PCB Design Engineering: A Comprehensive Guide for Aspiring Engineers

Printed Circuit Boards (PCBs) are the unsung heroes of modern technology, powering everything from smartphones to spacecraft. PCB design engineering is a specialized field that combines electrical engineering principles with artistic precision to create these complex and vital components. This article delves into the multifaceted world of PCB design engineering, providing a comprehensive guide for aspiring engineers and those curious about this dynamic discipline, covering essential skills, career paths, and the intricate design process involved in bringing electronic devices to life.

Understanding the Fundamentals of PCB Design Engineering

A robust grasp of fundamental electronics principles is the cornerstone of effective PCB design engineering. This involves a deep understanding of circuit theory, signal integrity, and power distribution, which dictates how well a PCB functions under various operational conditions. Neglecting these fundamentals can lead to performance issues, such as signal degradation, unstable power delivery, and ultimately, a non-functional electronic product.

The role of these fundamental concepts are: * **Circuit Theory:** Enables the engineer to understand how electrical current and voltage behave within the circuit. This encompasses understanding Ohm's law, Kirchhoff's laws, and various circuit analysis techniques. This knowledge forms the basis for how the components of the circuit will interact and is crucial for designing a functional circuit on the PCB. * **Signal Integrity:** Deals with maintaining the quality of electrical signals as they travel through the PCB. It focuses on minimizing signal distortion and ensuring that signals reach their destinations with minimal degradation. Factors such as trace impedance, reflections, and crosstalk are critical considerations in high-speed digital design. Signal integrity problems can lead to data corruption and unreliable operation. * **Power Distribution:** The method in which power is delivered to the components on the PCB. An effective design ensures that all components receive the required power with minimal fluctuations or noise. Improper power distribution can lead to unstable operation, component failure, and noise issues that can affect the entire system.

| Fundamental Principle | Description | Impact on PCB Design |

|---|---|---|

| Circuit Theory | Analysis of electrical circuits using Ohm's and Kirchhoff's laws. | Ensures correct voltage and current flow, proper component operation. |

| Signal Integrity | Maintaining signal quality during transmission. | Reduces signal distortion, reflections, and crosstalk for reliable operation. |

| Power Distribution | Efficient and stable supply of power to components. | Minimizes noise and fluctuations for stable and reliable component performance. |

Essential Skills for a PCB Design Engineer

A successful PCB design engineer requires a robust combination of technical skills and problem-solving acumen. This role demands proficiency in several key areas, ranging from fundamental electronics knowledge to practical application of design software, and an understanding of manufacturing processes. Mastery in these areas allows engineers to create effective, reliable, and manufacturable PCB designs.

- Deep Understanding of Electronic Components

A comprehensive grasp of various electronic components such as resistors, capacitors, inductors, diodes, transistors, and integrated circuits (ICs), is fundamental. This includes understanding their characteristics, applications, and limitations within a circuit design. - Proficiency in EDA Software

