Understanding the Versatile 400V Capacitor: Applications, Selection, and Safety

In our increasingly electronic world, the humble capacitor plays a vital role, often unnoticed but always essential. A common type, the 400V capacitor, is the workhorse in many power supplies, from small phone chargers to large industrial equipment. This seemingly simple component stores electrical energy and is critical for smooth operation of countless devices. This article will delve into the world of the 400V capacitor, explaining what it is, its diverse applications, how to select the right one, and crucial safety information to keep in mind. Just like the veins in our body ensure smooth flow, the 400V capacitor ensures electricity flows smoothly in our digital lives.

What is a 400V Capacitor?

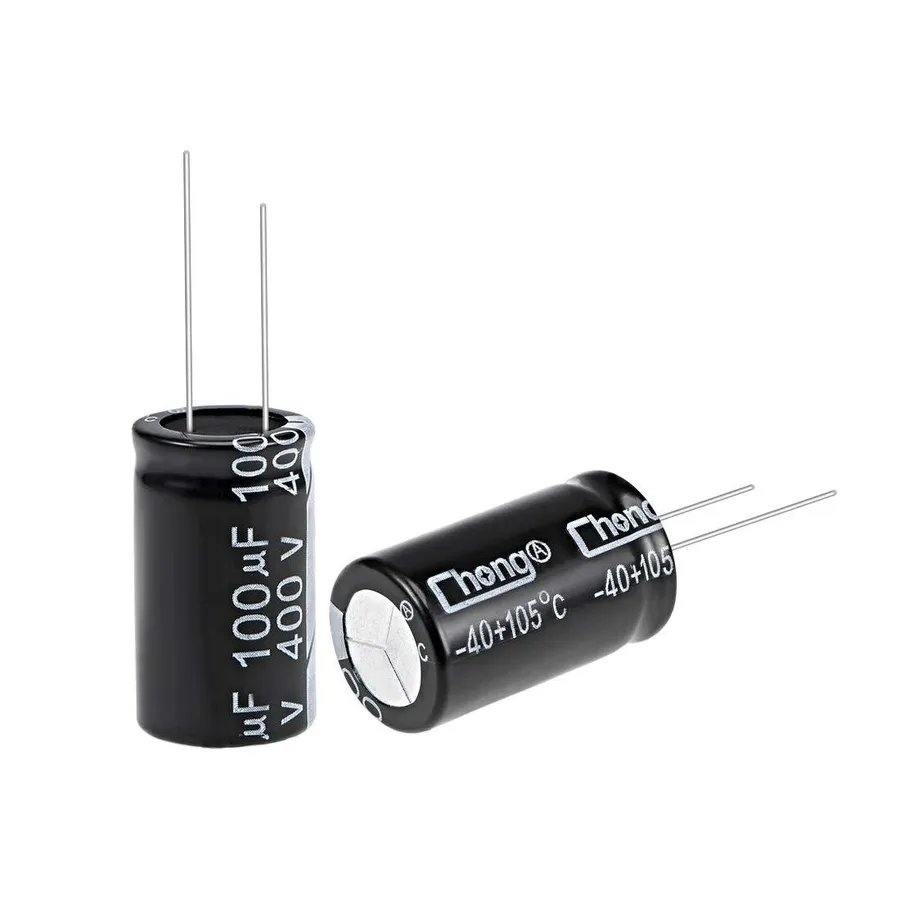

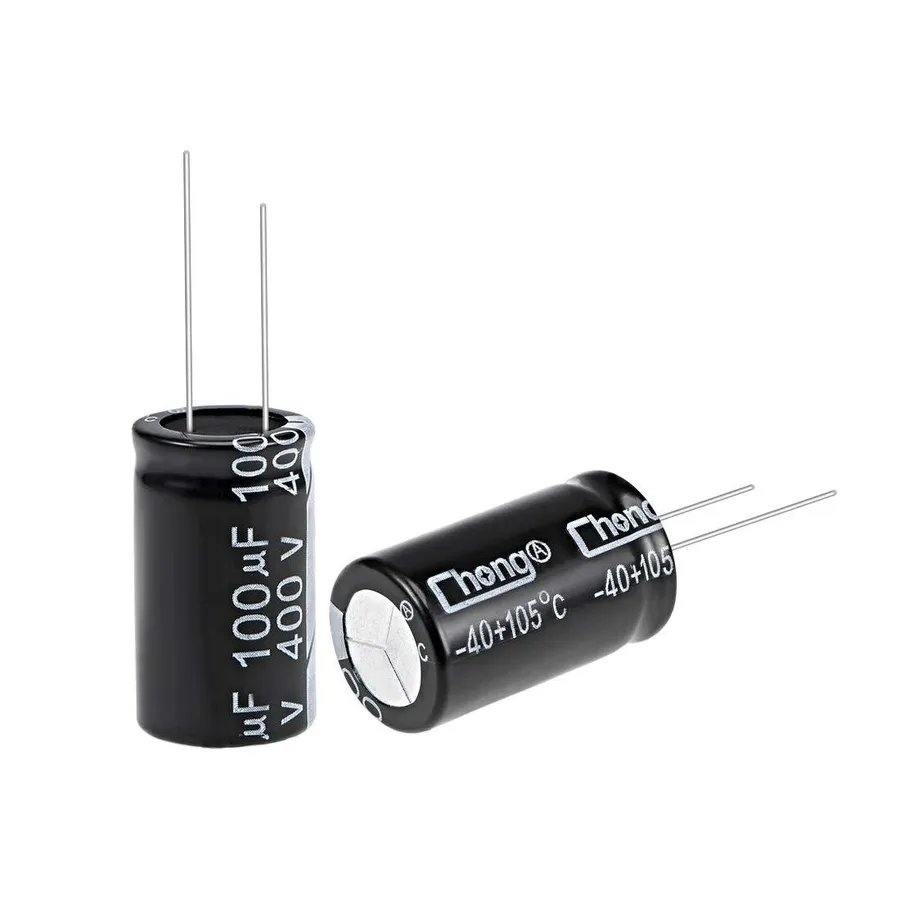

A 400V capacitor is a fundamental passive electronic component engineered to store electrical energy, with a specific design tolerance to withstand up to 400 volts. Its core function involves temporarily accumulating and releasing electrical charge, making it indispensable for filtering, decoupling, and ensuring stable operation in diverse electrical circuits.

At its heart, a capacitor consists of two conductive plates separated by a dielectric material. When voltage is applied, electrical charge accumulates on the plates, creating an electric field within the dielectric. The capacitor's ability to store charge is quantified by its capacitance, measured in Farads (F), with practical values often expressed in microfarads (µF), nanofarads (nF), or picofarads (pF). The 400V rating signifies the maximum voltage that the capacitor can safely handle without dielectric breakdown or permanent damage. It is imperative that the voltage applied to the capacitor does not exceed this value, as a failure to adhere to this rule can result in catastrophic failure of the capacitor and the system.

Common Applications of 400V Capacitors

400V capacitors are indispensable components across a wide range of electronic applications, primarily functioning to store and release electrical energy, filter out noise, and stabilize power delivery. Their ability to handle voltages up to 400V makes them suitable for various power-related applications.

