DC Link Capacitors: Powering Modern Electronics with Precision

Imagine the smooth, unwavering power delivery in your electric car or the consistent output of a solar inverter. At the heart of these seamless operations lies a seemingly simple component: the DC link capacitor. This often-overlooked device acts as a critical intermediary, smoothing out fluctuations and ensuring a stable flow of energy in countless modern applications. This article delves deep into the world of DC link capacitors, exploring their functionality, design, selection criteria, and the critical role they play in shaping our electrified world.

Understanding the Role of DC Link Capacitors

DC link capacitors are fundamental components in power electronic circuits, acting as energy reservoirs that stabilize DC voltage levels between the rectifier and inverter stages. Their primary function is to minimize voltage ripple and provide a consistent power supply, thereby ensuring efficient operation and preventing damage to sensitive electronics. These capacitors store energy during periods of high supply voltage and release it during voltage sags, effectively smoothing the DC bus voltage.

- Energy Storage

The capacitor acts as a buffer, storing electrical energy and releasing it as required by the load. - Voltage Ripple Reduction

They minimize voltage fluctuations on the DC link, ensuring stable operation of inverters and other downstream electronics. - Power Decoupling

They decouple the rectifier from the inverter, preventing load-induced disturbances from affecting the input side. - Transient Response

They provide instantaneous current during sudden load changes, facilitating smooth system operation.

DC Link Capacitors in Electric Vehicles

In electric vehicles (EVs), DC link capacitors are indispensable components, serving as a crucial intermediary for managing power flow between the battery, the inverter, and the electric motor. Their primary function is to stabilize the DC voltage, ensuring efficient and reliable performance of the electric drive system. These capacitors are also essential in managing regenerative braking, capturing energy during deceleration and feeding it back into the battery.

The role of DC link capacitors in EVs is multifaceted:

- Energy Buffering

DC link capacitors act as a temporary energy reservoir, smoothing out voltage fluctuations that occur during rapid acceleration and deceleration. This ensures a consistent power supply to the motor, enhancing performance. - Voltage Stabilization

The capacitors maintain a stable DC voltage level within the inverter circuit, minimizing voltage ripple and preventing damage to sensitive electronic components. This stable voltage is crucial for the optimal operation of the motor drive system. - Regenerative Braking Management

When the EV decelerates, the motor acts as a generator, sending energy back into the system. DC link capacitors manage this energy flow, enabling efficient energy recapture and preventing overvoltage issues during regenerative braking.

| Application | Function | Benefit |

|---|---|---|

| Normal Operation | Provides stable DC voltage to the motor inverter. | Ensures smooth and efficient motor operation. |

| Acceleration | Buffers energy to meet peak power demands. | Enhances vehicle performance by providing immediate energy for rapid acceleration. |

| Regenerative Braking | Captures and manages energy feedback. | Improves overall energy efficiency by reusing deceleration energy and reducing energy waste. |

The performance and reliability of an EV’s powertrain system is directly dependent on the quality and characteristics of the DC link capacitors. Therefore, careful selection and design considerations are essential for optimal EV performance and long-term reliability.

DC Link Capacitors in Renewable Energy Systems

DC link capacitors are indispensable components within renewable energy systems, functioning as vital intermediaries that ensure voltage stability and facilitate efficient power conversion, ultimately enabling seamless integration with the electrical grid. These capacitors are crucial in managing the fluctuating power output from renewable sources like wind and solar, maintaining a stable DC voltage for downstream inverters and power conversion equipment.

In wind energy systems, DC link capacitors mitigate voltage variations caused by the intermittent nature of wind power, smoothing out the power supplied to the grid. Similarly, in solar photovoltaic (PV) systems, these capacitors stabilize the DC voltage output from solar panels before it's inverted into AC power for distribution.

The effective management of voltage and current by DC link capacitors is pivotal in preventing grid instability and ensuring the consistent and reliable delivery of renewable energy. Their role is paramount in achieving optimal energy conversion efficiency and enhancing the long-term performance of renewable energy installations.

