Decoding EPCOS Capacitor Prices: A Comprehensive Guide

Capacitors, essential components in modern electronics, play a crucial role in countless devices. Among them, EPCOS capacitors, known for their quality and reliability, are widely used across various industries. From the tiny components powering our smartphones to the robust capacitors stabilizing industrial power grids, understanding the factors that influence the [epcos capacitor price] is key. This article will explore the variables that affect pricing, analyze different types, and provide a practical guide for both informational and transactional users looking to buy or understand these vital components.

Understanding EPCOS Capacitors: An Overview

EPCOS, now a part of TDK Corporation, is a globally recognized leader in the manufacturing of high-quality capacitors. Known for their reliability and performance, EPCOS capacitors are integral components across diverse applications, notably including industrial equipment, automotive systems, and consumer electronics. Their product portfolio primarily encompasses film capacitors and power capacitors, both of which are characterized by innovative design and robust performance.

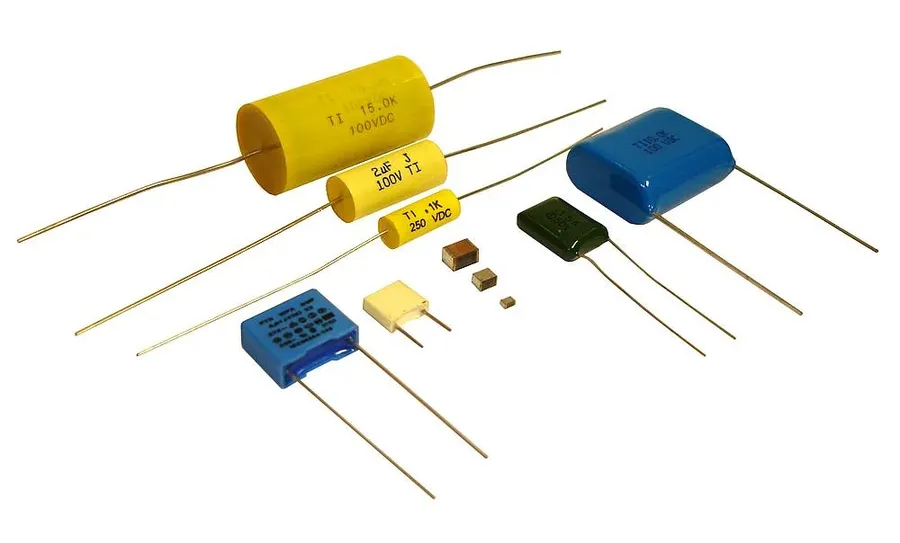

- Film Capacitors

Utilized for their self-healing properties, high current handling capabilities, and design flexibility. Constructed with thin layers of dielectric material and metal electrodes, these capacitors are ideal for applications requiring precision and stability. - Power Capacitors

Designed to manage high power levels in applications like power factor correction (PFC) and motor drives. They are engineered to handle extreme voltage and current demands, ensuring dependable operation in demanding conditions. These capacitors are built for high reliability and long operational life.

Key features common to EPCOS capacitors include:

- Self-Healing Properties

This feature allows the capacitor to recover from dielectric breakdowns, thereby prolonging its service life. - High Current Capability

Enables the capacitor to manage large current surges without compromising its performance. - Flexible Design

Capacitors are available in various form factors and configurations, allowing them to be easily integrated into different systems.

The broad application of EPCOS capacitors spans several key sectors:

- Industrial Applications

Including power supplies, motor drives, and industrial automation systems. - Automotive Industry

Used in electric vehicles (EVs), hybrid vehicles, and various automotive control units. - Consumer Electronics

Such as home appliances, audio equipment, and power adapters.

Factors Influencing EPCOS Capacitor Prices

The price of EPCOS capacitors, now a brand of TDK, is determined by a complex interplay of technical specifications, material choices, and market dynamics. Understanding these factors is crucial for making informed purchasing decisions and optimizing cost-effectiveness.

