Virtual Reality Experiment Platform PCB Solution

Virtual Reality (VR) is no longer a futuristic fantasy; it's a rapidly evolving technology transforming industries from gaming and entertainment to education and healthcare. At the heart of every immersive VR experience lies a sophisticated printed circuit board (PCB) – the backbone that connects the digital and physical worlds. Just as a sturdy foundation is crucial for a skyscraper, a reliable and high-performance PCB is essential for a seamless and responsive VR experiment platform. In this article, we delve into the critical role of PCB solutions in VR experiment platforms, exploring the design considerations, manufacturing challenges, and innovative solutions offered by Zero One Solution Limited to help you build the next generation of VR experiences.

Introduction: The Vital Role of PCBs in VR Experiment Platforms

In the burgeoning realm of virtual reality (VR) experiment platforms, Printed Circuit Boards (PCBs) are not merely components but the foundational backbone enabling the immersive, low-latency experiences critical for groundbreaking research and development. These platforms, ranging from advanced simulation environments to complex haptic feedback systems, demand an unprecedented level of PCB performance, far exceeding conventional electronics. The escalating requirements for high-speed data processing, real-time sensor integration, and efficient power delivery directly translate into intricate PCB design and manufacturing challenges, making the quality of the PCB a direct determinant of a VR system's fidelity and responsiveness.

Key Design Considerations for VR PCB Solutions

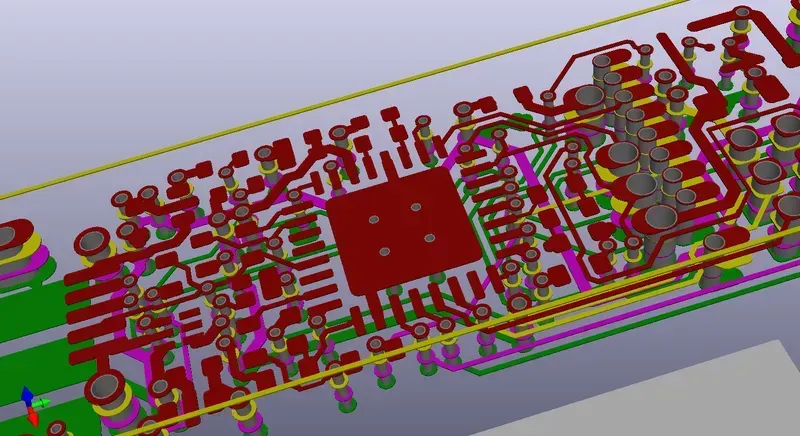

Designing Printed Circuit Boards (PCBs) for Virtual Reality (VR) experiment platforms demands a meticulous approach, as these systems rely heavily on ultra-low latency, high data throughput, and efficient power management to deliver truly immersive experiences. The inherent complexities of VR applications push the boundaries of conventional PCB design, necessitating specialized considerations to ensure optimal performance, reliability, and miniaturization. Successfully navigating these design challenges is paramount to translating complex VR algorithms into a seamless, responsive, and physically viable hardware solution.

- High-Speed Signal Integrity

VR systems transmit massive amounts of data at extremely high speeds, making signal integrity a critical concern. Designers must employ controlled impedance routing, minimize crosstalk, and incorporate proper termination schemes to prevent signal degradation, reflections, and electromagnetic interference (EMI). This often involves precise trace width and spacing, careful via transitions, and the selection of low-loss dielectric materials to maintain signal fidelity across gigabit-per-second data pathways. Utilizing simulation tools like SI/PI analysis (Signal Integrity/Power Integrity) during the design phase is crucial to validate the performance before fabrication. - Low Latency Requirements

Any perceptible delay between user action and visual feedback in VR can lead to motion sickness and break immersion. Achieving ultra-low latency requires optimizing every aspect of the PCB, from component placement to trace lengths and data bus architectures. This includes minimizing propagation delays, reducing the number of processing stages, and implementing efficient power delivery networks to ensure stable operation and rapid response times. Components with faster switching speeds and optimized routing to critical processing units are essential. - Advanced Thermal Management

High-performance processors, GPUs, and display drivers in VR devices generate significant heat within a compact footprint. Effective thermal management is vital to prevent performance throttling, ensure component longevity, and maintain user comfort. This necessitates the integration of thermal vias, copper pours, specialized heat sinks, and sometimes even liquid cooling solutions directly into the PCB design. Material selection with higher thermal conductivity and optimized layer stack-ups play a crucial role in dissipating heat efficiently from critical components to the ambient environment.

