Capacitor Electric Fans: Understanding Function, Replacement & Troubleshooting

Have you ever wondered why your electric fan starts with a little 'hum' before spinning into action? The secret lies in a small but vital component: the capacitor. This unassuming device is the unsung hero of many household appliances, including our beloved electric fans. This article will guide you through the purpose of capacitors in electric fans, common problems, replacement, and troubleshooting, giving you the knowledge to keep your fans running smoothly. Let's dive into the fascinating world of capacitor electric fans and unlock the tech behind the breeze.

The Role of Capacitors in Electric Fans

Capacitors are indispensable components in most electric fans, serving as the key to initiating and maintaining the rotational motion of the fan's motor, specifically in single-phase induction motors. Unlike shaded pole motors which have a simpler starting mechanism, single-phase induction motors require a phase shift in the electrical supply to generate a rotating magnetic field that drives the rotor. This phase shift is precisely what the capacitor provides, enabling the motor to start and operate efficiently.

Without a functional capacitor, a single-phase induction motor will not be able to create the rotating magnetic field needed for self-starting. This reliance on the capacitor for a phase shift is fundamental to the operation of electric fans and other appliances using single-phase induction motors.

Types of Capacitors Used in Electric Fans

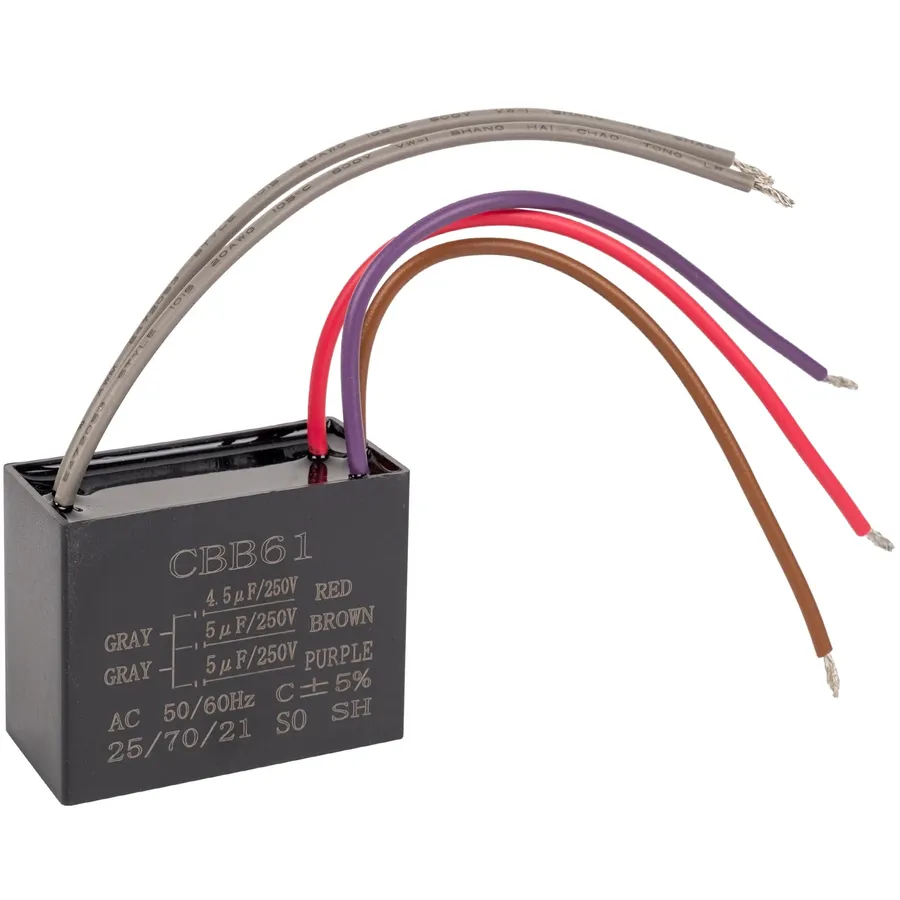

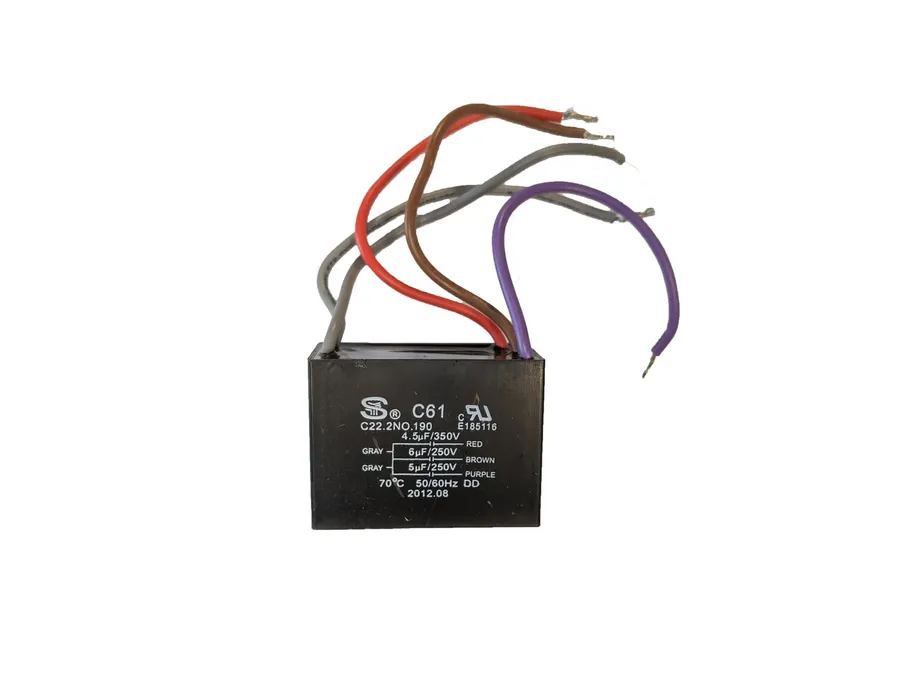

Electric fans, particularly those employing single-phase induction motors, predominantly utilize run capacitors to facilitate continuous operation. The most common type is the CBB61 capacitor, chosen for its reliability and suitability in providing the necessary phase shift for smooth motor function. While other types exist, they are less frequently encountered in modern fan designs.

| Capacitor Type | Common Application | Characteristics | Notes |

|---|---|---|---|

| CBB61 (Run Capacitor) | Most electric fans (ceiling, pedestal, table) | Film capacitor, non-polarized, rectangular casing | Designed for continuous duty; rated for specific voltage and capacitance |

| Start Capacitors (Electrolytic) | Older fan models or specialized motors | Electrolytic capacitor, often polarized, cylindrical casing | Designed for short duty cycles, typically to aid initial motor start; rarely seen in modern fans |