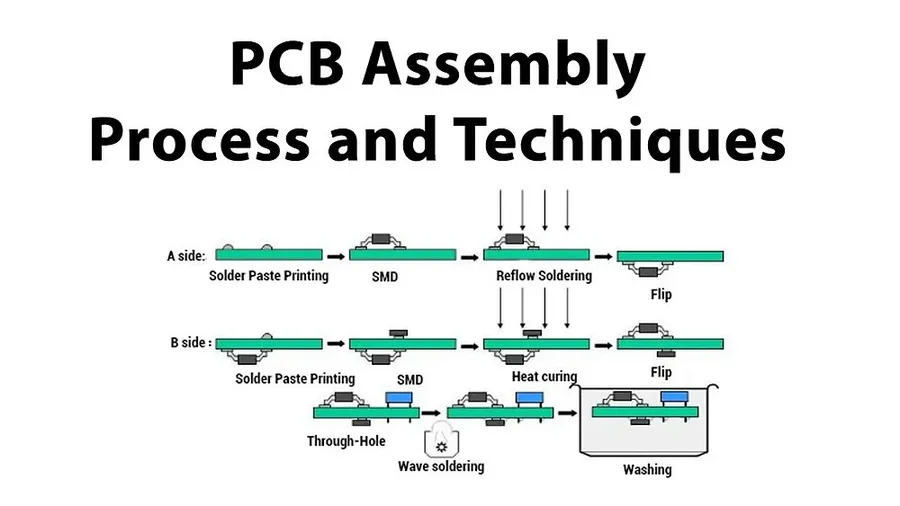

Expertise in Electronic Design Automation (EDA) software, such as Altium Designer, Cadence Allegro, or KiCad, is crucial. Engineers should be adept at using these tools for schematic capture, PCB layout, and simulation purposes. - Knowledge of PCB Fabrication Processes

Understanding the various stages of PCB manufacturing, including etching, drilling, plating, and soldering is essential. This enables engineers to design boards that are practical to manufacture and cost-effective. - Signal Integrity and EMC/EMI Principles

A strong grasp of signal integrity principles is needed to ensure the proper functioning of high-speed circuits. Engineers must also be aware of Electromagnetic Compatibility (EMC) and Electromagnetic Interference (EMI) mitigation techniques to design compliant boards. - Strong Analytical and Problem-Solving Abilities

The role requires strong analytical skills to interpret design specifications and solve complex problems related to circuit functionality and layout constraints. Engineers must have the ability to debug issues and offer solutions.

| Skill Category | Specific Skills | Importance |

|---|---|---|

| Technical Knowledge | Component knowledge, Circuit theory, Signal integrity, Power distribution | Essential for designing functional PCBs |

| Software Proficiency | EDA software usage, Schematic capture, PCB layout | Key for efficient design process |

| Fabrication Awareness | PCB manufacturing processes, material properties, DFM | Ensures designs are manufacturable |

| Analytical Skills | Problem-solving, debugging, optimization | Critical for overcoming design challenges |

The PCB Design Process: From Concept to Production

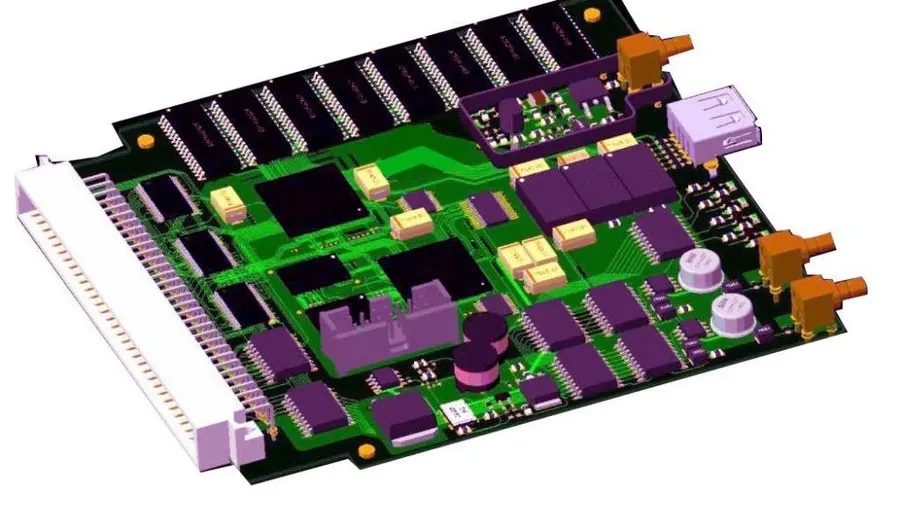

The creation of a printed circuit board (PCB) is a meticulous process that transforms an abstract electronic circuit design into a physical product. This process can be generally divided into several key stages, each requiring careful attention to detail to ensure the final product meets design specifications and functional requirements. These stages include schematic capture, component placement, trace routing, layer stack-up definition, and design validation, all of which contribute to the reliability and performance of the final PCB.

