Decoding Circuit Board Patterns: A Comprehensive Guide

Just like the intricate patterns found in nature, circuit board patterns are the blueprints of our modern electronics, enabling the flow of electricity to power the devices we use every day. This article will delve into the world of circuit board patterns, unraveling their complexities and revealing their crucial role in technology. We will explore their visual representation, design rules, and impact on the functionality of electronic devices, all while highlighting the crucial role of circuit board patterns in modern technology. We'll explore not just what they are, but why they are designed the way they are, offering insights into the fascinating world of micro-electronics.

What are Circuit Board Patterns?

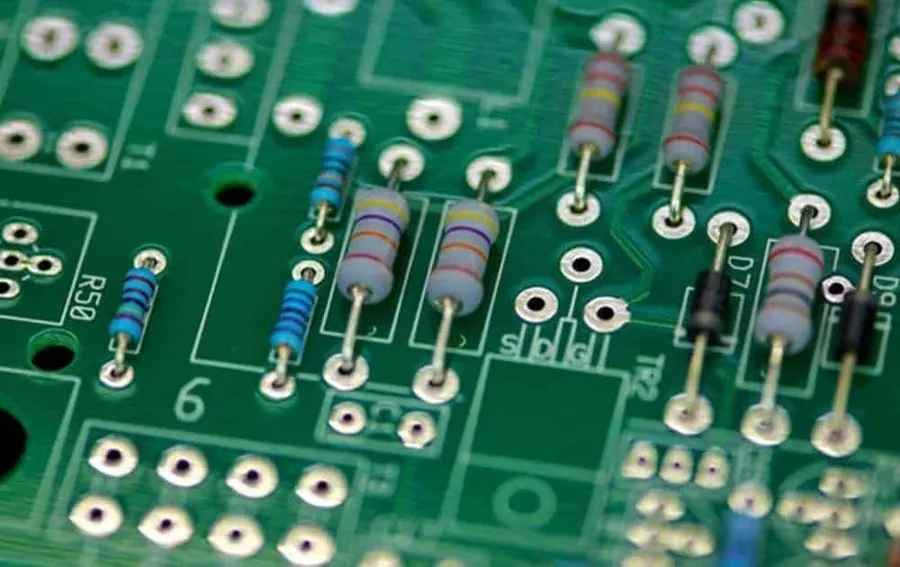

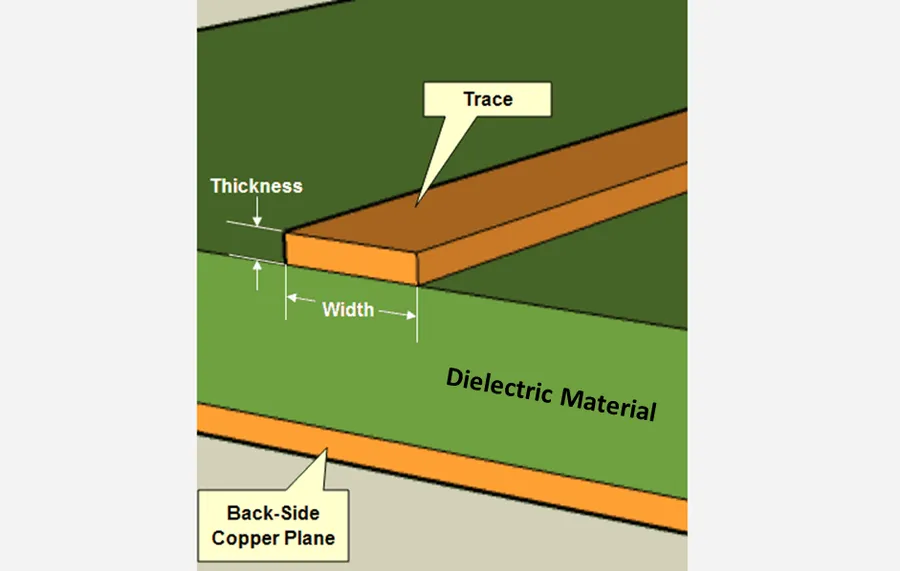

Circuit board patterns are the intricate visual blueprints that dictate the layout and electrical connections on a printed circuit board (PCB). These patterns, typically composed of conductive traces (lines), pads for component mounting, and vias (interlayer connections), form the physical embodiment of an electronic circuit's design, establishing the pathways for electrical signals and power distribution. The precision and accuracy of these patterns directly impact the functionality, performance, and reliability of the final electronic device.