- Power Supplies and Adapters

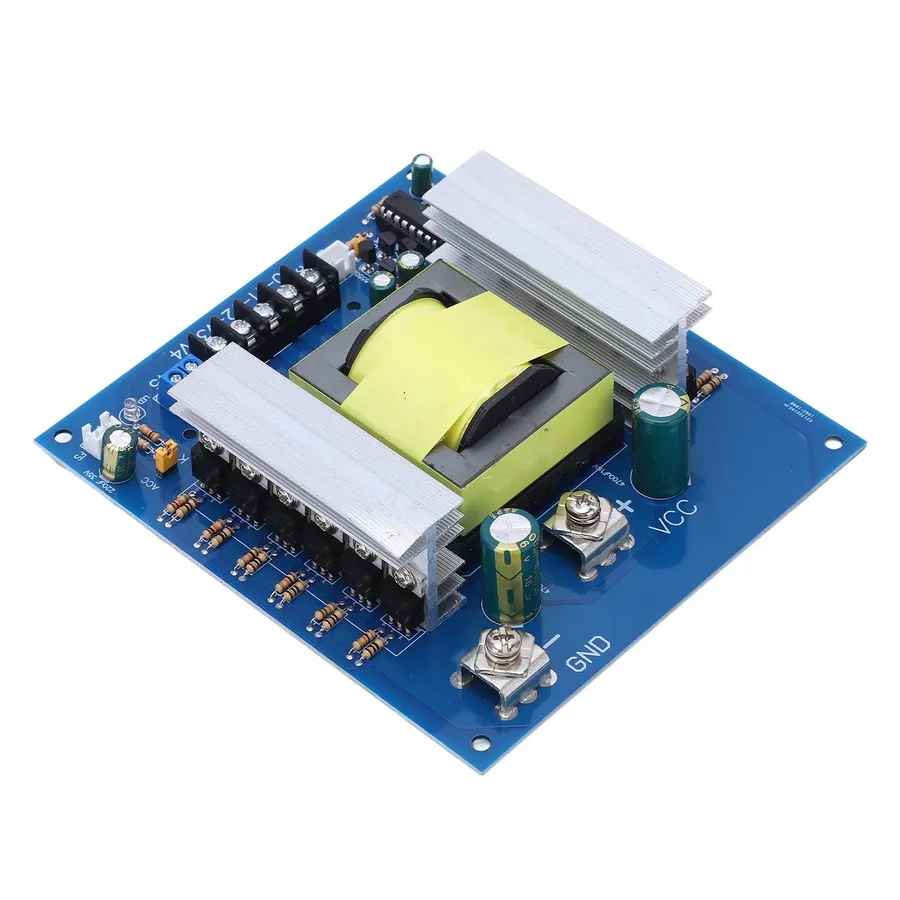

In AC-DC power supplies, including those found in chargers and adapters, 400V capacitors play a vital role in smoothing the rectified DC voltage, reducing ripple, and ensuring a stable output for electronic devices. - Audio Amplifiers

These capacitors are employed to smooth the power supply in audio amplifier circuits, reducing noise and providing stable power for high-fidelity audio reproduction. They help in decoupling stages and preventing unwanted oscillations. - Motor Control Circuits

400V capacitors are crucial in motor drive systems. They provide the required reactive power needed for motors and ensure stable and efficient motor operation by mitigating voltage fluctuations. - Industrial Equipment

In industrial settings, these capacitors are found in power conditioning circuits, inverters, and various control systems, where they provide reliable energy storage and filtering capabilities for robust performance under demanding conditions. - AC-DC Converters

400V capacitors are integral to the AC-DC conversion process, acting as energy buffers and filters to ensure a clean and consistent DC output. These converters can be found in a wide variety of applications, from consumer electronics to renewable energy systems. - Filtering Applications

These capacitors are used for filtering out noise and unwanted AC components from DC signals. This is crucial in ensuring the integrity of signal processing and reducing electrical interference.

| Application | Function | Typical Capacitor Type |

|---|---|---|

| Power Supplies | Smoothing, Filtering | Electrolytic, Film |

| Audio Amplifiers | Decoupling, Smoothing | Film, Electrolytic |

| Motor Control Circuits | Reactive Power, Smoothing | Electrolytic, Film |

| Industrial Equipment | Power Conditioning, Filtering | Electrolytic, Film |

| AC-DC Converters | Energy Storage, Filtering | Electrolytic, Film |

| General Filtering | Noise Reduction | Ceramic, Film |

Types of 400V Capacitors

400V capacitors are available in various types, each with distinct characteristics tailored to specific applications. Understanding these differences is crucial for selecting the correct component for your circuit. The three primary types are electrolytic, metal film, and ceramic capacitors, each offering unique advantages and disadvantages.