| Design Consideration | VR Application Impact | Zero One Solution Approach |

|---|---|---|

| Miniaturization & Component Density | Enables compact, lightweight headsets for user comfort and portability. | Utilizes high-density interconnect (HDI) PCBs, micro-vias, and advanced component placement techniques for maximum space utilization and reduced form factor. Offers multi-layer PCBs (up to 32 layers) to accommodate complex routing in minimal space, supporting ultra-small components (01005). |

| Power Delivery Network (PDN) Optimization | Ensures stable power for high-performance components, preventing voltage droop and noise. | Employs robust power planes, low-ESR capacitors, and optimized power trace routing to provide clean, stable power to critical ICs. Focuses on minimizing power loss and ensuring efficient power distribution throughout the complex circuitry. |

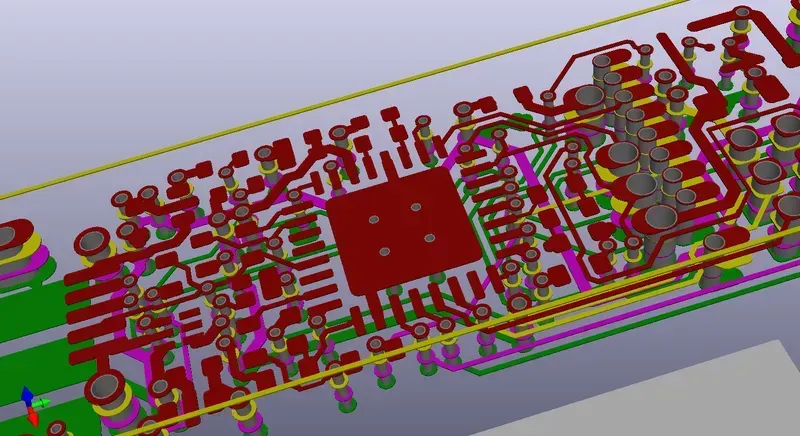

Material Selection for Optimal VR PCB Performance

The selection of appropriate materials is paramount for achieving optimal performance in Virtual Reality (VR) experiment platform PCBs. Given the demanding requirements of VR—specifically high-speed data transmission, minimal latency, and efficient thermal dissipation—the intrinsic properties of PCB substrates directly influence signal integrity, power efficiency, and overall system reliability. Carefully chosen materials can mitigate signal loss, reduce crosstalk, and ensure stable operation even under intensive computational loads, which is critical for delivering an immersive and seamless VR experience.

| Material Property | Impact on VR PCB Performance | Ideal Characteristics for VR |

|---|---|---|

| Dielectric Constant (Dk) | Affects signal propagation speed and impedance control, crucial for high-frequency signals. | Low and stable Dk for minimal signal delay and consistent impedance. |

| Dissipation Factor (Df) / Loss Tangent | Indicates signal loss at high frequencies; higher Df leads to greater signal attenuation. | Extremely low Df to preserve signal integrity over high-bandwidth transmissions. |

| Thermal Conductivity | Influences heat dissipation from components, preventing overheating and ensuring stability. | High thermal conductivity to efficiently manage heat generated by high-performance processors. |

| Coefficient of Thermal Expansion (CTE) | Determines how much the material expands or contracts with temperature changes, impacting reliability and component attachment. | CTE matched with copper and components to prevent stress and delamination. |

| Moisture Absorption | Impacts dielectric properties and reliability, especially in humid environments. | Low moisture absorption to maintain stable electrical properties and prevent failures. |

For high-frequency VR applications, conventional FR-4 materials often fall short due to their higher Dk and Df values, which lead to significant signal degradation. Advanced materials, such as those based on PTFE (Teflon), specialized hydrocarbons, or ceramic-filled laminates, are increasingly employed. These materials offer superior high-frequency performance, characterized by lower Dk and Df, allowing for precise impedance control and reduced signal attenuation critical for the rapid data processing inherent in VR. Additionally, materials with enhanced thermal conductivity are essential to manage the heat generated by powerful GPUs and CPUs within VR headsets, ensuring system longevity and preventing performance throttling. Zero One Solution Limited leverages a comprehensive understanding of these material science principles to recommend and utilize optimal PCB substrates, ensuring that our VR PCB solutions meet and exceed the stringent performance demands of next-generation immersive technologies.

