Get Instant PCB Quotes: Your Guide to Fast & Accurate Pricing

In today's fast-paced electronics industry, getting an instant PCB quote is crucial for rapid prototyping and efficient project management. Just like instant messaging revolutionized communication, instant PCB quoting platforms have changed how engineers and designers get their boards manufactured. This article will guide you through understanding how these platforms work, the key factors affecting price, and how to choose the best option for your next project. Discover how to quickly obtain your [instant pcb quote] and keep your projects moving forward.

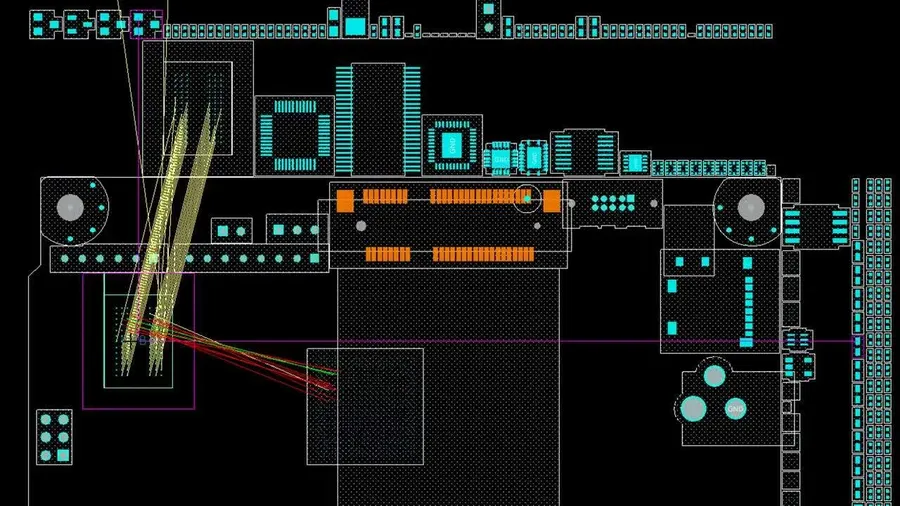

Understanding Instant PCB Quoting Systems

Instant PCB quoting systems utilize sophisticated algorithms and real-time data processing to rapidly estimate the cost of manufacturing printed circuit boards. These platforms allow users to input their design specifications and receive an immediate price quote, streamlining the procurement process and enabling faster decision-making.

At the heart of these systems lie complex algorithms that analyze various design parameters, including board dimensions, layer count, material type, and other specifications. These algorithms process this input data against a database of material costs, manufacturing rates, and overhead expenses to generate an estimated price.

The speed of these systems comes from the utilization of real-time calculations which enable quick turnaround times for quotes. These systems are designed to provide immediate feedback allowing engineers and designers to adjust their design or parameters and see the changes in real-time for rapid prototyping and efficient design cycles. The real time response allows for instant iteration.

Key Factors Affecting PCB Quote Prices

Several key factors directly influence the price of a printed circuit board (PCB) quote. Understanding these elements is crucial for optimizing costs and ensuring accurate pricing. The following breakdown details the primary cost drivers, offering insight into how each affects the overall quote.

| Factor | Description | Impact on Cost |

|---|---|---|

| Board Dimensions | The physical size of the PCB. | Larger boards require more material and processing, leading to higher costs. |

| Layer Count | Number of conductive layers in the PCB (e.g., single, double, or multi-layer). | Increased layers require additional processing and material, substantially increasing the price. |

| Material Type | The base material of the PCB (e.g., FR-4, aluminum, Rogers). | FR-4 is standard; specialized materials like aluminum or Rogers are more expensive. |

| Surface Finish | The coating applied to the conductive pads (e.g., HASL, ENIG, immersion silver). | ENIG and other advanced finishes are pricier than HASL due to materials and processing involved. |

| Solder Mask Color | The color of the solder mask layer. | Standard colors (green) are usually free. Custom colors may add to the cost. |

| Via Type | Type of vias used for connecting layers (e.g., through-hole, blind, buried). | Blind and buried vias add complexity and cost compared to through-hole vias. |

| Quantity | The number of PCBs in the order. | Larger orders typically have lower per-unit costs due to economies of scale. |

| Lead Time | The time required for manufacturing and delivery. | Faster turnaround times (expedited shipping) increase costs. |