The Importance of Circuit Board Patterns in Electronics

Circuit board patterns are fundamental to the functionality of virtually all electronic devices. These patterns, comprising conductive traces, pads, and vias, dictate the flow of electrical signals and power throughout the system. Their precise design is paramount as they directly influence signal integrity, power distribution, and overall system reliability.

The significance of these patterns extends beyond mere connectivity; they are integral in maintaining the desired electrical characteristics for optimal performance. Errors or inadequacies in pattern design can manifest as signal distortion, power fluctuations, and ultimately, device failure. Therefore, the process of designing, verifying, and fabricating circuit board patterns is critical in the electronics industry.

- Signal Integrity

Accurate patterns minimize signal reflections, crosstalk, and other forms of signal distortion that can degrade performance. Proper impedance matching and trace layout are critical aspects of design to ensure high-fidelity signal transmission. - Power Distribution

Circuit board patterns effectively distribute power to all components. Inadequate design can lead to uneven power supply, causing malfunctions and reduced operational efficiency of the electronics. Plane layers of the pattern, when well-designed, assist in distributing power effectively. - System Reliability

Correctly implemented patterns reduce the risk of shorts, opens, and other physical defects, which directly affect the reliability of the electronic product. High-quality pattern design contributes to a device's robustness and longevity by minimizing potential failure points.

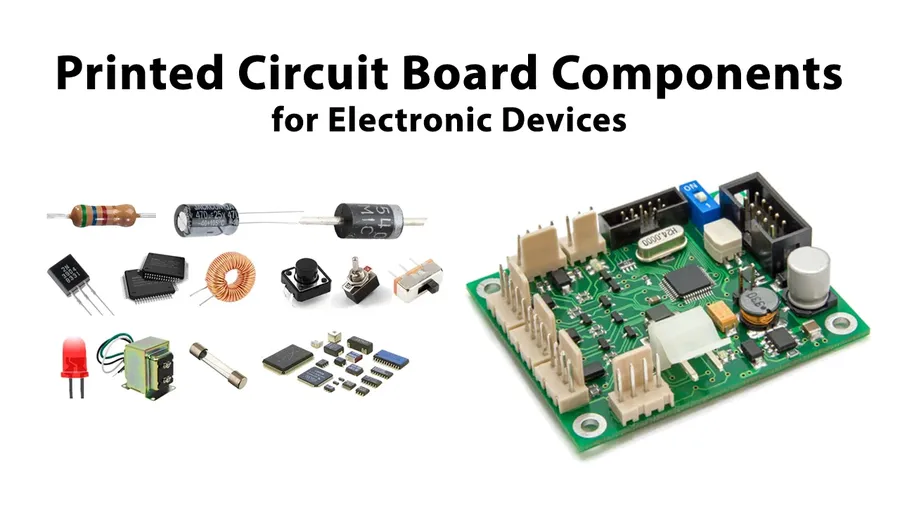

Key Elements of Circuit Board Patterns

Circuit board patterns are constructed from several fundamental elements, each playing a crucial role in the overall functionality of the electronic circuit. These elements include traces, vias, pads, and planes. Understanding their individual characteristics and functions is essential for effective PCB design.

| Element | Description | Function |

|---|---|---|

| Traces | Conductive pathways, usually thin lines of copper, that route electrical signals. | Carry signals and power between components. |

| Vias | Small plated through-holes that create connections between different layers of a multilayer PCB. | Facilitate vertical connections and signal routing between layers. |

| Pads | Exposed metal areas to which electronic components are soldered or connected. | Provide solder points for component mounting. |

| Planes | Large areas of solid copper, often used as power or ground planes. | Provide power distribution, ground connections, and shielding. |

The interplay and precise arrangement of these elements dictate the electrical behavior of the circuit. Careful consideration of their properties, such as trace width for impedance control, via size for current handling, and plane shape for effective power distribution and shielding, is paramount in ensuring a functional and reliable circuit board.

