Capacitor Price Guide: Understanding Costs & Finding the Best Deals

In today's world, capacitors are everywhere, quietly powering our electronic devices, from smartphones to air conditioners. Understanding capacitor costs is essential, whether you're an electronics hobbyist, an HVAC technician, or simply someone curious about how much these essential components cost. This guide will demystify capacitor pricing, exploring various types, factors influencing their prices, and how to secure the best deals. We'll also briefly discuss how the [capacitor price list] can fluctuate due to material costs, manufacturing techniques, and market demands.

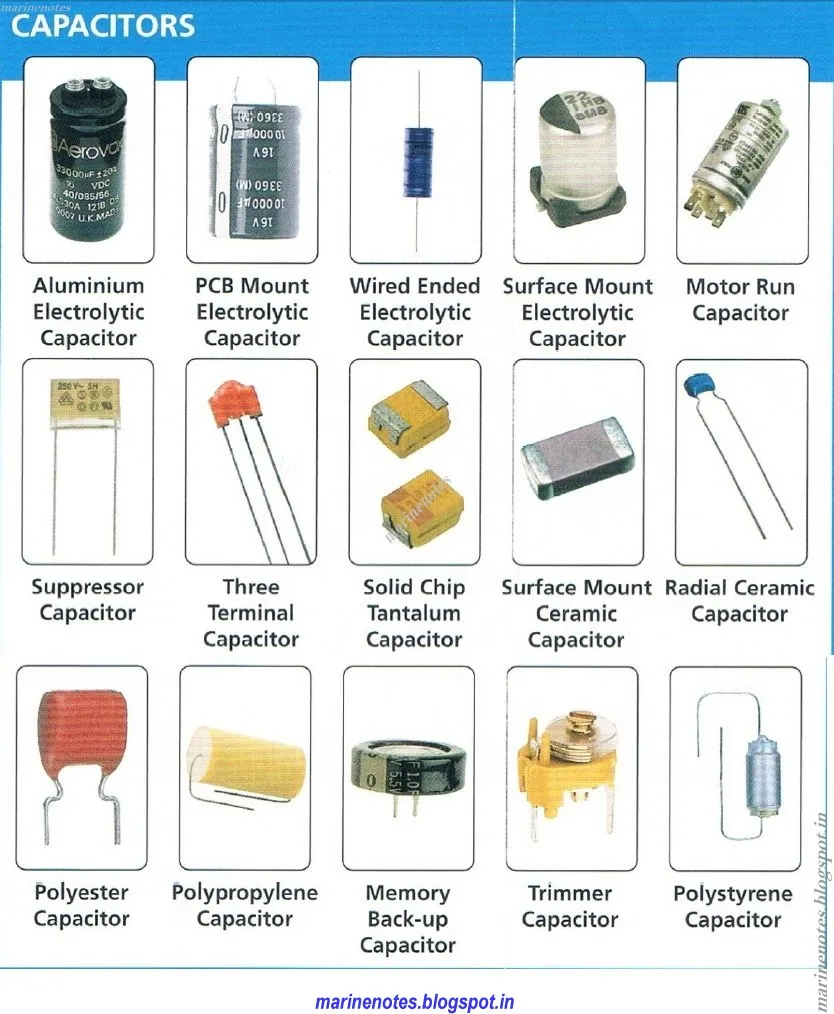

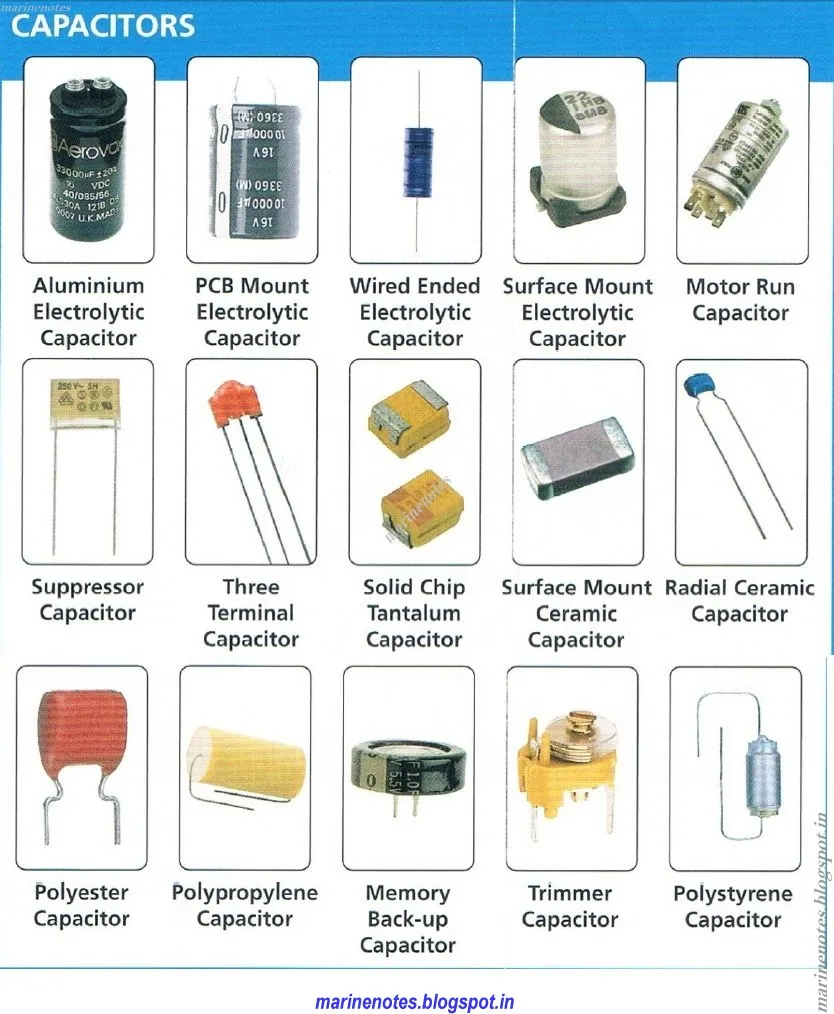

Understanding Different Types of Capacitors and Their Applications

Capacitors, fundamental components in electronic circuits, store electrical energy in an electric field. Their diverse types – electrolytic, ceramic, film, and tantalum – each possess unique characteristics that dictate their applications and consequently, their pricing. Understanding these differences is crucial when consulting a capacitor price list and selecting the appropriate component for a project.

| Capacitor Type | Material | Typical Applications | Key Characteristics | Price Sensitivity |

|---|---|---|---|---|

| Electrolytic | Aluminum or Tantalum with electrolyte | Power supplies, decoupling, filtering | High capacitance, polarized, moderate accuracy | Moderate |

| Ceramic | Ceramic dielectric | High-frequency circuits, bypass, coupling | Small size, low inductance, non-polarized | Low to Moderate |

| Film | Plastic film dielectric | Audio circuits, precision timing, power applications | High accuracy, low losses, various voltage ratings | Moderate to High |

| Tantalum | Tantalum pentoxide dielectric | Portable electronics, high-reliability applications | High capacitance, small size, relatively high cost | High |

Factors Influencing Capacitor Prices

Capacitor prices are not uniform; they are determined by a confluence of factors related to materials, manufacturing, electrical characteristics, and market dynamics. Understanding these variables is crucial when interpreting a capacitor price list and making informed purchasing decisions.