How to Accurately Input Your Design Specs for an Instant Quote

Accurate input of design specifications is paramount to obtaining a precise instant PCB quote. This section details the critical parameters and best practices for ensuring the accuracy of your online PCB quote, focusing on Gerber files, drill files, layer stackup, and tolerances.

- Gerber Files: The Cornerstone of Accurate Quotes

Gerber files are the standard format for PCB manufacturing data. Ensure that all layers (copper, solder mask, silkscreen) are exported correctly, with the correct aperture settings. Inconsistent or missing Gerber files will lead to an inaccurate quote or manufacturing errors. - Drill Files: Detailing Hole Specifications

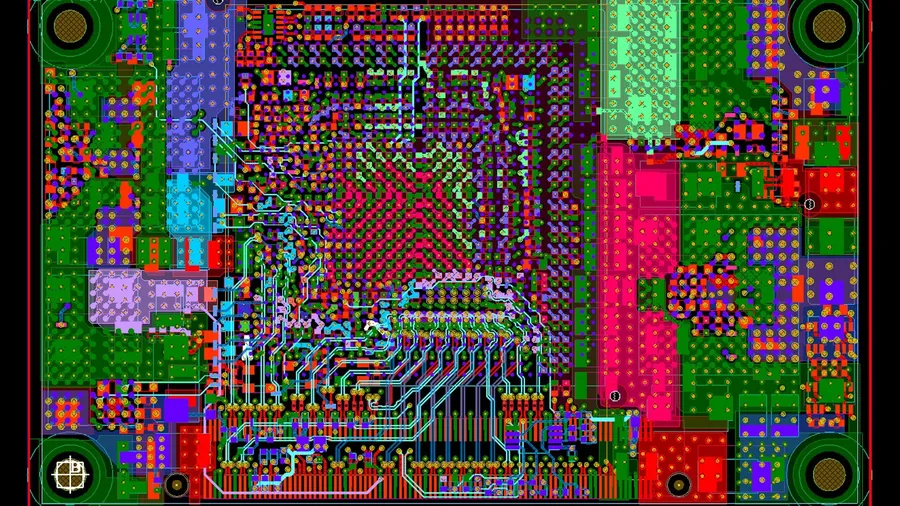

Drill files contain information about the location and size of holes. Make sure the drill file is in the correct format (Excellon is the standard), and that the drill sizes match your design precisely. Inaccuracies in drill data can lead to errors in the finished board. - Layer Stackup: Crucial for Multi-layer Boards

The layer stackup describes the arrangement of copper, dielectric, and other materials in a multi-layer PCB. Specifying the correct stackup (number of layers, material type, thickness of each layer) is necessary for both accurate quoting and proper manufacturing. - Tolerances: Defining Acceptable Variations

Tolerances define the allowable variations in PCB dimensions, feature sizes, and material properties. Ensure that the tolerances specified in your design align with the capabilities of the manufacturer and that all critical features fall within the specified tolerance limits to avoid potential manufacturing problems and cost increases. - File Naming Conventions:

Use a clear and organized file naming convention for all files, which helps avoid confusion and errors during the quoting and manufacturing process. For example, use suffixes like .GTL (Top Layer), .GBL (Bottom Layer) or .DRL for drill files.

Comparing Different PCB Manufacturers for the Best Instant PCB Quote

Selecting the right PCB manufacturer is crucial for securing a competitive instant PCB quote. Pricing structures can vary significantly based on a manufacturer's capabilities, location, and specializations. A thorough comparison of several manufacturers is recommended before making a commitment.