| Shaded-Pole Motor Capacitor (Rare) | Very old or small fans, not as efficient | Typically a small film capacitor | Used for specialized motors not in high power fans |

Capacitors are defined by their capacitance, measured in microfarads (µF), and voltage rating. The capacitance dictates the amount of phase shift the capacitor introduces, critical for creating a rotating magnetic field to drive the motor. The voltage rating specifies the maximum voltage the capacitor can withstand without failure. It is crucial to use capacitors with the correct capacitance and an equal or higher voltage rating.

Identifying a Faulty Fan Capacitor: Common Symptoms

A malfunctioning capacitor is a frequent cause of electric fan issues, often manifesting in noticeable symptoms that affect the fan's performance. Recognizing these signs early can help in timely diagnosis and repair, preventing further damage to the fan motor.

The following table outlines common symptoms of a faulty fan capacitor:

| Symptom | Description | Possible Cause |

|---|---|---|

| Slow Starting | The fan blades take a long time to start spinning or require a manual push. | Capacitor unable to provide sufficient initial torque |

| Humming Noises | The fan motor produces a humming sound but the blades don't rotate or rotates weakly. | Capacitor failure to create the necessary phase shift for starting |

| Failure to Start | The fan does not operate at all when switched on. | Capacitor is completely degraded or open circuit. |

| Reduced Fan Speed | The fan operates, but at a significantly lower speed than usual. | Capacitor is losing capacitance, affecting motor torque and speed. |

| Inconsistent Operation | The fan might start sporadically or operate erratically. | Intermittent capacitor fault or internal connection issues. |

It's crucial to distinguish between starting issues and speed-related problems. Starting issues, like slow starting or humming, often point to a capacitor that's failing to initiate the motor's rotation effectively. Speed control problems, on the other hand, indicate that while the capacitor might still be functional, its performance is degraded, leading to reduced torque and thus lower fan speeds. While less common, a damaged capacitor can also create a short-circuit, which would be indicated by the breaker being tripped or the fan not working at all and a burning smell.

