The Smart Furniture Control PCB Solution

In today's rapidly evolving technological landscape, the integration of smart technology into everyday objects has become increasingly prevalent. One area experiencing significant innovation is the furniture industry, where 'smart furniture' is transforming how we interact with our living spaces. At the heart of this transformation lies the Smart Furniture Control PCB (Printed Circuit Board), a critical component that enables advanced functionalities such as automated adjustments, integrated lighting, and connectivity features. Zero One Solution Limited, a leading provider of PCB solutions, is at the forefront of this revolution, offering comprehensive services from PCB design to manufacturing and assembly. But what exactly makes a PCB 'smart', and how can the right PCB solution elevate your smart furniture designs to the next level? This article will delve into the world of Smart Furniture Control PCBs, exploring their design, applications, and the critical role they play in the future of home automation.

Introduction to Smart Furniture and PCB Control

Smart furniture represents a paradigm shift in how we interact with our living spaces, seamlessly blending technology and everyday objects to enhance convenience, comfort, and efficiency. At the heart of this innovation lies the Printed Circuit Board (PCB), a critical component that acts as the central nervous system, enabling the advanced functionalities that define smart furniture.

Smart furniture is more than just electronically enhanced furniture; it's about creating responsive and intuitive environments that adapt to the user's needs. The growth of smart furniture is driven by increasing urbanization, smaller living spaces, and a greater demand for multi-functional solutions. From adjustable desks that promote ergonomic well-being to integrated lighting systems that enhance ambiance, smart furniture is transforming homes and offices alike.