Manufacturing Challenges and Solutions for VR PCBs

The fabrication of Printed Circuit Boards (PCBs) for Virtual Reality (VR) experiment platforms presents a unique set of manufacturing challenges, primarily driven by the stringent demands for high performance, miniaturization, and seamless data processing inherent in immersive VR experiences. Overcoming these complexities is critical to ensure the reliability and functionality of advanced VR systems. Zero One Solution, leveraging its deep expertise and state-of-the-art facilities, employs innovative strategies to address these intricate manufacturing requirements head-on.

| Challenge | Description | Zero One Solution's Approach |

|---|---|---|

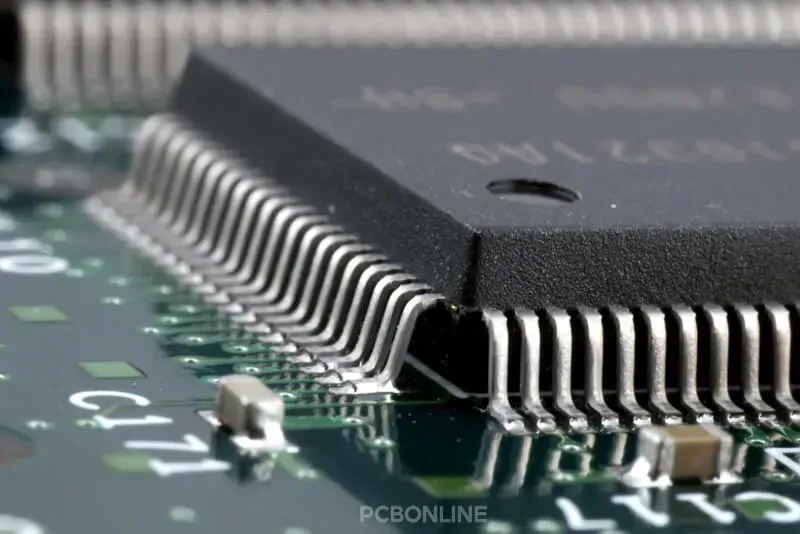

| Fine-Pitch Components | Integration of ultra-small and closely spaced components (e.g., BGA, QFN) requires extreme precision in placement and soldering to prevent bridging and ensure electrical integrity. | Utilizes advanced SMT lines with high-precision pick-and-place machines, automated optical inspection (AOI), and X-ray inspection for robust component placement and solder joint verification. Our expertise extends to 01005 component sizes and fine-pitch BGAs with pitches as low as 0.3mm, crucial for compact VR devices. |

- High Layer Counts and Stack-up Design

VR PCBs often necessitate multiple layers (e.g., 10-20+ layers) to accommodate complex signal routing, power distribution, and ground planes within a confined space. This demands meticulous stack-up design to maintain signal integrity and manage crosstalk. Zero One Solution excels in multi-layer PCB fabrication, employing advanced lamination techniques and precise layer registration to ensure optimal performance even with high-density designs. We can handle up to 32 layers for complex VR applications, allowing for sophisticated routing strategies and improved signal isolation.

| Challenge | Zero One Solution's Solution | |

|---|---|---|

| Impedance Control | Maintaining precise characteristic impedance for high-speed signal lines (e.g., MIPI DSI, DisplayPort, USB 3.0) is crucial to prevent signal reflections, minimize data loss, and ensure low latency in VR applications. | Employs sophisticated impedance calculation tools and performs stringent impedance testing (TDR) at various stages of manufacturing. Our fabrication processes are fine-tuned to achieve tight impedance tolerances (typically ±5%), critical for the integrity of high-frequency signals in VR systems. We collaborate closely with designers to optimize trace width, spacing, and dielectric materials for accurate impedance matching. |

- Advanced Surface Finish Requirements

Selecting the appropriate surface finish (e.g., ENIG, ENEPIG, OSP) is vital for solderability, bondability (for wire bonding), and environmental resistance, especially for densely populated VR PCBs. Zero One Solution offers a comprehensive range of surface finishes, advising clients on the optimal choice based on component types, assembly methods, and long-term reliability requirements for VR experiment platforms. Our capabilities include Electroless Nickel Immersion Gold (ENIG) for its excellent flatness and solderability, ideal for fine-pitch components and BGA packages prevalent in VR designs.