| Capacitor Type | Key Characteristics | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Electrolytic | High capacitance, polarized | Power supplies, smoothing circuits | High capacitance in small volume, cost-effective | Polarized, limited lifespan, higher ESR |

| Metal Film | Stable, non-polarized | Audio circuits, high-frequency applications | High stability, low ESR, good reliability | Lower capacitance for a given size, more expensive |

| Ceramic | Compact, non-polarized | High-frequency circuits, decoupling | Compact, inexpensive, good high-frequency response | Lower capacitance values, sensitive to voltage |

Selecting the Right 400V Capacitor: Key Factors

Selecting the appropriate 400V capacitor for a specific application is crucial for ensuring circuit performance and reliability. This selection process involves careful consideration of several key parameters, each playing a vital role in the capacitor's behavior within the circuit. Ignoring these factors can lead to suboptimal performance, component failure, or even safety hazards.

| Parameter | Description | Importance |

|---|---|---|

| Capacitance (µF) | The amount of charge the capacitor can store, measured in microfarads. | Determines the capacitor's ability to store and release energy. Must match the circuit's requirements to ensure proper operation. |

| Tolerance | The allowable deviation from the stated capacitance value, expressed as a percentage. | Indicates the accuracy of the capacitor's actual value compared to its nominal rating. Critical in circuits requiring precise timing or filtering. |

| Operating Temperature Range | The temperature range within which the capacitor will function correctly. | Essential to match the expected operating environment. Exceeding limits will reduce the lifespan or cause failure. |

| Lifespan | The expected operational duration of the capacitor, often expressed in hours. | Indicates how long the component is expected to work reliably. Should be considered for devices with a long operational life. |

| Physical Size | The dimensions and form factor of the capacitor. | Important for physical fit in device enclosures. Must be compatible with board layout and component spacing. |

| Voltage Rating | The maximum voltage the capacitor can safely withstand without damage. | While all the capacitors discussed here are 400V, it is important to ensure that you do not exceed the rated voltage when making component replacements. |

The selection process also benefits from considering the trade-offs between different capacitor types, each with their own characteristics. For example, while electrolytic capacitors offer high capacitance values in a relatively small package and at low cost, they are generally less tolerant of extreme temperatures and have shorter lifespans when compared to metal film capacitors. Therefore, a careful evaluation of all the parameters with respect to circuit needs is key to picking the correct capacitor.

400V Capacitor Specifications and Datasheets

A capacitor datasheet is a vital document that provides comprehensive information on a capacitor's performance and limitations, enabling engineers and users to select the appropriate component for their specific applications. These sheets detail crucial parameters, ensuring proper functioning and reliability within electronic circuits.

| Parameter | Description | Importance |

|---|---|---|

| Rated Capacitance | The nominal capacitance value, usually in microfarads (µF) or picofarads (pF). | Crucial for proper circuit operation. Mismatch can affect filtering, timing, and energy storage. |

| Rated Voltage | The maximum DC voltage the capacitor can safely withstand continuously. | Must exceed the maximum voltage expected in the application. Operating beyond this limit risks failure. |

| Tolerance | The acceptable deviation from the rated capacitance value, expressed as a percentage. | Impacts circuit accuracy. Tighter tolerances are required for precision applications. |

| Temperature Range | The permissible operating temperature range, typically specified in Celsius. | Operating outside this range can lead to performance degradation or premature failure. |

| Equivalent Series Resistance (ESR) | The inherent resistance within the capacitor, affecting its performance at high frequencies. | Critical in power supplies and filtering applications. Lower ESR is better. |

| Leakage Current | The small DC current that flows through the capacitor under a DC voltage. | Important in low-power applications. Higher leakage can cause power loss and component failure. |

| Lifespan | The expected operational lifespan of the capacitor, often specified in hours. | Affects the long-term reliability of the device. High lifespan is important in critical applications. |

| Physical Dimensions | The physical size and dimensions of the capacitor. | Crucial for PCB design and assembly. Should be considered before purchasing. |

| Polarity | Indicates whether the capacitor has a specific polarity (positive and negative terminals). | Critical for electrolytic capacitors. Incorrect polarity can cause damage or failure. |