Here's a breakdown of key factors to consider when comparing PCB manufacturers:

- Geographic Location

Manufacturers located closer to your location may offer faster shipping times and reduced costs. However, overseas manufacturers may provide more competitive pricing, especially for large volume orders. Consider the implications of time zones and language barriers when making your decision. - Manufacturing Capabilities

Not all manufacturers can handle every type of PCB design. Verify that the manufacturer can meet your specific requirements, such as the number of layers, board dimensions, material types (e.g., FR-4, aluminum), tolerances, surface finishes, solder mask colors and via types. Specialized requirements will often narrow the field. - Specialized Services

Some manufacturers offer additional services like PCB assembly, design for manufacturability (DFM) checks, and testing. These services can be bundled into your quote and streamline the manufacturing process, saving time and resources. - Certifications

Certifications such as ISO 9001, UL, and RoHS ensure a manufacturer adheres to quality standards and environmental regulations. These certifications are especially important for companies producing electronic products for regulated industries and can affect the product's marketability. - Pricing Structure

Pricing is affected by several factors such as material costs, labor, and overhead. Some manufacturers may offer lower per-unit costs for higher volume orders while others may specialize in rapid prototyping, focusing on quick turnaround for smaller orders, thus, affecting the unit price. - Lead Time

Consider the manufacturers' stated lead time for your order requirements. Faster turnaround times often come at a premium price but are necessary in some cases for development or market entry. Standard lead times will be more cost-effective.

| Manufacturer Aspect | Implication |

|---|---|

| Location | Impacts shipping cost & delivery time, potential time zone and language barriers |

| Capabilities | Determines if the design can be manufactured correctly. |

| Certifications | Guarantees quality and compliance with industry standards |

| Pricing Structure | Determines cost effectiveness based on volume & service. |

| Lead Time | Influences delivery timeline & cost |

Turnaround Time and Its Impact on PCB Quotes

Lead time, the duration between placing an order and receiving the manufactured PCBs, significantly influences the cost of production. PCB manufacturers typically offer a range of lead time options, each with its corresponding price point, allowing customers to balance time constraints against budget considerations when securing an instant PCB quote.

| Lead Time Option | Description | Typical Cost Impact | Best Use Case |

|---|---|---|---|

| Standard Production | Normal manufacturing timeframe, typically ranging from a few days to a couple of weeks, depending on the complexity and the manufacturer's capacity. | Baseline cost; most economical option. | Projects with no critical time constraints. |

| Quick Turn | Accelerated production that reduces the lead time significantly, often to a few days, ideal for prototyping and urgent projects. | Higher cost than standard production, reflecting the increased resource allocation. | Prototyping, time-sensitive projects. |

| Expedited Production | The fastest possible manufacturing option, often completed within 24-48 hours. This is a premium service designed for extremely urgent requirements. | Highest cost due to the exceptional effort and resource priority. | Emergency situations, critical project milestones. |

Choosing the right lead time impacts not only the schedule of your project but also your budget. Selecting a longer standard lead time will save costs, whereas choosing faster turnaround times will increase the price. Therefore, balancing project timelines against budget restraints is important for securing an optimal instant PCB quote.

Frequently Asked Questions About Instant PCB Quotes

Instant PCB quotes offer a rapid estimate for the cost of manufacturing your printed circuit boards. This section addresses common questions to clarify the process and help you obtain the most accurate and cost-effective quotes.

- What is the difference between an instant PCB quote and a final price?

An instant PCB quote is an automated estimate based on the design specifications you provide online. It serves as a preliminary figure. A final price, however, is typically determined after a detailed review of your design files by the manufacturer. This review considers factors that automated systems may not fully capture, such as complex design features or potential manufacturing challenges. The final price may include adjustments for material costs, specialized processes, or extra handling needed to fulfill your order. - What specific aspects should I scrutinize in a PCB quote from a manufacturer?

When reviewing a PCB quote, carefully examine several crucial elements. The board dimensions should match your design requirements and be accurately costed. Verify the number of layers, the material type (e.g., FR-4, aluminum), and the specified surface finish. Confirm the solder mask color and the type of vias used. Pay close attention to the manufacturing tolerances quoted, as these affect the precision and function of your circuit board. Finally, scrutinize the quantities, and delivery lead time options. - Can I get a lower PCB price with a larger order?