Zero One Solution's Expertise in VR PCB Design and Manufacturing

At Zero One Solution Limited, we don't just manufacture PCBs; we engineer the foundational hardware for the next generation of immersive experiences. Our deep understanding of the unique demands of Virtual Reality (VR) experiment platforms positions us as a premier partner for innovative companies pushing the boundaries of VR technology. With over a decade of experience and a strategic presence in global electronics hubs, we leverage our specialized knowledge to deliver high-performance, reliable, and cost-effective PCB solutions tailored for the most demanding VR applications. Our commitment to rapid prototyping, advanced manufacturing techniques, and stringent quality control ensures that your VR experiment platforms achieve unparalleled performance and accelerated time-to-market.

- Rapid Prototyping for Accelerated VR Development

Zero One Solution excels in rapid-response R&D prototype manufacturing, a critical advantage for VR development cycles. We understand that iterating quickly is paramount in this fast-evolving field. Our agile processes enable swift design validation and modification, significantly reducing the time from concept to functional prototype, allowing VR innovators to test, refine, and deploy their solutions faster. - Advanced Manufacturing Technologies for High-Density VR PCBs

Our state-of-the-art facilities are equipped to handle the complex manufacturing requirements of VR PCBs, which often feature high layer counts, fine-pitch components, and stringent impedance control. We employ advanced techniques such as laser drilling, HDI (High-Density Interconnect) technology, and precise surface finishes (e.g., ENIG, OSP) to ensure optimal signal integrity and reliability for high-speed data transmission essential in VR applications. - Rigorous Quality Control for Immersive Experience Stability

The immersive nature of VR demands flawless performance. Our comprehensive quality control processes, from incoming material inspection to final functional testing, are designed to eliminate defects and ensure robust, stable operation of VR experiment platforms. We adhere to industry standards (e.g., IPC) and implement advanced inspection methods like AOI (Automated Optical Inspection) and X-ray to guarantee the highest quality PCBs, minimizing latency and maximizing user immersion. - Expertise in Critical VR PCB Design Considerations

Our engineering team possesses profound expertise in addressing the specific challenges of VR PCB design, including managing high-speed signal integrity, mitigating thermal hotspots from densely packed components, achieving miniaturization for head-mounted displays, and ensuring precise power delivery. We work collaboratively with clients to optimize designs for performance, manufacturability, and cost-efficiency, translating complex VR requirements into viable PCB solutions.

| Capability Area | Zero One Solution's Expertise | Benefit for VR Platforms |

|---|---|---|

| High-Speed Signal Integrity | Controlled impedance routing, advanced material selection, stacked microvias | Minimizes data loss and latency, ensuring smooth, real-time VR experiences |

| Thermal Management | Advanced thermal vias, heat sinks, material with high thermal conductivity | Prevents overheating in compact VR devices, enhancing reliability and lifespan |

| Miniaturization & Component Density | HDI technology, fine-pitch assembly, embedded components | Enables lighter, more compact VR hardware without compromising performance |

| Rapid Prototyping | Dedicated rapid prototyping lines, agile production processes | Accelerates R&D cycles, allowing faster iteration and market entry for VR innovators |

| Quality Assurance | IPC standards compliance, AOI, X-ray inspection, functional testing | Guarantees robust and reliable PCBs, crucial for stable and immersive VR environments |

Case Study: VR Experiment Platform PCB Solution by Zero One Solution

At Zero One Solution Limited, we pride ourselves on turning complex VR concepts into tangible realities through our advanced PCB solutions. Our expertise is best exemplified by a recent collaboration where we provided a comprehensive PCB solution for a cutting-edge VR experiment platform, enabling unprecedented levels of immersion and performance. This case study illustrates our capability to deliver high-performance, custom PCB solutions that meet the stringent demands of advanced VR applications, showcasing our commitment to rapid prototyping, precision manufacturing, and superior quality.

