Rectifier Diodes: Mastering AC to DC Conversion

In our modern world, electronic devices are integral to daily life, and at the heart of many of these devices lies the crucial component – the rectifier diode. Like a one-way street for electricity, it transforms alternating current (AC) from your wall outlet into the direct current (DC) your electronics need, seamlessly powering our homes and industries. In this article, we will explore the world of rectifier diodes, uncovering their mechanism, applications, and how they help shape the electrical landscape.

Understanding the Basics of a Rectifier Diode

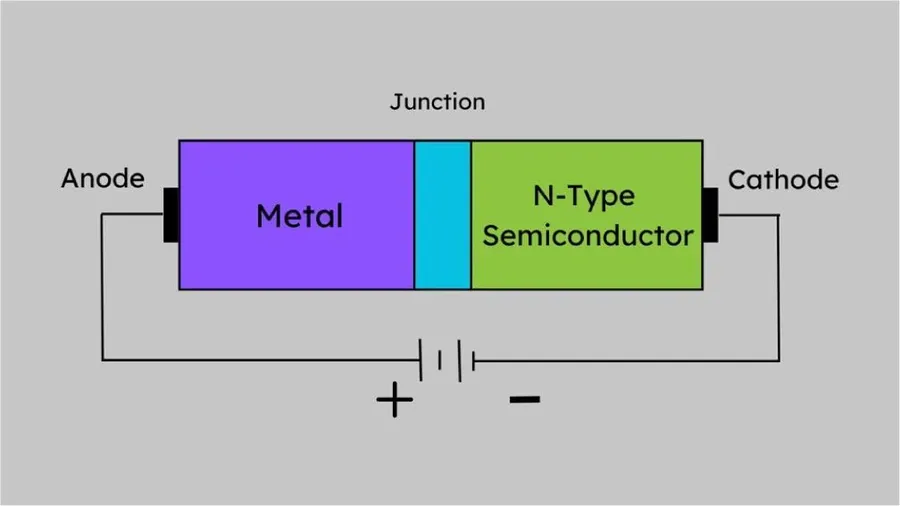

Rectifier diodes are fundamental semiconductor devices engineered to facilitate unidirectional current flow, thus enabling the crucial conversion of alternating current (AC) to direct current (DC). This essential functionality arises from the diode's inherent PN junction, which establishes distinct electrical behaviors at its two terminals: the anode and the cathode.

The PN junction, a core component of a rectifier diode, is formed by joining a p-type and n-type semiconductor material. When a positive voltage is applied to the anode relative to the cathode (forward bias), the diode allows current to flow easily. Conversely, when the voltage polarity is reversed (reverse bias), the diode acts as a high resistance barrier, effectively blocking current flow.

| Characteristic | Description |

|---|---|

| Material | Semiconductor (typically Silicon or Germanium) |

| Function | Allows current flow in one direction only |

| Terminals | Anode (+) and Cathode (-) |

| PN Junction | Formed by joining p-type and n-type semiconductor |

| Forward Bias | Low resistance, allows current to pass |

| Reverse Bias | High resistance, blocks current |

How Rectifier Diodes Work: A Detailed Explanation

Rectifier diodes, at their core, are semiconductor devices that leverage the unique properties of a PN junction to enable unidirectional current flow, crucial for converting alternating current (AC) to direct current (DC). This behavior is dictated by the concepts of forward and reverse bias, and understanding these concepts is key to comprehending how these diodes rectify current.

The PN junction of a rectifier diode is formed by joining a P-type semiconductor (doped with acceptor impurities) and an N-type semiconductor (doped with donor impurities). This junction creates a depletion region, an area devoid of free charge carriers. The behavior of this region dictates the overall function of the diode, acting as a kind of electrical valve.

When a positive voltage is applied to the P-type material (anode) with respect to the N-type material (cathode), the diode is said to be in forward bias. This causes the depletion region to shrink, allowing current to flow easily through the diode with minimal resistance. The energy barrier at the junction is overcome, permitting electrons to move from the N-side to the P-side and holes to move from the P-side to the N-side, causing current flow.