Common Circuit Board Pattern Design Principles

Effective circuit board design hinges on adherence to fundamental principles that ensure functionality, reliability, and performance. These principles encompass various aspects, including impedance control, trace geometry, power distribution, and signal integrity. A thorough understanding of these rules is crucial for engineers to create efficient and robust electronic devices.

| Design Principle | Description | Importance |

|---|---|---|

| Impedance Control | Maintaining a consistent impedance along signal traces to prevent reflections and signal loss. | Critical for high-speed signal transmission and maintaining signal integrity. Mismatched impedances can lead to signal distortion and errors. |

| Trace Width and Spacing | Determining the width of traces and the spacing between them based on signal current, impedance, and manufacturing capabilities. | Impacts impedance, current carrying capacity, and reduces crosstalk. Sufficient spacing avoids shorts and ensures proper isolation. |

| Power Distribution | Designing efficient power planes and traces to deliver stable and clean power to the various components of the circuit. | Ensures components receive adequate power without voltage drops. Proper power distribution reduces noise and thermal issues. |

| Minimizing Signal Interference | Employing techniques to minimize crosstalk and electromagnetic interference (EMI) between signal traces. | Reduces the impact of noise and prevents signal degradation. Strategies include shielding, trace routing, and ground plane optimization. |

| Grounding Strategy | Establishing proper ground connections to ensure signal return paths, minimizing noise and improving signal quality. | Ensures a stable reference point for all signals, preventing ground loops and reducing the impact of common-mode noise. |

| Thermal Management | Designing the circuit board layout to facilitate heat dissipation, preventing overheating and ensuring component reliability. | Crucial for components that generate heat. Adequate thermal management improves component lifetime and overall system stability. |

Types of Circuit Board Patterns

Circuit board patterns, the very essence of electronic connections, manifest in various forms, each tailored to specific application needs and complexities. These patterns dictate the flow of electrical signals and the physical connections of components. The selection of the appropriate type is crucial to the functionality and performance of electronic devices.

| Pattern Type | Description | Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Single-Sided | Traces and components on one side of the board. | Simple circuits, educational projects, basic consumer electronics. | Low cost, easy to manufacture. | Limited routing, not suitable for complex designs. |

| Double-Sided | Traces and components on both sides of the board. | Intermediate complexity devices, common in many applications. | Increased density, better routing flexibility. | More complex than single-sided, slightly higher cost. |

| Multilayer | Multiple layers of conductive material separated by insulating layers. | High-density electronics, complex circuitry, advanced applications. | Extremely high density, complex routing, enhanced functionality. | Higher cost, more complex to manufacture, longer lead time. |

| Flexible (Flex) | Circuits built on flexible substrate, bendable and adaptable. | Portable devices, wearables, applications requiring flexibility. | Lightweight, flexible, adaptable to various shapes. | Higher manufacturing cost, more fragile than rigid boards. |