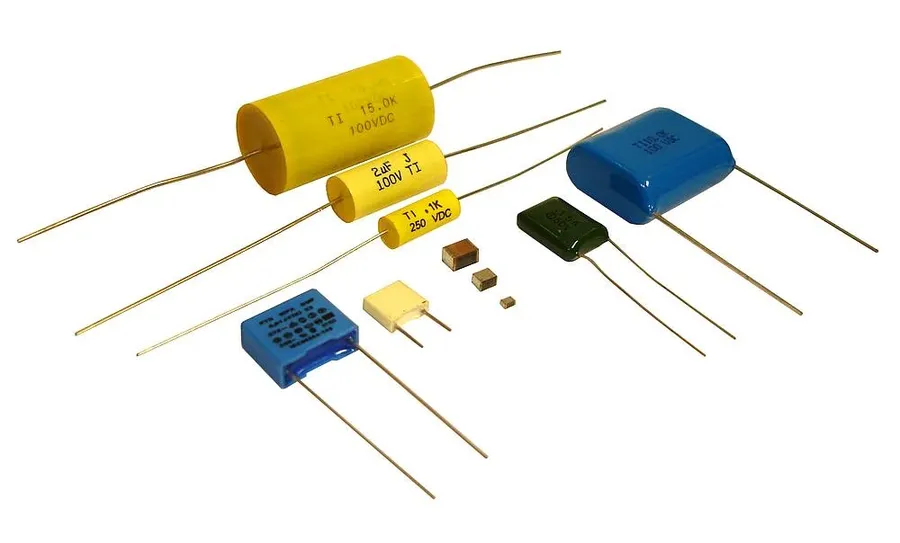

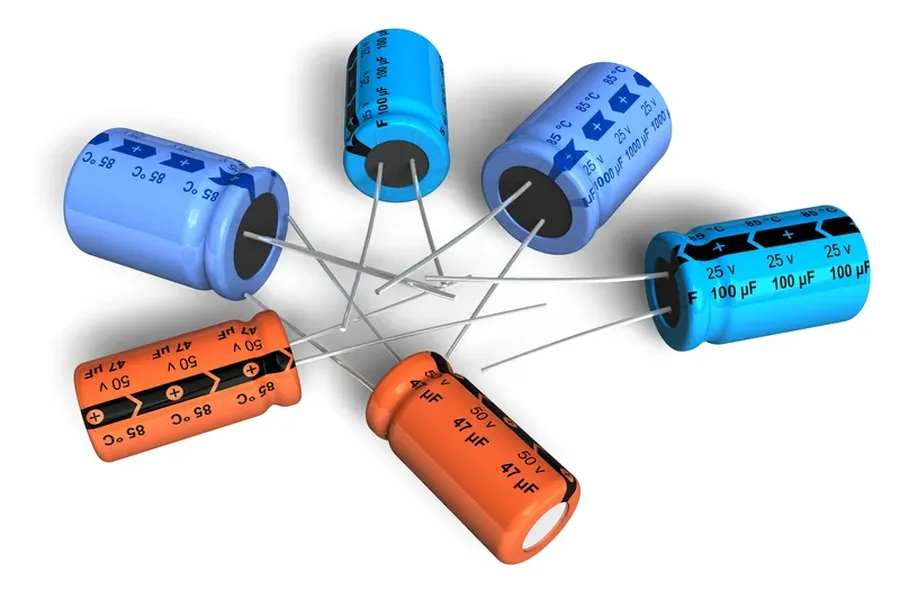

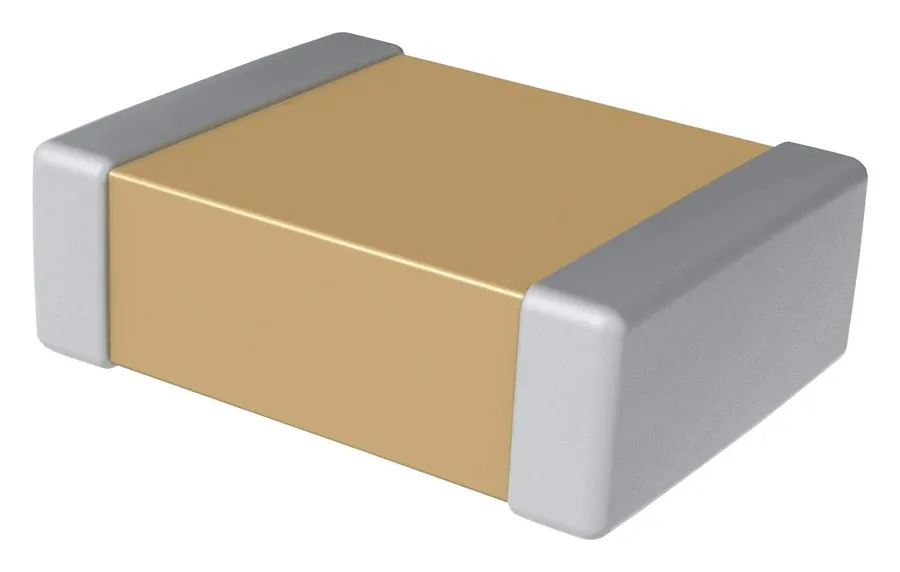

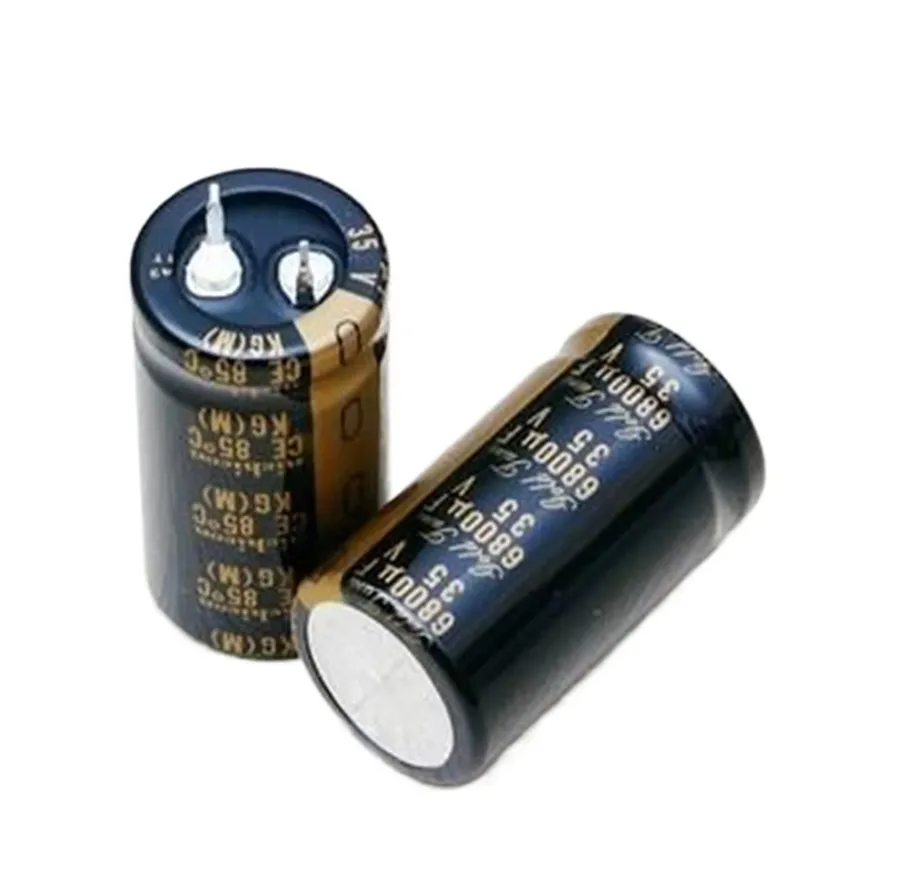

Types of DC Link Capacitors: Film, Electrolytic, and MLCC

DC link capacitors are crucial components in power electronics, and their performance is heavily influenced by the type of capacitor technology employed. This section provides a detailed comparison of film, electrolytic, and multilayer ceramic (MLCC) capacitors, highlighting their unique characteristics, advantages, disadvantages, and suitability for various DC link applications.

| Feature | Film Capacitors | Aluminum Electrolytic Capacitors | MLCC (Multilayer Ceramic Capacitors) |

|---|---|---|---|

| Reliability | High, long lifespan | Moderate, can degrade over time | High, very robust |

| Capacitance | Moderate, lower than electrolytics | High, good for bulk capacitance | Low to moderate |

| Size | Moderate to large | Moderate to large | Small, compact |

| ESR (Equivalent Series Resistance) | Low | Moderate to high | Very Low |

| Temperature Range | Wide | Limited | Wide |

| Cost | Moderate to High | Low to Moderate | Moderate |

| Applications | High reliability systems, inverters, EV | Bulk energy storage, general purpose | High frequency circuits, compact designs |

| Advantages | High reliability, low ESR, good temperature stability | High capacitance, cost-effective for bulk storage | Small size, low ESR, good high-frequency performance |

| Disadvantages | Larger size for similar capacitance, Higher cost | Limited lifespan, temperature sensitive, Higher ESR | Limited capacitance compared to electrolytics, can exhibit capacitance variation with voltage |