How to Choose a Replacement Fan Capacitor

Selecting the correct replacement capacitor for an electric fan is critical for optimal performance and safety. The primary focus should be on matching the original capacitor's capacitance (measured in microfarads, µF) and voltage rating (measured in Volts, V). Deviating from these specifications can lead to motor malfunction or even failure.

Here is a detailed breakdown of key considerations when selecting a replacement fan capacitor:

- Capacitance (µF)

The most crucial factor is matching the capacitance value. The replacement capacitor must have the same µF rating as the original. A mismatch can affect the motor's starting torque, speed, and overall performance, potentially causing overheating or damage. Look for the capacitance rating printed directly on the capacitor body. - Voltage Rating (V)

The voltage rating of the replacement capacitor must be equal to or higher than the original. Using a capacitor with a lower voltage rating than specified can cause it to fail prematurely or even burst due to excessive voltage. Higher voltage ratings will not negatively affect performance, it will simply give it an additional margin of safety. - Physical Dimensions

While not electrically critical, ensure that the replacement capacitor physically fits within the fan's housing. Note the size of the existing capacitor. There are times that a capacitor with a higher voltage rating can have a bigger profile than the original, so be sure to check that. - Tolerance

Capacitors have a specified tolerance, usually expressed as a percentage (e.g., ±5%). This indicates the acceptable deviation from the nominal capacitance. While minor variations within the tolerance range are acceptable, selecting a capacitor with a tighter tolerance is preferable for optimal and consistent performance. This is not that critical. - Capacitor Type

Most electric fans use run capacitors, typically CBB61 or similar types. Confirm that the replacement is of the same type. Do not try to replace a run capacitor with a starting capacitor.

In summary, the replacement capacitor's specifications must be identical to the original, except that you can select a capacitor that has a higher voltage rating, and should fit physically in the housing. Always prioritize matching the capacitance exactly, and use a voltage equal to or higher than the original to ensure the safe and efficient operation of your electric fan.

Step-by-Step Guide to Replacing a Fan Capacitor

Replacing a fan capacitor is a straightforward task that can often restore a malfunctioning electric fan to its full operational capacity. However, safety is paramount when working with electrical components. This section provides a detailed, step-by-step guide for safely and effectively replacing a fan capacitor.

- Safety First: Disconnect Power

Before beginning any work, ensure the fan is completely disconnected from the power source. This typically involves unplugging the fan or switching off the corresponding circuit breaker in your electrical panel. Double check that power is disconnected before proceeding. - Access the Capacitor

The capacitor is usually located within the fan motor housing or in a control box attached to the fan. You may need to remove screws or covers to access it. Take photos of the wiring before disconnecting any wires. This photo will be crucial for reassembly. - Discharge the Old Capacitor

Capacitors can store an electrical charge, even when disconnected from power. Before touching the capacitor terminals, discharge it using a suitable insulated tool such as a screwdriver with an insulated handle. Briefly connect the terminals with the tool. This prevents electrical shock. - Identify and Note the Wiring

Carefully observe and note how the capacitor is wired to the fan motor. Take clear photos or make a diagram, to prevent miswiring. Ensure you note which wire goes to which terminal on the capacitor. Incorrect wiring can damage the fan or cause it to malfunction. - Disconnect the Old Capacitor

Carefully disconnect the wires from the old capacitor. You may need to use pliers or a small screwdriver to loosen the terminals. Be very careful not to break the terminals of the fan motor or wires. Ensure that the wires are in good condition - Install the New Capacitor

Connect the wires to the new capacitor, ensuring that each wire is connected to the correct terminal, matching the wiring diagram or the photos you took in the previous step. Ensure terminals are securely connected. - Reassemble the Fan

Carefully reassemble the fan, making sure all parts are fitted back correctly. Screw back any covers or panels that you removed to access the capacitor. Once reassembled, check the fan to ensure no wires are pinched or exposed. - Test the Fan

Reconnect the fan to the power source and turn it on. Observe the fan's start-up and operation. It should now start smoothly and run at its normal speed. If the fan still doesn't work or runs incorrectly, review the wiring.