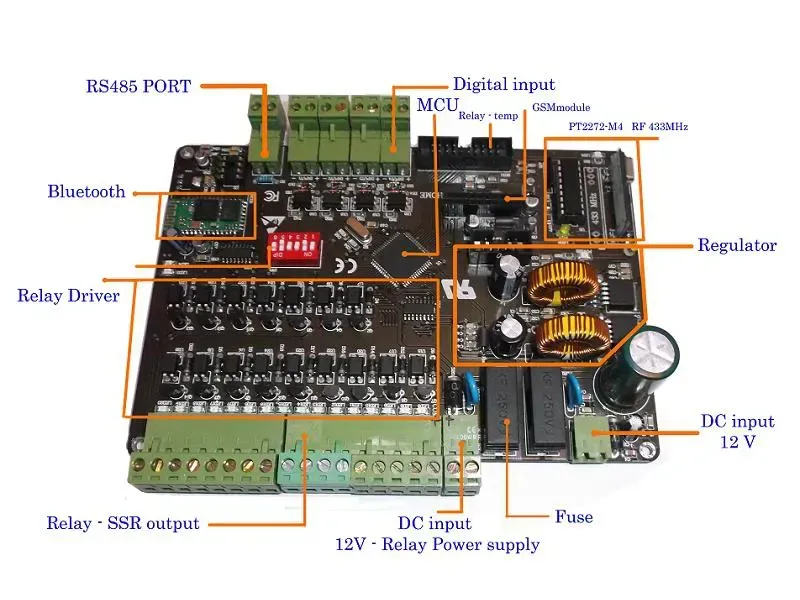

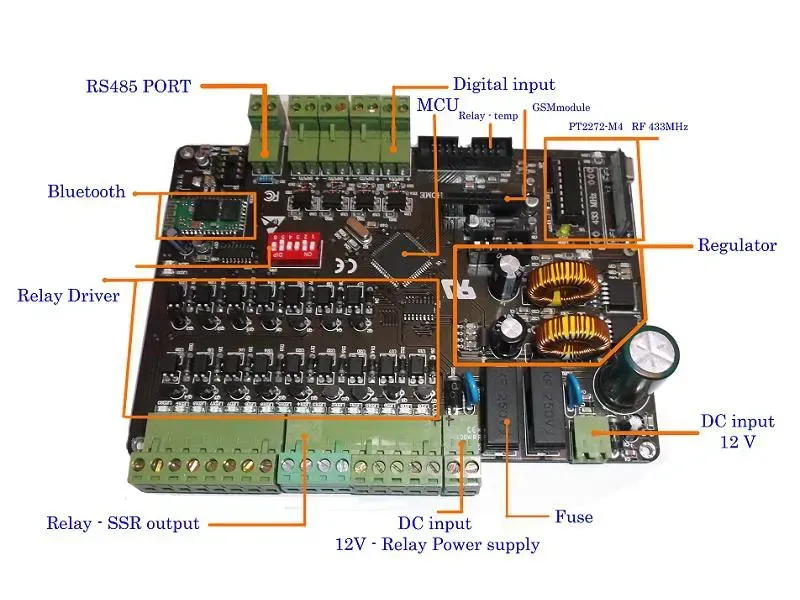

The PCB is the unsung hero of smart furniture, facilitating the integration of various technologies into a cohesive and functional unit. It provides the necessary electronic pathways and control mechanisms for features such as:

- Adjustable Height and Position

PCBs control motors and sensors to allow users to easily adjust the height and position of desks, chairs, and tables for optimal comfort and ergonomics. - Integrated Lighting

PCBs manage LED lighting systems, enabling dimming, color adjustments, and automated lighting based on time of day or user preferences. - Wireless Charging

PCBs facilitate wireless charging capabilities, allowing users to charge their devices by simply placing them on designated surfaces. - Connectivity Options

PCBs enable Bluetooth, Wi-Fi, and other connectivity options, allowing smart furniture to communicate with other smart devices and home automation systems. - Sensor Integration

PCBs support the integration of various sensors, such as occupancy sensors, temperature sensors, and air quality sensors, to provide real-time data and automated adjustments.

In essence, PCBs are the key enablers of the sophisticated features that define smart furniture, providing the necessary control, connectivity, and intelligence to create truly adaptive and user-centric environments.

Key Features Enabled by Smart Furniture Control PCBs

Smart furniture control PCBs unlock a range of features that significantly enhance user experience and convenience. These features, enabled by sophisticated PCB design and functionality, transform traditional furniture into interactive and responsive elements within the modern living space.

- Adjustable Height

Smart furniture, such as desks and tables, can be equipped with adjustable height functionality, allowing users to customize the furniture's height to their preference. This feature promotes better posture and ergonomics, reducing strain and discomfort during prolonged use. PCBs integrate sensors and motors to achieve precise and smooth height adjustments, enhancing user comfort and productivity. - Integrated Lighting

Incorporating LED lighting directly into furniture offers both aesthetic appeal and functional benefits. Smart furniture control PCBs enable dimming, color adjustments, and programmable lighting effects, creating ambiance and task-specific illumination. This integration reduces clutter and provides a seamless lighting solution, enhancing the overall environment. - Wireless Charging

Integrating wireless charging capabilities into furniture, such as nightstands and desks, allows users to conveniently charge their devices without the need for cables. Smart furniture control PCBs manage power distribution and charging protocols, ensuring safe and efficient wireless charging. This feature adds a layer of convenience, keeping devices charged and ready for use. - Connectivity Options

Smart furniture can be equipped with various connectivity options, including Bluetooth, Wi-Fi, and USB ports, allowing seamless integration with other smart devices and networks. Control PCBs manage these connections, enabling users to control furniture functions via smartphone apps or voice commands. This connectivity enhances the furniture's utility, making it an integral part of the smart home ecosystem. - Smart Storage Solutions

Advanced smart furniture incorporates intelligent storage solutions, such as motorized drawers and compartments, controlled by PCBs. These features enhance accessibility and organization, optimizing space utilization. Users can remotely control and monitor storage functions, adding a layer of security and convenience. - Environmental Monitoring

Some smart furniture includes sensors that monitor environmental conditions such as temperature, humidity, and air quality. The PCBs process this data, providing users with real-time feedback and enabling automated adjustments to maintain optimal comfort levels. This feature promotes a healthier living environment and enhances overall well-being.

PCB Design Considerations for Smart Furniture

Effective PCB design for smart furniture necessitates careful attention to several key considerations. Size constraints due to furniture aesthetics, efficient power management for battery-operated devices, effective heat dissipation to ensure user safety and component longevity, and judicious component selection for reliability are all paramount. Compact and efficient designs are essential to seamlessly integrate the PCB into the furniture while upholding both functionality and aesthetic appeal.

