Mastering Motherboard Design: A Comprehensive Guide

Motherboard design, the invisible backbone of every electronic device, from the simplest computer to the most complex server. Beyond its function of connecting all the essential components within a system, the intricate process of designing a motherboard is a captivating blend of engineering and ingenuity. Just like the network of a city's roads and electrical grids, it plays a vital role in how information and power flow. Understanding the motherboard design is crucial to grasp the full potential of modern technology, and in this article, we will explore its intricacies, providing a detailed guide to mastering this fascinating field, from conceptualisation to fabrication.

Understanding Motherboard Fundamentals

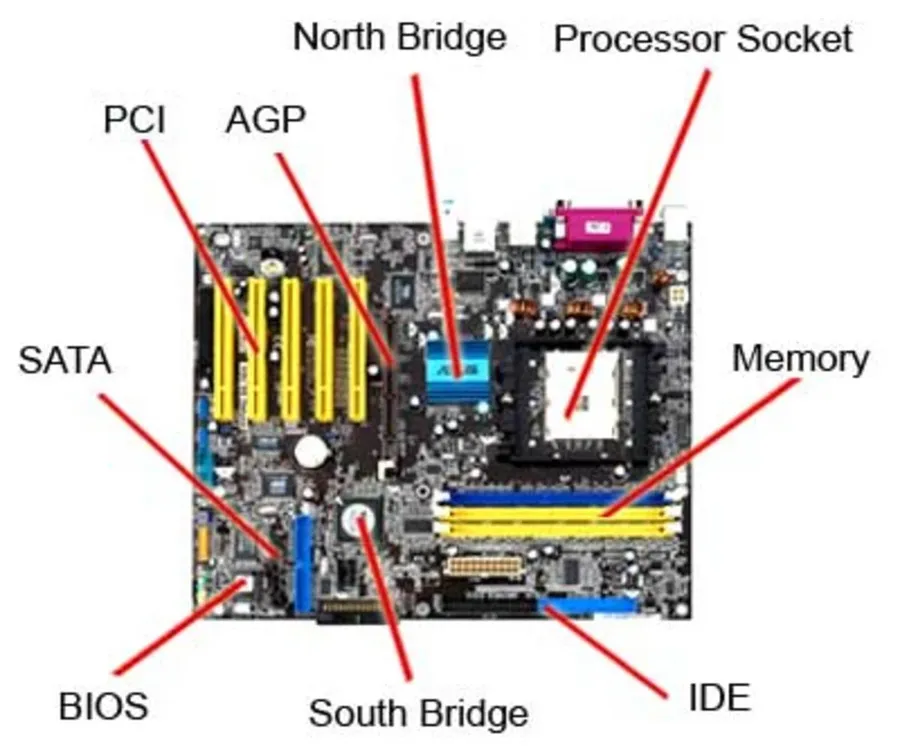

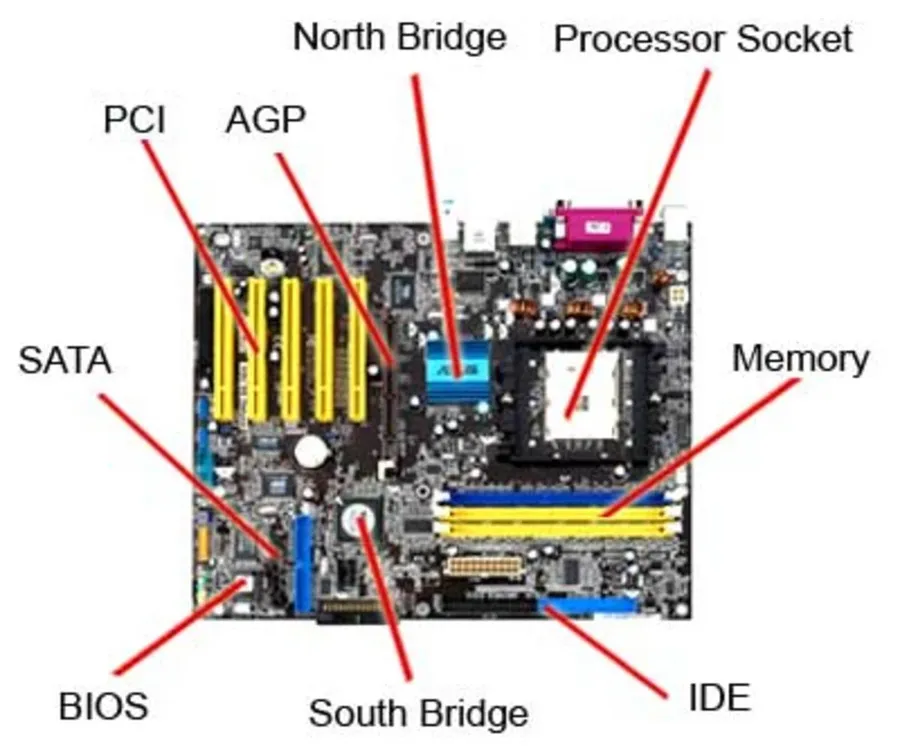

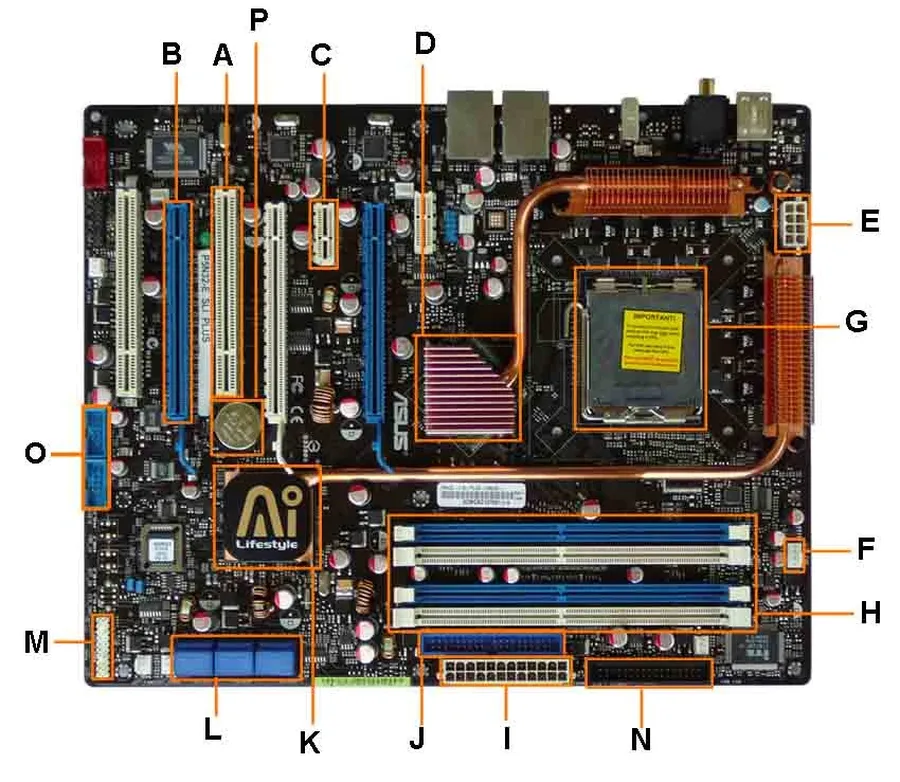

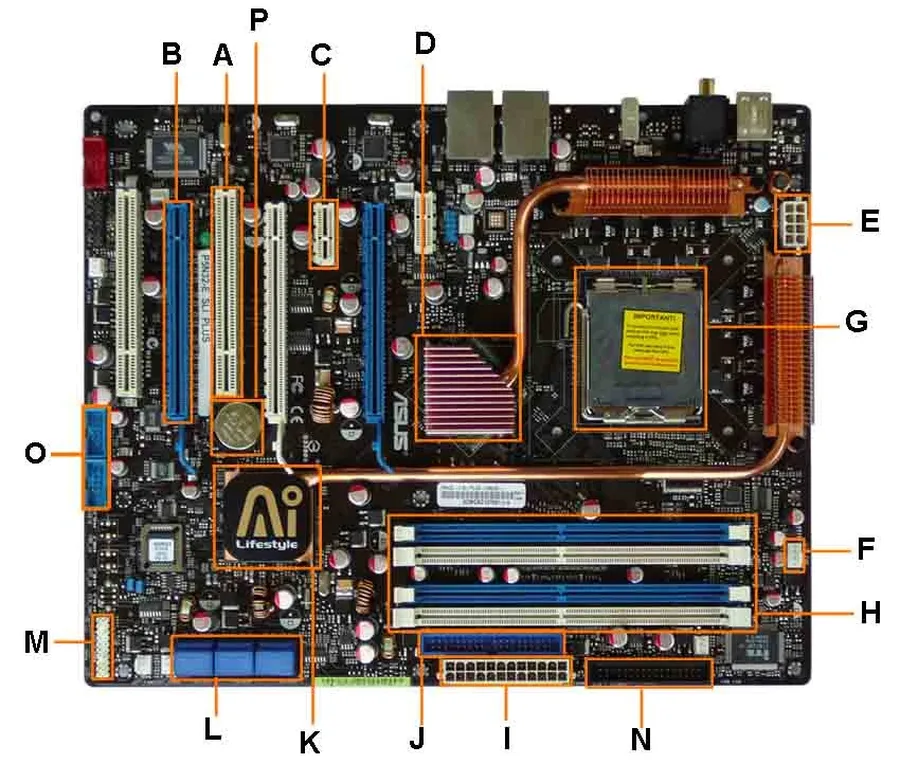

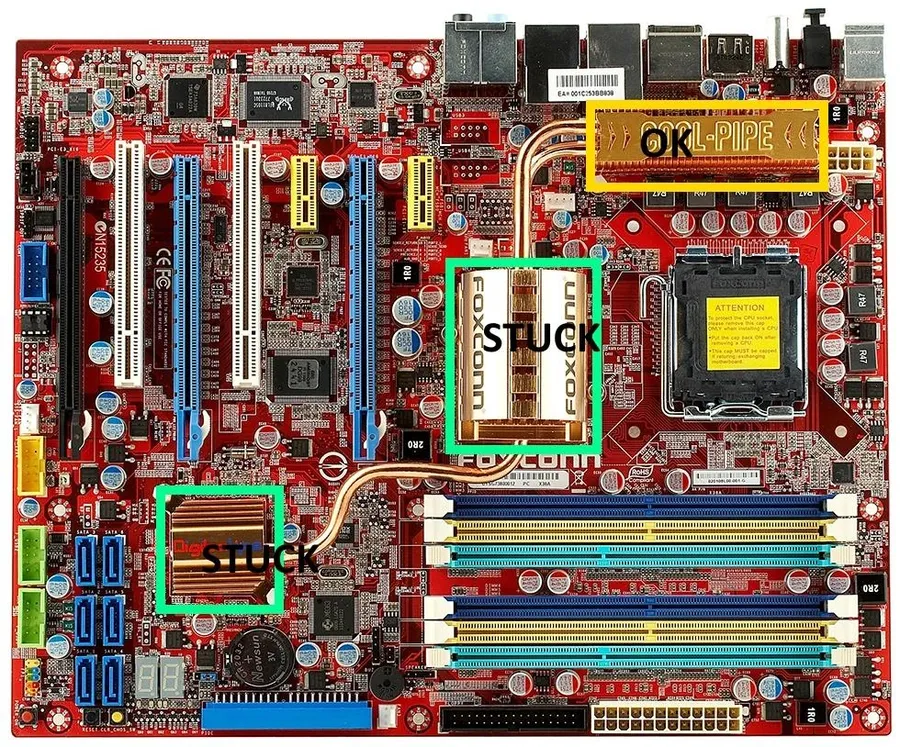

A motherboard serves as the central printed circuit board (PCB) within a computer or electronic device, providing the foundational framework for all other components. Its primary function is to act as a communication hub, facilitating data exchange and power delivery among vital elements such as the CPU, RAM, storage devices, and expansion cards. This section will provide a detailed overview of the core components and their individual functions.

| Component | Function | Design Considerations |

|---|---|---|

