Find Reliable Capacitor Suppliers Near You for All Your Needs

From powering the smallest gadgets to starting massive air conditioning units, capacitors are essential components in modern technology. Finding reliable capacitor suppliers near me shouldn't be a hassle. Just like how the human heart relies on the smooth function of its valves, our electronic circuits depend on the precise performance of capacitors. This article will guide you through finding the best local suppliers for all your capacitor needs, ensuring your projects run smoothly and efficiently, whether it's for a quick fix or a large-scale project.

Understanding Your Capacitor Needs

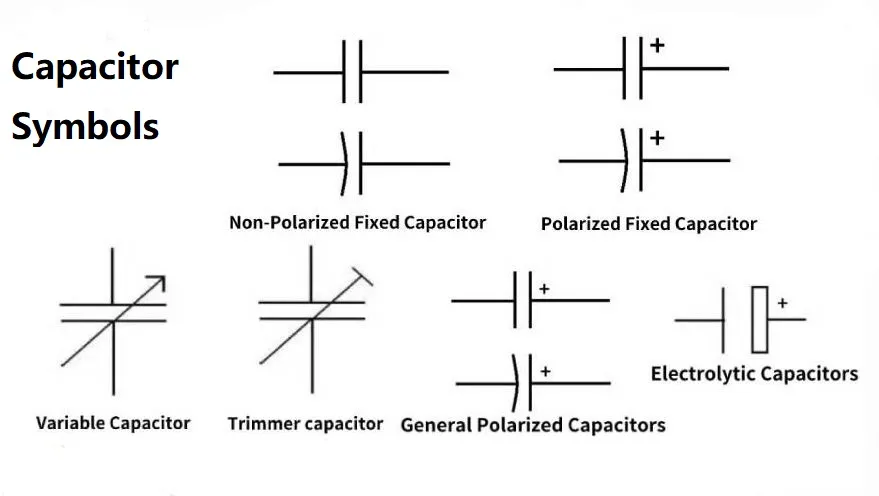

Before embarking on a search for 'capacitor suppliers near me,' it is paramount to accurately define the type of capacitor required for your specific application. Capacitors are fundamental electronic components that store electrical energy, and selecting the correct type, voltage, and capacitance is crucial for proper circuit operation and longevity. This foundational step will significantly streamline your search for appropriate suppliers and prevent costly errors.

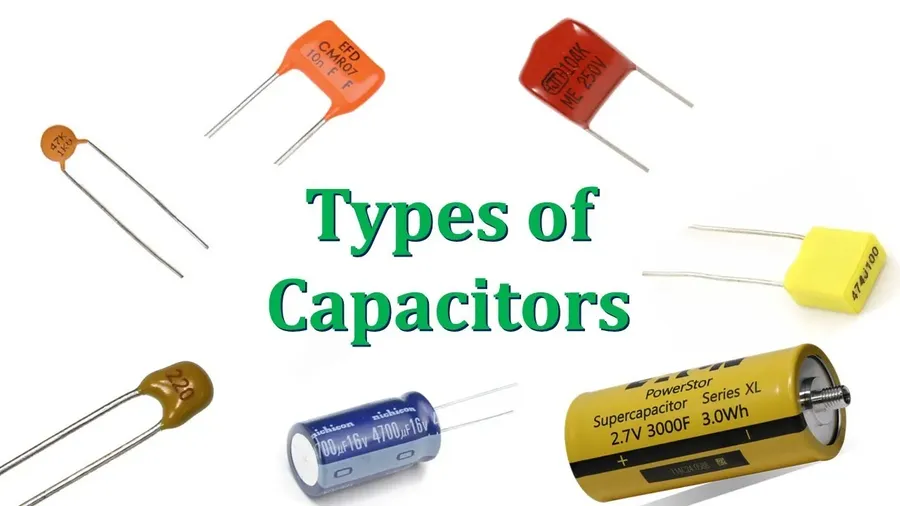

- Capacitor Types

Common capacitor types include ceramic, electrolytic, film, and motor run capacitors. Each has unique properties making them suitable for different applications. For example, ceramic capacitors are typically used for high-frequency applications, while electrolytic capacitors offer high capacitance values in smaller packages and are frequently used for power supply smoothing. Motor run capacitors, as the name suggests, are specialized for motor applications, with film capacitors being another popular option due to their stability and high precision. - Voltage Requirements

Capacitors have a maximum voltage rating, and exceeding this rating can cause failure. Always check the voltage rating of the old component to make sure your new component will be compatible with the circuit in question. - Capacitance Requirements

The capacitance is measured in microfarads (µF) or picofarads (pF), determining how much charge a capacitor can store. The capacitance is always written on the component. It is critical that the correct capacitance is used when replacing a capacitor.