Below is a breakdown of the key variables that affect the cost of EPCOS capacitors:

- Capacitance

Measured in Farads (F), microfarads (µF), or picofarads (pF), capacitance directly impacts the price. Higher capacitance values generally lead to higher costs due to the increased amount of dielectric material and complexity in manufacturing. - Voltage Rating

The maximum voltage that a capacitor can safely handle is a critical factor. Higher voltage ratings necessitate thicker dielectric layers and more robust construction, which increases production costs and, consequently, the price. - Tolerance

Capacitance tolerance refers to the allowed deviation from the specified value (e.g., ±5%, ±10%). Tighter tolerances demand more precise manufacturing processes, increasing costs. Capacitors with tighter tolerance are generally priced higher. - Size and Dimensions

The physical dimensions and form factor of the capacitor contribute to the overall cost. Smaller, more compact capacitors with equivalent performance can often command higher prices due to more intricate manufacturing requirements. - Packaging

The packaging type, such as radial lead, axial lead, or surface mount, will also affect pricing. Surface mount components often have an associated price premium. - Material of Construction

The type of dielectric material used (e.g., polypropylene, polyester, ceramic) has a significant impact on the cost. Each dielectric material is chosen for specific performance characteristics, and some are more expensive to produce than others. - Special Features

Features such as safety certifications, temperature rating, self-healing properties, high current capability, and expected operational life all add complexity and will impact price. Higher performance translates to higher cost. - Quantity Purchased

Purchasing quantities will drastically impact pricing. Bulk purchases will usually reduce the cost per unit significantly through economies of scale. Single orders will reflect a higher price per unit. - Regional Pricing Variations

Pricing can vary based on geographical location due to differing labor costs, transportation fees, and import/export tariffs. Market conditions and competition within a region also play a factor.

| Factor | Impact on Price | Why |

|---|---|---|

| Capacitance | Increase | More dielectric material required. |

| Voltage Rating | Increase | Thicker dielectric layers, more robust construction. |

| Tolerance | Increase | More precise manufacturing. |

| Size | Increase (Generally for smaller) | More intricate manufacturing. |

| Material | Variable | Depending on dielectric used. |

| Special Features | Increase | Higher Performance. |

| Quantity | Decrease (Bulk Orders) | Economies of scale. |

| Region | Variable | Varying labor cost, and market conditions. |

Types of EPCOS Capacitors and Their Price Ranges

EPCOS, now a part of TDK, manufactures a wide array of capacitors, each designed for specific applications and exhibiting varying price points. This section will outline the main types of EPCOS capacitors, their typical price ranges, and their common applications to guide purchasing decisions effectively.

The price of an EPCOS capacitor is influenced by its type, which directly correlates to its design, materials and manufacturing process. Below, each category is broken down, providing information on typical prices and their applications.

| Capacitor Type | Description | Typical Price Range (USD) | Typical Applications |

|---|---|---|---|

| Film Capacitors | Includes Polypropylene (MKP), Polyester (MKT), and other variations. Known for high stability and reliability. | 0.10 - 5.00 (per unit, varies greatly by size and specs) | General electronics, audio equipment, power supplies, and motor control. |

| Power Capacitors | Encompasses Power Factor Correction (PFC), motor run, and DC link capacitors. These handle high power applications. | 5.00 - 1000+ (per unit, varies significantly by rating) | Industrial power systems, renewable energy inverters, electric vehicle charging, and high power motor applications. |

| DC Link Capacitors | Specialized film capacitors designed for high DC voltage applications with low inductance. | 2.00 - 500 (per unit, dependent on voltage and capacitance) | Inverters, renewable energy systems, electric vehicle drives. |

Note that price ranges are highly variable depending on specific electrical characteristics such as capacitance, voltage ratings and tolerance. Furthermore, the exact price will be influenced by purchase volume and the source. These values represent typical retail prices.

- Film Capacitors:

Generally offer high reliability and self-healing capabilities. The price is impacted by the dielectric material (e.g., polypropylene is more expensive than polyester) and the design parameters. - Power Capacitors:

Designed for handling higher voltages and current. Cost is primarily driven by the power rating (kVAr), voltage rating, and any additional safety features. - DC Link Capacitors:

Optimized for low inductance and high voltage requirements. Specific construction techniques required for these capacitors impact the cost.

EPCOS Film Capacitor Pricing: A Deeper Dive

This section provides an in-depth analysis of EPCOS film capacitor pricing, focusing on how various factors such as voltage, capacitance, and specific series impact cost. We will explore practical examples with average prices for common part numbers, as well as key design and construction features that contribute to price variations.

