Mastering Digital Integrated Circuit Design: A Comprehensive Guide

In today's tech-driven world, digital integrated circuits (ICs) are the unsung heroes powering everything from our smartphones to supercomputers. This intricate field, known as digital integrated circuit design, involves crafting microscopic electronic circuits to perform logical operations. This article will guide you through the complex yet fascinating world of digital IC design, explaining its principles, processes, and practical applications, connecting it to the core of modern technology and innovation.

Fundamentals of Digital IC Design

The foundation of digital integrated circuit (IC) design lies in the understanding of fundamental digital circuit building blocks. These include logic gates—such as AND, OR, NOT, NAND, NOR, and XOR—Boolean algebra, and number systems like binary and hexadecimal. These elements are crucial for implementing complex digital functionalities within integrated circuits.

| Concept | Description | Relevance to Digital IC Design |

|---|---|---|

| Logic Gates | Basic electronic components that perform logical operations on one or more inputs to produce a single output. | Form the fundamental building blocks for all digital circuits within ICs. |

| Boolean Algebra | A branch of algebra in which the values of variables are the truth values true and false, usually denoted 1 and 0, respectively. | Provides the mathematical framework for designing and analyzing digital logic. |

| Number Systems (Binary, Hexadecimal) | Methods for representing numerical values. Binary uses base-2 (0 and 1), while hexadecimal uses base-16 (0-9 and A-F). | Essential for representing and manipulating digital data within the IC. |

The Digital IC Design Flow: From Specification to Silicon

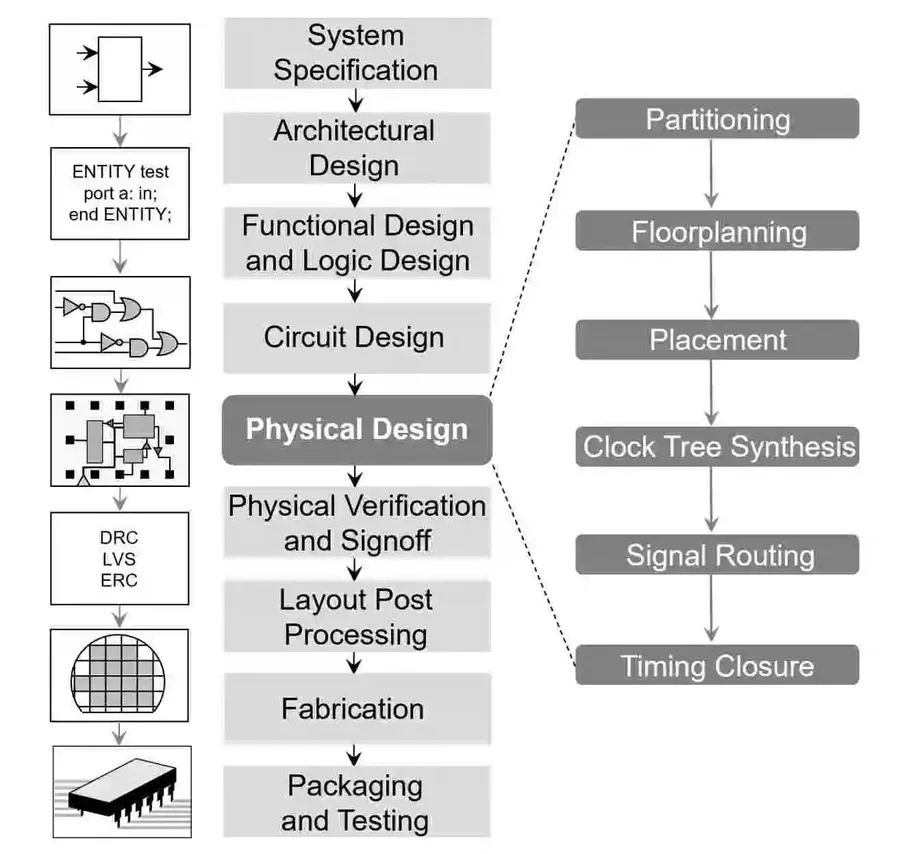

The digital integrated circuit (IC) design flow is a systematic and multi-stage process that transforms a high-level concept into a physical silicon chip. This flow ensures that the final fabricated IC meets the desired functional, performance, and reliability specifications. Each stage employs specialized tools and methodologies, requiring a deep understanding of both theoretical principles and practical implementation techniques.