| Chipset | Manages data flow between the CPU, memory, and peripherals. It defines the motherboard's capabilities and compatibility. | Choice of chipset impacts the CPU and RAM compatibility, number of expansion slots, and overall feature set. Heat dissipation is a key concern. |

| CPU Socket | Provides a physical interface for the CPU, establishing the connection for data and power delivery. | Socket type determines the compatible CPUs. Securing the CPU correctly is paramount to avoid damage to pins and ensure proper heat sink contact. |

| RAM Slots | Accommodates RAM modules, enabling the system to access and use memory for processing data. | Design includes considerations for the number of slots, type of RAM supported (e.g. DDR5), and electrical connections that permit high-speed data transfer. |

| Expansion Slots | Allow for the integration of additional components such as graphics cards, sound cards, or network adapters. | Layout should ensure physical and electrical clearance for various card sizes and proper data transmission rates (e.g., PCIe lanes). |

| Connectors | Provide interfaces for power delivery, data transfer with storage drives, and peripheral device connections. | Placement and number of connectors are guided by the system design, and must consider user access and signal integrity of the connections. |

Initial Setup: Planning Your Motherboard Design

The initial phase of motherboard design is crucial, setting the foundation for a successful project. This stage involves defining project requirements, selecting components, and creating preliminary schematics, all of which are informed by the intended use case and any constraints.

