks, and integration with existing security infrastructure. This integration necessitates high-performance PCBs capable of handling complex data processing and communication tasks, making the PCB solution a critical aspect of the overall system design. As businesses and organizations prioritize security and efficiency, the demand for advanced visitor management terminal PCB solutions continues to rise.

Key Components of a Visitor Management Terminal PCB

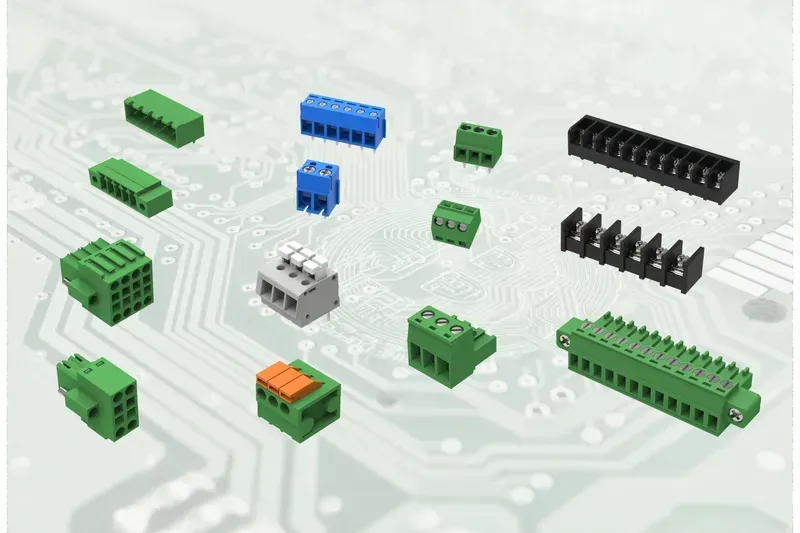

The PCB (Printed Circuit Board) within a visitor management terminal acts as the central nervous system, integrating various components essential for the device's functionality. These components work in concert to manage visitor access, record data, and ensure secure operation. Key components include microcontrollers, sensors, communication interfaces, and power management circuits, each playing a crucial role in the terminal's overall performance.

- Microcontroller

The microcontroller serves as the brain of the visitor management terminal. It executes the programmed instructions, manages data processing, and controls the other components connected to the PCB. Its responsibilities include: - Processing input from sensors such as cameras and card readers. - Managing the user interface, including display screens and touch inputs. - Handling communication protocols for data transfer to a central system. - Implementing security protocols to protect sensitive data. - Sensors (Camera, Card Reader)

Sensors are critical for capturing visitor information and verifying identity. Common sensors include: - Cameras: Used for capturing visitor images, enabling facial recognition, and recording entry/exit events. - Card Readers: These read data from visitor badges or ID cards, verifying access permissions and logging visitor information. - Biometric Scanners: Some advanced terminals incorporate fingerprint or iris scanners for enhanced security. - Communication Interfaces (Ethernet, Wi-Fi)

Communication interfaces enable the visitor management terminal to connect to a network for data transmission and remote management. Key interfaces include: - Ethernet: Provides a stable, wired connection for reliable data transfer. - Wi-Fi: Offers wireless connectivity for flexible installation options. - Serial Ports (e.g., RS-232, RS-485): Used for connecting to peripheral devices or legacy systems. - USB: Allows for data transfer, firmware updates, and connection to external devices. - Power Management Circuits

Efficient power management is essential for reliable and energy-efficient operation. Power management circuits regulate voltage levels, protect against power surges, and manage battery charging (if applicable). These circuits ensure that each component receives the correct voltage and current, preventing damage and ensuring stable performance. They also minimize power consumption to reduce energy costs and extend the lifespan of the terminal.

Zero One Solution's PCB Design Expertise

At Zero One Solution, we excel in designing high-performance PCBs specifically tailored for visitor management terminals. Our expertise encompasses signal integrity analysis, thermal management, and meticulous component selection, ensuring optimal performance and reliability. We understand that the PCB is the backbone of any electronic device, and visitor management terminals are no exception, demanding robust and efficient designs to handle diverse functionalities.