- Specification

This initial phase involves defining the IC's functionality, performance, power consumption, and area constraints. Detailed requirements are documented, often including use cases, input/output specifications, and performance targets. This stage serves as the blueprint for the entire design process, setting clear objectives that must be met throughout development. For example, the system's required clock speed, memory capacity and the kind of data it will need to process will all be specified. - Design Entry (HDL)

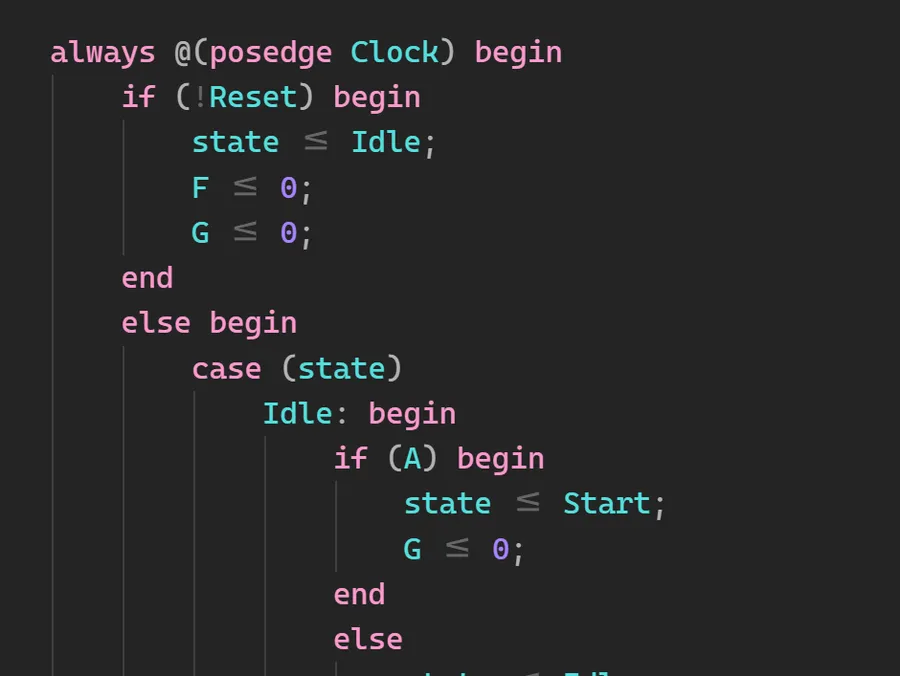

The design is captured using Hardware Description Languages (HDLs) such as Verilog or VHDL. This involves writing code that precisely describes the digital circuits' behavior and structure. The HDL code forms the basis for simulation and subsequent steps. This stage is crucial for the creation of a digital representation that can be automatically processed by Electronic Design Automation (EDA) tools. Different coding styles impact the performance and resource utilization of the final implementation. For example, using non-blocking assignments for sequential logic and blocking assignments for combinational logic is good practice. - Simulation

The HDL code is simulated to verify the functional correctness of the design. This step helps to identify and correct design flaws early in the process. Testbenches are created to simulate various operating scenarios, exposing potential issues such as timing violations and logical errors. Thorough simulation is critical to avoid costly mistakes that may be very costly to fix at later stages. Different simulation tools are used for different levels of abstraction. For example, a gate-level simulation will take place to verify the final netlist generated from the design. - Synthesis

The HDL code is translated into a gate-level netlist, which is a description of the design in terms of standard logic gates. This process involves utilizing logic synthesis tools and linking them with the target technology library. Optimizations are performed to meet performance and area constraints. The output of synthesis is a hardware-description that is technology specific and represents the logical arrangement of the design. The synthesis process also verifies timing and resource utilization based on the target technology. - Physical Design (Placement and Routing)

The physical design stage involves placing the standard cells (or other circuit elements) on the silicon die and routing the connections between them. The goal is to ensure that the resulting layout is both functional and optimal. Placement must be done in a way that minimizes the interconnect length and reduces congestion. Routing involves determining the physical paths for the signals, subject to design rule checks (DRC). Tools like Cadence Innovus or Synopsys IC Compiler are frequently used. - Verification

The design is verified at multiple stages. This includes functional verification, timing analysis, and layout versus schematic (LVS) checks. Verification is essential to ensure the design meets performance requirements and is free of errors before moving into fabrication. Functional verification checks for correct logic operation; timing verification ensures that signals are propagated within specified time limits; and LVS verifies that the physical layout is consistent with the original schematic. Formal verification techniques are also used to ensure design correctness. - Fabrication

The final step is to send the verified design to a semiconductor foundry for fabrication. This involves creating the masks, which are used to pattern the silicon wafers during the fabrication process. The fabrication process is highly complex and involves many steps, such as deposition, etching, and doping. Post-fabrication, the chip is tested to confirm its correct function before it is packaged for use. This stage involves high precision equipment and requires a very clean environment.