- Define Project Requirements

Begin by clearly outlining the intended purpose of the motherboard. Consider its application (e.g., gaming, server, embedded system), performance requirements, and desired features. Document these specifications as they will drive subsequent design decisions. This process should be detailed, including interface requirements (USB, Ethernet, Display outputs etc.). - Component Selection

Carefully choose components based on performance, cost, availability, and compatibility. The central processing unit (CPU), random access memory (RAM), and chipset are key components that will influence many aspects of the design. Selection should involve rigorous comparison of part specifications. - Preliminary Schematics

Create a basic block diagram outlining the main functional blocks of the motherboard, such as the CPU, memory, and peripheral interfaces. These diagrams must include critical information such as data flow direction and power domain.

| Planning Stage Element | Key Considerations |

|---|---|

| Project Requirements Definition | Application (e.g., gaming, server), performance targets, functional specifications, power constraints, physical size |

| Component Selection | CPU selection, RAM type and size, chipset features, compatibility, power requirements, availability, cost. |

| Preliminary Schematics | Block diagram of core functional units, data flow direction, primary power domains and distribution scheme |

Schematic Design: Mapping the Motherboard's Architecture

Schematic design is the crucial process of creating a detailed electrical diagram that represents the motherboard's architecture. This stage involves mapping out all electrical connections between components, considering signal integrity, power distribution, and component interfacing, and it is the blueprint for the physical PCB layout. Success in this phase determines the fundamental viability of the motherboard.

Key considerations during the schematic design phase include:

- Signal Integrity:

Ensuring that electrical signals travel from one component to another without significant loss or distortion. This involves controlling impedance, minimizing signal reflections, and managing crosstalk. - Power Distribution:

Designing a stable and efficient power delivery network to supply all components with the correct voltages and currents. This includes selecting appropriate voltage regulators and designing power traces capable of carrying required current with minimal voltage drop and noise. - Component Interfacing:

Correctly connecting components based on their datasheets and specifications to ensure seamless interaction. Proper interfacing prevents malfunctions and ensures all parts work together effectively. - Tool Selection:

Choosing the right EDA (Electronic Design Automation) software, such as Altium Designer, Eagle, or KiCad. The right tool supports efficient drawing, simulation, and verification of the schematic.