- Schematic Capture

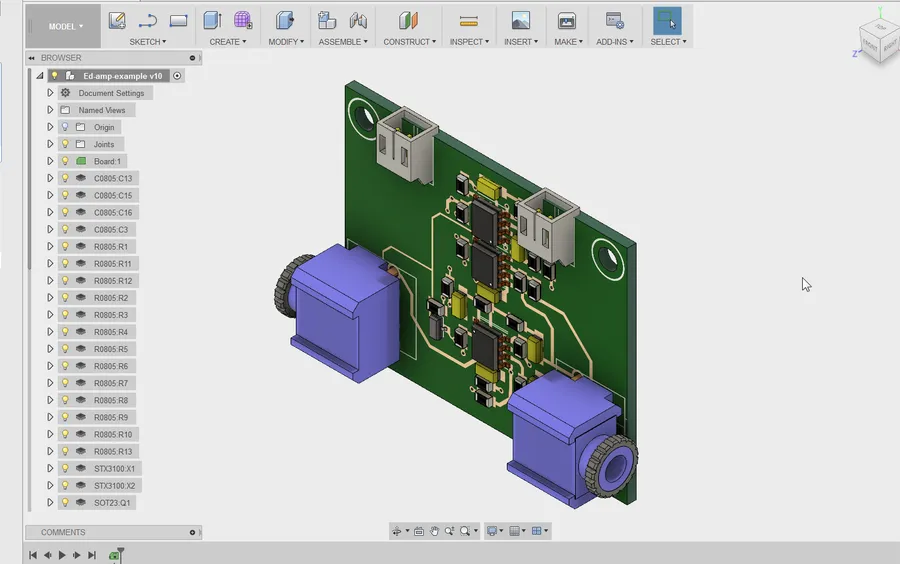

The initial phase involves translating the circuit's functional requirements into a schematic diagram. This representation uses standardized symbols to depict electronic components and their interconnections. Accurate schematic capture is crucial as it forms the blueprint for the physical PCB layout. Errors at this stage can propagate through the design process, leading to significant problems. EDA (Electronic Design Automation) tools are integral in this process, allowing engineers to create and verify circuit designs efficiently. - Component Placement

Once the schematic is complete, the next step is to place components strategically on the PCB layout. This step involves considering numerous factors, such as thermal management, signal integrity, and component size. Optimal placement minimizes signal path lengths, reduces interference, and ensures efficient assembly. EDA tools offer visualization features that aid in optimizing placement with considerations for manufacturing needs as well. - Trace Routing

Trace routing is where the connections depicted in the schematic are implemented as physical tracks on the PCB layers. This involves defining the paths for electrical signals, paying close attention to trace width, impedance, and spacing to prevent signal degradation, ensure impedance matching, and minimize interference. High-speed signals require meticulous routing techniques, and EDA tools automate much of the trace routing with considerations for design rules. - Layer Stack-up Definition