Where to Find Capacitor Suppliers: Local and Online Options

When seeking 'capacitor suppliers near me,' both local and online avenues present distinct advantages. Local stores offer immediate access, while online retailers provide a broader selection and often competitive pricing.

- Local Electronics Stores

These stores often stock common capacitor types and values. They offer the benefit of immediate purchase, allowing for quick replacements or repairs. However, selection might be limited. - Hardware Stores

Hardware stores, like Ace Hardware and Home Depot, typically carry capacitors for common household appliances and HVAC systems. While convenient for immediate needs, their inventory is usually specific to these applications and may lack specialized components. - HVAC Suppliers

HVAC suppliers such as Ferguson specialize in capacitors for heating, ventilation, and air conditioning systems. They generally offer a good selection of motor run and start capacitors but may not cater to general electronics needs. - Online Retailers

Online platforms offer an expansive selection of capacitor types, brands, and specifications. Retailers like Amazon, eBay, and dedicated electronic component distributors provide access to a wider inventory, often at competitive prices. Consider delivery times and costs when purchasing online. - Industrial Suppliers

Companies like Grainger and ThomasNet focus on industrial-grade components. They often have a wide variety of capacitors, but may have minimum order quantities and are more focused on bulk purchases. These are suitable if you need components for larger projects or industrial applications.

Key Factors When Choosing a Capacitor Supplier

Selecting the right capacitor supplier involves careful consideration of several critical factors to ensure you receive reliable components that meet your specific needs. This goes beyond just finding the closest option and focuses on quality, availability, and overall service.

- Supplier Reputation

A supplier's reputation speaks volumes about the reliability of their products and services. Look for established companies with a history of providing quality components. Check online reviews and ratings to assess customer experiences. A strong reputation is often a good indicator of product consistency and reliable customer service. - Product Availability

Ensure the supplier stocks the specific types of capacitors you require. Availability is key, especially for time-sensitive projects. Verify their inventory for the range of capacitors (ceramic, electrolytic, film, motor run, etc.), voltage, and capacitance. A supplier should be able to offer the specific component to match your equipment's specifications. - Pricing

Compare prices across different suppliers to find a balance between cost and quality. While low prices might be attractive, it's crucial to consider the product's overall quality and the supplier's reputation. Be wary of prices that are significantly below the market average, which could indicate lower quality or counterfeit parts. - Delivery Options

Check the supplier’s delivery options and shipping times. For local capacitor suppliers, consider pickup options if available. Understand if the supplier has their own delivery fleet, or if they use a third-party service. For online suppliers, factor in shipping costs and time when assessing the overall cost. - Customer Service

Good customer service is vital for resolving issues and obtaining technical support. Evaluate the supplier's responsiveness, expertise, and availability to answer your questions. A reliable supplier will offer prompt support and clear communication, especially when dealing with critical components.

Specific Capacitor Types and Applications

Capacitors are not universally interchangeable; their specific design and characteristics dictate their applications. Understanding the nuanced differences between capacitor types is paramount when searching for 'capacitor suppliers near me'. This section focuses on the crucial types of capacitors and their unique roles, including AC capacitors essential for HVAC systems and motor start capacitors necessary for motor operations. It is vital to ensure your supplier stocks the precise type of capacitor needed for your particular application, along with being aware of their key operating parameters.

- AC Capacitors

Primarily utilized in air conditioning units, AC capacitors facilitate the starting and running of compressor and fan motors. They are designed to handle alternating current and are typically rated for higher voltages. - Motor Start Capacitors

These capacitors are specifically designed to provide a high surge of current to start an electric motor. They are generally not meant for continuous operation and are often used in conjunction with a run capacitor. - Motor Run Capacitors

Unlike start capacitors, run capacitors are designed for continuous duty, maintaining motor efficiency and smooth operation during normal running conditions, commonly found in fans, pumps, and compressors. - Ceramic Capacitors

Known for their compact size and wide range of capacitance values, ceramic capacitors are suitable for high-frequency applications and general-purpose electronic circuits, including decoupling and filtering. - Electrolytic Capacitors

Electrolytic capacitors are characterized by their high capacitance-to-volume ratio, making them suitable for power supply filtering and energy storage applications, although they have polarity sensitivity and limited lifespan. - Film Capacitors