- What are the primary size constraints in designing PCBs for smart furniture?

Smart furniture often demands PCBs be as small and unobtrusive as possible to maintain the aesthetic design of the furniture. Designers must optimize component layout and consider multi-layer PCBs to minimize the board's footprint while accommodating all necessary components and functionalities. - How is power management handled in smart furniture PCBs, especially for battery-powered applications?

Efficient power management is crucial to maximize battery life in wireless smart furniture. This involves using low-power components, implementing power-saving modes, and carefully designing the power distribution network to minimize losses and ensure stable operation across different functional modes. - What strategies can be employed to manage heat dissipation in smart furniture PCBs?

Given the enclosed nature of furniture, heat dissipation can be a challenge. Strategies include using thermally conductive materials, incorporating heat sinks, strategically placing heat-generating components, and optimizing PCB layout to promote airflow and minimize hotspots, ensuring both user safety and component longevity. - What are the key factors to consider when selecting components for smart furniture PCBs?

Component selection should prioritize reliability, size, power efficiency, and operating temperature range. Choosing components that can withstand the environmental conditions within furniture and offer a long operational life is essential. Also, adherence to industry standards and certifications is crucial for safety and performance. - How do design choices impact the overall cost of smart furniture PCBs?

Design choices significantly affect PCB cost. Using standard components, optimizing layer count, and minimizing board size can reduce material and manufacturing expenses. Balancing performance requirements with cost-effective design practices is crucial for commercial viability. - What role does simulation play in the PCB design process for smart furniture?

Simulation tools are vital for verifying the performance and reliability of smart furniture PCBs before fabrication. Simulations can predict signal integrity, power distribution, thermal behavior, and electromagnetic compatibility, enabling designers to identify and correct potential issues early in the design cycle, reducing development time and costs. - How important is it to consider future upgrades and modularity in the PCB design for smart furniture?

Designing PCBs with modularity and future upgrades in mind allows for easier maintenance, repair, and feature enhancements. Using standardized interfaces, reserving space for additional components, and implementing firmware update capabilities can extend the lifespan and functionality of smart furniture, providing long-term value to consumers.

Material Selection for Durability and Performance

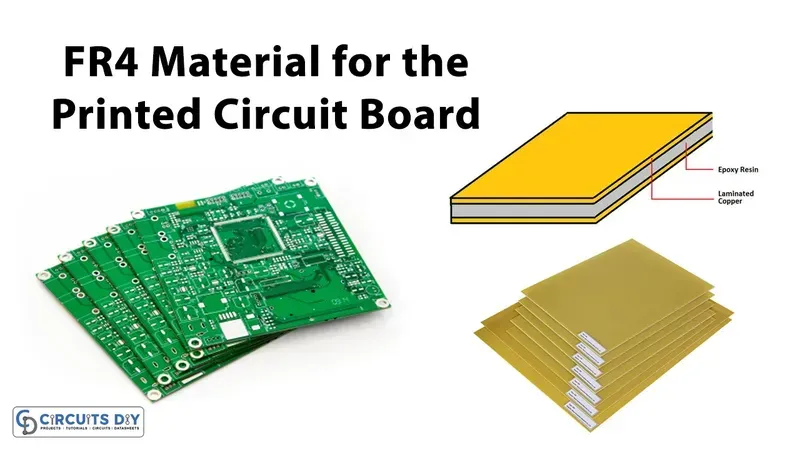

Selecting the appropriate PCB materials is crucial for ensuring the durability and long-term performance of smart furniture control systems. The materials must withstand various environmental factors, mechanical stresses, and operational conditions to guarantee reliability. Different materials offer distinct advantages, and the choice depends on the specific requirements of the application. This section explores commonly used PCB materials, comparing their properties and suitability for smart furniture applications.