EPCOS, now under the TDK brand, offers a wide array of film capacitors, each designed for specific applications. The pricing is influenced by a complex interplay of factors that go beyond simple capacitance and voltage ratings.

The analysis below will explore these factors and highlight how they contribute to the overall cost of the capacitor.

- Capacitance and Voltage Rating

Higher capacitance and voltage ratings typically lead to higher prices. For example, a capacitor with 10 uF and 630 V rating will cost more than a capacitor with 1 uF and 100 V, all other parameters being equal. - Series Type

Different EPCOS film capacitor series, such as the B32xxx series, cater to specific applications and performance needs. The B3265x series, for example, a general-purpose film capacitor, may be priced differently from the B3277x series, which is designed for harsh environments. - Metallization Pattern

The metallization pattern on the film affects electrical performance and thus the price. Thicker metallization or specific patterns that enhance current handling capabilities may increase the price. - Winding Type

The winding type influences the capacitor's performance characteristics such as equivalent series resistance (ESR) and inductance (ESL), which can affect price. For example, a segmented winding, which can reduce ESL, is likely to be higher priced than a standard winding. - Lead Type

Lead type and construction, like through-hole versus surface mount, and lead material (tin, copper, etc.), can contribute to pricing differences. Surface mount devices will typically be lower priced than through-hole components as well as the length of the lead as well.

| EPCOS Series | Typical Application | Capacitance Range | Voltage Range | Average Price (USD, example) | Key Features |

|---|---|---|---|---|---|

| B32651 | General Purpose | 0.01 uF - 10 uF | 100V - 1000V | $0.10 - $1.50 | Compact Size, Self-Healing |

| B32776 | High Pulse Load | 0.001 uF - 1 uF | 400V - 1600V | $0.50 - $3.00 | High Current Capability, Robust Construction |

| B32711 | Automotive | 0.047 uF - 4.7 uF | 100V - 630V | $0.75 - $4.00 | AEC-Q200 Qualified, High Reliability |

| B32671 | Snubber Circuits | 0.001 uF - 0.1 uF | 630V - 2000V | $1.20 - $6.00 | High dV/dt Capability |

It's essential to note that these are approximate price ranges and can vary based on order quantity, supplier, and specific part number characteristics. For precise pricing, referring to distributor websites like Mouser or Digikey is recommended. Keep in mind that additional design options can greatly affect the price of the final component and these examples are typical price ranges for the lowest common variation of the specified series.

EPCOS Power Capacitor Pricing: Understanding the Cost Drivers

The pricing of EPCOS power capacitors is influenced by a unique set of factors, primarily revolving around their power handling capabilities, voltage requirements, and operational frequency. These components, designed for robust performance in demanding applications, exhibit price variations that directly correlate with these key specifications.

Unlike film capacitors, which focus more on capacitance and voltage ratings, power capacitors, including PFC (Power Factor Correction), motor run, and DC link capacitors, have pricing strongly tied to their reactive power rating (measured in KvAr), as well as the voltage and frequency they are designed to handle. The intended application and its specific performance requirements significantly impact the final price.

| Type of EPCOS Power Capacitor | Key Price Drivers | Typical Applications | Price Range (Illustrative) |

|---|---|---|---|

| PFC Capacitors | KvAr rating, Voltage, Frequency | Power factor correction in industrial systems | Medium to High |

| Motor Run Capacitors | Voltage, Capacitance, Frequency | Single-phase motors in appliances, HVAC | Low to Medium |

| DC Link Capacitors | Voltage, Capacitance, Current handling capability | Inverters, Converters, power electronics | Medium to High |

A higher KvAr rating signifies a capacitor's ability to manage more reactive power, directly translating to a higher price. Additionally, capacitors designed for higher voltage applications or for use in high-frequency circuits command higher prices due to the specialized materials and construction techniques required.

Real-world price examples include a 25 KvAr PFC capacitor, designed for 400V operation, which may cost significantly more than a lower KvAr, lower voltage rated capacitor from the same manufacturer. Similarly, high-voltage DC link capacitors, essential for electric vehicle applications, often have premium pricing due to their stringent performance and safety requirements. It’s also important to note that the demand for high-performance capacitors in high-voltage applications can cause an increase in pricing due to increased demand and manufacturing costs.