| Factor | Description | Impact on Price |

|---|---|---|

| Material Costs | The type of materials used in capacitor construction significantly impacts price. Tantalum, often used in high-performance capacitors, is more expensive than aluminum, commonly used in electrolytic capacitors. Similarly, the cost of ceramic materials varies depending on the dielectric properties. | Higher material cost translates to higher capacitor price. Tantalum capacitors are typically more expensive than aluminum or ceramic capacitors. |

| Manufacturing Complexity | The precision required in manufacturing processes, including layer stacking, material deposition, and quality control, adds to the overall cost. Smaller, more precise capacitors with tighter tolerances require more advanced and expensive manufacturing processes. | More complex manufacturing results in higher prices. Specialized fabrication techniques increase production cost. |

| Voltage and Capacitance Ratings | Capacitors with higher voltage and capacitance ratings are generally more expensive. These higher ratings demand more robust construction with higher quality materials, larger capacitor sizes, and more complex manufacturing. | Capacitors with higher voltage and capacitance ratings command premium prices. |

| Tolerance | Capacitor tolerance is the range of acceptable variance in its actual capacitance value from its nominal value. Tighter tolerance requirements demand precision and more rigorous quality control in manufacturing, which results in increased cost. | Capacitors with tight tolerance values have a higher cost. |

| Order Volumes | The number of capacitors ordered significantly impacts price. Bulk orders typically attract volume discounts, while smaller, one-off orders are usually more expensive per unit. | Prices per unit decrease with increasing order volume, as manufacturers can reduce unit production cost. |

| Market Demand and Availability | The fluctuating demands in the market and the availability of certain materials or specialized components can affect pricing. Shortages of specific materials can lead to price hikes, and similarly, very high demands can affect pricing. | Prices vary based on market fluctuations. |

Capacitor Pricing for Various Applications

Capacitor pricing is significantly influenced by their intended application. The requirements of each application dictate specific performance characteristics, leading to diverse manufacturing processes and materials, ultimately affecting the price. A capacitor price list will show that capacitors used for HVAC systems, consumer electronics, industrial equipment, and tube radios vary considerably in cost due to these different requirements.

| Application | Typical Capacitor Types | Price Range (USD) | Key Characteristics |

|---|---|---|---|

| HVAC (e.g., AC Capacitor Replacement) | Motor Run Capacitors (Typically Film) | $10 - $50+ | High voltage, High capacitance, robust design for motor starting and running. |

| Consumer Electronics (e.g., Smartphones, PCBs) | Ceramic, Electrolytic Capacitors | $0.01 - $1 (per piece) | Small size, moderate voltage, diverse capacitance range for filtering and decoupling. |

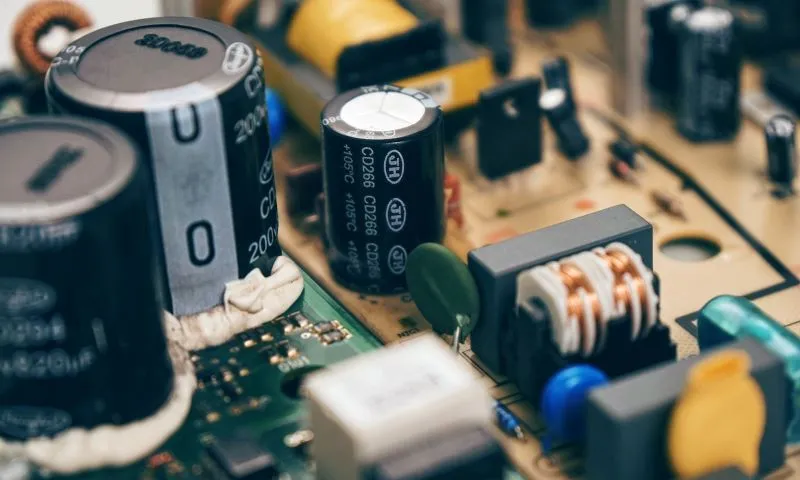

| Industrial Equipment (e.g., Power Supplies) | Electrolytic, Film, Tantalum Capacitors | $0.10 - $10+ (per piece) | High reliability, high voltage, high capacitance for power conversion and smoothing. |

| Tube Radios (e.g., Vintage Audio) | Paper, Electrolytic Capacitors (Often vintage) | $1 - $20+ (per piece, often vintage) | High voltage, Moderate capacitance, specific vintage sizes, often with a premium for NOS (new old stock). |

The table above demonstrates that prices for capacitors vary significantly depending on application specific needs. For example, HVAC systems require high-voltage motor run capacitors, leading to a higher cost than smaller capacitors used in consumer electronics. Industrial applications will often demand high-reliability capacitors, driving up the costs. When consulting a capacitor price list, ensure that the specifications match the requirements of the intended application to avoid unnecessary costs or performance issues.