In contrast, when a negative voltage is applied to the P-type material, the diode is in reverse bias. The depletion region expands, significantly increasing the resistance to current flow. In this state, the diode effectively blocks current, allowing only a tiny leakage current to flow. The energy barrier at the junction becomes too large for charge carriers to cross, thus stopping current flow.

This asymmetrical conductance is the fundamental principle of rectification. AC current periodically changes direction, but when passed through a rectifier diode, the diode allows current to flow only when it's in the forward bias, effectively eliminating one half of the AC cycle. The resulting current, while not a perfect DC, is a pulsating DC which can then be further filtered and regulated for various applications.

The rapid switching between conduction and blocking states when the polarity of the AC source changes, along with the specific voltage drop during forward conduction and its high reverse blocking voltage capabilities, are the core characteristics that make rectifier diodes suitable for transforming AC power into DC power. The efficiency of this conversion depends on the diode's characteristics and the specific circuit configuration used.

Rectifier Diode Types and Characteristics

Rectifier diodes are not a monolithic entity; they are available in various types, each tailored to specific performance requirements. These variations primarily revolve around their construction and materials, which dictate their electrical characteristics. Understanding these differences is critical for selecting the appropriate diode for a given application.

| Type | Forward Current (Iₑ) | Reverse Voltage (Vₑ) | Switching Speed | Typical Applications |

|---|---|---|---|---|

| Standard Rectifier Diode | Moderate | Moderate to High | Relatively Slow | General-purpose rectification, low-frequency power supplies |

| Fast Recovery Diode | Moderate | Moderate to High | Faster than Standard Diodes | Switching power supplies, high-frequency rectification |

| Schottky Diode | Moderate | Low | Very Fast | High-frequency rectification, low voltage power supplies, solar power |

- Forward Current (Iₑ)

This parameter indicates the maximum amount of continuous current the diode can safely conduct in the forward direction. Exceeding this limit can cause irreversible damage due to overheating. Datasheets specify this at various temperatures. - Reverse Voltage (Vₑ)

The maximum reverse voltage a diode can withstand without breaking down and conducting in the reverse direction. This is also known as the Peak Inverse Voltage (PIV). Exceeding PIV can damage the diode and must be taken into consideration. - Switching Speed

Characterizes how quickly the diode can switch between the conducting (forward biased) and non-conducting (reverse biased) states. Faster switching speeds are required in high frequency applications. - Temperature Coefficient

The change in the diodes electrical characteristics with respect to temperature variations. This must be considered as operating temperature of a rectifier diode can greatly effect performance.

Selecting the proper type of rectifier diode requires a careful analysis of the application's voltage and current requirements, as well as operational frequency. Standard diodes are adequate for low-frequency applications with modest current requirements, while Schottky diodes are used for high-speed, low-voltage circuits where efficiency is a priority. Fast recovery diodes bridge the performance gap, offering improvements in switching speed compared to standard types.

Rectifier Diode Applications: Where are they used?

Rectifier diodes are fundamental components in numerous electronic systems, primarily due to their ability to convert alternating current (AC) into direct current (DC). This unidirectional current flow characteristic makes them indispensable in any application that requires a stable DC power source from an AC supply. Their versatile nature means you will encounter them in everyday household electronics, industrial power transmission systems, and critical automotive circuits.