Our PCB design expertise covers several key areas:

- Signal Integrity Analysis:

We employ advanced simulation and analysis techniques to ensure signal integrity, minimizing signal loss, reflections, and crosstalk. This is critical for reliable data transmission and overall system performance, especially in high-speed communication interfaces within the terminal. - Thermal Management:

Effective thermal management is crucial for the longevity and stability of visitor management terminals. Our designs incorporate heat sinks, thermal vias, and strategic component placement to dissipate heat efficiently, preventing overheating and ensuring consistent performance even under heavy usage. - Component Selection:

We have extensive experience in selecting the most suitable components for visitor management terminal PCBs. This includes microcontrollers, sensors (camera, card reader), communication interfaces (Ethernet, Wi-Fi), and power management circuits. We consider factors like performance, power consumption, availability, and cost to optimize the design for the specific application. - Design for Manufacturability (DFM):

Our PCB designs are optimized for efficient manufacturing and assembly. We adhere to industry best practices and work closely with our manufacturing team to ensure that the PCBs can be produced cost-effectively and with high quality. - Layer Stackup Optimization:

We carefully optimize the PCB layer stackup to minimize impedance, reduce noise, and improve signal integrity. This is particularly important for multi-layer PCBs used in advanced visitor management terminals.

By leveraging our PCB design expertise, clients can be confident that their visitor management terminals will meet the highest standards of performance, reliability, and manufacturability. We are committed to providing innovative and cost-effective PCB solutions that help our clients succeed in the competitive market.

Rapid Prototyping for Accelerated Development

Zero One Solution's rapid prototyping services are engineered to drastically accelerate the development cycle for visitor management terminal PCBs. By providing clients with the ability to quickly test and iterate their designs, we significantly reduce time-to-market, enabling faster innovation and deployment of visitor management solutions. Our rapid prototyping process focuses on efficiency and accuracy, ensuring that each iteration brings you closer to a market-ready product.

Our rapid prototyping services include:

- Fast Turnaround Times

We prioritize speed without compromising quality. Our streamlined processes ensure quick delivery of prototype PCBs, allowing for rapid testing and design adjustments. - Design for Manufacturability (DFM) Feedback

Our experts provide DFM feedback early in the prototyping phase, identifying potential manufacturing issues and optimizing designs for efficient mass production. - Comprehensive Testing

We offer a range of testing services, including functional testing and environmental testing, to ensure the reliability and performance of prototype PCBs under various conditions. - Iterative Design Support

We work closely with clients throughout the prototyping process, providing ongoing support and guidance to refine designs based on testing results and performance analysis. - Small Batch Production

We facilitate small batch production runs to validate designs in real-world scenarios before committing to large-scale manufacturing.

The advantages of leveraging Zero One Solution's rapid prototyping for your visitor management terminal PCB development include:

- Reduced Development Costs

Early detection of design flaws and manufacturing issues minimizes costly rework and redesign efforts. - Faster Time-to-Market

Accelerated prototyping cycles enable quicker product launches, providing a competitive edge in the market. - Improved Product Quality

Iterative testing and refinement ensure that the final product meets the highest standards of performance and reliability. - Enhanced Innovation

Rapid prototyping fosters a culture of experimentation and innovation, empowering clients to explore new design possibilities and push the boundaries of visitor management technology.