Where to Buy EPCOS Capacitors: A Price Comparison

Sourcing EPCOS capacitors requires careful consideration of various factors beyond just price. This section provides a comparative analysis of different purchasing avenues, examining price, availability, authenticity, and lead times to guide your procurement decisions.

| Source | Price | Availability | Authenticity | Lead Time | Pros | Cons |

|---|---|---|---|---|---|---|

| Online Distributors (e.g., Mouser, Digikey) | Competitive, but can vary based on quantity | Generally high stock levels | High, as they are authorized distributors | Typically short; 1-3 days in stock items | High authenticity, reliable, detailed datasheets | Higher cost for single/low quantity orders, may not offer bulk discounts |

| Marketplaces (e.g., eBay, Alibaba) | Potentially lower, very variable | Can be variable, often dependent on individual sellers | Risk of counterfeit components, need to verify seller credibility | Highly variable | Potential for lower cost, large selection | Authenticity concerns, longer shipping times, unreliable sources |

| Local Suppliers | Variable, depends on supplier and region | Stock levels vary widely | Depends on supplier reputation, need verification | Can be short if items are in local stock | Personal relationship, local support, faster delivery | Potentially higher prices, limited selection, may not have necessary documentation. |

| Direct from TDK (EPCOS) | Potentially lower, bulk-oriented | May require minimum order quantities, typically large | Guaranteed authenticity | Longer lead time for custom orders | Guaranteed authenticity, direct support, large bulk discounts possible | Large minimum order quantities, typically long lead time. |

- Tips for finding the best deals

- Compare Prices: Check multiple sources before making a purchase.

- Consider Quantity: Bulk orders typically result in lower per-unit prices.

- Look for Promotions: Distributors and suppliers often have seasonal or special promotions.

- Negotiate: For large orders, consider negotiating directly with suppliers.

- Verify Authenticity: Especially when buying from marketplaces, carefully check seller reviews and component markings.

Frequently Asked Questions About EPCOS Capacitors and Their Pricing

This section addresses common questions regarding EPCOS capacitors, providing detailed insights into their quality, applications, manufacturing, and selection process to assist you in making informed decisions and understanding pricing factors.

- Are EPCOS capacitors any good?

Yes, EPCOS capacitors, now under the TDK brand, are generally considered high-quality components. They are well-regarded for their reliability, performance, and adherence to stringent industry standards. Their film capacitors, in particular, are known for their self-healing properties and long operational life, making them suitable for demanding applications. This reputation is backed by extensive testing and a long history of use across various sectors. - What is an EPCOS capacitor?

EPCOS was a major manufacturer of capacitors, inductors, and other electronic components. It is now a part of TDK Electronics. An EPCOS capacitor, therefore, refers to a capacitor that was originally designed and produced by EPCOS, and now often produced under the TDK brand. These capacitors cover a wide range, including film capacitors (polypropylene, polyester, etc.), power capacitors, and ceramic capacitors. They are characterized by their specific electrical properties, materials, and intended applications. - Who makes EPCOS capacitors now?

EPCOS is now a part of TDK Electronics. Therefore, TDK manufactures and sells the capacitors previously branded as EPCOS. While the EPCOS brand name may still appear on some older stock, new components are branded TDK. This transition ensures continuity in the quality and performance of the product line, but it is important to keep in mind the current branding. - How do I choose the right EPCOS capacitor for my application?

Selecting the correct EPCOS (or TDK) capacitor involves considering several factors. Firstly, the capacitance value must meet your design requirements. Secondly, the voltage rating must be sufficient to handle the circuit's operating conditions. Other important factors include the capacitor's tolerance, temperature range, size constraints, and expected lifespan. If using film capacitors, consider metallization patterns, winding type, and lead type which can influence performance and cost. For power capacitors, you must consider the KvAr rating and frequency. Always refer to the manufacturer's datasheet to match a capacitor's specifications with your circuit's requirements. Furthermore, consider the specific safety certifications required for your application. - Do EPCOS capacitor prices vary significantly?