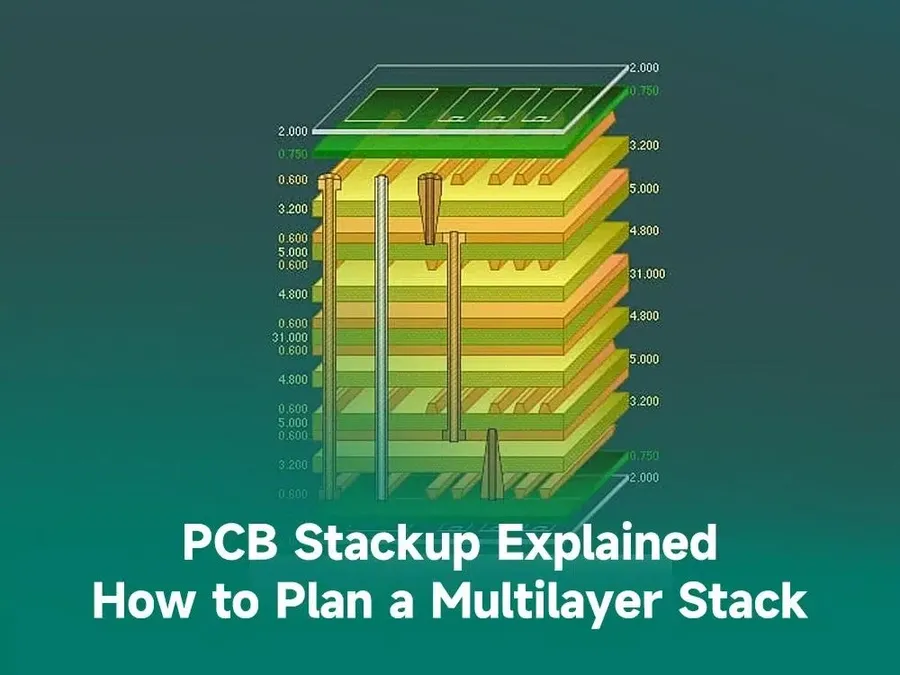

The layer stack-up refers to the arrangement of conductive (copper) and insulating (dielectric) layers within the PCB. Selecting an appropriate stack-up is crucial for achieving optimal signal integrity, controlled impedance, and electromagnetic compatibility (EMC). Decisions made at this stage significantly impact the performance and reliability of the PCB. A well-considered layer stack-up ensures predictable behavior and reduces the risk of signal quality issues. - Design Validation

After the PCB layout is complete, design validation is essential to ensure the final design adheres to design rules and specifications, such as impedance matching, signal integrity, thermal management, and EMC. This phase involves running various simulations and analyses to identify potential issues. EDA tools provide built-in features for design rule checks (DRC), signal integrity analysis, and thermal simulations, ensuring a robust and reliable PCB design. Addressing these validations ensures fewer problems when manufacturing the PCB.

Choosing the Right PCB Design Software

Selecting the appropriate PCB design software is a critical decision that profoundly affects a PCB engineer's efficiency and the overall quality of the final product. The market offers a range of Electronic Design Automation (EDA) tools, each with unique features, strengths, and limitations. This section delves into several leading EDA software options, including Altium Designer, Cadence Allegro, and KiCad, to guide you in choosing the tool that best aligns with your project requirements and technical proficiency.

| Software | Pros | Cons | Typical Use Cases | Pricing Model |

|---|---|---|---|---|

| Altium Designer | Comprehensive feature set, user-friendly interface, strong component library management, active community support. | Higher cost, can be resource-intensive, potential learning curve for beginners. | Complex, multi-layer boards, high-speed designs, professional environments. | Subscription-based |

| Cadence Allegro | Robust capabilities for advanced PCB design, excellent signal integrity analysis, suitable for large and complex projects. | Steeper learning curve, higher cost, more complex licensing. | High-density interconnect (HDI) designs, high-speed digital systems, aerospace and defense applications. | Perpetual License and Subscription Model |

| KiCad | Free and open-source, versatile, active community, good for small projects. | Less sophisticated feature set compared to commercial options, may require manual library management. | Hobbyist projects, educational purposes, small to medium-sized designs, prototyping. | Free and Open Source |

| EAGLE | User-friendly interface, good for small to medium projects, subscription available | Limited capabilities for complex designs, component library can be challenging. | Hobbyist projects, educational purposes, prototyping. | Subscription-based |

| PADS Professional | Complete schematic and layout tools, robust analysis and verification tools, strong integration with other design suites. | Higher cost and potential resource-intensive for smaller designs. | High-speed digital designs, analog circuits, and RF/microwave applications. | Perpetual License and Subscription Model |

Navigating PCB Layer Stack-Up

The layer stack-up in a printed circuit board (PCB) is a critical design aspect that significantly influences signal integrity, impedance control, and electromagnetic compatibility (EMC). A well-planned stack-up optimizes performance by managing signal return paths, reducing crosstalk, and controlling impedance, while a poorly designed one can lead to signal degradation and increased noise.