HDL (Hardware Description Languages): Verilog and VHDL

Hardware Description Languages (HDLs) are fundamental to modern digital integrated circuit design, providing a means to describe and model the behavior and structure of digital circuits at a high level of abstraction. Verilog and VHDL are the two dominant HDLs used in the industry, each with its own strengths and applications. Understanding these languages is crucial for any digital IC designer.

| Feature | Verilog | VHDL |

|---|---|---|

| Origin | Developed by Gateway Design Automation (now Cadence) in 1984. | Developed under the U.S. Department of Defense in 1980s. |

| Syntax | C-like, relatively concise and easier for software engineers to learn. | Ada-like, more verbose and strict, promoting structured design. |

| Abstraction Levels | Supports register-transfer level (RTL) and gate level descriptions well, suitable for design and verification. | Supports multiple abstraction levels from behavioral to gate-level, suitable for complex system design and simulation. |

| Data Types | Fewer built-in data types, more flexible but can lead to ambiguity. | Strongly typed with more explicit data types, enhancing code clarity and error detection. |

| Concurrency | Relies on procedural constructs (always blocks) to describe concurrent operations. | Explicitly supports concurrent operations through process statements, making concurrency representation more transparent. |

| Use Cases | Widely used in North America, particularly for ASIC design. | Commonly used in Europe and for complex, high-reliability designs including FPGA. |

| Learning Curve | Considered to have a gentler learning curve initially. | Steeper initial learning curve due to its verbosity and strong typing. |

| Industry Adoption | Highly adopted in industry and academia. | Strong adoption in industry, particularly in aerospace, defense and high-reliability applications. |

Both Verilog and VHDL are IEEE standards, ensuring their wide adoption and interoperability across various design tools. The choice between them often depends on project requirements, team expertise, and regional preference. Many design flows utilize both languages, leveraging their respective strengths at different stages of the design process.

Key considerations when working with HDLs include understanding their respective syntax, semantic nuances, and effective coding styles. High-quality HDL code is crucial for creating designs that are not only functionally correct but also synthesizable and performant. Efficient coding styles involve avoiding common pitfalls like race conditions, ensuring clear and modular designs, and employing the correct abstraction levels for the task at hand.

Digital IC Design Styles: Full Custom, Standard Cell, and FPGA

Digital integrated circuit (IC) design employs diverse methodologies to implement digital circuits, each with its unique advantages and trade-offs. This section delves into three prominent design styles: full custom, standard cell-based, and Field-Programmable Gate Array (FPGA) based design, exploring their characteristics, applications, and comparative aspects.

| Design Style | Description | Performance | Cost | Time to Market | Flexibility | Typical Applications |

|---|---|---|---|---|---|---|

| Full Custom | Layout and optimization of every transistor and interconnect. | Highest possible performance. Optimal area utilization | Highest cost for design and manufacturing. | Longest development time. | Maximum flexibility | High-performance ASICs, processors, memory controllers |

| Standard Cell | Utilizes pre-designed logic gates (standard cells) placed and routed automatically. | Good performance, slightly lower than full custom. | Moderate cost for design and manufacturing. | Moderate development time. | Moderate flexibility. | General-purpose logic, embedded systems, ASICs |

| FPGA | Implements logic using configurable logic blocks and programmable interconnections. | Moderate to lower performance. | Lowest initial cost, but can be expensive for high volume production | Fastest development time. | Highest flexibility | Prototyping, low-volume applications, adaptable hardware |

Choosing the right design style depends critically on project specific requirements and constraints. Full custom design, while offering unparalleled performance, demands significant resources and expertise. Standard cell design provides a balanced approach, suitable for many applications, while FPGA based design caters to prototyping and projects requiring flexibility and fast turnaround times.