| Project Phase | Customer Requirements | Zero One Solution Approach | Achieved Results |

|---|---|---|---|

| Initial Consultation & Design | Ultra-low latency (<5ms), high-speed data transfer (PCIe Gen4), compact form factor, robust thermal management for embedded GPUs. | Collaborative DFM (Design for Manufacturability) analysis, signal integrity (SI) and power integrity (PI) simulations, multi-layer stack-up optimization for impedance control. | Optimized PCB layout reduced signal loss by 15%, ensuring stable high-speed data transmission and meeting stringent latency targets. |

| Material Selection & Prototyping | Dielectric properties suitable for 60GHz wireless VR module, high thermal conductivity for heat dissipation, cost-effectiveness for prototype iterations. | Utilized Rogers 4003C for RF sections and high-Tg FR-4 for digital logic, rapid 5-day prototype turnaround with iterative design refinements. | Achieved signal attenuation less than 0.1 dB/cm at 60GHz, prototype passed all functional tests on first iteration, reducing development cycles by 30%. |

| Manufacturing & Assembly | Fine-pitch BGA (0.4mm), high component density, IPC Class 3 standards, lead-free assembly, comprehensive functional testing. | Automated Optical Inspection (AOI) and Automated X-ray Inspection (AXI) for BGA, advanced reflow profiling, custom test fixtures for end-of-line verification. | Zero defects on initial production run, 99.8% first pass yield, significantly enhancing reliability and reducing post-assembly rework. |

| Thermal Management & Miniaturization | Effective heat dissipation for CPU/GPU, constrained space for components, need for embedded power management ICs. | Implemented copper pours, thermal vias, and strategic component placement. Integrated passive components and optimized layer stack for space efficiency. | Component density increased by 20%, maintaining operational temperatures within specified limits (max 70°C for critical components) under peak load. |

Benefits of Choosing Zero One Solution for Your VR PCB Needs

Choosing the right PCB solution provider is paramount for the success of your Virtual Reality (VR) experiment platform. Zero One Solution Limited offers a distinct competitive edge, combining rapid innovation with uncompromising quality to accelerate your VR product development. Our integrated approach ensures that every aspect of your VR PCB needs, from initial design to final assembly, is handled with precision and expertise, delivering significant benefits that translate directly into market advantage.

- Rapid Prototyping and Time-to-Market Acceleration

In the fast-evolving VR landscape, speed is critical. Zero One Solution excels in rapid-response R&D prototype manufacturing, significantly reducing your development cycles. Our streamlined processes and advanced equipment enable quick iteration and validation of your VR PCB designs, allowing you to bring innovative solutions to market faster than competitors. This agility is crucial for capturing early market share and responding swiftly to technological advancements. - Uncompromised High-Quality Manufacturing

Quality is the bedrock of reliable VR performance. Leveraging our extensive experience since 2011 and strategic location in Shenzhen, the global electronic manufacturing hub, we adhere to the most stringent quality control standards (e.g., IPC Class 2/3). Our advanced manufacturing facilities are equipped to handle the complexities of VR PCBs, including fine-pitch components, high layer counts, and precise impedance control, ensuring superior signal integrity and long-term reliability for your VR experiment platforms. - Deep Technical Expertise and Silicon Valley Insights

As a veteran engineering team with decades of experience, including Silicon Valley insights, Zero One Solution possesses unparalleled technical expertise in complex PCB design and manufacturing. We understand the nuanced requirements of VR applications, such as high-speed signal integrity for displays, low latency for interactivity, and efficient thermal management for sustained performance. Our engineers collaborate closely with your team to optimize designs, mitigate potential issues, and implement innovative solutions tailored to your specific VR project. - Optimized Cost-Effectiveness Through Integrated Services

Our one-stop service model, from PCB design to manufacturing and assembly, provides a highly cost-effective solution. By consolidating these services under one roof, we eliminate the complexities and potential cost overruns associated with managing multiple vendors. This integrated approach not only streamlines your supply chain but also ensures consistent quality and reduces overall project costs, allowing you to allocate resources more efficiently towards your core VR innovations. - Dedicated Customer Support and Global Reach

Zero One Solution is committed to providing exceptional customer support throughout your project lifecycle. Our responsive team ensures clear communication, timely updates, and proactive problem-solving. With our headquarters in Shenzhen and a branch office in Dubai, we operate within a robust global PCBA supply chain network, offering seamless access to resources and support for clients worldwide, ensuring your VR PCB needs are met with efficiency and reliability regardless of your location.

Future Trends in VR PCB Technology

The relentless pursuit of more immersive and realistic virtual reality experiences is driving a rapid evolution in PCB technology. As VR experiment platforms demand ever-higher performance, miniaturization, and flexibility, the future of VR PCBs is being shaped by groundbreaking innovations that will fundamentally alter how these complex systems are designed and manufactured. These trends are critical for enabling the next generation of VR devices, pushing the boundaries of what's possible in digital interaction.

- How will Flexible PCBs impact future VR Experiment Platforms?