Impact of Using Incorrect Capacitor Values

Using a capacitor with an incorrect capacitance value in an electric fan can lead to a cascade of issues, affecting motor performance, longevity, and overall safety. The capacitor is crucial for providing the necessary phase shift to create the rotating magnetic field that drives the motor, and deviations from the specified value can have significant consequences.

| Capacitor Value | Impact on Motor | Potential Risks |

|---|---|---|

| Lower than Specified (uF) | Reduced torque, difficulty starting, slower running speed, increased motor temperature. | Overheating, premature motor failure, reduced lifespan, potential fire hazard if motor seizes. |

| Higher than Specified (uF) | Excessive torque, potential overspeeding of the motor (may not be immediately apparent), increased current draw. | Increased stress on motor windings, premature failure, potential for insulation breakdown, shortened lifespan. |

| Significantly Different Values | Severe starting issues, humming or buzzing sound, motor damage likely. | High risk of motor burnout, potential fire hazard, likely motor and capacitor failure. |

It's essential to understand that capacitors are designed to work within specific parameters. Capacitance (measured in microfarads, or uF) and voltage are key parameters that must be adhered to. Even seemingly small deviations in capacitance can have a significant cumulative effect on the motor’s performance and lifespan. Using a capacitor with a higher voltage rating than specified is acceptable and can actually increase the safety margin but capacitance must be exact.

Frequently Asked Questions About Electric Fan Capacitors

This section addresses common questions and concerns regarding electric fan capacitors, providing clear, concise answers to help users understand their function, troubleshooting, and replacement.

- What is the primary function of a capacitor in an electric fan?

In single-phase induction motors, like those in most electric fans, capacitors provide the necessary phase shift to create a rotating magnetic field. This field is crucial for starting the motor and maintaining its rotation. Without a functioning capacitor, the motor would not be able to start and operate efficiently. - What are the signs that a fan capacitor might be faulty?

Common symptoms of a failing capacitor include the fan struggling to start, a slow startup, unusual humming noises coming from the motor, and reduced fan speed. In some cases, the fan may not start at all, indicating a complete failure of the capacitor. - Can a bad capacitor stop a fan from working?

Yes, a completely failed capacitor will prevent the electric fan motor from starting. This occurs because the necessary phase shift required to induce rotation is no longer provided, and the motor cannot generate the required starting torque. - How much does replacing a fan capacitor typically cost?

The cost to replace a fan capacitor is relatively low. The capacitor itself usually costs between $5 to $20 depending on the specifications and place of purchase. If you hire an electrician the cost will increase depending on the labor involved, but DIY replacement is generally straightforward for most models. - Can I use a capacitor with a slightly different capacitance value than the original?

It is strongly advised to use a capacitor with the *exact same* capacitance value (measured in microfarads, µF) as the original. Using a different value, even slightly higher or lower can impact the motor's performance and longevity, causing issues like overheating, reduced fan speed and premature failure. While a minor voltage rating increase is acceptable (e.g., replacing a 250V with a 400V), the capacitance should always match. - Do fan capacitors affect the fan's speed?

While the primary function of a capacitor is to start the motor, a failing capacitor can indeed cause a noticeable drop in the fan's operating speed. This is because the capacitor impacts the efficiency of the motor's magnetic field rotation, and reduced efficiency translates to lower rotational speed. - Are ceiling fan capacitors universally interchangeable?

No, ceiling fan capacitors are not universally interchangeable. While many use the CBB61 type, they are specific to the motor design. It is critical to replace a fan capacitor with one that matches both the capacitance (µF) and the voltage rating of the original component. It's important to consult the motor's rating plate or the capacitor's markings to ensure compatibility. Using the incorrect specifications may cause the fan to not work or even damage the motor.