Key Considerations in Digital IC Design: Power, Performance, and Area

Digital integrated circuit (IC) design inherently involves a complex interplay between power consumption, performance, and the physical area occupied by the circuit. These three parameters are often interdependent, and optimizing for one can negatively impact the others. Achieving an optimal design requires a careful balance tailored to the specific application requirements.

| Parameter | Description | Unit | Impact |

|---|---|---|---|

| Power Consumption | The amount of electrical energy used by the circuit. | Watts (W) | Affects heat dissipation, battery life, and overall system reliability. Lower power is generally desired for portable and energy-efficient designs. |

| Performance | The speed at which the circuit performs its intended functions. | Hertz (Hz) for clock frequency; seconds for latency | Determined by clock frequency, propagation delays, and latency. Higher performance (higher clock frequency, lower latency) is desired but often comes at a power cost. |

| Area | The physical space occupied by the circuit on the silicon die. | Square millimeters (mm²) | Impacts cost, yield, and overall chip size. Smaller area is desirable for cost reduction and higher integration density. |

These key design parameters are tightly coupled, creating trade-offs that require careful consideration during the design process. For example, increasing the clock frequency to improve performance typically leads to higher power consumption. Similarly, reducing the area by using smaller transistors can result in higher leakage currents, which contribute to static power dissipation. Effective digital IC design involves employing various optimization techniques to navigate these constraints and achieve the best balance for the intended application.

Advanced Digital Circuit Design: Clocking, Pipelining, and Power Management

Advanced digital circuit design delves into sophisticated techniques to optimize performance, manage power, and ensure reliable operation. Key areas include clock distribution networks, pipelining, and various power management strategies, all crucial for high-speed and energy-efficient integrated circuits.

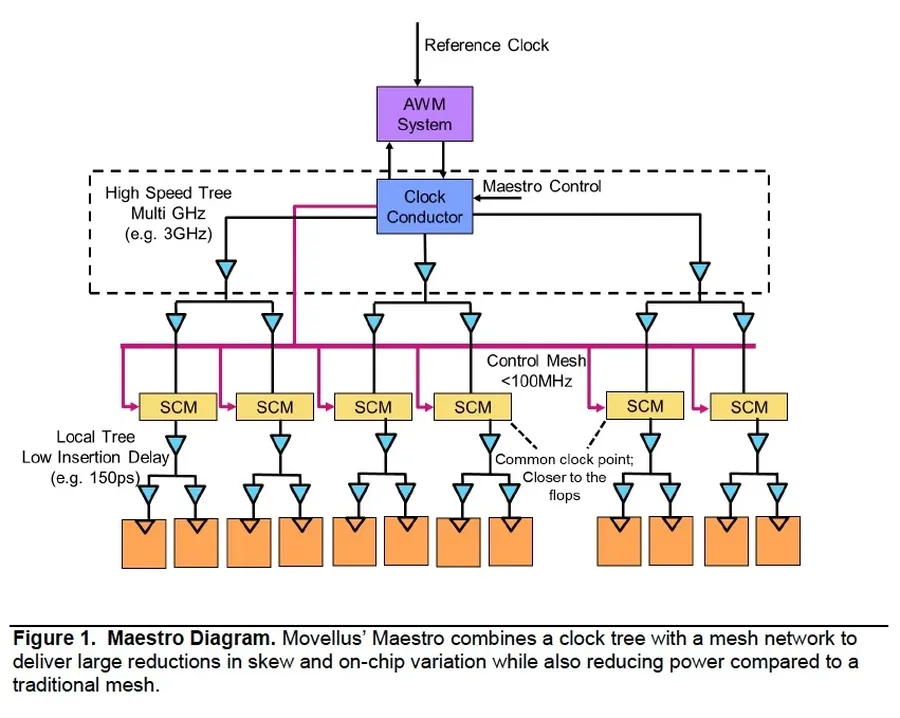

Clocking strategies are fundamental to synchronous digital circuits, with distribution networks needing careful design to minimize skew and jitter. Pipelining is a technique to increase the throughput of a circuit by introducing pipeline stages, effectively overlapping the execution of instructions. Finally, power management is paramount due to increased density and the need to limit power consumption and heat dissipation. These advanced techniques are essential for designing high-performance and energy-efficient integrated circuits.

| Technique | Description | Advantages | Challenges |

|---|---|---|---|

| Clock Distribution Networks | Delivers the clock signal to all parts of the chip with minimal skew and jitter. | Ensures synchronous operation of the digital circuits. | Difficult to design with low skew and jitter for large and complex chips. Susceptible to process variations. |

| Pipelining | Divides a processing task into multiple stages, allowing for concurrent execution. | Increases the overall throughput and clock frequency. | Increased latency. Can lead to increased area due to pipeline registers and more complex control logic. |

| Power Management | Techniques to reduce power consumption including dynamic frequency scaling, clock gating, and power gating. | Extends battery life, reduces heat dissipation and lowers cost. | Added complexity to the chip control. Can impact performance if not done well. Potential for performance penalty when switching between modes. |

Digital IC Design Verification and Testing

Verification and testing are critical stages in the digital integrated circuit (IC) design process, ensuring that the final fabricated chip operates correctly and meets the predefined specifications. Verification aims to confirm the design's correctness before fabrication, while testing validates the fabricated chip's functionality against the specifications.