Here's a comparative overview of PCB materials commonly used in smart furniture applications:

| Material | Description | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|---|

| FR-4 | Fiberglass epoxy laminate | Cost-effective, widely available, good electrical insulation | Lower thermal performance compared to metal core, can be brittle | General-purpose smart furniture PCBs, low-power applications |

| Aluminum | Aluminum core with a dielectric layer | Excellent heat dissipation, mechanically robust, good for high-power applications | More expensive than FR-4, can be heavier | LED lighting control, power supplies, applications requiring significant heat dissipation |

| Flexible PCBs (Flex PCBs) | Flexible polymer substrates (e.g., polyimide) | High flexibility, lightweight, can fit into tight spaces, good for dynamic applications | Higher cost, lower component density compared to rigid PCBs | Adjustable height mechanisms, foldable furniture, applications requiring movement or complex shapes |

| Metal Core PCB(MCPCB) | A type of PCB that contains a base metal material as a heat spreader | Effective thermal management, Enhanced durability | High cost, Signal integrity concerns | LED lighting, power conversion |

- What environmental factors should be considered when selecting PCB materials for smart furniture?

Consider temperature variations, humidity levels, exposure to chemicals (cleaning agents), and potential physical stresses. The material should maintain its integrity and performance under these conditions. - How does the choice of PCB material affect the thermal management of smart furniture?

Materials like aluminum offer superior heat dissipation compared to FR-4. Effective thermal management is crucial for components generating significant heat, such as LEDs or power supplies, to prevent overheating and ensure longevity. - Are flexible PCBs suitable for all types of smart furniture?

Flexible PCBs are ideal for applications requiring movement, bending, or fitting into tight spaces. However, they may not be the best choice for applications requiring high component density or rigid support. - What are the cost implications of choosing different PCB materials?

FR-4 is generally the most cost-effective option, while aluminum and flexible PCBs are more expensive. Consider the trade-offs between cost, performance, and application requirements when making your selection. - How does material selection impact the long-term reliability of smart furniture?

Choosing the right material ensures that the PCB can withstand environmental factors and operational stresses over time, preventing failures and extending the lifespan of the smart furniture. For example, using a material with good moisture resistance in humid environments can prevent corrosion and signal degradation. - What is the role of CTE (Coefficient of Thermal Expansion) in PCB material selection?

CTE is crucial because it measures how much a material expands or contracts with temperature changes. Matching the CTE of the PCB material to the CTE of the components minimizes stress on solder joints, preventing cracks and failures due to thermal cycling. Selecting materials with compatible CTE values is vital for long-term reliability, especially in environments with fluctuating temperatures. - How does the flammability rating of PCB materials affect safety in smart furniture?

Flammability ratings, such as UL94V-0, indicate a material's ability to resist burning. Choosing materials with high flammability ratings enhances safety by reducing the risk of fire hazards. This is particularly important in furniture that integrates electrical components, as it helps prevent fire propagation in case of a short circuit or other electrical malfunction. Compliance with safety standards ensures that the furniture meets regulatory requirements and provides a safe environment for users.

Manufacturing and Assembly Processes

The manufacturing and assembly processes for PCBs in smart furniture are specialized to meet the unique demands of these applications. These processes ensure that the PCBs are not only functional but also seamlessly integrated into the furniture design, contributing to the overall aesthetic and user experience. This section provides an overview of these processes, focusing on techniques like Surface Mount Technology (SMT), Through-Hole Technology, and automated assembly, all tailored for smart furniture PCBs.

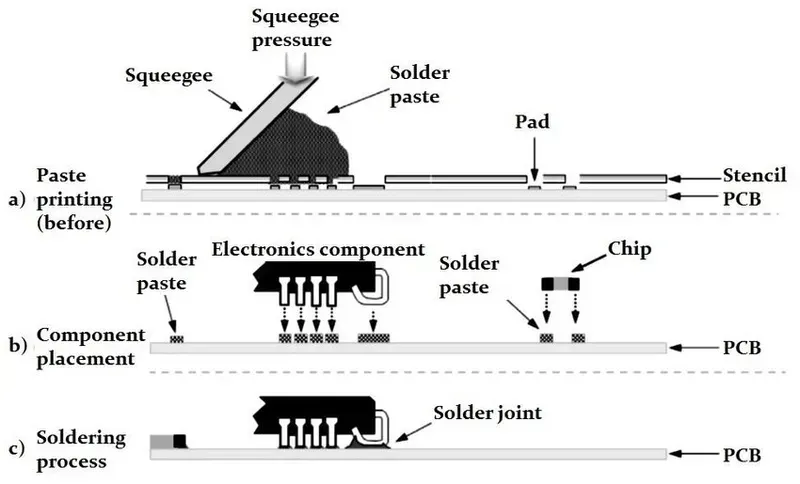

- Surface Mount Technology (SMT)