Replacing a 400V Capacitor: Step-by-Step Guide

Replacing a 400V capacitor requires careful attention to safety and technical details. This process involves removing the old component and installing a suitable replacement, ensuring the continued proper functioning of the electrical device. The procedure demands basic soldering skills, and an understanding of electrical safety is essential.

- Safety First: Disconnect Power and Discharge

Before commencing any work, ensure the device is completely powered off. Critically, discharge the capacitor using a suitable resistor to avoid electrical shock. Capacitors, especially 400V ones, can retain a significant charge even when disconnected from the power source. - Identify the Correct Replacement

Acquire a replacement capacitor with the exact capacitance (measured in microfarads, µF) and voltage rating (400V or higher). Check the datasheet of the component. Exceeding the original voltage rating can be acceptable (e.g. replacing 400V with 450V), but the capacitance should be the same, unless the circuit design allows a different value. - Note the Polarity (for Electrolytic Capacitors)

Electrolytic capacitors are polarized, meaning they have a positive and a negative terminal. Observe the old capacitor's polarity markings (usually a stripe on the negative terminal) before removal, and ensure that you align the replacement's polarity correctly. Reverse polarity may lead to capacitor failure and damage to the device. - Remove the Old Capacitor

Use a soldering iron and desoldering tool (or desoldering wick) to carefully remove the old capacitor. Heat the solder joints on the capacitor leads and gently extract it without excessive force. Clean the soldering pads. Avoid damaging the traces on the printed circuit board. - Install the New Capacitor

Position the new capacitor on the circuit board, making sure the leads are inserted correctly into the designated holes. If the component is an electrolytic capacitor, ensure the polarity matches the PCB markings. Solder the leads securely, and ensure no loose connections exist. Excess solder should be avoided to not cause short circuits. - Inspect the Soldered Joints

After soldering, carefully inspect each joint. There should be sufficient solder for a strong electrical connection, but the joint should not be excessive or have stray solder causing short circuits. A good solder joint will have a smooth, shiny appearance. - Test the Device

Reassemble the device. Test it to see if the replacement is successful, and if all functions of the device work as they should. If there are any issues, immediately power off the device and double check your work.

400V Capacitor Safety: Precautions and Best Practices

400V capacitors, while essential components in electronic circuits, pose significant safety risks due to their capacity to store high voltage. Improper handling can result in electrical shock, burns, and damage to equipment. Therefore, adhering to strict safety protocols is paramount when working with these components.

- Discharge Before Handling

Capacitors can retain a charge even when the power is off. Always discharge a 400V capacitor using a suitable discharge tool (e.g., a resistor with appropriate rating) before handling. This will prevent electrical shock. Never short the terminals with a metallic object. Use an insulated discharge tool. - Never Exceed the Rated Voltage

Operating a capacitor above its rated voltage of 400V can lead to catastrophic failure, including rupture, fire, or explosion. Ensure that the voltage in the circuit does not exceed the capacitor's rating under any circumstances. Always choose a capacitor with a voltage rating higher than the maximum circuit voltage. - Observe Polarity

Electrolytic capacitors are polarized and must be connected with the correct polarity. Incorrect polarity can lead to failure and possible damage. Most electrolytic capacitors have clear markings to indicate polarity (+ and -), always check the polarity before soldering. The positive lead is often longer than the negative. - Use Insulated Tools

When working with capacitors, use insulated tools to reduce the risk of accidental electrical contact. Avoid using metallic tools that can conduct electricity and cause shorts. - Work in a Safe Environment

Ensure the work area is clean, dry, and free from clutter. Good lighting is essential, and remove any conductive materials from your work area. This reduces the chance of accidents and promotes a focused working environment. - Protective Gear

Use personal protective equipment (PPE) such as safety glasses or goggles to safeguard your eyes and wear insulated gloves to minimize the risk of electrical shock. - When to Seek Professional Help

If you are uncertain about any of the above procedures or lack experience, seek professional assistance from a qualified technician or engineer. Do not attempt to replace or handle these components if you are unfamiliar with the risks.