The schematic is not just a visual representation; it contains crucial design data used to generate the bill of materials (BOM) for purchasing components. It is also the foundation for netlisting, a process that is essential for transferring the design to the PCB layout phase.

Effective schematic design requires a thorough understanding of electronic principles, component characteristics, and the target application of the motherboard. Thorough planning and simulation at this stage reduces errors and costly rework during the later PCB layout and testing phases.

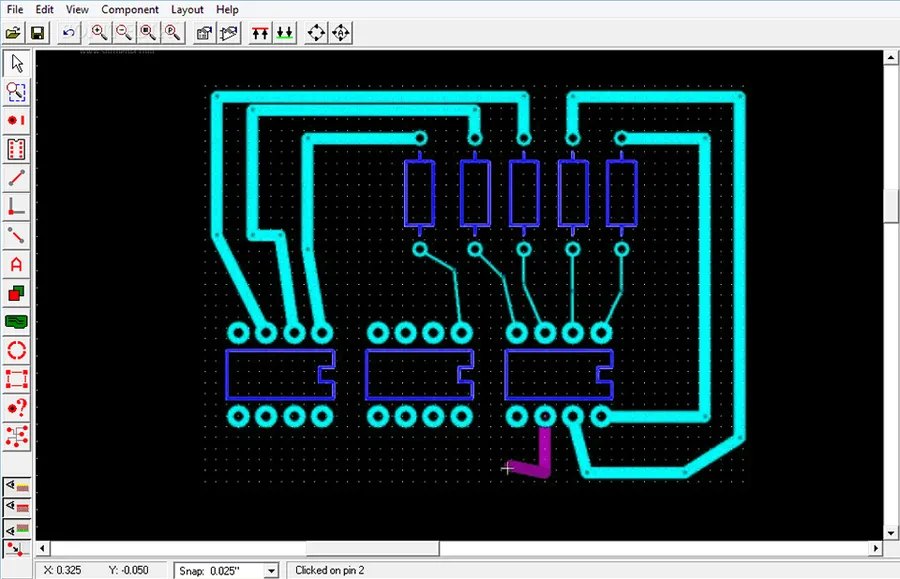

PCB Layout: Turning the Schematic into Reality

The Printed Circuit Board (PCB) layout is the critical stage where the abstract schematic design takes physical form, transforming a conceptual electrical diagram into a tangible, functional circuit. This phase demands meticulous planning and execution to ensure the motherboard functions as intended, adhering to performance, reliability, and manufacturability standards.

The PCB layout is not merely a mechanical assembly; it's a complex engineering challenge that involves optimizing signal integrity, managing thermal dissipation, and ensuring electromagnetic compatibility (EMC). Effective PCB layout is critical for minimizing signal reflections, reducing crosstalk, and achieving a robust and reliable motherboard design.

- Optimal Trace Routing

Trace routing dictates how electrical signals travel across the board. Careful planning minimizes signal path lengths and impedance mismatches. Techniques like differential pair routing are essential for high-speed signals, ensuring that signal and return paths are closely matched to prevent signal distortion. The shortest path is not always optimal; maintaining consistent impedance is key to avoiding reflections. - Layer Management

Multi-layer PCBs provide the necessary space for complex circuits. Strategic allocation of signal, power, and ground layers is vital. Ground planes are designed to act as reference planes for signals, minimizing inductance and controlling impedance. Power planes provide stable voltage levels with low impedance to minimize noise and voltage fluctuations, which can affect component performance and introduce errors. Layer arrangements must prioritize signal integrity and power distribution efficiency. - Thermal Considerations