Average Cost of AC Capacitor Replacement in 2024

The cost of replacing an AC capacitor in 2024 is influenced by several factors, including the capacitor's type and rating, the HVAC system's complexity, and local labor rates. Understanding these variables is crucial for accurately estimating replacement expenses. Typically, the total cost ranges from $100 to $250, encompassing both the component itself and the labor involved.

| Cost Factor | Description | Typical Impact on Price |

|---|---|---|

| Capacitor Type & Rating | Capacitors vary in capacitance (measured in microfarads or µF) and voltage, as well as physical size, materials, and construction which impact cost. | Higher capacitance and voltage ratings typically increase the cost. Specialized designs also carry premium prices. |

| HVAC System Complexity | Some HVAC systems require more intricate access for capacitor replacement or have specific capacitor configurations. | More complex systems lead to higher labor costs due to increased time and skill needed. |

| Local Labor Rates | The hourly rate for HVAC technicians can vary significantly based on location. | Areas with a higher cost of living usually have higher labor costs for replacement. |

| Geographic Location | Market rates and supply chain logistics can vary considerably from city to city. | Local market conditions influence both the cost of the capacitor and the cost of the labour. |

It's essential to note that these figures are averages. Actual costs can deviate due to specific circumstances. For instance, systems requiring unique or hard-to-find capacitor specifications will tend towards the higher end of the cost spectrum. Additionally, regional variances in pricing due to market demand and service provider fees should be considered.

Where to Buy Capacitors: Online vs. Local Suppliers

The decision of where to purchase capacitors—whether online or from local suppliers—hinges on a trade-off between cost, convenience, and immediacy. Online marketplaces offer a wider selection and often lower prices, while local suppliers provide faster access and potentially more personalized customer service. Understanding these differences is critical when using a capacitor price list to make informed purchasing decisions.

| Factor | Online Suppliers (e.g., Alibaba, Specialized Retailers) | Local Suppliers |

|---|---|---|

| Price | Generally lower due to reduced overhead and direct sourcing. | Potentially higher due to overhead and smaller purchasing volumes. |

| Selection | Extensive range of capacitors from various manufacturers worldwide. | More limited selection based on local distributor agreements and inventory. |

| Convenience | Shopping from anywhere, 24/7. Easy price comparison and product research. | Requires physical visit to the store during business hours. |

| Shipping Time | Typically requires shipping time, which can range from a few days to several weeks. | Immediate availability of in-stock items. |

| Customer Service | May be limited to online support. Returns can be more cumbersome. | Potentially more personalized assistance with immediate access to product expertise. |

| Minimum Order Quantity | Often includes minimum order quantities for bulk purchases, especially on platforms like Alibaba. | Typically more flexible for smaller quantity purchases. |

| Authenticity and Quality | Risk of counterfeit products, requiring diligence to verify supplier reputation. | Generally more trustworthy in terms of product authenticity and quality. |

Tips for Getting the Best Deals on Capacitors

Securing the most favorable capacitor prices requires a strategic approach that extends beyond simply comparing a capacitor price list. This involves understanding market dynamics, purchasing efficiently, and ensuring that product specifications align precisely with project requirements.

- Bulk Purchasing

One of the most effective strategies for reducing the unit cost of capacitors is to buy in bulk. Suppliers often offer significant discounts for larger orders. This approach is particularly beneficial for projects requiring numerous capacitors of the same specification, as seen in many manufacturing and repair scenarios. - Reputable Suppliers

Opting for reputable suppliers is crucial to guarantee the quality and authenticity of the capacitors. While tempting, low prices from unverified sources may lead to unreliable components or counterfeits, ultimately costing more in the long run due to failures and replacement costs. Stick with established distributors or manufacturer-authorized vendors for quality assurance. - Precise Specification Matching