- Power Supplies for Electronics and Appliances

Virtually all electronic devices, from smartphones and laptops to televisions and kitchen appliances, utilize rectifier diodes in their power supplies. These diodes convert the AC voltage from the mains outlet into the DC voltage required for the device's internal circuitry, enabling it to operate reliably. - Battery Chargers

Rectifier diodes are integral to battery charging circuits. They ensure that the current flows in the correct direction to charge the battery without backflow. This is crucial in all battery-powered devices, from mobile phones and electric vehicles to power tools, ensuring safe and efficient charging. - Automotive Circuits

In automobiles, rectifier diodes are used in alternators to convert the AC output from the alternator into the DC power needed to charge the car's battery and operate other electrical systems. This application is vital to maintaining consistent electrical power in a vehicle. - Industrial Power Transmission

Rectifiers are employed in high-voltage direct current (HVDC) power transmission systems. They convert AC power generated at power plants into DC, which is then transmitted over long distances with lower losses. At the receiving end, inverters convert the DC back to AC for distribution. This is particularly important for transmitting power across vast distances and connecting grids. - Solar Power Systems

In photovoltaic solar power installations, rectifier diodes are essential in preventing reverse current flow from the battery back into the solar panels. They ensure the efficient charging of batteries, storing the converted solar energy, which can later power homes or industrial applications. - Welding Machines

Welding machines utilize high-current rectifier diodes to convert the AC input to a controlled DC output, which is required for stable and effective welding operations. The high current capabilities of rectifier diodes allow for reliable and precise control of welding parameters.