Both processes are essential for mitigating design flaws, reducing the likelihood of costly re-spins, and ensuring the delivery of reliable and high-quality integrated circuits. These steps occur at different design phases, employing diverse methodologies and tools.

- Verification Stages

Verification is an ongoing process that occurs throughout the design cycle, from the initial specification to the final layout. Common verification techniques include: Functional verification: Ensuring the design behaves as intended using simulation, Emulation: Using a hardware prototype to verify system-level functionality and timing performance, Formal verification: Mathematically proving the correctness of the design using formal methods, Timing verification: Assessing whether the design meets timing constraints, often using static timing analysis. - Testing Methodologies

Testing occurs after fabrication to ensure the silicon die meets the design specifications. Testing methods include: Automated Test Equipment (ATE): Applying test vectors to the fabricated chip and measuring the responses. Built-In Self-Test (BIST): Incorporating test circuitry on the chip, to test at lower cost and ease test generation. Fault modeling: Simulating faults in circuits to test these potential faults. Scan testing: Method used to set the internal states in digital circuits and read results, to improve observability and controllability. Boundary scan testing: A method to test connections between chips

| Aspect | Verification | Testing |

|---|---|---|

| Purpose | Ensure design correctness before fabrication | Validate fabricated chip functionality |

| Timing | Performed during design phases | Performed after chip fabrication |

| Methods | Simulation, Emulation, Formal Verification, Static Timing Analysis | Automated Test Equipment (ATE), Built-In Self-Test (BIST), Fault Modeling, Scan Testing |

| Goal | Detect design flaws and prevent costly re-spins | Ensure chip meets specifications and performs reliably |

Frequently Asked Questions about Digital IC Design

This section addresses frequently asked questions regarding digital integrated circuit design, offering clear, concise answers to provide a deeper understanding of the field and its practical aspects. These questions range from career paths to software tools and emerging trends.

- What are the primary areas of specialization within digital IC design?

Digital IC design encompasses several specializations, including front-end design (RTL design and verification), back-end design (physical implementation, placement, routing, timing analysis), and specialized areas like low-power design, high-speed design, and design for testability (DFT). Each specialization requires a specific skill set and expertise. - Is a career in digital IC design a promising path?

Yes, digital IC design is a highly promising and rewarding career path. The demand for skilled digital IC designers remains high due to the increasing complexity and pervasiveness of electronics in everyday life. Job opportunities are available in diverse sectors, including semiconductor companies, electronic design automation (EDA) tool vendors, research institutions, and consumer electronics companies. Strong growth and excellent compensation are common in this field. - How does one embark on a career as a digital IC designer?

To become a digital IC designer, a formal education in electrical engineering, computer engineering, or a related field is generally necessary, often at the Bachelor's or Master's degree level. Key elements for skill development include mastering hardware description languages (Verilog, VHDL), understanding digital logic and computer architecture, and gaining hands-on experience with design tools. Internships and projects are essential in developing practical skills and getting real-world design experience. Continuous learning is vital due to the ever-evolving nature of the technology. - What are some concrete examples of digital IC design in action?