Carefully matching capacitor specifications to your application needs is imperative. Over-specifying (choosing components with higher ratings than required) often results in unnecessary expenses. It's essential to have a deep understanding of the project requirements to ensure that components are neither under- nor over-specified, thereby optimizing cost and functionality. Use datasheets from reputable manufacturers for this purpose. - Comparative Pricing

Always compare prices from multiple sources before making a purchase. Use a capacitor price list as a starting point but also explore online marketplaces, local distributors, and manufacturer websites. Pricing discrepancies are not unusual, especially when considering factors such as volume discounts or different shipping costs. However, do not solely focus on the lowest price; consider total cost of ownership, which includes factors like reliability and lead time. - Strategic Timing of Purchases

Price variations of capacitors can occur depending on the time of year due to supply and demand fluctuations. For example, prices might increase in peak manufacturing periods. Planning purchases ahead and understanding these cycles might help you secure better pricing. - Consider Equivalent Parts

There may be equivalent capacitors from different brands that have similar specifications but are offered at different prices. Exploring these alternative options can provide a cost-effective approach to procurement. - Negotiate with Suppliers

When dealing with large orders or establishing an ongoing relationship with a supplier, do not hesitate to negotiate for a better price. Often, suppliers are willing to offer additional discounts for loyal clients or substantial purchases. This can be especially true when purchasing directly from the manufacturers.

Frequently Asked Questions about Capacitor Costs

Understanding the cost of capacitors can be complex due to the variety of types, specifications, and applications. This section addresses common questions to provide clarity on capacitor pricing and related factors, helping you navigate a capacitor price list effectively.

- How much do capacitors typically cost?

Capacitor costs vary widely based on type, capacitance, voltage rating, and quantity. Simple ceramic capacitors can cost just a few cents, while specialized high-voltage or high-capacitance capacitors can cost hundreds of dollars. Always consult a detailed capacitor price list from reputable suppliers for accurate pricing. - What is the most economical type of capacitor?

Ceramic capacitors are generally the least expensive due to their simple construction and widespread availability. However, they may not be suitable for all applications. Electrolytic capacitors are also relatively inexpensive, but their characteristics and lifespan may limit their use in some circuits. - How long do AC capacitors typically last?

AC capacitors, commonly used in HVAC systems, typically last between 5 to 15 years depending on operating conditions, such as ambient temperature and usage frequency. However, extreme temperatures and electrical stresses can significantly reduce their lifespan. Regular maintenance and monitoring are important. - Can I operate my AC unit without a capacitor?

No, an AC unit typically cannot function properly without a working capacitor. The capacitor is crucial for providing the initial energy required to start the compressor motor. Without it, the motor may fail to start or overheat, potentially causing damage to the AC unit and further expenses. Always replace a faulty AC capacitor promptly. - Why do capacitor prices vary so much?

Prices fluctuate due to several factors, including raw material costs (e.g., tantalum is more expensive than aluminum), manufacturing complexity, precision requirements, and the volume purchased. High-tolerance, high-voltage, or high-capacitance capacitors typically command higher prices due to these reasons. Order quantities and supplier margins also influence the final price listed on a capacitor price list. - Does the brand of capacitor affect the price?

Yes, the brand can significantly influence the price. Well-established brands often have higher prices due to their reputation for reliability, quality control, and stringent testing. Lower-cost brands may not offer the same levels of quality or reliability. When consulting a capacitor price list, consider the brand's reputation and if the price reflects your reliability requirements. - Are there price differences between online and local suppliers?

Yes, generally, online suppliers often offer more competitive prices due to lower overheads and a broader customer base. However, local suppliers might offer the advantage of immediate availability and direct customer support. It’s essential to weigh the benefits of price versus immediate need when deciding where to buy.

Understanding Capacitor Lifespan and Replacement

Capacitor lifespan is a critical factor in the reliability of electronic circuits and systems. Their performance and longevity are significantly influenced by operating conditions such as temperature, voltage, and current, directly affecting their price and replacement needs, as reflected in a capacitor price list.