The number of layers in a PCB stack-up can range from a simple two-layer board to complex multi-layer designs, depending on the specific application's requirements. Each layer has a specific purpose and contributes to the overall functionality of the PCB. Key considerations in designing a stack-up include layer material (dielectric constant), layer thickness, copper thickness, and the arrangement of power and ground planes.

| Layer Type | Function | Considerations |

|---|---|---|

| Signal Layer | Carries signal traces | Route traces to minimize impedance mismatches and crosstalk; careful placement of traces is critical for signal integrity. |

| Power Plane | Provides stable power distribution | Acts as a low impedance path for power delivery; essential for stable power and reduces noise. |

| Ground Plane | Serves as a return path and reduces noise | Creates an impedance reference; reduces electromagnetic interference and improves signal integrity. |

| Dielectric Layer | Insulates between layers | Determines impedance; Material dielectric constant effects performance. |

Specific configurations, such as the microstrip and stripline, also play a role. In a microstrip configuration, a signal trace is placed on the surface of the PCB with a ground plane below it. A stripline configuration, on the other hand, is where a signal trace is embedded between two ground or power planes, offering better EMC performance but higher fabrication costs.

Selecting the proper layer stack-up depends on the specific application needs, taking into account factors such as the signal frequency, the required impedance control, and the level of electromagnetic interference (EMI) expected. Careful analysis and simulation are recommended to ensure that the layer stack-up will provide optimal performance and compliance with design requirements.

Career Paths for PCB Design Engineers

PCB design engineering offers diverse career paths, from hands-on product development to specialized consulting roles. The field demands a blend of technical acumen and problem-solving skills, leading to various opportunities for professional growth and specialization. Advancement often requires continuous learning, mastery of new technologies and a keen understanding of industry trends.

| Career Path | Description | Required Skills | Advancement Opportunities |

|---|---|---|---|

| Product Development Engineer | Involved in the entire product lifecycle, from initial concept to final production. Designs and tests PCBs for specific products. | Strong understanding of electronic components, circuit theory, and PCB design software. Proficient in testing and validation methods. | Project lead, engineering manager, director of engineering |

| Hardware Engineer | Focuses on the overall hardware design of electronic systems, including PCB design and integration with other components. | Expertise in system-level design, integration, and testing. Familiarity with different hardware architectures and communication protocols. | Senior hardware engineer, technical lead, chief technology officer |

| Specialized PCB Consultant | Provides expert advice and solutions to clients, often focusing on complex designs or specific industry sectors. | Deep expertise in specialized areas like high-speed design, RF design, or thermal management. Excellent communication and problem-solving abilities. | Lead consultant, project manager, subject matter expert |

| Research and Development Engineer | Engages in research for next generation PCB design technologies and materials. | Strong background in materials science, advanced design techniques, and simulation tools. Innovative thinking is critical. | Research lead, principal investigator, academic positions |

| PCB Layout Designer | Specializes in the physical layout of PCBs based on schematics. Focus on efficient routing and manufacturability. | Proficiency in PCB layout software, understanding of design for manufacturing (DFM), and attention to detail. | Senior layout designer, layout team lead, design manager |

Frequently Asked Questions About PCB Design Engineering

This section addresses common queries regarding PCB design engineering, offering clear and concise answers to help aspiring engineers understand the field. We aim to provide essential information about the role, career path, required qualifications, and how to successfully start a career in PCB design.

- What exactly does a PCB Design Engineer do?

A PCB design engineer is responsible for creating the physical layout of electronic circuits on a printed circuit board. This involves taking an electrical schematic and translating it into a manufacturable PCB design, including component placement, trace routing, and ensuring the board meets electrical and mechanical specifications. The engineer ensures signal integrity, power distribution, and manufacturability. - What is the typical salary range for a PCB Design Engineer?

Salaries for PCB design engineers can vary based on experience, location, and the specific industry. Entry-level positions may start around $60,000 - $80,000 per year, while experienced engineers can earn upwards of $120,000 or more. Specialized roles in high-demand sectors can command even higher compensation. - What specific educational background is needed to become a PCB Design Engineer?

A bachelor's degree in electrical engineering, electronics engineering, or a closely related field is typically required. Coursework in circuit theory, electromagnetic fields, and computer-aided design (CAD) is highly beneficial. Practical experience through internships or co-op programs can be very helpful to get a job. - What is the career progression like for PCB Design Engineers?