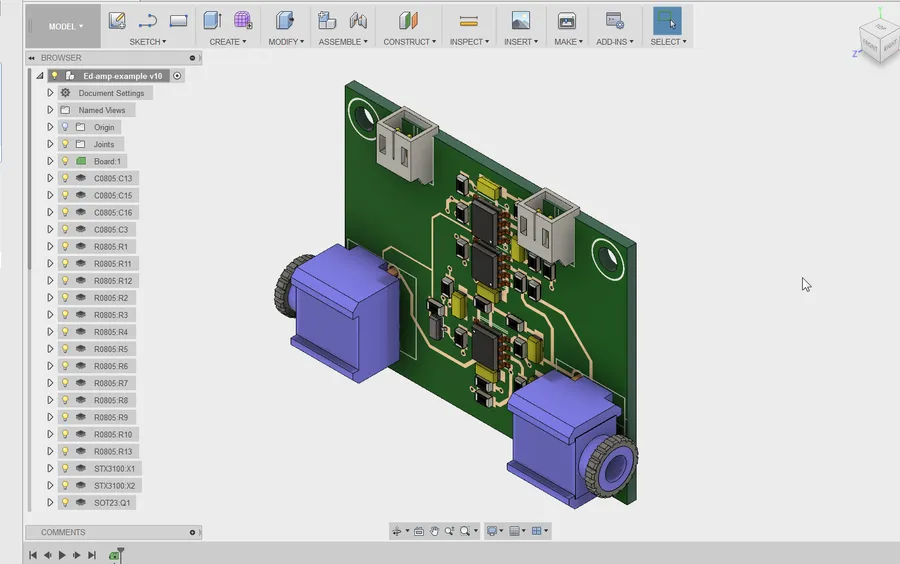

Circuit Board Patterns: Design Tools and Software

The design and manipulation of circuit board patterns rely heavily on specialized software and design tools. These tools have revolutionized the process, enabling engineers to create intricate and precise layouts with enhanced efficiency and accuracy, and are indispensable for modern electronic product development. These tools not only automate complex tasks but also offer features for simulation and verification, ensuring designs are manufacturable and functional before physical prototyping.

Below are some of the key features and functionalities of these tools:

- Schematic Capture

This functionality allows engineers to create a logical representation of the electronic circuit, defining the components and their interconnections. It serves as the foundation for the physical layout of the circuit board. - PCB Layout

PCB layout tools provide a graphical environment for designing the physical arrangement of components and traces on the circuit board. They offer features for placing components, routing traces, and managing board layers. - Simulation and Analysis

Many design tools include simulation capabilities, which enable engineers to analyze the electrical performance of the design before fabrication. This helps identify potential issues and optimize the layout. - Design Rule Checking (DRC)

DRC ensures that the design adheres to the manufacturing constraints and design rules, avoiding fabrication issues. It automatically checks for violations such as insufficient trace spacing or incorrect via sizes. - Gerber File Generation

The design tools can generate standard files used by PCB fabrication houses to produce the physical boards. This includes Gerber files, which contain layout information for each layer of the circuit board. - Component Libraries

Design tools often incorporate extensive libraries of electronic components. These libraries contain accurate 2D and 3D models of the components, as well as associated footprint data, greatly simplifying the design process.

Here's a comparison of some popular circuit board design software packages, highlighting their strengths and weaknesses:

| Software | Strengths | Weaknesses | Cost |

|---|---|---|---|

| Altium Designer | Comprehensive feature set, excellent routing, strong community support. | High cost, steep learning curve for beginners. | High |

| KiCad | Open source, free to use, actively developed, good for hobbyists. | User interface not as polished as commercial options, may require additional setup. | Free |

| Eagle (Autodesk) | Popular among hobbyists and small businesses, good online support, accessible price point. | Feature set not as extensive as high-end options, large designs can be slow. | Moderate |

| OrCAD (Cadence) | Powerful simulation tools, widely used in industry, capable of complex designs. | High cost, can be difficult to master for simple projects. | High |

| PADS Professional (Siemens) | Highly scalable for large-scale enterprise designs, advanced signal integrity analysis. | Very high cost, targeted at large companies, overkills for simple tasks. | Very High |