Yes, generally, larger order quantities typically result in a lower per-unit cost for PCBs. This is due to the economies of scale manufacturers achieve with larger production runs. The initial setup costs are spread over more units, resulting in a lower average price. It is often beneficial to request quotes for various quantities of PCBs to determine optimal order levels. - What file formats are used by instant PCB quoting systems?

Instant PCB quoting systems generally accept Gerber files, which are the industry standard for PCB manufacturing. Additionally, some platforms may support other file formats such as ODB++, or Eagle/Altium files directly. Ensure that the files you upload are accurate, complete and adhere to the specific requirements of the manufacturer's system, including all layers and drill files. Incomplete or incorrect file formats can lead to inaccurate quotes or production delays. - How accurate are instant PCB quotes, and what factors can impact the final cost?

Instant PCB quotes are generally accurate for standard designs. However, the final price can vary based on various factors not captured during automated quoting. These include complex board shapes, specialized materials not part of standard production, intricate designs, specific quality requirements, and any design issues identified during the manufacturer's DFM (Design for Manufacturing) review. These could cause price adjustments. For complex projects, consider getting a quote review to avoid surprises. - Is it possible to obtain free instant PCB quotes?

Yes, many online PCB manufacturers provide free instant quote services as a tool for attracting and assessing potential clients. These quotes are typically preliminary and do not obligate you to place an order, which allows you to evaluate different options and determine the best value and supplier for your PCB requirements. Taking advantage of multiple free quote systems helps benchmark pricing.

Optimizing Your Design for Cost-Effective PCB Manufacturing

Strategic design choices can substantially reduce PCB manufacturing costs without sacrificing functionality. By carefully considering material selection, layer count, and board dimensions, significant savings can be realized when obtaining an instant PCB quote.

- Material Selection

Opting for standard materials like FR-4 instead of exotic alternatives (e.g., high-Tg, polyimide) reduces cost. FR-4 is the most commonly used and readily available, leading to lower manufacturing expenses. Consider the application's thermal and electrical demands before choosing more expensive materials. - Layer Count

Minimizing the number of layers in your PCB design directly reduces complexity and cost. A two-layer or four-layer board is generally more affordable than a complex multilayer design. Carefully evaluate if additional layers are necessary for functionality, or if routing can be optimized on fewer layers. - Board Dimensions and Shape

Standard board sizes and rectangular shapes reduce material waste and are easier to process. Complex shapes can lead to higher manufacturing costs due to increased material wastage and more difficult machining. Utilize standard panelization strategies where appropriate. - Via Types and Density

Blind and buried vias increase complexity and cost. Use through-hole vias whenever possible. Reducing via density, particularly the use of microvias, can also lower costs. Consider the routing and electrical requirements of your design when selecting the appropriate vias. - Component Selection

Using readily available and standard components reduces both component cost and potentially assembly costs. Unique or less common components might be more expensive and require special handling. Consider the lifecycle and availability of components during the design phase. - Surface Finish

Selecting a standard surface finish like HASL (Hot Air Solder Leveling) is typically more cost-effective than more advanced finishes like ENIG (Electroless Nickel Immersion Gold). Choose the appropriate finish based on the environmental conditions and expected lifespan of the product. - Solder Mask Color

Standard solder mask colors (e.g., green) are usually cheaper than non-standard colors. While color choice can be important for aesthetics, consider its impact on cost if you are on a tight budget.

Beyond the Quote: What to Expect After Submitting Your Order

Receiving an instant PCB quote is just the initial step in the PCB manufacturing process. Understanding what transpires after submitting your order is crucial for a smooth transition from design to production. This stage involves several key processes, including design review, potential DFM feedback, and order finalization, all of which directly influence the final outcome and delivery timeline.