Frequently Asked Questions About 400V Capacitors

This section addresses common questions regarding 400V capacitors, providing practical insights into their usage, replacement, and safety considerations. These answers are grounded in electrical engineering principles and aim to enhance user understanding.

- Can I use a 450V capacitor instead of a 400V capacitor?

Yes, using a 450V capacitor as a replacement for a 400V capacitor is generally safe and acceptable. A capacitor's voltage rating indicates the maximum voltage it can safely withstand. Using a capacitor with a higher voltage rating than required will not harm the circuit and can actually improve the capacitor's lifespan and reliability. The capacitance value should always match the original component's specification, however. - What are 4.7 uF and 2.2 uF 400V capacitors commonly used for?

4.7 uF and 2.2 uF 400V capacitors are typically used in applications requiring stable power filtering and signal decoupling. The 4.7 uF capacitor, due to its higher capacitance, may be used in power supplies for smoothing out voltage fluctuations, while the 2.2 uF capacitor might be used for signal coupling or filtering where a smaller capacitance is sufficient. These specific values are often chosen based on the frequency and impedance characteristics of the circuits they are used in, ensuring optimal circuit performance and stability. - Why are 400V capacitors commonly found in power adapters?

400V capacitors are commonly used in power adapters due to the voltage levels present in the AC mains input. The 400V rating provides a safety margin when the adapter rectifies and filters the incoming AC voltage, which can fluctuate and have transient spikes. This high-voltage rating ensures the capacitor can handle these transient voltages and provide a stable DC output. Additionally, the 400V rating is a standard for many mains-powered applications. - Is it dangerous to handle a charged 400V capacitor?

Yes, it is dangerous to handle a charged 400V capacitor. These capacitors store substantial electrical energy and can deliver a severe electric shock if discharged through the body. Always discharge a capacitor completely using an appropriate resistor or tool before handling it or performing any maintenance. Failure to do so can result in serious injury or even death. - How do I know what capacitance value of a 400v capacitor I need?

The capacitance value of a 400V capacitor required for an application is determined by the specific circuit's needs. The capacitance value is typically measured in microfarads (uF) and is often determined by circuit simulations, or it can be read on the side of the original component. Always use a capacitor with the same value, or use an equivalent with the correct values for your circuit requirements. Incorrect values could lead to degraded performance, circuit failure, or overheating. - What is the typical lifespan of a 400V capacitor?

The typical lifespan of a 400V capacitor depends on various factors including its type, the operating temperature, and applied voltage. Electrolytic capacitors tend to degrade over time due to electrolyte evaporation and are sensitive to temperature and voltage stresses. Metal film and ceramic capacitors usually offer a longer lifespan. Datasheets should always be consulted for the manufacturer's expected operational life, under specified operating conditions, which may vary significantly based on the capacitor type and quality.

The 400V capacitor may seem like a simple electronic component, but it is a crucial component in the smooth operation of many electronic devices. This article has explored different aspects of 400V capacitors, from understanding their function and types to selecting them, and ensuring safe handling practices. By applying the knowledge discussed, you can better appreciate and work with these components in a variety of applications. Furthermore, by understanding the importance of specifications like voltage and capacitance, you can make sure you select the best capacitor for the job. Whether you're repairing a device or designing a circuit, understanding the 400V capacitor is key for success, and it's a vital component that keeps our digital world powered up and running smoothly.

AnyPCBA

AnyPCBA