Film capacitors offer good stability, low loss, and high reliability, making them versatile for various applications including audio, power electronics, and high-frequency circuits.

| Capacitor Type | Primary Application | Key Parameters | Special Considerations |

|---|---|---|---|

| AC Capacitor | Air Conditioners, HVAC systems | High voltage rating, capacitance in microfarads (µF) | Specific ratings must match OEM specifications |

| Motor Start Capacitor | Electric motor starting | High surge current rating, short duty cycle | Designed for intermittent use; not for continuous operation |

| Motor Run Capacitor | Continuous motor operation | Specific capacitance and voltage ratings, continuous duty cycle | Maintains motor efficiency during normal operation |

| Ceramic Capacitor | General electronic circuits, high frequency | Compact, wide range of capacitance values, stability | Suitable for decoupling and filtering applications |

| Electrolytic Capacitor | Power supply filtering, energy storage | High capacitance-to-volume ratio, polarity sensitivity | Limited lifespan and should be carefully rated for specific voltage and temperature |

| Film Capacitor | Audio, power electronics, high-frequency | Good stability, low loss, high reliability | Versatile for various applications |

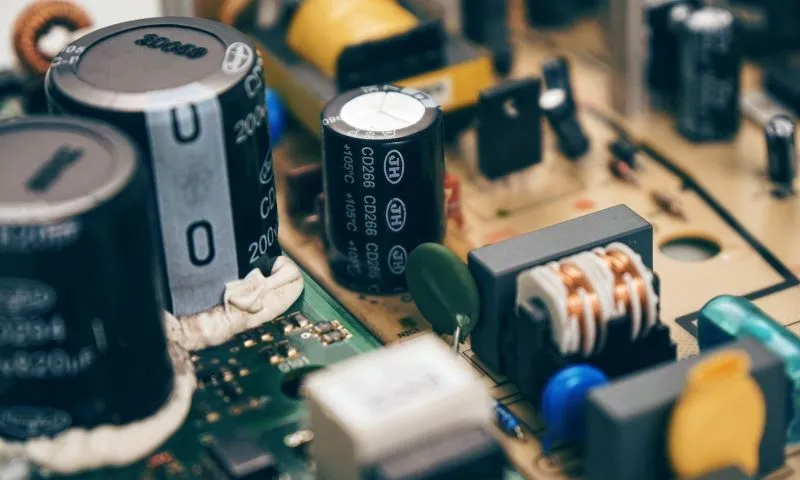

Troubleshooting Common Capacitor Issues

Identifying capacitor problems early can prevent further equipment damage. Capacitors, being critical components in electrical circuits, are prone to failure, indicated by specific symptoms. Recognizing these signs, and understanding their causes, allows for timely and effective replacement, ensuring equipment reliability and safety. Proper diagnosis is key to successful repairs. When in doubt, always consult with a qualified professional, particularly when working with high-voltage devices.

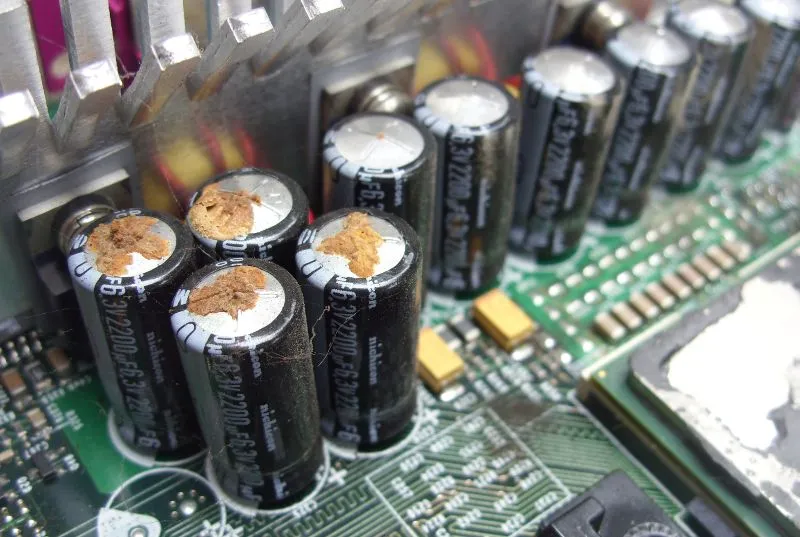

- Bulging or Swelling

A physically deformed capacitor, often with a rounded top or sides, indicates internal pressure buildup due to electrolyte degradation or overheating. This is a clear sign of failure and needs immediate replacement. - Leaking Electrolyte