- Design Review and Verification

After receiving your instant quote and placing your order, the PCB manufacturer will typically conduct a comprehensive review of your submitted design files. This review aims to identify any potential issues that might impact manufacturing or functionality. This process ensures that the design adheres to the manufacturer's capabilities and can be produced reliably. - Design for Manufacturing (DFM) Feedback

If the manufacturer detects potential problems, such as insufficient spacing, trace width issues, or via problems, they will provide DFM feedback. This feedback is critical because it allows you to address any issues and make necessary adjustments to your design before moving into production. This step avoids costly rework and ensures a higher yield rate during manufacturing. - Order Finalization and Confirmation

Once the design passes DFM or any required revisions are made, the order will be finalized. This includes confirming the board specifications, quantity, delivery timeline, and final price. Payment is typically processed at this stage, and a formal production schedule is established. - Manufacturing Process Initiation

After confirmation, the manufacturing process begins. This involves several stages, including PCB fabrication, assembly (if required), testing, and quality control. The timeline varies depending on the complexity of the board, the manufacturer's capabilities, and the chosen service level (standard, quick turn, expedited). - Delivery and Tracking

The final stage involves shipping the finished PCBs to your location. Most manufacturers provide tracking information so that you can follow the progress of your delivery and anticipate arrival. Be sure to inspect the delivered PCBs upon arrival to confirm they meet specifications.

Actionable Tips for Securing the Best PCB Quotes

Securing the most competitive PCB quote requires a strategic approach that extends beyond simply submitting your design files. By proactively optimizing your design and understanding the nuances of manufacturer pricing, significant cost savings can be achieved. This section provides actionable tips to help you obtain the best possible pricing for your PCB fabrication needs, with a focus on strategic planning and informed decision-making to ensure you get the most advantageous instant PCB quote.

- Plan for Volume Discounts

PCB manufacturers often offer substantial discounts for larger production runs. If your project allows, consider ordering in higher quantities to reduce the per-unit cost. Analyze your projected needs and explore if combining prototypes with initial production runs can trigger these discounts. - Explore Alternative Materials

While FR-4 is the most common PCB substrate, other materials may be more cost-effective for specific applications. Investigate alternatives like CEM-1 or flexible substrates, keeping in mind their thermal and mechanical properties to make informed choices. Confirm these material alternatives meet your required specifications. - Optimize Board Dimensions and Shape

Non-standard board shapes and sizes can lead to increased costs due to material waste and processing complexities. Standardizing your board dimensions and utilizing panelization, where multiple PCBs are manufactured on a single panel, can significantly reduce costs. Aim for designs that maximize material usage and manufacturer efficiency. - Negotiate with Manufacturers

Don't hesitate to discuss pricing with manufacturers. Building relationships with vendors and understanding their cost structures can lead to better deals and long-term cost reductions. This includes inquiring about potential discounts and exploring cost-saving alternatives within the manufacturer's specific capabilities. - Standardize Components and Finishes

Using commonly available components and standard surface finishes will lower your cost. Exotic or custom specifications often come with higher premiums due to specialized processes. Stick with industry standards where possible to streamline manufacturing and reduce expenses. - Consider a Consolidated Order

If you have multiple projects, combining them into a single large order can qualify you for bulk discounts. Consolidating orders minimizes set-up costs for manufacturers, which can translate into significant cost savings for you. - Provide Accurate and Complete Documentation

Complete and accurate Gerber files, drill files, and other design documents can minimize errors and avoid costly rework, which will reduce the final cost. Ensure that all the necessary data is provided at the time of the quote request. This reduces manufacturing delays and additional charges due to errors or omissions.

Instant PCB quoting has transformed the electronics industry, providing engineers and designers with fast and transparent pricing options. By understanding the factors influencing these quotes and carefully preparing your design specifications, you can ensure cost-effective and high-quality PCB manufacturing. Remember that getting the right [instant pcb quote] is the first step towards successfully bringing your electronic product to life. Don't hesitate to compare various quotes and consult with manufacturers for your next project.

AnyPCBA

AnyPCBA