Selecting the Right DC Link Capacitor: Key Parameters

Selecting the appropriate DC link capacitor is crucial for the reliable and efficient operation of power electronic systems. This process involves carefully considering several key parameters to ensure the capacitor meets the specific demands of the application. These parameters include voltage rating, capacitance value, current handling capability, temperature characteristics, and physical size, each contributing uniquely to the overall performance and longevity of the system.

| Parameter | Description | Importance |

|---|---|---|

| Voltage Rating | The maximum DC voltage the capacitor can withstand continuously without failure. | Essential to prevent dielectric breakdown and ensure safe operation. The capacitor's voltage rating must exceed the expected maximum system voltage. |

| Capacitance Value | The amount of charge the capacitor can store at a given voltage. | Determines the energy storage capacity and ripple voltage characteristics. The value affects the system's ability to buffer voltage fluctuations. |

| Current Handling Capability | The maximum current (RMS and peak) the capacitor can safely handle without overheating or damage. | Critical for preventing thermal runaway and ensuring the longevity of the capacitor. The capacitor must be able to handle the expected current within the system. |

| Temperature Characteristics | The capacitor’s performance variations across its operating temperature range. | Affects capacitance, ESR (Equivalent Series Resistance), and lifespan. It is vital to select a capacitor with suitable temperature performance for its environment. |

| Physical Size | The dimensions and form factor of the capacitor. | Important for integrating into the application, space limitations, and compatibility with the physical enclosure or mounting requirements. |

Matching the capacitor specifications to the application requirements is crucial for optimal performance and reliability. It involves a thorough analysis of the system’s voltage, current, and temperature profiles to ensure the chosen capacitor meets the operational demands, maintains performance within the operational environment, and complies with size constraints. This rigorous approach is vital to avoiding premature failure and ensuring the efficient operation of the DC link in your power electronics system.

DC Link Capacitor Design Considerations

Designing a system incorporating DC link capacitors requires a holistic approach, addressing not only the capacitor selection but also the broader circuit environment. This includes careful consideration of circuit layout, thermal management, and protective measures to ensure the capacitor's reliability and the system's overall performance.

Proper PCB design, effective heat dissipation, and implementation of robust protection strategies are crucial for optimal DC link capacitor performance. Neglecting these aspects can lead to premature capacitor failure, system instability, and compromised reliability.

- PCB Layout

The physical arrangement of the components on the PCB significantly impacts circuit performance. Proper layout minimizes parasitic inductance and resistance, which affect the capacitor's effective impedance and its ability to handle ripple currents. Keep high-current paths short and wide to reduce inductance, and place the capacitor as close to the power electronics device as possible to minimize stray inductance. - Thermal Management

DC link capacitors, especially electrolytic types, are sensitive to temperature. Excessive heat can accelerate capacitor aging and reduce its lifespan. Effective heat management is critical. Strategies include using heat sinks, forced air cooling, and strategically placing components to maximize airflow. Monitor the capacitor’s operating temperature and ensure it stays within specified limits. Thermal vias placed under the capacitor can also help with heat transfer. - Protection Measures

Implementing protection circuits is vital to safeguard the DC link capacitor and prevent damage from overvoltage or overcurrent conditions. This may involve using voltage clamping devices like transient voltage suppression (TVS) diodes and fuses to protect the capacitor and system from damage caused by excessive current flow or transient events. Ensure the protection devices are rated to handle the system’s fault conditions.

| Design Aspect | Considerations | Implications |

|---|---|---|

| PCB Layout | Short, wide traces, minimize parasitic inductance, close proximity to power devices | Reduced impedance, improved current handling, minimized voltage drop |

| Thermal Management | Heat sinks, forced air cooling, strategic component placement, thermal vias | Extended capacitor lifespan, stable performance, prevention of premature failure |

| Protection Measures | TVS diodes, fuses, overcurrent and overvoltage protection circuits | Protection against transient events, prevention of capacitor damage, improved system reliability |

Frequently Asked Questions About DC Link Capacitors

This section addresses common queries about DC link capacitors, providing clear and concise answers to enhance understanding of their function and application.

- How do DC link capacitors work?