SMT is a dominant technique where components are mounted directly onto the surface of the PCB. This method is highly efficient for mass production and allows for higher component density, which is crucial for the compact designs often required in smart furniture. SMT offers advantages like reduced size and weight, lower manufacturing costs, and improved electrical performance due to shorter lead lengths. - Through-Hole Technology

While SMT is prevalent, Through-Hole Technology is still used for components that require a stronger physical connection to the PCB. In this process, component leads are inserted through drilled holes in the board and then soldered on the opposite side. This method is suitable for larger components or those that may be subject to mechanical stress, ensuring a robust and reliable connection. - Automated Assembly

Automated assembly lines are critical for the efficient and precise manufacturing of smart furniture PCBs. These lines typically involve pick-and-place machines that accurately position components onto the board, followed by automated soldering processes such as reflow soldering for SMT and wave soldering for through-hole components. Automation reduces human error, increases production speed, and ensures consistent quality. - PCB Cleaning

After soldering, PCBs undergo cleaning to remove flux residues and other contaminants that can affect performance and reliability. Cleaning processes may involve aqueous cleaning, solvent cleaning, or semi-aqueous cleaning, depending on the type of flux used and the specific requirements of the application. Clean PCBs ensure better adhesion of conformal coatings and improve long-term reliability. - Conformal Coating

To protect the PCB from environmental factors such as moisture, dust, and chemicals, a conformal coating is often applied. This thin layer of protective material conforms to the contours of the board and its components, providing an additional layer of insulation and preventing corrosion. Conformal coatings can be acrylic, epoxy, silicone, or urethane-based, each offering different levels of protection and application characteristics. - Inspection and Testing

Throughout the manufacturing and assembly process, rigorous inspection and testing are conducted to ensure the quality and functionality of the PCBs. This includes visual inspection, automated optical inspection (AOI), in-circuit testing (ICT), and functional testing. These tests help identify any defects or malfunctions early in the process, allowing for timely correction and preventing costly failures in the field. - Quality Control

Stringent quality control measures are implemented throughout the entire manufacturing and assembly process to ensure that the PCBs meet the required specifications and standards. This includes monitoring process parameters, conducting statistical process control (SPC), and implementing corrective actions to address any deviations. A robust quality control system ensures that the final product is reliable, durable, and performs as expected.

Testing and Quality Assurance

Rigorous testing and quality assurance are paramount in ensuring the reliability and safety of smart furniture control PCBs. These procedures validate the functionality, durability, and compliance of the PCBs with industry standards, guaranteeing customer satisfaction and minimizing potential risks. Comprehensive testing identifies potential defects or weaknesses, preventing premature failure and ensuring long-term performance.

- Why is testing crucial for Smart Furniture Control PCBs?

Testing identifies defects early, ensures reliability, and validates adherence to safety standards, preventing potential hazards and product malfunctions. - What functional tests are performed on these PCBs?

Functional testing involves simulating real-world operating conditions to verify that the PCB performs all intended functions correctly, including signal integrity, power delivery, and communication protocols. - What environmental tests are conducted?

Environmental tests assess the PCB's ability to withstand various environmental conditions, such as temperature extremes, humidity, vibration, and shock, ensuring reliable operation in diverse settings. These tests often include thermal cycling, humidity testing, and vibration analysis. - What compliance standards apply to Smart Furniture Control PCBs?

Compliance standards vary by region and application but often include UL, CE, and RoHS. These standards ensure that the PCBs meet specific safety, electromagnetic compatibility, and environmental requirements. Compliance testing involves evaluating the PCB against these standards and obtaining necessary certifications. - How is automated optical inspection (AOI) used in PCB quality assurance?