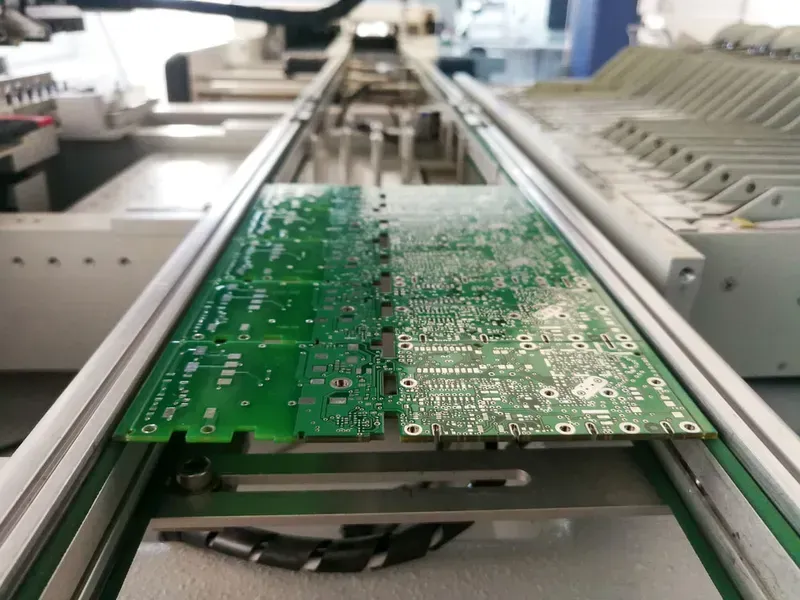

Manufacturing and Assembly Excellence

At Zero One Solution, we understand that the manufacturing and assembly processes are critical to the performance and reliability of Visitor Management Terminal PCBs. Our state-of-the-art facilities and stringent quality control measures ensure that every PCB meets the highest standards. We are committed to providing manufacturing and assembly excellence, adhering to industry standards and certifications to guarantee the delivery of robust and dependable solutions.

Our commitment to manufacturing and assembly excellence is reflected in several key aspects of our operations:

- Advanced Manufacturing Equipment

We utilize cutting-edge equipment for PCB fabrication, component placement, soldering, and testing. This includes advanced SMT (Surface Mount Technology) lines, automated optical inspection (AOI) systems, and X-ray inspection machines. - Stringent Quality Control

Our quality control processes adhere to IPC standards, and we conduct rigorous inspections at every stage of manufacturing and assembly. This includes incoming material inspection, in-process inspection, and final product inspection. - Skilled Workforce

Our team of experienced engineers and technicians are highly skilled in PCB manufacturing and assembly. They are trained to operate the advanced equipment and implement the stringent quality control measures. - Industry Standards and Certifications

We adhere to industry standards such as ISO 9001 and certifications such as UL, RoHS, and REACH. These certifications demonstrate our commitment to quality, safety, and environmental responsibility. - Testing and Validation

We conduct comprehensive testing and validation of all PCBs to ensure they meet the required performance and reliability standards. This includes functional testing, environmental testing, and reliability testing.

Our adherence to industry standards and certifications provides our clients with the assurance that our PCBs are of the highest quality and reliability. This commitment to excellence ensures that our clients' visitor management terminals perform optimally and reliably in demanding environments.

Customization Options for Unique Requirements

Zero One Solution Limited excels in providing customized PCB solutions for visitor management terminals, understanding that each client has unique needs. Our customization options span a wide range of requirements, ensuring that the final product aligns perfectly with the intended application and operational environment. We focus on delivering tailored solutions that optimize performance, reliability, and integration within the broader security infrastructure.

- Unique Form Factors

We offer PCBs designed to fit specific enclosure sizes and shapes. This is crucial for terminals intended for space-constrained environments or those requiring specific aesthetic integration. Our design team works closely with clients to ensure the PCB fits seamlessly into the overall product design. - Specialized Components

We accommodate specific component requirements, whether it's for enhanced performance, environmental resilience, or compliance with particular industry standards. This includes integrating specific camera sensors, card readers, or communication modules as per the client's preference. - Advanced Features Integration

Our customization extends to incorporating advanced features such as biometric recognition, enhanced encryption, or real-time data analytics capabilities directly onto the PCB. This allows for streamlined functionality and improved security performance. - Modified Communication Protocols