Rectifier Diodes in Different Circuit Configurations

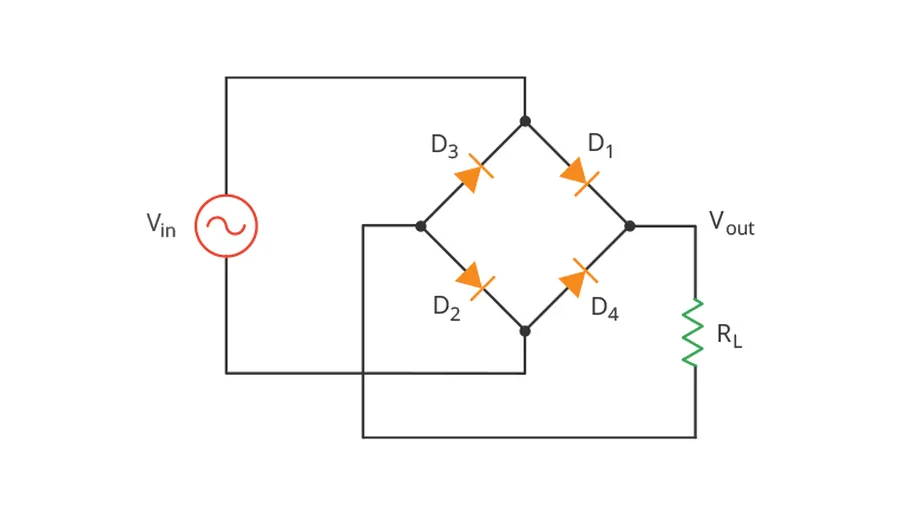

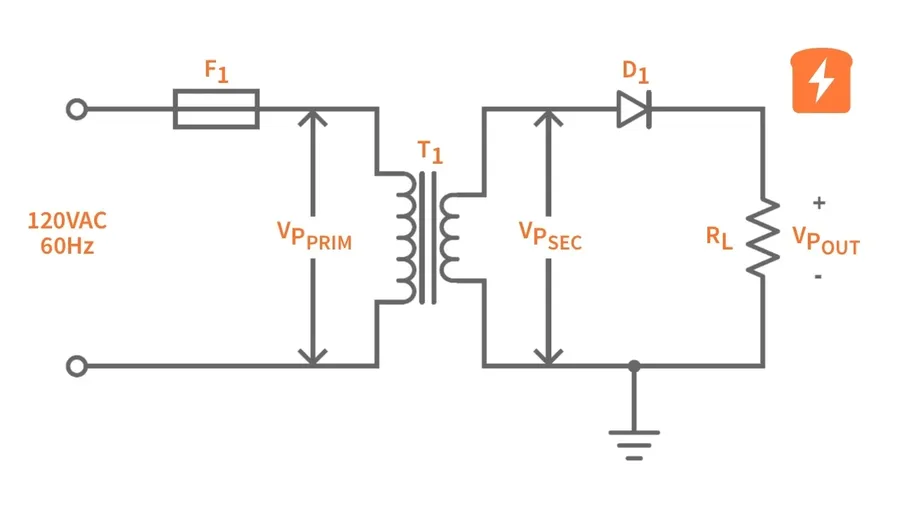

Rectifier circuits utilize diodes to convert alternating current (AC) into direct current (DC). The choice of circuit configuration, such as half-wave, full-wave, or bridge rectifiers, significantly impacts the efficiency and quality of the rectified DC output. Each configuration has unique characteristics, advantages, and drawbacks, making the selection dependent on specific application requirements.

| Circuit Configuration | Number of Diodes | Efficiency | Output Characteristics | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Half-Wave Rectifier | 1 | 40.6% | Pulsating DC with significant ripple | Simple design, low cost | Low efficiency, high ripple content, requires large filter capacitors, only utilizes one half of AC cycle |

| Full-Wave Rectifier (Center-Tapped) | 2 | 81.2% | Less ripple than half-wave, smoother DC output | Higher efficiency compared to half-wave, utilizes both half cycles | Requires a center-tapped transformer, higher component count than half-wave |

| Full-Wave Bridge Rectifier | 4 | 81.2% | Smoother DC output with less ripple, more efficient than half-wave | High efficiency, no center-tapped transformer required, uses both half cycles of AC input | Higher component count |

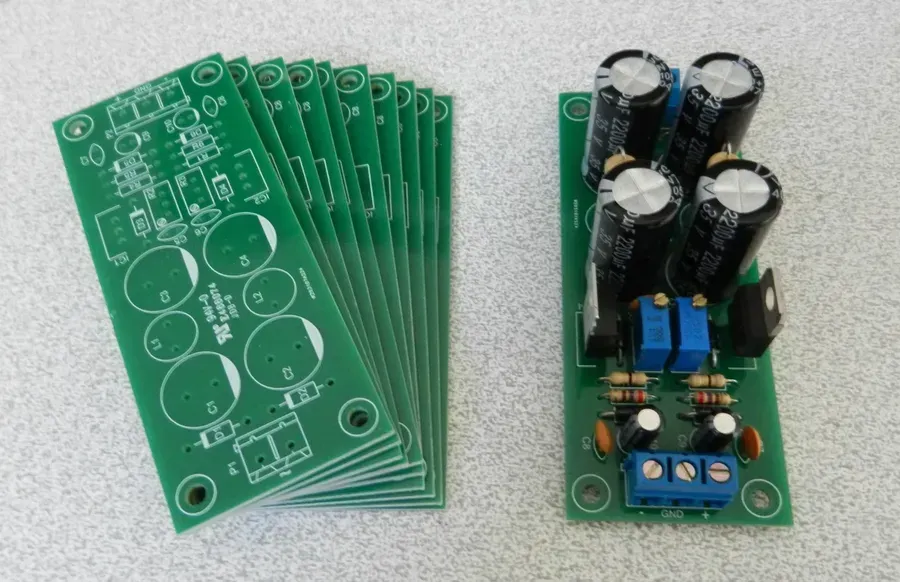

The half-wave rectifier is the simplest, using a single diode to pass only one half of the AC waveform. This simplicity comes at the cost of low efficiency and high ripple in the output DC, requiring substantial filtering. Full-wave rectifiers, employing either a center-tapped transformer with two diodes or a bridge configuration with four diodes, utilize both halves of the AC cycle, providing a more efficient and smoother DC output, though at a slightly increased component cost. The bridge rectifier is particularly versatile as it does not need a center-tapped transformer. The choice of rectifier type thus becomes a trade-off between circuit complexity, efficiency, and required output quality.

Testing and Troubleshooting Rectifier Diodes

Accurately testing and troubleshooting rectifier diodes is crucial for maintaining the reliability of electronic circuits. This section provides a comprehensive guide on using a multimeter to assess diode functionality and identifying potential failure points, as well as using a basic circuit model to observe performance.