Yes, EPCOS (TDK) capacitor prices can vary considerably depending on several factors. Capacitance value, voltage rating, tolerance, physical dimensions, and the capacitor's material all contribute to the cost. Moreover, film capacitor prices are impacted by metallization, winding type and lead type; for power capacitors, KvAr and application needs will affect the final price. Buying in bulk generally reduces the unit price, while special features such as high temperature operation or safety certifications can increase cost. Different distributors also have varying pricing. - How can I verify the authenticity of an EPCOS capacitor?

Given the prevalence of counterfeit electronic components, verifying the authenticity of EPCOS (TDK) capacitors is critical. Purchase from authorized distributors (such as Mouser or Digikey) and avoid unofficial sources. Check for consistent brand markings, part numbers, date codes and packaging compared to genuine TDK datasheets and online resources. If the capacitor is a film capacitor, the metallization and winding pattern should align with datasheets and specifications. If you are unsure, contact TDK directly for verification.

Practical Tips for Buying EPCOS Capacitors

Acquiring EPCOS capacitors, especially at competitive prices, requires a strategic approach. This section offers actionable advice to secure the best deals, verify authenticity, and avoid counterfeit products, ensuring you select the correct capacitor for your specific application needs.

Here's a breakdown of essential practical tips:

- Sourcing

Compare prices across multiple sources such as authorized distributors (Mouser, Digikey), reputable online marketplaces, and local suppliers. Be wary of significantly lower prices, as they often indicate counterfeit parts or lower quality. Prioritize authorized distributors for guaranteed authenticity but expect slightly higher prices. If using online marketplaces, check the vendor's rating, reviews, and seller history. Local suppliers may offer quick delivery, but also check their legitimacy. - Authenticity Verification

Carefully examine product packaging for proper labeling, branding, and logos. Ensure that part numbers match manufacturer's specifications and cross-reference them with datasheets available from TDK/EPCOS website. Inspect capacitors for physical anomalies like deformed leads, damaged coating, or poor printing on the component itself. Request lot codes and trace them back to the manufacturer. Consider batch testing of samples from large orders for further verification. - Application Specific Selection

Always refer to the device's specification or the manufacturer's application notes to select the correct capacitor for the intended use, paying attention to capacitance, voltage rating, tolerance, and temperature range requirements. Ensure the chosen capacitor has necessary safety certifications if needed. Consider the long-term performance requirements such as life expectancy, ripple current handling, and operating frequency. Understand the tradeoffs between cost, size, and performance of a capacitor to optimize your design and budget.

The following checklist is designed to guide your purchasing decision:

- Specification Alignment

Confirm the capacitor specifications (capacitance, voltage, tolerance, temperature range) match your application needs, and double check the datasheet. - Source Legitimacy

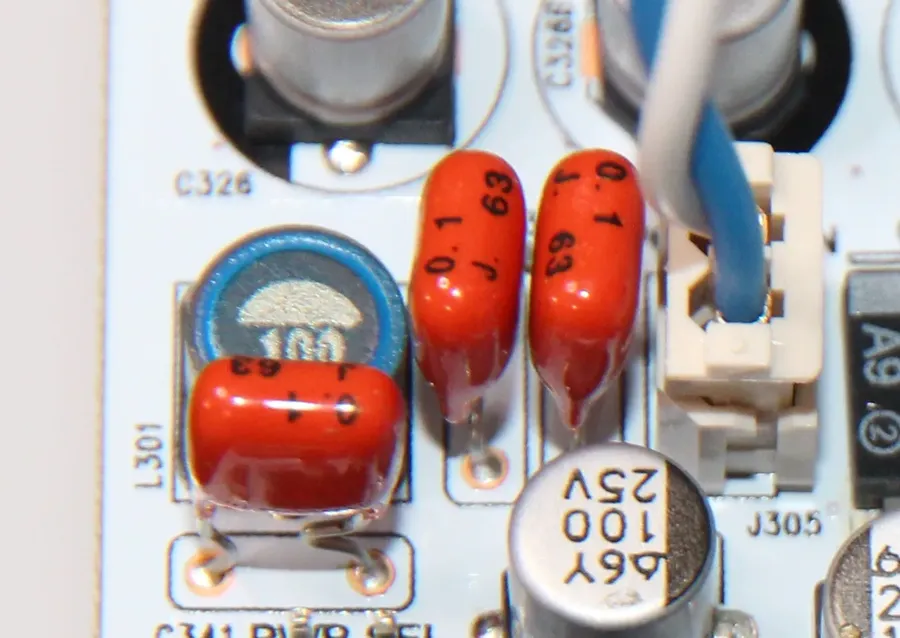

Buy only from authorized distributors and suppliers to ensure product authenticity and reliability. When using marketplaces, prioritize well-rated sellers with a strong sales history. - Visual Inspection