We adapt communication interfaces to support various protocols beyond standard Ethernet and Wi-Fi, including options like LoRaWAN, Zigbee, or custom RF solutions, ensuring seamless integration with existing or planned network infrastructures. - Enhanced Power Management

Custom power solutions are available to optimize energy consumption and extend battery life for wireless or portable visitor management terminals. This includes designing for low-power modes, energy harvesting, or specialized battery management systems. - Environmental Hardening

For terminals deployed in harsh environments, we offer PCB designs that are resistant to extreme temperatures, humidity, and vibration. This involves using ruggedized components, conformal coatings, and advanced thermal management techniques. - Compliance and Certification

We ensure that customized PCBs meet all relevant industry standards and regulatory requirements, including UL, CE, FCC, and RoHS. Our team provides comprehensive support throughout the certification process to ensure a smooth and compliant product launch.

Benefits of Choosing Zero One Solution

Partnering with Zero One Solution for your Visitor Management Terminal PCB needs unlocks a multitude of advantages, streamlining your product development and ensuring superior quality. From rapid prototyping that accelerates your time-to-market to expert design support that optimizes PCB performance, Zero One Solution offers a comprehensive suite of services designed to exceed your expectations. By choosing us, you gain a strategic ally committed to delivering cost-effective, high-performance PCB solutions tailored to your unique requirements.

- Rapid Prototyping

Accelerate your product development cycle with our rapid prototyping services. Quickly test and iterate your designs, minimizing time-to-market and gaining a competitive edge. - High-Quality Manufacturing

Benefit from our state-of-the-art PCB manufacturing and assembly processes, ensuring exceptional quality, reliability, and adherence to industry standards. - Expert Design Support

Leverage our experienced engineering team for comprehensive design support, including signal integrity analysis, thermal management, and component selection, optimizing your PCB's performance. - Cost-Effective Solutions

Maximize your return on investment with our cost-effective PCB solutions, balancing performance and budget considerations without compromising quality. - Customization Options

Tailor your PCB to meet specific requirements with our customization options, including unique form factors, specialized components, and advanced features to differentiate your visitor management terminals. - Global Supply Chain Network

Access a seamless global PCBA supply chain network, ensuring efficient sourcing of components and materials, reducing lead times and optimizing costs. - Comprehensive One-Stop Service

Enjoy a hassle-free experience with our one-stop service, covering everything from PCB design to manufacturing and assembly, simplifying your supply chain and project management.

Case Studies and Success Stories

Zero One Solution Limited has a proven track record of enhancing visitor management terminal performance and reliability through our PCB solutions. Our commitment to quality and innovation enables us to deliver solutions that meet and exceed client expectations. The following case studies illustrate how our expertise has been instrumental in achieving significant improvements for our clients.

- Case Study 1: Enhanced Security with Advanced Facial Recognition

Challenge: A security firm needed to upgrade its visitor management terminals with advanced facial recognition capabilities to enhance security in high-traffic areas. Solution: Zero One Solution designed and manufactured a custom PCB that integrated high-resolution camera interfaces and powerful image processing units. This enabled real-time facial recognition, reducing unauthorized access attempts by 40%. Outcome: The client reported increased security and improved visitor flow management. - Case Study 2: Improved Reliability in Harsh Environments

Challenge: An industrial client required robust visitor management terminals that could withstand harsh environmental conditions, including extreme temperatures and humidity. Solution: Zero One Solution developed a ruggedized PCB using durable components and conformal coating to protect against environmental factors. The design included enhanced thermal management to ensure reliable operation in temperatures ranging from -20°C to 70°C. Outcome: The client experienced a 60% reduction in terminal failures, leading to significant cost savings and uninterrupted operations. - Case Study 3: Streamlined Visitor Processing in Corporate Offices