A rectifier diode’s primary function is to allow current flow in one direction (forward bias) and block it in the opposite direction (reverse bias). Testing involves verifying this behavior using a multimeter.

A common failure mode for a rectifier diode is either an open circuit, preventing current flow in both directions, or a short circuit allowing current in both directions. These faults will disrupt the expected AC to DC conversion process. Another common failure involves a forward voltage drop that exceeds the datasheet specifications which reduces the efficiency of the rectification.

| Test | Multimeter Reading (Ideal Diode) | Interpretation |

|---|---|---|

| Forward Bias | 0.6-0.7V (Silicon) / 0.2-0.3V (Schottky) | Indicates proper forward conduction |

| Reverse Bias | OL or Infinite Resistance | Indicates proper reverse blocking |

| Open Circuit Test | OL or Infinite Resistance in both directions | Indicates a broken or disconnected diode |

| Short Circuit Test | 0 resistance in both directions | Indicates a shorted diode |

A simple circuit model, consisting of a rectifier diode in series with a resistor and an AC source, can be built to visually observe the diode’s function with an oscilloscope. By observing the output waveform, you can confirm whether rectification is occurring.

Rectifier Diode Selection Criteria: What to Consider

Selecting the appropriate rectifier diode for a given application requires a thorough understanding of several key parameters and operational conditions. Proper diode selection ensures optimal circuit performance, reliability, and longevity. This section details the essential factors to consider when choosing a rectifier diode, enabling engineers and designers to make informed decisions.

Key factors to consider when selecting a rectifier diode include:

- Peak Inverse Voltage (PIV)

The maximum reverse voltage that a diode can withstand without breaking down. It must be greater than the peak reverse voltage expected in the circuit, typically 20-50% higher for a safety margin. Exceeding PIV can lead to diode failure. - Forward Current (IF)

The maximum forward current the diode is designed to handle continuously. This value must be at least equal to or greater than the maximum current expected to flow through the diode in the application. Insufficient forward current rating leads to overheating and failure. - Average Rectified Forward Current (IO)

This parameter indicates the average current the diode can handle during rectification cycles. It is used to select rectifier diodes in circuits where current loads may vary. The calculation depends on the type of circuit, such as half wave or full wave. - Forward Voltage Drop (VF)

The voltage drop across the diode when it is conducting in the forward direction. A lower VF minimizes power loss and heat generation. This is particularly important for high-current applications where efficiency is paramount. - Reverse Recovery Time (trr)

The time it takes for the diode to stop conducting when switched from forward to reverse bias. Fast recovery diodes have lower trr values, which are crucial in high-frequency circuits to reduce switching losses. Standard diodes with higher trr are suitable for low frequency application. - Operating Temperature

The range of temperatures within which the diode can operate reliably. Ensure that the operating conditions of the circuit remain within this range. High temperature can reduce the life of the diode and cause failure. - Package Type

The physical housing and connection type of the diode. Different packages offer varying thermal performance, ease of mounting and space efficiency. Package type directly impacts the design of the circuit board. - Thermal Characteristics

Thermal impedance from junction to ambient and junction to case are important parameters for heat management of the diode. If the ambient temperature is high, then choosing a diode with low thermal impedance is essential, especially for high current applications.

| Parameter | Description | Impact on Circuit Design |

|---|---|---|

| Peak Inverse Voltage (PIV) | Maximum reverse voltage diode can withstand | Avoid breakdown; select with safety margin |

| Forward Current (IF) | Maximum forward current the diode can handle | Prevent overheating and failure; choose adequate rating |

| Average Rectified Forward Current (IO) | Average current during rectification cycles | Select based on application-specific average current needs |

| Forward Voltage Drop (VF) | Voltage drop across diode when conducting | Minimize power loss; use lower VF for high-current applications |

| Reverse Recovery Time (trr) | Time to stop conducting from forward to reverse | Critical in high-frequency circuits; fast recovery diodes preferred |

| Operating Temperature | Temperature range for reliable operation | Ensure operating conditions within range; avoid overheating |

| Package Type | Physical housing and connection type | Impacts thermal performance, mounting, and space |

| Thermal Characteristics | Thermal resistance from junction to ambient and junction to case | Helps manage heat dissipation; critical for high-power applications |

By meticulously assessing each of these criteria, engineers can confidently select a rectifier diode that meets the specific demands of their application, ensuring the system operates efficiently and reliably.