Career paths can vary, but often start with entry-level roles focused on specific design tasks. With experience, engineers may progress to more complex design projects, lead design teams, become project managers, or move into specialized roles such as signal integrity or high-speed PCB design. Further progression can also lead to managerial and director roles in hardware design. - What specific skills are crucial for a PCB Design Engineer?

Key skills include a strong grasp of electronic circuit design, proficiency in PCB design software (like Altium Designer, Cadence Allegro, or KiCad), understanding of PCB manufacturing processes, knowledge of signal integrity and EMC/EMI, and the ability to troubleshoot design issues. Strong problem-solving skills and attention to detail are also essential. - What should I look for when searching for a job as a PCB Design Engineer?

When looking for PCB Design Engineering positions, consider companies that align with your interests in the specific field and offer good opportunities for professional development and growth. Also, make sure to check the company culture, the projects involved, work-life balance and benefits. - How should I prepare for a PCB Design Engineering interview?

To prepare for an interview, review the fundamentals of PCB design and be prepared to discuss your experience with design software, your understanding of circuit analysis, and your approach to solving design challenges. Practice explaining your design decisions and problem-solving processes. Bring a portfolio, if possible, of previous design work and be ready to discuss it with the interviewer. Show enthusiasm for the field and willingness to learn new things.

Advanced Topics in PCB Design Engineering

As PCB design engineering advances, specialization in niche areas becomes increasingly important. This section delves into advanced topics such as high-speed PCB design, thermal management, and RF PCB design, providing a deeper understanding of these critical aspects for experienced engineers looking to expand their expertise.

These advanced disciplines require in-depth knowledge of specific principles and methodologies beyond fundamental PCB design practices, focusing on performance optimization and signal integrity in increasingly complex designs. Further expertise in these areas positions engineers as highly specialized contributors within the industry.

| Topic | Description | Key Considerations |

|---|---|---|

| High-Speed PCB Design | Focuses on signal integrity and impedance control at high frequencies to ensure reliable data transmission. | Transmission line effects, impedance matching, crosstalk reduction, termination techniques. |

| Thermal Management in PCB Design | Addresses heat generation and dissipation to prevent component overheating and ensure reliable operation of electronic devices. | Heat sink design, thermal vias, airflow management, material selection. |

| RF PCB Design | Deals with designing printed circuit boards for radio frequency applications that need low signal loss, minimize interference, and achieve precise impedance control. | Antenna placement, impedance matching, shielding, substrate selection. |

The Future of PCB Design Engineering

The field of PCB design engineering is undergoing a rapid transformation, driven by advancements in artificial intelligence (AI), automation, and material science. These innovations are not only streamlining the design process but also enabling the creation of more complex, efficient, and high-performance electronic systems. Adapting to these changes will be critical for PCB design engineers to remain competitive and innovative.

Below are key trends shaping the future of PCB Design Engineering:

- AI-Powered Design Tools

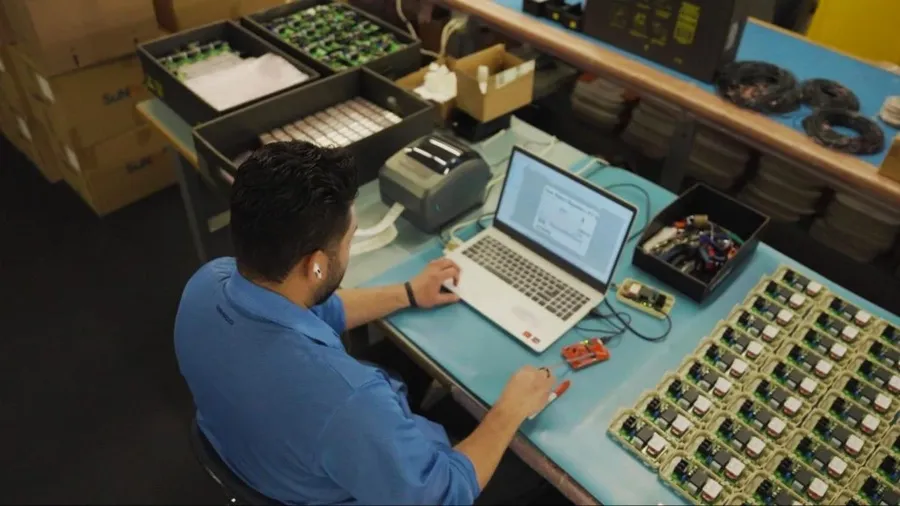

AI algorithms are increasingly being integrated into EDA software to automate complex tasks such as component placement, trace routing, and design rule checking. This reduces design time and optimizes PCB layouts for performance and manufacturability. AI can also predict potential design issues, enabling proactive corrections and enhancing design robustness. - Automation and Robotics

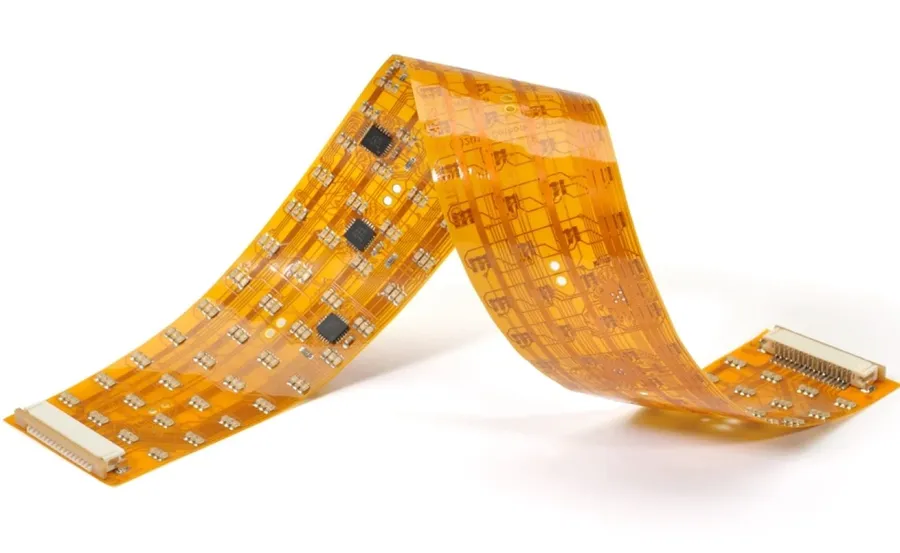

Automated manufacturing processes and robotic assembly lines are becoming more prevalent in PCB fabrication and assembly. This trend demands that PCB designs are optimized for automated processes to ensure efficiency and reduce errors. PCB design engineers will be responsible for creating designs that fully leverage the capabilities of automated manufacturing equipment. - Advanced Materials

The emergence of new materials, including flexible substrates, novel dielectrics, and high-performance metals, is opening new possibilities for PCB designs. These materials enable the creation of smaller, lighter, and more efficient electronic devices, which are crucial for applications in wearables, IoT, and high-speed computing. - High-Speed and High-Frequency Design

The increasing demand for faster data transmission and higher operating frequencies is pushing the limits of PCB design. This trend requires engineers to have an in-depth understanding of signal integrity, impedance control, and electromagnetic compatibility (EMC) principles to design reliable high-speed PCBs. - 3D PCB Design

As devices become more complex and compact, 3D PCB design is gaining traction. This involves the use of multi-layer PCBs and the integration of components into the Z-dimension, making it possible to design smaller and denser electronic systems. Design tools are evolving to accommodate these multi-dimensional designs.

PCB design engineering is at the forefront of technological advancement, enabling innovations across industries. A solid understanding of the fundamentals, paired with the right skills and continuous learning, will empower aspiring engineers to succeed in this dynamic and rewarding field. As technology continues to evolve, PCB design engineering will remain critical to the creation of cutting-edge devices. The future will require the development of more adaptable, sophisticated and innovative solutions to power next generation technologies and the design engineers will be right there on the front lines of innovation.

AnyPCBA

AnyPCBA