Circuit Board Pattern Fabrication Process

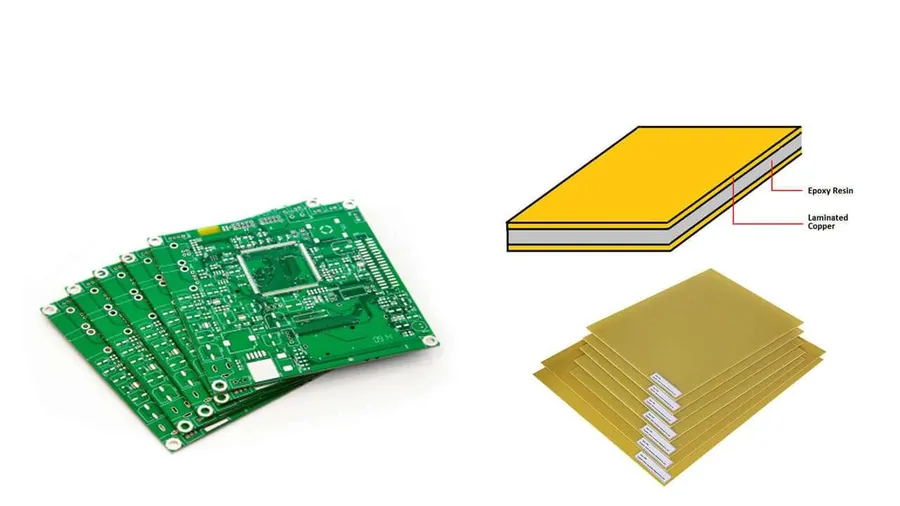

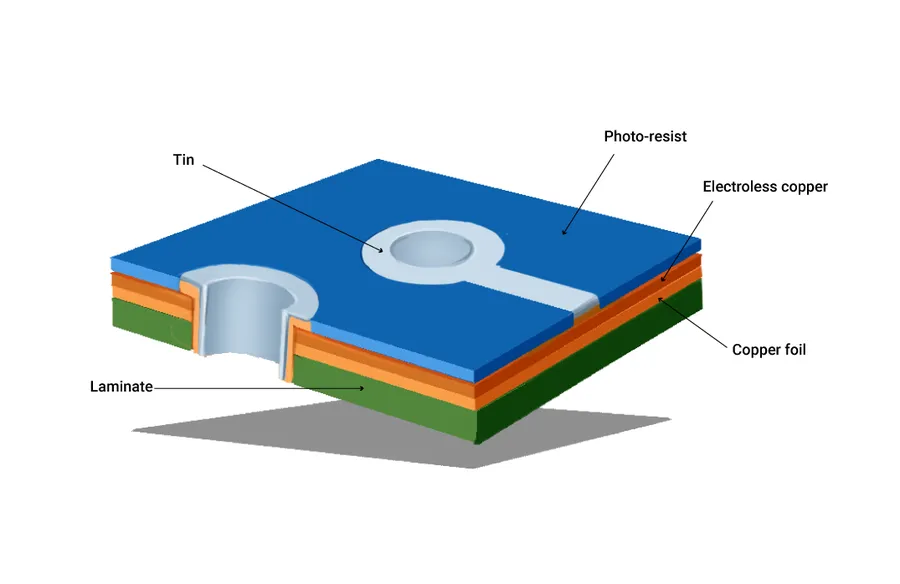

The fabrication process transforms meticulously designed circuit board patterns into physical printed circuit boards (PCBs). This multi-stage process demands high precision to ensure the final product accurately reflects the design, guaranteeing the intended electrical performance. Key steps include etching, drilling, and plating, each requiring careful control and execution.

The fabrication process typically involves the following sequential stages:

- Pattern Transfer

The circuit pattern is transferred onto a copper-clad board using methods like photolithography. A photosensitive resist is applied, exposed to UV light through a mask containing the circuit pattern, and then developed, leaving the desired pattern of resist on the copper. - Etching

The board is immersed in a chemical etchant solution that removes the exposed copper, leaving behind only the copper protected by the resist. This step accurately defines the circuit traces and pads as defined in the design. - Drilling

Drilling machines precisely create holes for vias (interlayer connections) and component leads, using computer-controlled drill bits. The accuracy of the drilling is critical for proper component placement and electrical connections. - Plating

A thin layer of metal, often copper and then tin or gold, is plated onto the board to improve conductivity, solderability, and protect exposed copper from corrosion. This process also plates the inner walls of the drilled holes, creating conductive vias. - Solder Mask Application

A solder mask is applied to the board, with openings created for solderable pads, preventing solder from flowing where it's not intended and protects the circuit traces from environmental damage. - Silkscreen Printing

Silkscreen printing applies legends, part numbers, and logos to the PCB, providing identification and reference points for assembly and debugging. - Final Testing and Inspection

After fabrication, PCBs undergo electrical testing and visual inspection to verify that they meet the design specifications and have no defects, guaranteeing performance and reliability.

The precision required in each of these steps cannot be overstated. Any deviation can lead to a non-functioning board, making careful adherence to the design specifications and manufacturing tolerances paramount. Advancements in fabrication technologies constantly drive improvements in accuracy and efficiency, enabling the manufacture of increasingly complex and high-density PCBs.