Heat generated by components must be managed to prevent overheating. Copper is used for heat sinking and vias can transfer heat from hotter to cooler layers. Components with high power consumption require careful placement to prevent the accumulation of heat on the PCB. Proper thermal design enhances board longevity and reliability by maintaining components within their operating temperature limits. - Electromagnetic Compatibility (EMC)

Minimizing electromagnetic interference (EMI) is crucial to prevent the motherboard from disrupting other electronic equipment and vice versa. Shielding layers and careful routing practices help control electromagnetic fields. EMC guidelines are rigorous and meeting them is a critical aspect of designing reliable systems. Shielding ensures that the emissions and susceptibility of the motherboard are within regulatory limits. - Effective Use of PCB Design Tools

Modern PCB design tools, such as Altium Designer, Eagle, or KiCad, provide features for schematic capture, PCB layout, and simulation. These tools enable designers to create complex layouts, simulate signal behavior, and verify the design's performance before manufacturing. Mastering these tools is essential for efficient and precise PCB design. Features include auto-routing, layer stack management, and 3D visualization capabilities.

Component Sourcing and Selection

Selecting the correct electronic components is paramount in motherboard design, directly impacting its performance, reliability, and overall cost. This process involves a careful evaluation of various factors, from component specifications to their availability and cost-effectiveness, and it is crucial for ensuring a design's success.

| Factor | Description | Importance |

|---|---|---|

| Component Specifications | Detailed parameters such as voltage ratings, current handling, operating frequency, tolerance, and signal characteristics. | Essential to match the needs of the circuit design and ensure proper functionality. |

| Cost | The price of the components, considering both unit cost and bulk discounts. It significantly influences the final product cost. | Critical for maintaining budget and product competitiveness. Cost should be balanced with performance requirements. |

| Availability | The accessibility of components, considering lead times, stock levels, and supplier reliability. Components should be readily available to avoid production delays. | Crucial for meeting project timelines and sustaining manufacturing processes. |

| Quality and Reliability | Ensuring that components meet quality standards and have a high level of reliability. Choosing reputable manufacturers and verifying quality certificates. | Fundamental for product longevity and customer satisfaction; poor-quality components can lead to early failure. |

| Manufacturer Reputation | The manufacturer's experience, certifications, and user feedback | Helps to ensure that the components are high quality and reliable, mitigating any potential risks. |

| Datasheets and Documentation | Checking the datasheets provided by the manufacturer for accuracy and completeness. | Essential for understanding the full capabilities and limitations of the component, ensuring optimal utilization in the circuit design. |

Effective component selection is a multifaceted process that requires thorough research and a practical understanding of the tradeoffs between cost, availability, and performance. Utilizing reputable suppliers, adhering to best practices, and paying close attention to datasheets and component specifications are all key to success.

Advanced Techniques in Motherboard Design

Advanced motherboard design techniques are essential for achieving high-speed data transfer, signal integrity, and overall system stability and efficiency. These techniques address the challenges of modern high-performance computing and ensure that motherboards can reliably handle increasing data rates and power demands.

- Impedance Matching

Ensuring that the characteristic impedance of signal traces matches the impedance of the source and load is critical to minimize signal reflections and maintain signal integrity. This is often accomplished through precise trace width and spacing adjustments. - Differential Pair Routing

This involves routing two signal traces in close proximity to each other to carry a signal and its inverse, reducing common-mode noise and improving signal immunity to electromagnetic interference (EMI). Proper spacing and length matching are crucial for high-speed data transmission. - Advanced Power Delivery

Modern motherboards require complex power delivery networks to handle varying current demands from components such as the CPU and GPU. This includes the use of multi-phase voltage regulators (VRMs), careful component selection, and strategic placement to minimize voltage drops and maintain stable power supply. - Signal Integrity Analysis