DC link capacitors act as energy storage buffers within power electronic circuits. They smooth out voltage fluctuations by storing electrical energy when the input voltage is higher than the desired level and releasing it when the input voltage is lower. This ensures a stable DC voltage supply to the load, such as an inverter or motor. Specifically, they reduce voltage ripple and maintain a consistent voltage, vital for the proper functioning of downstream components. - How is the value of a DC link capacitor chosen?

Choosing the appropriate capacitor value depends on several factors, including the application's voltage requirements, current demands, permissible voltage ripple, and operating frequency. Generally, a higher capacitance value is necessary for higher power applications to mitigate voltage fluctuations and to handle larger ripple currents. The capacitance is also related to the switching frequency of the power converter; lower frequencies typically require larger capacitors. Careful calculation and often empirical testing are crucial for selecting the correct value for optimal performance and longevity. - What is the purpose of a DC link?

The DC link serves as an intermediate DC voltage bus in power electronic systems. It is typically positioned between a rectifier (which converts AC to DC) and an inverter (which converts DC to AC) or a DC-DC converter. Its purpose is to decouple the input and output stages, providing a stable DC voltage source and energy buffer. This decoupling reduces harmonics, smooths out voltage fluctuations, and provides a consistent power supply, which is essential for efficient and reliable power conversion. - What happens when a capacitor is connected to a DC source?

When a capacitor is connected to a DC source, it initially draws a significant charging current, which is limited only by the circuit's internal resistance and the source impedance. This charging current quickly decreases as the capacitor accumulates charge, and its voltage rises to match the DC source voltage. Once charged, the capacitor blocks DC current and only allows transient or AC current flow, which is why it functions as a DC voltage buffer. It's important to ensure the voltage rating of the capacitor is not exceeded to prevent damage. - Why are DC link capacitors important in electric vehicles?

In electric vehicles (EVs), DC link capacitors are crucial for smoothing the DC voltage from the battery or during regenerative braking, providing a stable power supply to the motor inverters. The fluctuating power demand from acceleration, deceleration, and regenerative braking generates a highly variable voltage output. The DC link capacitor buffers these fluctuations, delivering a stable DC link voltage to the inverter, and ensuring the motor performs optimally while maximizing efficiency and lifespan. - How do temperature variations impact the performance of DC link capacitors?

Temperature significantly affects the performance and lifespan of DC link capacitors. Higher temperatures can reduce the capacitor's lifetime due to accelerated degradation of the dielectric material, which in turn causes capacitance loss and increased equivalent series resistance (ESR). Conversely, excessively low temperatures can reduce capacitance and ESR, which can lead to suboptimal performance. Selecting capacitors rated for appropriate operating temperatures and employing thermal management techniques are essential for long-term reliability. - What is the difference between film capacitors, electrolytic capacitors, and MLCCs in DC link applications?

Film capacitors offer high reliability, low ESR, and are self-healing, but are generally larger and more expensive. Electrolytic capacitors, while more compact and cost-effective, have lower reliability, limited lifespan, and higher ESR, and are susceptible to drying out over time. MLCCs, or Multi-Layer Ceramic Capacitors, are extremely compact, have very low ESR, and are highly reliable, but they typically have lower capacitance values compared to film and electrolytic capacitors. The appropriate choice depends on the specific application requirements including size, cost, reliability and lifespan considerations.

DC Link Capacitor Calculation and Considerations for 3-Phase Inverters

Determining the correct capacitance for DC link capacitors in 3-phase inverters is crucial for ensuring stable and efficient operation. The capacitor acts as a buffer, smoothing out voltage ripples caused by switching actions and load variations. Proper calculation and selection of this capacitance are essential for optimizing inverter performance and longevity, minimizing harmonic distortion and preventing premature failure.

The calculation of the DC link capacitance involves several critical factors, primarily related to the ripple current and the permissible voltage ripple. These are outlined as follows:

- Ripple Current (I_ripple)

The ripple current is the alternating component of the current flowing through the capacitor. It's primarily caused by the switching action of the inverter. The capacitor needs to be able to handle the RMS value of this current without overheating. The amplitude and frequency of the ripple current depend on the inverter topology, modulation strategy, and switching frequency. - Permissible Voltage Ripple (ΔV)

The allowable voltage ripple on the DC link is a critical design parameter. A larger ripple can cause instability in the inverter's control, increase harmonic distortion, and potentially damage other components. Typically, the voltage ripple is maintained within a few percent of the nominal DC link voltage, which usually depends on the tolerance of connected components such as IGBTs. - Load Current (I_load)

The load current drawn by the inverter is a key factor. The magnitude of the capacitor current is determined by the load characteristics. The load current affects the charge/discharge rate and thus the size of the capacitor. - Switching Frequency (f_sw)

The switching frequency of the inverter directly influences the frequency of the ripple current. Higher switching frequencies typically reduce the required capacitance value but may lead to higher switching losses and EMI. This requires careful balancing based on design goals.