AOI uses cameras to visually inspect PCBs for defects like missing components, solder joint issues, and trace imperfections. It enhances the accuracy and efficiency of quality control. AOI systems can detect even minor flaws that might be missed by manual inspection, ensuring higher product quality. - What role does in-circuit testing (ICT) play in PCB testing?

ICT uses electrical probes to test individual components and circuits on the PCB, verifying their functionality and detecting shorts, opens, and incorrect component values. It is an essential step to ensure the PCB meets design specifications. - How does Zero One Solution Limited ensure the quality of its Smart Furniture Control PCBs?

Zero One Solution Limited employs rigorous testing procedures, including functional testing, environmental testing, AOI, and ICT. We adhere to strict quality management systems and compliance standards to guarantee the reliability and safety of our PCBs. Our comprehensive approach minimizes the risk of defects and ensures customer satisfaction.

Zero One Solution Limited: Your Partner in Smart Furniture PCB Solutions

At Zero One Solution Limited, we understand the intricate demands of smart furniture PCB design, manufacturing, and assembly. With a proven track record in delivering high-quality, rapid-turnaround solutions, we are your ideal partner for bringing innovative smart furniture concepts to life. From initial design to final product, we offer comprehensive support, ensuring your PCBs meet the highest standards of performance and reliability.

- Expertise in PCB Design

Our team of experienced engineers specializes in creating efficient and compact PCB layouts tailored for smart furniture applications. We optimize for size constraints, power management, and thermal dissipation to ensure seamless integration. - Advanced Manufacturing Capabilities

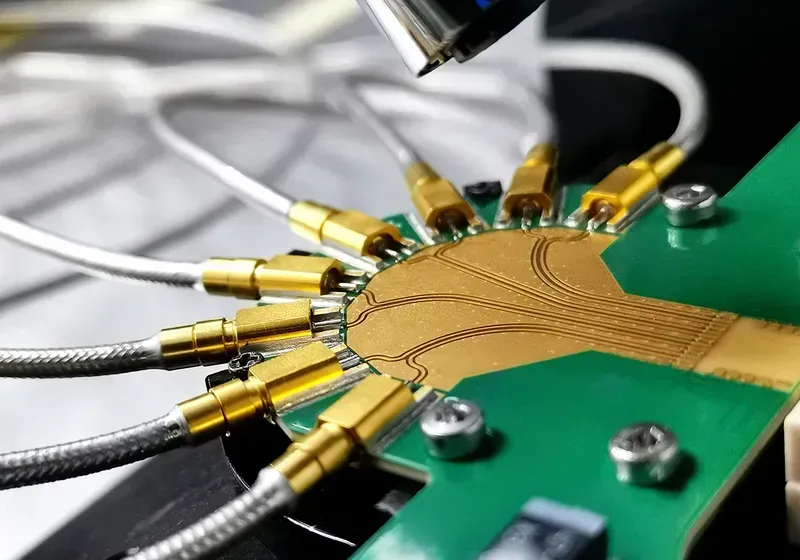

Leveraging state-of-the-art equipment and processes, we provide high-precision PCB manufacturing services. We support a wide range of materials, including FR-4, aluminum, and flexible PCBs, to meet diverse application requirements. - Comprehensive Assembly Services

We offer full-service PCB assembly, including SMT and through-hole technologies, ensuring accurate and reliable component placement. Our automated assembly techniques guarantee consistent quality and high throughput. - Rapid Prototyping

Accelerate your product development cycle with our rapid prototyping services. We enable quick iterations and testing, helping you refine your designs and bring innovative smart furniture solutions to market faster. - Global Supply Chain Network

Headquartered in Shenzhen, China, and with a branch office in Dubai, we operate within a strategic global supply chain network. This ensures seamless access to worldwide resources and support, optimizing cost-effectiveness and reducing lead times. - Rigorous Testing and Quality Assurance

We adhere to stringent testing procedures to ensure the reliability and safety of our PCBs. Our testing covers functional performance, environmental conditions, and compliance with industry standards. - Commitment to Innovation

We are dedicated to staying at the forefront of PCB technology, continuously exploring new materials, processes, and techniques to enhance the performance and functionality of smart furniture. Partner with us to unlock the full potential of your smart furniture designs.