Visible signs of fluid leakage from the capacitor's casing is indicative of a damaged or failing seal, often accompanied by corrosion. This is especially common in electrolytic capacitors and demands a replacement. - Performance Issues

When the connected equipment shows erratic behavior, such as intermittent operation, reduced power, humming noises, or complete malfunction, it may indicate a faulty capacitor. These issues often stem from a loss of capacitance or internal short circuits. - Audible Noises

Unusual humming, buzzing, or hissing sounds emanating from or near the capacitor are often signs of a pending or existing failure. Capacitors should function silently and any deviation from this suggests a problem. - Increased Operating Temperature

If the capacitor is noticeably hotter than usual, it signals a potential problem. Elevated temperatures can accelerate component degradation and are often precursors to complete failure. It is important to check capacitor with a thermal camera.

When replacing a capacitor, always ensure you match the voltage, capacitance, and type, and adhere to safety regulations. Improper capacitor replacement may result in device damage, equipment malfunction or present a serious safety risk. If you are not comfortable with the replacement procedure, please contact a trained professional.

Using a Higher or Lower Capacitance/Voltage Capacitor

When replacing capacitors, it is crucial to understand the implications of using components with different voltage or capacitance ratings. Using a capacitor with a lower voltage rating than specified for the device is dangerous and should never be done, as it can lead to component failure or even safety hazards. While using a capacitor with a higher capacitance rating may sometimes be acceptable, it is not universally safe and requires careful evaluation. Consulting product specifications or seeking professional advice is critical to prevent damage or operational issues.

The voltage rating of a capacitor indicates the maximum voltage it can safely handle, while the capacitance indicates the amount of charge it can store. These are distinct but interdependent parameters.

Here's a breakdown of using different capacitance and voltage ratings:

- Voltage Rating

The voltage rating on a capacitor must always be equal to or greater than the voltage in the application. Never use a capacitor with a lower voltage rating; it could fail catastrophically, leading to equipment damage or pose a fire risk. A higher voltage rating is generally acceptable, although it can lead to increased size and cost. - Capacitance Rating

Capacitance, measured in microfarads (µF), affects the amount of charge the capacitor can store. Replacing a capacitor with a slightly higher capacitance can sometimes work, especially when used in filtering applications. However, using a significantly different value can negatively affect circuit operation. For timing circuits and motor start capacitors, it is generally critical to match the capacitance rating as closely as possible to the original component.

It's essential to consult product documentation or seek expert advice when considering variations in capacitor ratings. The potential implications for a given application may be complex.

Frequently Asked Questions About Capacitor Replacement and Usage

This section addresses common questions regarding capacitor replacement, compatibility, and usage, offering clear and concise answers based on fundamental electrical engineering principles.

- Is it safe to use a 440V capacitor in place of a 370V capacitor?

Yes, using a capacitor with a higher voltage rating is generally acceptable and safe. The voltage rating indicates the maximum voltage the capacitor can withstand without failure. Using a capacitor with a higher voltage rating will not affect the performance of the circuit and can provide an additional margin of safety. However, it is critical not to use a capacitor with a lower voltage rating than specified, as it could lead to capacitor failure and pose a safety hazard. - How do I identify the correct replacement capacitor?

To find a suitable replacement, carefully examine the existing capacitor. Typically, crucial specifications like capacitance (measured in microfarads, µF or uF), voltage rating (in Volts, V), and operating temperature range are printed on the capacitor's casing. If the original capacitor is no longer readable, check the device's manual or consult a technician. Key parameters such as the type of capacitor (e.g., electrolytic, film, ceramic), its dimensions, and terminal type (e.g., radial, axial, snap-in) must also be considered for a proper replacement. - Can I replace a capacitor with one having a higher microfarad (uF) rating?

Replacing a capacitor with one of a slightly higher capacitance (uF) rating may sometimes be acceptable, but it’s crucial to consult the equipment's specifications or manufacturer guidelines to confirm. Changes in capacitance can affect circuit timing, tuning, and overall performance. A higher capacitance value can cause the circuit to operate differently than intended. Always ensure that the tolerance range of the new capacitor is adequate and that the voltage rating is equal to or higher than the original. - Is it acceptable to substitute a 40+5 uF capacitor with a 45+5 uF capacitor?