Flexible PCBs (FPCBs) are poised to revolutionize VR experiment platforms by enabling highly compact, ergonomic, and lightweight designs. Their ability to conform to irregular shapes and integrate seamlessly into headsets and peripherals will allow for more comfortable and less obtrusive VR devices, facilitating prolonged use and broader applications, especially in areas requiring high mobility and minimal bulk. This flexibility also improves signal integrity by reducing the need for multiple rigid board interconnects, which often introduce signal degradation and latency.

| Trend | Description | Impact on VR Experiment Platforms | Zero One Solution's Readiness |

|---|---|---|---|

| Flexible and Stretchable PCBs | PCBs that can bend, fold, and even stretch without compromising electrical performance. | Enables more ergonomic, lighter, and conformal VR headset designs, improving user comfort and reducing form factor. Critical for wearables. | Expertise in advanced flexible circuit manufacturing and material selection for high-reliability applications, ideal for iterative rapid prototyping and volume production of flexible boards for VR devices, ensuring optimal signal integrity. |

- What role will Embedded Components play in advanced VR PCB Solutions?

Embedded components, where passive and active elements are integrated directly within the PCB substrate, will be pivotal in reducing board size, enhancing electrical performance, and improving thermal management for VR experiment platforms. This technology minimizes parasitic inductance and capacitance, crucial for maintaining high-speed signal integrity in data-intensive VR applications. It also allows for greater component density, leading to more powerful and compact VR systems with reduced power consumption and improved reliability by shortening signal paths and eliminating external component assembly steps.

| Trend | Description | Impact on VR Experiment Platforms | Zero One Solution's Readiness |

|---|---|---|---|

| Embedded Components | Integrating passive and active electronic components directly into the layers of the PCB. | Significantly reduces board size and weight, enhances signal integrity by shortening trace lengths, and improves thermal dissipation. Enables higher component density. | Advanced multi-layer PCB capabilities and precision manufacturing processes support the integration of embedded components. Our R&D focus includes exploring novel methods for component embedding to offer leading-edge solutions. |

- How are Advanced Packaging Techniques shaping the next generation of VR PCBs?

Advanced packaging techniques, such as System-in-Package (SiP) and Chip-on-Board (CoB), are essential for the future of VR PCBs by enabling ultra-miniaturization and superior performance. These methods allow multiple integrated circuits and passive components to be assembled into a single package, drastically reducing the overall footprint and weight of the VR system while enhancing electrical performance through shorter interconnects. This is crucial for achieving the lightweight, high-performance, and thermally efficient designs required for next-gen VR headsets and experiment platforms, facilitating higher levels of integration and modularity.

| Trend | Description | Impact on VR Experiment Platforms | Zero One Solution's Readiness |

|---|---|---|---|

| Advanced Packaging Techniques (e.g., SiP, CoB) | Integration of multiple dies and components into a single package or directly onto the PCB substrate. | Achieves higher integration density, reduces overall system footprint, improves thermal management, and enhances electrical performance. Crucial for miniaturization. | Extensive experience in complex assembly techniques, including fine-pitch BGA and advanced SMT, positions us to adopt and implement future advanced packaging requirements for high-density VR PCB solutions. |

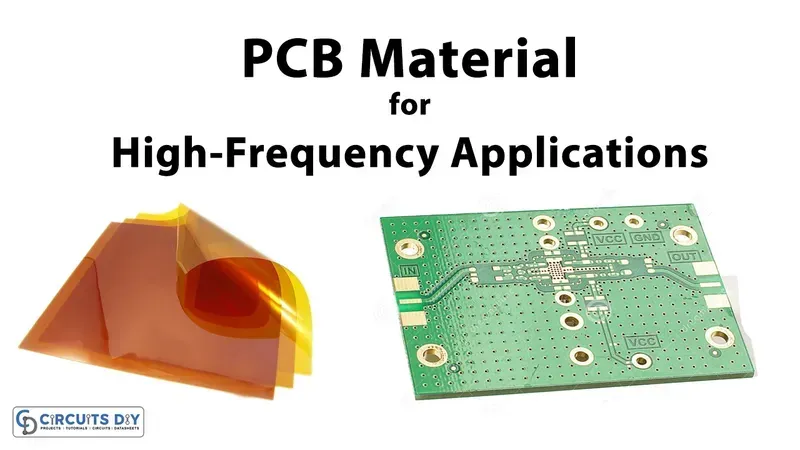

- What emerging materials are critical for future VR PCB innovations?