Case Studies: Successful Smart Furniture Implementations

Zero One Solution Limited has been at the forefront of providing PCB solutions that power innovative smart furniture designs. Our expertise in PCB design, manufacturing, and assembly has enabled numerous clients to bring their smart furniture concepts to life. The following case studies highlight how our PCB solutions have played a pivotal role in successful smart furniture implementations, demonstrating the tangible benefits of our expertise and services.

Case Study 1: Adjustable Height Smart Desk

Challenge: A leading office furniture manufacturer sought to develop a smart desk with adjustable height functionality, integrated cable management, and a sleek, modern design. The key challenge was to integrate all the necessary electronics into a compact and reliable PCB solution.

Solution: Zero One Solution Limited designed and manufactured a multi-layer PCB that integrated the height adjustment motor controls, sensor inputs, and power distribution circuitry. The PCB was designed with size constraints in mind, ensuring it fit seamlessly within the desk's frame. We also provided rapid prototyping services, allowing the client to test and refine the design quickly.

Result: The smart desk was a commercial success, praised for its smooth and quiet height adjustment, intuitive controls, and reliable performance. Zero One Solution Limited's PCB solution played a critical role in enabling these features, contributing to the desk's overall functionality and user satisfaction.

Case Study 2: Smart Bed with Integrated Lighting and Wireless Charging

Challenge: A furniture company specializing in bedroom furnishings aimed to create a smart bed featuring integrated ambient lighting, wireless charging for mobile devices, and sleep monitoring capabilities. The challenge was to design a PCB that could manage multiple functionalities while ensuring user safety and minimizing electromagnetic interference.

Solution: Zero One Solution Limited developed a flexible PCB solution that could be seamlessly integrated into the bed frame. The PCB incorporated LED lighting controls, wireless charging circuitry, and sensor interfaces for sleep monitoring. We also implemented rigorous testing procedures to ensure compliance with safety standards and minimize EMI.

Result: The smart bed was well-received by consumers, offering a blend of comfort, convenience, and advanced technology. The integrated lighting created a relaxing ambiance, while the wireless charging feature eliminated the need for bedside cables. Zero One Solution Limited's PCB solution ensured reliable performance and user safety, contributing to the product's overall success.

Case Study 3: Smart Living Room Set with App-Controlled Features

Challenge: A furniture retailer planned to launch a premium smart living room set with app-controlled reclining, integrated speakers, and adjustable lumbar support. The key challenge was creating a central control PCB that could handle all these features and communicate seamlessly with a mobile app.

Solution: Zero One Solution Limited designed a sophisticated PCB with a microcontroller, Bluetooth connectivity, and motor control circuits. The PCB was programmed to receive commands from the mobile app, allowing users to adjust the furniture settings remotely. We also provided firmware development support to ensure seamless integration between the hardware and software.

Result: The smart living room set stood out in the market, offering a unique blend of comfort and technology. The app-controlled features added a new level of convenience, allowing users to customize their seating experience. Zero One Solution Limited's comprehensive PCB solution and firmware support played a crucial role in bringing this innovative product to market.

The Future of Smart Furniture and PCB Technology

The smart furniture industry is on the cusp of a technological revolution, with advancements in PCB technology playing a pivotal role. As homes and offices become increasingly connected, the demand for smarter, more intuitive furniture solutions will drive innovation in both design and functionality. This section explores the emerging trends and potential future advancements in smart furniture and PCB technology, focusing on connectivity, sensor integration, and user interfaces.