Check the packaging and components for any signs of damage, poor printing or inconsistent branding that may suggest counterfeit parts. - Traceability

Verify the manufacturing lot code and date codes if available, and where possible, trace these back to the manufacturer. - Compliance

Ensure the capacitor meets the necessary safety and environmental certifications, which may be indicated by markings or specifications on the product or packaging, such as UL, VDE, or RoHS. - Testing

If purchasing in bulk, consider performing initial tests on a small number of samples to verify specifications and performance before accepting the entire batch. - Price

Compare pricing across multiple sources and be wary of extremely low prices that are far below market average. Investigate the seller thoroughly if prices seem too good to be true.

Future Trends in EPCOS Capacitor Pricing and Technology

The capacitor market, including EPCOS (now TDK) products, is subject to ongoing evolution driven by technological advancements, material science breakthroughs, and global economic factors. Understanding these trends is crucial for anticipating future pricing and availability of EPCOS capacitors.

Several factors suggest a likely trajectory for capacitor development and pricing:

- Material Costs and Supply Chain Dynamics

Raw material prices (e.g., polypropylene, polyester, metals for electrodes) directly impact capacitor production costs. Global supply chain disruptions, geopolitical instability, and trade policies can all lead to price volatility. Anticipating these fluctuations will help in planning for capacitor procurements. - Technological Advancements in Capacitor Design

Emerging trends in capacitor technology include: higher energy density capacitors, improved temperature tolerance, and miniaturization. These advancements will likely influence future generations of EPCOS products and potentially lower costs over the long run. New materials, manufacturing processes, and improved component integration will also contribute to increased performance. - Increased Demand for High Performance Capacitors

The increasing adoption of electric vehicles, renewable energy systems, and advanced industrial equipment drives demand for high-performance capacitors. Increased demand will lead to economies of scale, which in turn may lower prices. Additionally, these specialized applications may also require unique capacitors with higher performance requirements, which can increase their prices. - Sustainability and Environmental Regulations

Growing environmental concerns are leading to regulations on material usage and waste management. Manufacturers are increasingly focusing on sustainable materials and production processes. This may impact long term pricing, as new materials and production process can increase costs or it can promote more efficient production methods and thus lead to lower costs.

Specific areas where EPCOS capacitors may see advancements include:

- Enhanced film capacitors

Development of film capacitors with improved metallization techniques, resulting in higher reliability and smaller form factors. EPCOS may introduce new film technologies that can provide improved temperature, and voltage tolerance, leading to more efficient and durable capacitors. - Advanced power capacitors

Focus on increasing the energy density and power handling capabilities of power capacitors. This includes designs for more efficient PFC and motor drive applications. Advancements here include improved thermal management and novel dielectric materials. - Miniaturization

The trend toward miniaturization is expected to continue to push for even smaller component sizes without compromising performance. This includes development of new packaging techniques for more efficient board space utilization. - Integration

Continued integration of capacitors within modules, and systems, along with improved capacitor packaging technologies. This also includes the use of digital control systems that may improve capacitor life, efficiency and cost.

It is important to note that these are potential trends. While EPCOS and TDK are at the forefront of capacitor technology, actual product releases and price points will depend on a multitude of evolving factors. Keeping abreast of technical literature and manufacturer announcements is highly recommended.

Understanding the [epcos capacitor price] requires careful consideration of the capacitor's type, specifications, and source. From film capacitors in everyday electronics to high-power capacitors in industrial applications, EPCOS (TDK) provides reliable options. This guide has equipped you with the knowledge to navigate pricing factors, compare sources, and make informed decisions. As technology evolves, expect further innovations in capacitor design and potentially, price adjustments, so staying updated is crucial for getting the best value.

AnyPCBA

AnyPCBA