A simplified formula can be used as a starting point for capacitance calculation. However, this formula often needs adjustment based on specific conditions and is based on the first principle of the charge-discharge cycle of the capacitor.

C = \frac{I_{ripple}}{2 \cdot f_{sw} \cdot \Delta V}

Where:

- C

is the required capacitance in Farads. - I_ripple

is the peak ripple current in Amperes. - f_sw

is the switching frequency in Hertz. - ΔV

is the permissible voltage ripple in Volts.

It's important to note that this simplified formula provides a starting estimate. In practice, more comprehensive analysis and simulations, especially with Finite Element Analysis (FEA), may be needed. The effective capacitance under operating conditions can be affected by various factors such as temperature and frequency, thus requiring adjustments to the calculated value. Additionally, derating factors for voltage, current, and temperature should be applied based on the capacitor manufacturer's specifications to ensure reliable operation.

| Parameter | Description | Impact on Calculation |

|---|---|---|

| Ripple Current | AC current component through the capacitor due to switching | Directly influences the required capacitance value; higher ripple current requires larger capacitance |

| Voltage Ripple | Permissible variation in DC link voltage | Determines the stability of the system; tighter voltage ripple requirements necessitate higher capacitance |

| Switching Frequency | Rate at which inverter switches operate | Higher switching frequency leads to smaller capacitance; but also increases switching losses and EMI. |

| DC Bus Voltage | Nominal DC voltage level in the inverter | Sets capacitor voltage rating |

| Load Characteristics | Type and current demands of the load driven by the inverter | Dictates the amount of charge/discharge current, influencing capacitance requirements |

Advancements and Future Trends in DC Link Capacitor Technology

The field of DC link capacitor technology is undergoing rapid evolution, driven by the increasing demands for higher performance, smaller size, and extended lifespan in modern power electronics. This section explores emerging trends in material science, capacitor design, and integration methods that are shaping the future of these critical components.

- Material Science Innovations

The development of new dielectric materials is central to improving capacitor performance. Research is focused on materials with higher permittivity (increased energy storage per volume) and higher temperature stability. Examples include advanced polymer films, ceramics with tailored microstructures, and nanocomposite materials combining the strengths of multiple materials. These advancements directly enable the reduction of capacitor size while maintaining or improving performance characteristics like ESR (Equivalent Series Resistance) and current handling. - New Capacitor Technologies

Beyond traditional film, electrolytic, and MLCC capacitors, new technologies are emerging. These include hybrid capacitors that combine the characteristics of different capacitor types (e.g., combining the high energy density of electrochemical capacitors with the low ESR of film capacitors), and thin-film capacitors which offer very precise control of material deposition and layer thickness, enabling improved capacitance density. Research is also being conducted on new electrode materials such as graphene and other 2D materials to further improve capacitor characteristics. - Integration and Packaging

Advanced integration techniques, such as embedding capacitors directly into PCBs (printed circuit boards) or power modules, reduce parasitic inductance and improve thermal management. These techniques also enable more compact designs, reducing overall system size and cost. The development of high-density packaging solutions is crucial to achieving the size and performance targets of modern electronics. - Self-Healing and Smart Capacitors

Research is also underway into self-healing capacitor technologies. Such technology enables the capacitor to repair itself from small defects, preventing the capacitor from failing and increasing its lifespan. Integrated sensing and monitoring capabilities are also being explored allowing the capacitor to be a more intelligent component, providing data on temperature, voltage, and current to ensure proper operation and predictive maintenance.

DC link capacitors are the unsung heroes of modern power electronics, quietly ensuring the stable and efficient operation of a multitude of devices, from electric vehicles to renewable energy systems. Understanding their role, types, and selection criteria is crucial for engineers and designers looking to create reliable and high-performing electrical systems. As technology advances, DC link capacitors will continue to evolve, playing an ever-increasingly vital role in a more electrified world, pushing the boundaries of what's possible in energy storage and power conversion.

AnyPCBA

AnyPCBA