Several key trends are poised to shape the future of smart furniture:

- Enhanced Connectivity

The integration of 5G and Wi-Fi 6E technologies promises faster, more reliable connectivity for smart furniture. This will enable seamless communication between devices, facilitating features like remote control, automated adjustments, and real-time data monitoring. Imagine chairs that adjust posture based on biometric data or desks that optimize lighting based on ambient conditions. - Advanced Sensor Integration

Expect to see a proliferation of sensors embedded within smart furniture. These sensors will monitor a range of parameters, including temperature, humidity, air quality, and user biometrics. This data can be used to personalize the furniture's settings and provide valuable insights into the user's health and well-being. For example, a smart bed could track sleep patterns and adjust firmness and temperature for optimal rest. - Intuitive User Interfaces

The future of smart furniture will emphasize intuitive and user-friendly interfaces. Voice control, gesture recognition, and haptic feedback will become increasingly common, allowing users to interact with their furniture in a natural and seamless way. Touchless control will also gain importance due to hygiene considerations. - Sustainable Materials and Manufacturing

Environmental consciousness will drive the adoption of sustainable materials and manufacturing processes in the smart furniture industry. PCBs made from biodegradable materials and energy-efficient designs will become increasingly prevalent. Furthermore, modular designs that allow for easy upgrades and repairs will extend the lifespan of smart furniture and reduce waste. - Artificial Intelligence and Machine Learning

AI and machine learning algorithms will play a crucial role in optimizing the performance of smart furniture. These technologies can analyze user data to personalize settings, predict maintenance needs, and automate tasks. For instance, an AI-powered desk could learn a user's preferred standing and sitting times and automatically adjust its height accordingly.

The advancements in PCB technology will be crucial to realizing these future possibilities:

- Flexible and Stretchable PCBs

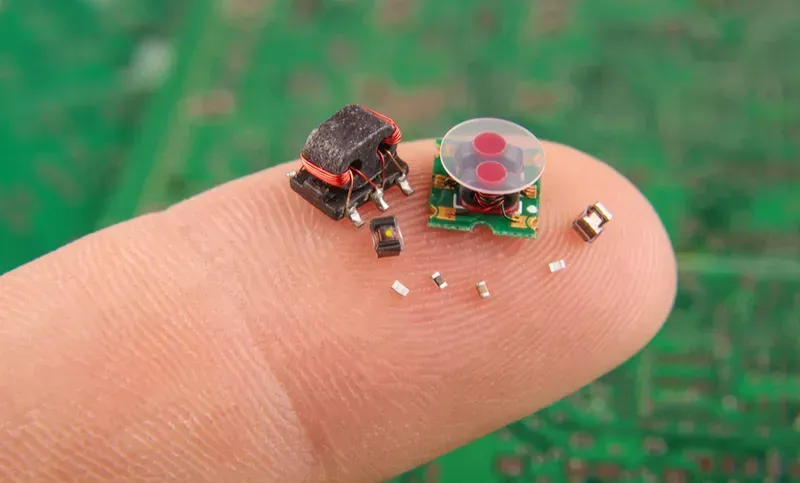

These PCBs will enable the creation of smart furniture with unconventional shapes and designs. They can be seamlessly integrated into fabrics and other materials, allowing for the development of truly embedded smart functionalities. - Miniaturized Components

Smaller, more efficient components will allow for denser PCB designs, enabling more features to be packed into a smaller space. This is particularly important for smart furniture applications where aesthetics and ergonomics are key considerations. - Improved Power Management

Advanced power management techniques will be essential for extending the battery life of wireless smart furniture. This includes the use of energy-harvesting technologies and low-power components.

The integration of these technologies will not only enhance the functionality and convenience of furniture but also transform the way we interact with our living and working spaces. Zero One Solution Limited is committed to staying at the forefront of these advancements, providing innovative PCB solutions that enable the future of smart furniture.

In conclusion, the Smart Furniture Control PCB is a cornerstone of the evolving smart home landscape. Its ability to integrate seamlessly into furniture designs, enabling advanced functionalities and enhanced user experiences, makes it an indispensable component for manufacturers looking to innovate. Zero One Solution Limited is committed to providing cutting-edge PCB solutions that meet the demands of this dynamic market. Whether you're developing adjustable desks, smart lighting solutions, or connected seating, our expertise in PCB design, manufacturing, and assembly ensures that your smart furniture concepts become a reality. Contact Zero One Solution Limited today to discover how our PCB solutions can revolutionize your smart furniture designs and bring your innovative ideas to life. Let's build the future of smart living, together. Share this article and join the conversation about the future of smart furniture!

AnyPCBA

AnyPCBA