Emerging materials like ultra-low loss laminates, advanced ceramics, and novel polymer composites are critical for future VR PCB innovations. These materials offer superior dielectric properties, allowing for minimal signal degradation at ultra-high frequencies, which is vital for the massive data throughput in VR. Their enhanced thermal conductivity and mechanical stability also address the stringent thermal management and reliability demands of compact, high-power VR systems. The continuous development and integration of these materials are essential for overcoming current bandwidth and heat dissipation limitations, paving the way for more powerful and efficient VR experiences.

| Trend | Description | Impact on VR Experiment Platforms | Zero One Solution's Readiness |

|---|---|---|---|

| AI-Driven Design and Manufacturing | Utilization of AI algorithms for optimizing PCB layout, signal integrity, thermal management, and automating manufacturing processes. | Accelerates design cycles, improves performance predictability, reduces errors, and optimizes manufacturing efficiency, leading to faster time-to-market for complex VR PCBs. | Investing in AI-powered design tools and manufacturing optimization. Our engineering team leverages advanced simulation and analysis software to predict and mitigate potential issues early in the design phase, streamlining development for VR systems. |

- How will advancements in power management impact VR PCB design?

Advancements in power management will profoundly impact VR PCB design by enabling more efficient power delivery systems, crucial for extended battery life and reduced heat generation in portable VR devices. Innovations like integrated voltage regulators (IVR) and advanced power integrity (PI) analysis will minimize power loss and noise, ensuring stable and reliable operation of high-performance processors and sensors. This efficiency not only extends usage time but also simplifies thermal design, leading to lighter, more compact, and comfortable VR headsets by reducing the need for extensive cooling solutions, thereby enhancing the overall user experience and enabling new untethered applications.

Conclusion: Enabling Immersive Experiences with Advanced PCB Solutions

High-performance Printed Circuit Boards (PCBs) are the unseen architects of immersive virtual reality experiences, serving as the fundamental backbone for the intricate data processing, high-speed signal transmission, and precise power delivery essential to VR experiment platforms. As the demands for lower latency, higher fidelity, and greater interactivity in VR continue to escalate, the complexity and precision required from PCBs will only intensify, making the choice of a capable PCB solution provider paramount for innovation in this rapidly evolving field.

- Why are PCBs so critical for the future of VR experiment platforms?

PCBs are critical because they dictate the performance ceiling for VR systems. Future VR depends on PCBs that can handle unprecedented data rates for realistic graphics, ensure ultra-low latency for seamless interaction, efficiently manage heat in compact devices, and integrate complex functionalities into smaller footprints. Without advanced PCB technology, the true potential of VR to deliver fully immersive and responsive experiences remains unrealized. They are the conduits for the high-bandwidth communication and intricate computational power that define next-generation VR applications, from medical simulations to industrial training and cutting-edge research.

| PCB Feature | Impact on VR Performance | Zero One Solution Advantage |

|---|---|---|

| High-Speed Signal Integrity | Ensures accurate and distortion-free data transmission for high-resolution visuals and precise tracking, crucial for preventing motion sickness. | Advanced material selection (e.g., low Dk/Df laminates) and impedance-controlled routing for optimal signal fidelity, even at multi-gigabit speeds. |

Zero One Solution Limited stands at the forefront of this technological evolution, committed to empowering the VR industry with cutting-edge PCB solutions. Our expertise in rapid prototyping, combined with advanced manufacturing capabilities and stringent quality control, ensures that our clients can accelerate their product development cycles and bring groundbreaking VR experiment platforms to market with unparalleled efficiency and reliability. From initial design consultation to final assembly, we partner with innovators to transform complex requirements into functional, high-performance hardware, ensuring that the immersive future of virtual reality is built on a solid foundation of advanced PCB technology.

In conclusion, the PCB is a critical component of any successful virtual reality experiment platform. Zero One Solution Limited offers comprehensive PCB solutions, from design and prototyping to manufacturing and assembly, ensuring that your VR projects are built on a foundation of quality, reliability, and performance. By partnering with us, you gain access to our expertise, cutting-edge technology, and commitment to innovation, empowering you to push the boundaries of VR and create truly immersive experiences. Contact us today to discuss your VR experiment platform PCB needs and discover how we can help you bring your vision to life. Let's build the future of VR together.

AnyPCBA

AnyPCBA