Typically, substituting a 40+5 uF capacitor with a 45+5 uF capacitor might be acceptable if the device's tolerances allow for it, and if the voltage rating is the same or higher, it is a safe replacement. The primary consideration is that the capacitance is within the acceptable range for the device. However, it's crucial to check the device specifications before making the substitution as deviations might impact the performance or lifespan of your equipment. - What are the potential risks of using a capacitor with incorrect voltage or capacitance ratings?

Using a capacitor with a lower voltage rating than specified can lead to premature failure, potential damage to the connected circuit, and possible safety risks such as fire or explosion. Utilizing a capacitor with incorrect capacitance, especially when it is significantly different from the specified one, could result in circuit malfunctions, performance degradation, or component damage, by altering the timing, current, or other electrical parameters of the circuit. - What are the best practices when replacing capacitors?

When replacing capacitors, always disconnect the power to the device before handling the components. It's essential to ensure the new capacitor has the exact or higher voltage rating and compatible capacitance as the original one. Additionally, ensure that the new capacitor is installed with the correct polarity (when applicable), and handle capacitors with care to avoid physical damage during replacement. It is advisable to discharge any stored charge in the capacitor before attempting removal or installation to prevent electric shock.

Comparing Major Capacitor Suppliers

When searching for 'capacitor suppliers near me,' several options exist, ranging from local hardware stores to specialized online distributors. Each supplier offers a different mix of product variety, pricing, and service. Below is a comparison to help you identify the best fit for your specific needs.

| Supplier | Products | Pros | Cons |

|---|---|---|---|

| Ace Hardware | Home AC capacitors | Convenient, local access | Limited selection, may not carry specialized capacitors |

| Ferguson | HVAC capacitors | Wide selection, expert advice available | Higher prices compared to some general retailers |

| West Florida Components | Various electronic components | Wide selection of capacitors | Primarily an online retailer, may require shipping time |

| Grainger | Motor capacitors | Industrial-grade, reliable capacitors | May not stock all types of capacitors commonly used in consumer electronics |

| Home Depot | AC capacitors | Convenient, can pick up in-store for immediate needs | Limited selection, often focusing on common household AC applications |

| ThomasNet | Industry distributors | Extensive selection, multiple brands | Often requires minimum order quantities, better suited for larger needs |

| Elliott Electronic Supply | Wide range of capacitors | Large online selection | May not have a physical presence in all regions, requiring shipping |

Maintaining and Storing Capacitors

Proper maintenance and storage are crucial for extending the lifespan and ensuring the reliable performance of capacitors. Environmental factors and handling practices significantly affect their operational integrity. By adhering to established guidelines, premature capacitor failure can be prevented, resulting in cost savings and enhanced equipment reliability.

- Environmental Conditions

Store capacitors in a cool, dry environment with stable temperatures. Avoid locations where temperatures fluctuate widely or reach extreme highs or lows. High humidity can cause corrosion and degrade dielectric materials, reducing the capacitor’s lifespan. Direct sunlight can also negatively impact the capacitors, causing degradation. - Temperature Considerations

The ideal storage temperature for most capacitors is between 5°C and 35°C. Ensure that storage temperatures remain below their maximum operating temperature for proper function when deployed. - Physical Handling

Capacitors should be handled with care to prevent damage. Avoid dropping or subjecting them to physical shocks. Use gloves when handling capacitors to prevent oil and dirt contamination, which can affect performance. Improper physical handling can damage internal components such as the dielectric materials. - Protection from Contamination

Keep capacitors clean from dust, moisture and oil. Store them in a sealed bag or container when not in use to keep them dry and protected from dust. Contaminants on the capacitor terminals or casing could lead to reduced performance and premature failure. - Regular Inspections

Visually inspect capacitors periodically for signs of damage, such as bulges, leaks, or corrosion. Early detection of issues can help prevent complete failure and potential damage to the equipment. - Proper Discharge

Before handling any capacitor, discharge it properly to avoid potential electric shock or damage to the capacitor itself. Use an appropriate resistor to discharge the capacitor slowly until voltage is safe to touch.

Finding the right ‘capacitor suppliers near me’ can significantly impact your project's success and reliability. From understanding your needs to comparing local and online options and exploring key considerations and FAQs, this guide will help you navigate and make informed decisions. Remember, when you need reliable capacitors for your home, electronics projects, or HVAC, local and online sources like Ace Hardware or Elliott Electronic Supply have options, but be sure to compare based on your specific needs and project requirements. Making the right choice when selecting your capacitor supplier ensures optimal performance and longevity for your electronics. The right capacitor will ensure seamless operation, just like a smooth flow of energy through an intricate network.

AnyPCBA

AnyPCBA