Frequently Asked Questions about Circuit Board Patterns

This section addresses common questions regarding circuit board patterns, offering concise and precise answers to enhance understanding of PCB design and manufacturing.

- What is a circuit board pattern?

A circuit board pattern, also known as a PCB layout, is the blueprint defining the conductive pathways, component placements, and connections on a printed circuit board. It's a precise arrangement of traces, pads, vias, and other elements that dictate the functionality of the electronic device. - How are circuit board patterns created?

Circuit board patterns are typically designed using specialized software, such as CAD (Computer-Aided Design) tools, that allows engineers to create the layout of the board digitally. The pattern is then transferred to the board through a fabrication process that may involve etching, drilling, and plating. - What are the fundamental rules of PCB design related to patterns?

Basic rules include maintaining proper trace width and spacing to achieve desired impedance, minimizing loop areas to reduce interference, strategically placing decoupling capacitors, ensuring adequate power distribution, and following specific component manufacturer guidelines. Adhering to these principles ensures functionality, signal integrity, and manufacturability. - What are the common types of circuit boards?

The three primary types are single-sided boards, where conductive patterns exist on one side of the substrate; double-sided boards, with conductive patterns on both sides; and multilayer boards, which have three or more conductive layers that enable complex interconnections. - What are traces, vias, and pads in a circuit board pattern?

Traces are the conductive pathways, usually made of copper, that carry electrical signals. Vias are plated-through holes that connect conductive layers. Pads are conductive surfaces for soldering electronic components onto the circuit board. These elements are fundamental for creating the electrical network on a PCB. - What role does impedance control play in circuit board patterns?

Impedance control ensures that the signal travels with minimum reflection and distortion through the trace. Matching the impedance of the trace to the signal's source and destination is critical for high-frequency signal integrity, especially in high-speed communication circuits. - How does the circuit board pattern impact the performance of an electronic device?

The precision of the circuit board pattern directly affects the performance and reliability of an electronic device. Poorly designed patterns can lead to signal degradation, power loss, electromagnetic interference, and device malfunctions. Correct pattern design is critical for optimal functionality and longevity.

Future Trends in Circuit Board Pattern Design

The evolution of circuit board pattern design is being propelled by the increasing complexity and miniaturization of electronic devices. Future trends are geared towards addressing the demands for higher performance, greater density, and enhanced flexibility in electronic circuits.

- Advanced Materials

The industry is actively exploring new materials with superior electrical and thermal properties. These include advanced ceramics, composites, and polymers which can facilitate higher operating temperatures, better signal transmission and improved thermal management for circuit boards. - High-Density Interconnect (HDI) Designs

HDI technology, with its microvias, fine lines and tight spacing, is critical for creating more compact and functional boards. Future trends are leaning towards even finer features to pack more functionality into smaller footprints, driving innovation in fabrication techniques. - Flexible and Stretchable Circuits

Flexible circuits, employing materials such as polyimide and liquid crystal polymers, are becoming more common in wearable and IoT devices due to their ability to conform to various shapes and surfaces. The development of stretchable electronics will take this further, allowing for use in dynamic applications where the board needs to change shape. - 3D Circuit Board Design

Moving beyond traditional 2D designs, 3D circuit board technology is emerging as a solution to further increase component density. These multi-layered structures allow for vertical integration of components and interconnections, creating more complex and compact electronic assemblies. - AI-Driven Design Optimization

Artificial intelligence (AI) is being adopted to optimize circuit board layouts. AI algorithms can help streamline the design process, improve signal integrity, and minimize the time required for layout while taking into consideration manufacturing constraints.

Circuit board patterns are indeed the unsung heroes of modern technology. They are the intricate maps of our electronic devices, essential for efficient functionality and reliability. From the simple lines connecting components to the sophisticated designs found in complex devices, understanding these patterns offers insights into the heart of electronics. As technology advances, these patterns will only become more crucial, showcasing the ongoing evolution of circuit board design. Just as natural patterns reflect underlying processes, so do circuit board patterns—revealing the sophisticated interplay of technology. The future of electronics hinges on continued innovation in this foundational element.

AnyPCBA

AnyPCBA