Troubleshooting Common Electric Fan Capacitor Issues

Replacing a fan capacitor is often the first step in restoring a malfunctioning electric fan, however, it is not always the sole cause of the problem. If your fan continues to exhibit issues after a capacitor replacement, it's crucial to investigate other potential culprits.

- Motor Issues

The electric motor itself is a common source of fan problems. Over time, the motor windings can degrade or become damaged due to overheating, wear and tear, or other electrical issues. If the motor's internal components are compromised, it can exhibit symptoms similar to a bad capacitor, such as slow starting or humming. To diagnose a motor problem, check for unusual noises, resistance in the rotor, or overheating. If the motor is indeed faulty, it usually requires replacement. - Wiring Problems

Loose or corroded wiring connections within the fan's electrical circuit can also prevent proper operation. These wiring issues can manifest as intermittent operation or complete failure of the fan. Inspect all wiring connections carefully, ensuring each wire is securely connected and that there is no sign of damage or corrosion. A multimeter can be helpful in testing the continuity of the circuit. Repair or replace any damaged wires and connectors as needed. - On/Off Switch Problems

The fan's on/off switch can wear out or become faulty over time, preventing the fan from starting or operating correctly. If the switch is malfunctioning, it may not properly complete the electrical circuit even if the capacitor and wiring are sound. Inspect the switch for damage or signs of wear, and test it for continuity using a multimeter. If the switch is not working as expected, it will need to be replaced. - Speed Control Issues

While capacitors primarily handle motor starting and running, a separate speed controller (if present) can also be a source of issues. This is especially relevant for multi-speed fans that use switches to change speed or variable speed motors using speed controllers. If your fan is operating at only one speed or not changing speeds as expected, check the speed control components and wiring. - Bearing Problems

Although not directly related to electrical components, worn-out bearings can cause excessive friction within the motor, leading to slow operation or the motor overheating. This may appear to be an electrical problem but is a mechanical issue. If your fan's motor makes unusual rattling or grinding sounds, or doesn't rotate freely, check the bearings.

Where to Buy Capacitors for Electric Fans

The availability of replacement capacitors for electric fans has expanded significantly, offering consumers multiple avenues for purchase. This section outlines the various sources where you can find the correct capacitor for your fan, whether you prefer the convenience of online shopping or the immediacy of a local store.

- Online Retailers

Major online marketplaces like Amazon and eBay are popular for their wide selection of fan capacitors. These platforms often provide competitive pricing, customer reviews, and convenient delivery options. When purchasing online, ensure that you carefully verify the capacitor specifications, including capacitance, voltage, and tolerance to guarantee compatibility. Also be sure to check the seller's reviews. - Local Hardware Stores

Local hardware stores and home improvement centers are convenient sources for purchasing fan capacitors, especially when an immediate replacement is needed. These stores often stock common capacitor sizes for fans. Check the availability of specific capacitors before your visit or you can call ahead to ensure they stock what you are looking for. The prices are likely to be higher than online. - Electrical Supply Stores

Electrical supply stores, whether locally or online, are also a reliable source for sourcing fan capacitors. These stores specialize in electrical components and offer a wide selection of capacitor types, including those that are less commonly found in other retail outlets. They can also provide expert advice if required. - Online Specialty Stores

Several online retailers specialize in electronic components, such as capacitors, and may carry specific or hard-to-find capacitors for electric fans. These stores typically offer a greater range of products, but may require more familiarity with the specific technical requirements of the fan's capacitor.

Capacitors are fundamental for the smooth and efficient operation of many electrical appliances, with the capacitor electric fan being a prime example. Understanding their function, being able to diagnose capacitor issues, and knowing how to replace them can extend the lifespan of your electric fans and save you money. By equipping yourself with the knowledge outlined in this article, you’re well-prepared to tackle capacitor related challenges. This not only ensures the consistent cool breeze you expect but also adds to the growing narrative of a society that seeks not only to use technology but to understand it. And, as always, remember to prioritize safety when dealing with electrical components.

AnyPCBA

AnyPCBA