Frequently Asked Questions About Rectifier Diodes

This section addresses common queries regarding rectifier diodes, clarifying their functionality, applications, and differences compared to other diode types. These answers are based on fundamental principles of semiconductor physics and electrical engineering.

- What is the primary difference between a switching diode and a rectifier diode?

While both are diodes, the key difference lies in their intended application and performance characteristics. Rectifier diodes are optimized for handling high current and lower frequency AC signals, focusing on efficient conversion to DC. Switching diodes, conversely, are designed for high-speed switching operations, often at lower currents and high frequencies. Rectifiers emphasize current handling, while switching diodes emphasize speed. - What is the specific role of a diode within a rectifier circuit?

The diode's primary function in a rectifier circuit is to allow current flow in only one direction. This one-way conduction property is essential for converting alternating current (AC), which changes direction, to direct current (DC), which flows in a single direction. In essence, the diode acts as an electrical valve, ensuring current moves unidirectionally through the circuit, thus 'rectifying' the AC input. - What are the consequences if a rectifier diode fails in a circuit?

If a rectifier diode fails, it can manifest in several ways, depending on the nature of the failure. A shorted diode will provide a direct path for current in both directions, potentially leading to overheating or damage to other components due to excessive current. Conversely, an open diode will block current flow entirely, preventing the rectification process, leading to a malfunction of the circuit it is part of, this can have a significant impact on performance, including equipment failure. - What is the fundamental purpose of a rectifier in an electrical system?

A rectifier is a circuit designed to convert alternating current (AC) into direct current (DC). This process is crucial because most electronic devices and systems require a stable DC power supply. AC is the standard form of electricity supplied through power grids, and it must be converted to DC before powering electronic circuits. This conversion is achieved via diodes using the unidirectional current flow property to ensure the current is flowing in one direction only. - Can a rectifier diode be used to regulate voltage?

Rectifier diodes, by themselves, do not regulate voltage. Their primary function is current rectification, not voltage stabilization. Although they reduce the AC ripple voltage in a rectified DC output, they do not provide any real voltage regulation. Voltage regulation is typically achieved using components like zener diodes or integrated voltage regulator circuits in addition to the rectifying diodes. - How does the forward voltage drop of a rectifier diode affect circuit performance?

The forward voltage drop, typically around 0.7V for silicon diodes, is a voltage loss across the diode when it is conducting. This voltage drop reduces the available DC output voltage from the rectifier and converts a portion of the electrical power to heat which affects the overall efficiency and heat management of the circuit, and therefore needs to be accounted for during the circuit design and component selection phases. - Why are some rectifier diodes designed with a higher reverse voltage rating?

The reverse voltage rating specifies the maximum voltage a diode can withstand when it's reverse-biased without breaking down. This is critical in applications with fluctuating voltage levels, or where a high reverse voltage might occur. A higher rating provides protection against damage from exceeding the reverse voltage limit, ensuring diode and circuit reliability. Exceeding this rating leads to irreversible damage of the diode.

The rectifier diode, a seemingly simple component, plays a vital role in modern electronics by enabling the conversion of AC power to DC. From the smallest gadgets to large industrial machinery, rectifier diodes are indispensable. By mastering their principles and applications, we can gain a deeper understanding of electronics and appreciate the intricate workings of the devices that power our world. The future of the rectifier diode is likely to focus on efficiency and miniaturization, continuing to play its essential role.

AnyPCBA

AnyPCBA