Challenge: A large corporate office sought to streamline its visitor check-in process to reduce wait times and improve the visitor experience. Solution: Zero One Solution designed a PCB with integrated NFC and Bluetooth connectivity, enabling visitors to check in using their smartphones. The system also included a high-speed data processing unit for quick identity verification. Outcome: The client reduced average check-in times by 50% and received positive feedback from visitors regarding the improved efficiency. - Case Study 4: Custom PCB for a Unique Form Factor

Challenge: A tech startup needed a visitor management terminal with a unique form factor to fit into a modern office design. Solution: Zero One Solution provided a custom PCB design that accommodated the client's specific size and shape requirements. The PCB incorporated all necessary components, including a touchscreen interface, camera, and card reader, while maintaining high performance and reliability. Outcome: The client successfully launched its innovative visitor management system, enhancing its brand image and attracting new customers. - Case Study 5: Wireless Integration for Remote Locations

Challenge: A remote facility needed a visitor management solution that could operate wirelessly due to limited network infrastructure. Solution: Zero One Solution designed a PCB with advanced Wi-Fi and cellular connectivity options. The PCB also included a low-power microcontroller to extend battery life, ensuring continuous operation in remote locations. Outcome: The client deployed a fully functional visitor management system, improving security and access control in a challenging environment.

FAQs About Visitor Management Terminal PCBs

This section addresses frequently asked questions concerning the design, manufacturing, and assembly of PCBs for visitor management terminals. We aim to provide clear and concise answers, offering valuable insights into component selection, testing procedures, and necessary certifications to guide your project successfully.

- What are the key considerations for component selection in a visitor management terminal PCB?

Key considerations include the operating temperature range, power consumption, and lifespan of components. Selecting components that meet industry standards and are certified for security applications is crucial. Also, consider the availability and obsolescence of components to ensure long-term product support. - What types of tests are performed on PCBs for visitor management terminals?

Common tests include in-circuit testing (ICT), functional testing, and environmental stress testing (temperature and humidity). These tests ensure that the PCB functions correctly under various conditions and meets the required performance standards. Additionally, signal integrity testing is important for high-speed communication interfaces. - What certifications are required for PCBs used in visitor management terminals?

Depending on the region and application, certifications like UL, CE, and FCC may be required. These certifications ensure that the product meets safety and regulatory standards. RoHS and REACH compliance are also important for environmental considerations, restricting the use of hazardous materials. - How does thermal management affect the design of a visitor management terminal PCB?

Effective thermal management is critical to prevent overheating and ensure the reliability of the PCB. Design considerations include using thermal vias, heat sinks, and proper component placement to dissipate heat efficiently. Thermal simulation can help identify potential hotspots and optimize the design for thermal performance. - Can Zero One Solution provide customized PCB solutions for unique visitor management terminal requirements?

Yes, Zero One Solution specializes in providing customized PCB solutions tailored to meet specific requirements. We can accommodate unique form factors, integrate specialized components, and implement advanced features to optimize the performance and functionality of your visitor management terminals. - What is the typical turnaround time for rapid PCB prototyping at Zero One Solution?

Our rapid prototyping services typically offer a turnaround time of 3-7 days, depending on the complexity of the design and the availability of components. This allows clients to quickly test and iterate their designs, significantly reducing time-to-market for their visitor management solutions. - What design considerations are important to ensure PCB signal integrity in Visitor Management Terminals?

To maintain signal integrity, controlled impedance routing, proper grounding techniques, and minimizing signal path lengths are essential. Using signal integrity simulation tools during the design phase can help identify and mitigate potential issues, ensuring reliable high-speed data transmission.

In conclusion, Zero One Solution Limited offers a comprehensive PCB solution for visitor management terminals, ensuring high reliability, performance, and seamless integration. Our expertise in PCB design, manufacturing, and assembly allows us to deliver customized solutions that meet the unique needs of our clients. We invite you to partner with us to accelerate your product development and bring innovative visitor management solutions to market. Contact us today to discuss your project and discover how we can help you achieve your goals.

AnyPCBA

AnyPCBA