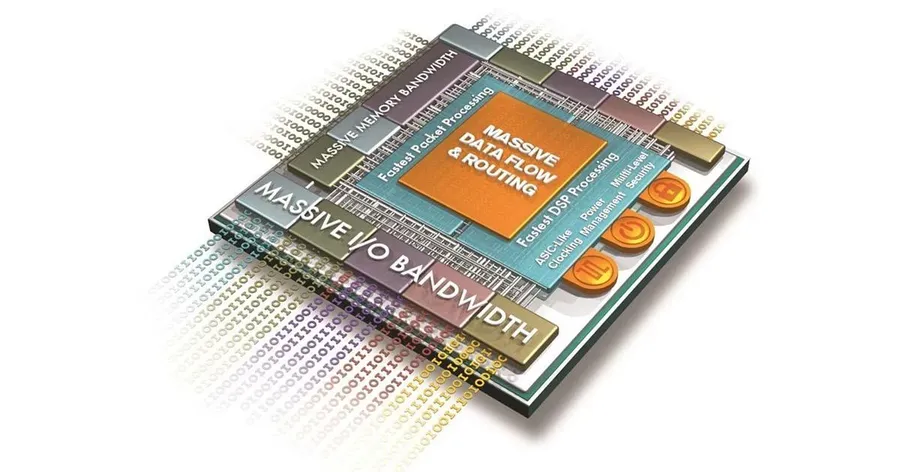

Examples of digital IC designs are pervasive in our technology. Consider the microprocessors inside our computers, the system-on-chips (SoCs) within smartphones, memory chips used for storage, and application-specific integrated circuits (ASICs) in networking equipment and automotive control systems. Every single digital device that we interact with daily involves digital IC design. - What software tools are essential in digital IC design?

Digital IC design relies heavily on specialized software tools. Key tools include HDL simulators (e.g., ModelSim, VCS), synthesis tools (e.g., Design Compiler, Genus), place and route tools (e.g., Innovus, ICC2), and verification tools (e.g., Questa, JasperGold). These tools facilitate various stages of design, from conceptualization to physical layout and verification. - What recent trends are shaping the digital IC design industry?

Several key trends are influencing the digital IC design landscape. These include the increasing integration of artificial intelligence (AI) and machine learning (ML) into design tools, the rise of 3D IC integration for improved density and performance, the growing adoption of advanced packaging techniques, and the demand for low-power design solutions due to the proliferation of mobile devices and IoT applications. Furthermore, the complexity of designs is driving the need for more advanced verification methodologies. - What educational resources would you recommend for learning digital IC design?

For those seeking to learn digital IC design, many credible resources are available. Numerous universities offer courses at the graduate and undergraduate level with curricula focused on hardware design, computer architecture, and VLSI design. Online learning platforms such as Coursera, edX, and Udemy provide access to digital IC design courses from various universities and industry experts. Also, numerous books focused on digital design concepts and tools are readily available. Additionally, exploring design software tutorials, vendor documentation, and related conferences will be beneficial.

The Future of Digital Integrated Circuit Design

The field of digital integrated circuit (IC) design is rapidly evolving, driven by the ever-increasing demands for higher performance, lower power consumption, and greater integration density. Emerging trends like artificial intelligence (AI) integration, 3D ICs, and neuromorphic computing are poised to redefine the landscape of digital IC design, presenting both significant opportunities and formidable challenges.

- AI Integration in Digital ICs

The incorporation of AI accelerators and machine learning (ML) capabilities directly onto digital ICs is becoming increasingly prevalent. This trend allows for edge processing, reducing latency and improving the efficiency of AI applications. Key areas include specialized hardware for deep learning and inference. - 3D Integrated Circuits

3D ICs, which stack multiple layers of active devices, are emerging as a promising approach to increase integration density and reduce interconnect lengths, leading to improved performance and reduced power consumption. This technology enables more complex systems in a smaller footprint. Challenges remain in thermal management and manufacturing. - Neuromorphic Computing

Neuromorphic computing aims to mimic the structure and function of the human brain, utilizing architectures such as spiking neural networks. This paradigm shift offers the potential for highly efficient computation, particularly for tasks that involve pattern recognition and learning. Research focuses on creating specialized hardware, including memristors, to support this unconventional approach. - Quantum Computing

While still in its early stages, quantum computing holds immense promise for solving complex problems that are currently intractable for classical computers. Quantum digital circuits will demand entirely new design and verification methodologies. The potential impact on fields like cryptography and materials science is substantial. - Advanced Packaging Technologies

Innovation in packaging technology is crucial to keep pace with the advancements in digital ICs. Techniques like through-silicon vias (TSVs), chiplets, and advanced substrate materials are key enablers for 3D ICs and heterogenous integration. These advancements address thermal management and signal integrity at the system level.

Digital integrated circuit design is a complex field that sits at the heart of modern electronics. From fundamental logic gates to advanced power management techniques, this guide has explored the core concepts of digital IC design. By understanding its processes, tools, and considerations, aspiring and current engineers can contribute to the continuous evolution of technology and shape our digital future. The continuous advancements in this field, driven by innovation and the pursuit of performance and efficiency, make it a dynamic and essential area of study. With the growing demand for higher performing and more energy efficient devices, the future of digital integrated circuit design will remain an exciting frontier in engineering.

AnyPCBA

AnyPCBA