Using simulation software to analyze signal propagation and reflection characteristics and to ensure signal quality, thereby mitigating issues like ringing, undershoot and overshoot. This process helps to refine and validate the design before physical implementation. - Layer Stackup Optimization

Careful consideration of the PCB layer stackup, including signal and ground planes, is essential to minimize impedance discontinuities and optimize signal return paths. Proper stackup improves EMI performance and signal quality and efficiency.

| Technique | Description | Benefits |

|---|---|---|

| Impedance Matching | Matching trace impedance to source/load | Minimizes signal reflection, ensures signal integrity |

| Differential Pair Routing | Routing signal and its inverse closely together | Reduces common-mode noise, improves EMI immunity |

| Advanced Power Delivery | Complex VRMs and power network design | Provides stable power to components, reduces voltage drops |

| Signal Integrity Analysis | Simulation for signal propagation analysis | Ensures signal quality, mitigates ringing/undershoot/overshoot issues. |

| Layer Stackup Optimization | Strategic use of PCB layers | Minimizes impedance discontinuities, improves EMI performance |

Testing and Verification: Ensuring Motherboard Reliability

Thorough testing and verification are paramount to ensuring the reliability of a motherboard. This phase involves a series of rigorous tests to identify and rectify any potential issues, guaranteeing the board's performance aligns with design specifications before deployment. Neglecting this phase can lead to costly failures and compromises in system stability.

- Functional Testing

This initial stage involves verifying that the motherboard's core functionalities are working as intended. It includes confirming the CPU operation, RAM accessibility, and proper functioning of the various input/output (I/O) interfaces, like USB, SATA, and Ethernet. - Stress Testing

Stress testing pushes the motherboard to its operational limits to evaluate its endurance under heavy loads. This type of testing helps identify issues that may arise during peak performance, including overheating, power instability, or component failures. Testing tools and software will typically simulate peak processing, data transfer and communication between components. - Signal Integrity Checks

Signal integrity is critical for ensuring accurate data transmission on the motherboard. These checks employ specialized equipment, such as oscilloscopes and time-domain reflectometers (TDRs), to assess signal quality, identify reflections, impedance mismatches, and crosstalk. - Power Delivery System Analysis

This involves in-depth analysis of the motherboard's power delivery system. The goal is to verify if voltage regulation circuits provide correct voltage and power levels to all components under various load conditions. This check ensures components will not fail prematurely due to power issues. - Thermal Analysis

Thermal analysis identifies hotspots and ensures the thermal management system is effective. It involves measuring component temperature with thermal sensors or cameras, and ensuring adequate heat dissipation to prevent overheating and damage. This step is important to prevent component damage due to heat. - Environmental Testing

For certain applications, environmental testing is necessary. This can involve subjecting the motherboard to various temperature, humidity, and vibration conditions, which helps determine the durability and stability of the board under different environment.

Frequently Asked Questions About Motherboard Design

This section addresses common questions and concerns regarding motherboard design, providing concise answers and practical advice to help you better understand the intricacies of this critical component of computer systems.

- How difficult is it to design a motherboard?

Designing a motherboard is a complex task that requires a strong understanding of electrical engineering, digital logic, and PCB design principles. It's not a beginner-friendly project and typically involves a team of specialized engineers. The difficulty lies in managing signal integrity, power distribution, thermal management, and ensuring compatibility between various components. It often requires specialized software, simulation tools, and a deep understanding of component datasheets. - What are the fundamental steps to create a motherboard?

The process starts with defining the specifications and requirements, followed by component selection. The next phase is the schematic design, which maps out the electrical connections and functionalities. This is then followed by the PCB layout, where the physical arrangement of components and traces is planned. After manufacturing, testing and verification of performance, stability and reliability are essential. Each step requires precision and a strong understanding of design principles. - What are the common types of motherboards in a computer?