- Temperature Effects

Elevated temperatures accelerate the degradation of capacitor materials, particularly electrolytic capacitors. High temperatures increase the rate of electrolyte evaporation and chemical reactions, leading to reduced capacitance and increased equivalent series resistance (ESR). Conversely, extremely low temperatures can reduce the effectiveness of the dielectric. Manufacturers usually provide a temperature rating range, which when exceeded, can reduce expected lifespan. - Voltage Impact

Operating capacitors consistently near or above their rated voltage will significantly shorten their lifespan. This over-voltage stress can lead to dielectric breakdown, causing irreversible damage and failure. Operating at lower voltages typically extends the capacitor's life, so designs should keep voltage safety margins in mind. Capacitor price lists might show higher prices for capacitors with higher voltage ratings to accommodate these operational demands. - Current and Ripple

High ripple current causes internal heating within a capacitor due to the inherent ESR. This heating exacerbates the issues mentioned in Temperature Effects leading to faster degradation. The RMS ripple current rating provided in specifications must be respected to ensure the intended capacitor lifespan. High-ripple-current capacitors will generally have different prices compared to those designed for low-ripple applications. - Signs of Capacitor Failure

Common signs of capacitor failure include bulging or leaking cases (especially for electrolytic capacitors), reduced capacitance, increased ESR, and erratic circuit behavior. In AC applications, such as HVAC systems, a failing capacitor can lead to a motor that fails to start, or runs inconsistently. Such situations necessitate replacement which will be reflected in the maintenance or repair costs. - Replacement Timing

Capacitor replacement is generally needed when a capacitor shows signs of failure or when it has reached or exceeded its rated lifespan or rated operational hours, typically specified in the datasheets. While routine replacement may seem unnecessary, in critical applications preventive replacement is recommended to avoid system failure. The capacitor price list is used in this maintenance cycle to estimate and plan the needed replacements. - General Advice for Extended Lifespan

To extend the life of capacitors, ensure they are operated within their specified voltage, temperature, and ripple current ratings. Good circuit design, appropriate heat dissipation and choosing higher rated components will help significantly extend lifespan. Furthermore, consider replacing capacitors when recommended or when there is a routine maintenance cycle or a known weakness in a product. Consult a [capacitor price list] to budget for future replacements, which is an important part of proactive maintenance.

Comparative Analysis: Common Capacitor Types and Costs

A comparative analysis of capacitor costs reveals significant price variations based on type, capacitance, and voltage ratings. Understanding these differences is crucial when consulting a capacitor price list to ensure the right components are selected for any given application. The following table provides a general overview of cost ranges for common capacitor types; these are indicative and can fluctuate based on manufacturer, quantity, and specifications.

| Capacitor Type | Typical Capacitance Range | Typical Voltage Range | Cost per unit (USD - Small Quantity) | Application Examples |

|---|---|---|---|---|

| Electrolytic | 0.1 µF to 100,000+ µF | 6.3 V to 500+ V | $0.10 - $5.00+ | Power supplies, audio circuits, general purpose |

| Ceramic | 1 pF to 10 µF | 10 V to 1000+ V | $0.05 - $1.00 | High frequency circuits, decoupling, filtering |

| Film | 100 pF to 100 µF | 50 V to 2000+ V | $0.20 - $5.00+ | Precision timing, audio equipment, high voltage applications |

| Tantalum | 0.1 µF to 1000 µF | 2.5 V to 125 V | $0.30 - $10.00+ | High reliability circuits, portable devices, medical equipment |

Understanding the capacitor landscape is crucial, whether you're replacing a faulty AC unit component or building a complex electronics project. This guide should help you navigate the [capacitor price list], making informed decisions based on different types of capacitors, their applications, and market prices. Keep in mind that prices can fluctuate, so it's always good to check multiple sources and stay informed. With this knowledge, you are better equipped to find the right capacitors for your needs at the best possible cost. Always choose parts that meet specific requirements, avoid cutting corners for critical applications and be mindful of the lifespan of the component for safety and efficiency.

AnyPCBA

AnyPCBA