Motherboards vary in size and form factor, the most common types being ATX (Advanced Technology Extended), microATX, and mini-ITX. ATX motherboards are the standard for most desktop computers, offering more expansion slots. MicroATX boards are smaller and have fewer slots, suitable for more compact builds. Mini-ITX is the smallest form factor, often used in small form factor PCs or embedded systems. Motherboards also vary in terms of chipset and socket types, which determine CPU and RAM compatibility. - Why do motherboards fail and what are some ways to prevent this?

Motherboard failures are often caused by electrical issues, overheating, component degradation, physical damage, or manufacturing defects. To avoid failures, it's crucial to ensure proper ventilation and cooling, use a high quality power supply, handle components carefully, and avoid over-tightening screws. Regular maintenance, like removing dust build-up, can also extend the motherboard's lifespan. - What software tools are used in motherboard design?

Professional motherboard design relies on specialized software such as Altium Designer, Cadence Allegro, and KiCad. These tools facilitate schematic capture, PCB layout, and simulation, enabling designers to create and test complex circuits accurately. Choosing the right tool depends on the complexity of the project, the features required, and budget constraints. - What are some key considerations for signal integrity in motherboard design?

Maintaining signal integrity is critical for high-speed data transfer on a motherboard. Key considerations include trace impedance control, minimizing trace length, using controlled impedance routing, and proper termination techniques. Differential pairs and impedance matching are essential for avoiding signal reflections and interference, ensuring reliable data transmission. - What are the critical aspects of power distribution in a motherboard design?

The power distribution network (PDN) is essential for stable motherboard operation. It requires careful design of power planes, bypass capacitors, and voltage regulators to deliver clean and consistent power to all components. Proper PDN design minimizes voltage drops, reduces noise, and prevents component damage or system instability. Proper placement of decoupling capacitors close to the load helps to maintain clean power delivery.

Future of Motherboard Design: Trends and Innovations

The landscape of motherboard design is continually evolving, driven by advancements in technology and shifting user demands. This section explores emerging trends and cutting-edge innovations that are poised to reshape the future of motherboard design, focusing on modular architectures, novel materials, and transformative possibilities.

Key trends include:

- Modular Motherboard Design

Modular designs are gaining traction, allowing users to swap out components like CPUs, RAM, and GPUs independently. This approach offers flexibility, upgradeability, and reduces electronic waste by enabling partial upgrades rather than replacing entire motherboards. - Advanced Materials

The integration of advanced materials such as graphene and carbon nanotubes is being explored for improved thermal management, increased electrical conductivity, and enhanced durability. These materials can lead to more efficient and robust motherboards. - AI-Driven Design Optimization

Artificial intelligence and machine learning are increasingly being used to optimize motherboard layouts and component placements. AI algorithms can analyze vast datasets to identify optimal design configurations that minimize signal interference, improve power efficiency, and reduce production costs. - Integrated Chiplet Design

The integration of chiplets (small, specialized dies) on motherboards is an emerging trend. This approach facilitates the integration of heterogeneous components, thereby increasing performance and flexibility while reducing manufacturing costs. It also promotes greater customization based on specific application needs. - Enhanced Power Delivery Systems

Advancements in power delivery systems, such as more efficient voltage regulators and power management integrated circuits (PMICs), are becoming increasingly important to support high-performance components and reduce power consumption. This includes advanced cooling solutions.

These trends signify a shift towards more adaptable, efficient, and sustainable motherboard designs, driven by innovative engineering and cutting-edge technological advancements.

Mastering motherboard design is a journey that blends theoretical knowledge with hands-on application. From understanding the fundamental aspects of a motherboard's components to mastering complex PCB layouts, this article has offered a comprehensive guide for enthusiasts and professionals alike. As we look to the future, innovation and new design techniques will continue to transform the landscape of motherboard design. By understanding the challenges, the possibilities, and the evolution of motherboard design, we can pave the way for the future of technology, where the motherboard remains a foundational pillar.

AnyPCBA

AnyPCBA