SMD Capacitors: A Comprehensive Guide to Types, Identification, and Applications

In today's miniaturized world of electronics, surface mount device (SMD) capacitors play a crucial role, much like the unsung heroes in your smartphone or laptop. These tiny components, often smaller than a grain of rice, are essential for storing and releasing electrical energy, enabling our modern devices to function smoothly. This article delves into the depths of SMD capacitors, exploring their types, how to identify them, their diverse uses, and how they are tested, offering a gateway to understanding the silent workhorses of modern electronics.

What are SMD Capacitors?

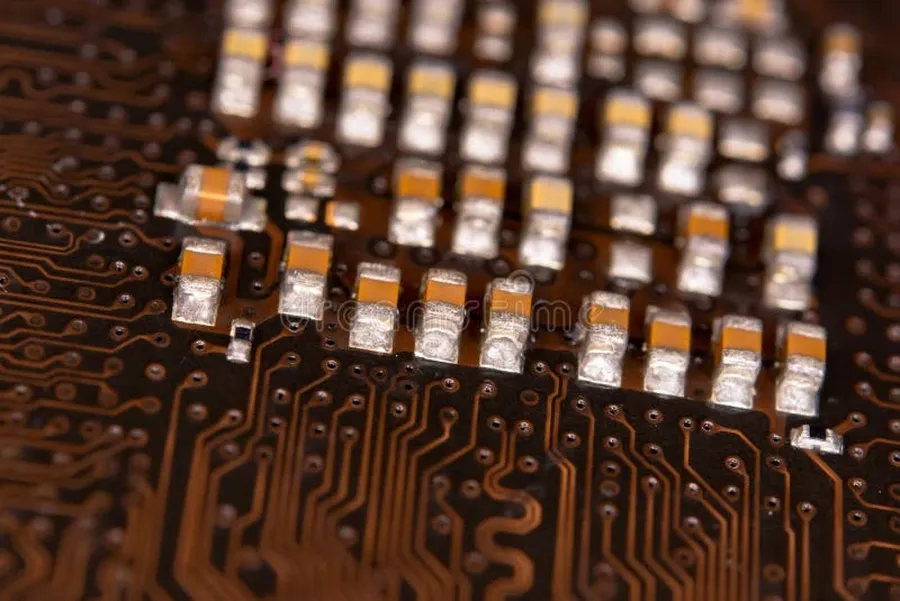

Surface Mount Device (SMD) capacitors are electronic components designed for direct mounting onto the surface of a printed circuit board (PCB). Unlike traditional leaded capacitors, SMDs lack wire leads; instead, they utilize metallic pads that are soldered directly to the PCB's conductive traces. This surface mount technology enables high-density circuit designs, making SMD capacitors essential in compact and complex modern electronics.

The primary function of a capacitor is to store electrical energy in an electric field. In circuits, they are used for filtering, decoupling, timing, and energy storage applications. SMD capacitors offer several advantages over their leaded counterparts, including reduced size, lower inductance, and ease of automated assembly, enabling more efficient and cost-effective manufacturing of electronic devices.

Types of SMD Capacitors

Surface Mount Device (SMD) capacitors are integral components in modern electronics, and they are available in several types, each with unique characteristics suited to different applications. This section details the most common types: ceramic (MLCC), tantalum, electrolytic, and film capacitors.

| Capacitor Type | Material | Properties | Common Applications |

|---|---|---|---|

| Ceramic (MLCC) | Ceramic dielectric (e.g., barium titanate) | High capacitance, low ESR, stable with temperature and frequency, non-polarized, small size | Bypass, decoupling, filtering, general-purpose applications, widely used in consumer electronics |

| Tantalum | Tantalum pentoxide dielectric | High capacitance, relatively stable, polarized, higher ESR than MLCCs | Power rail filtering, bulk storage, higher voltage and temperature applications |

| Electrolytic | Aluminum or tantalum with a liquid or solid electrolyte | High capacitance, polarized, higher ESR, larger size, limited frequency response | Bulk storage, power filtering, smoothing, applications where high capacitance is needed |

| Film | Polyester, polypropylene, or other plastic films | High voltage and current handling, low ESR and ESL, precise values | High frequency and precision circuits, audio equipment, power supplies, high voltage applications |

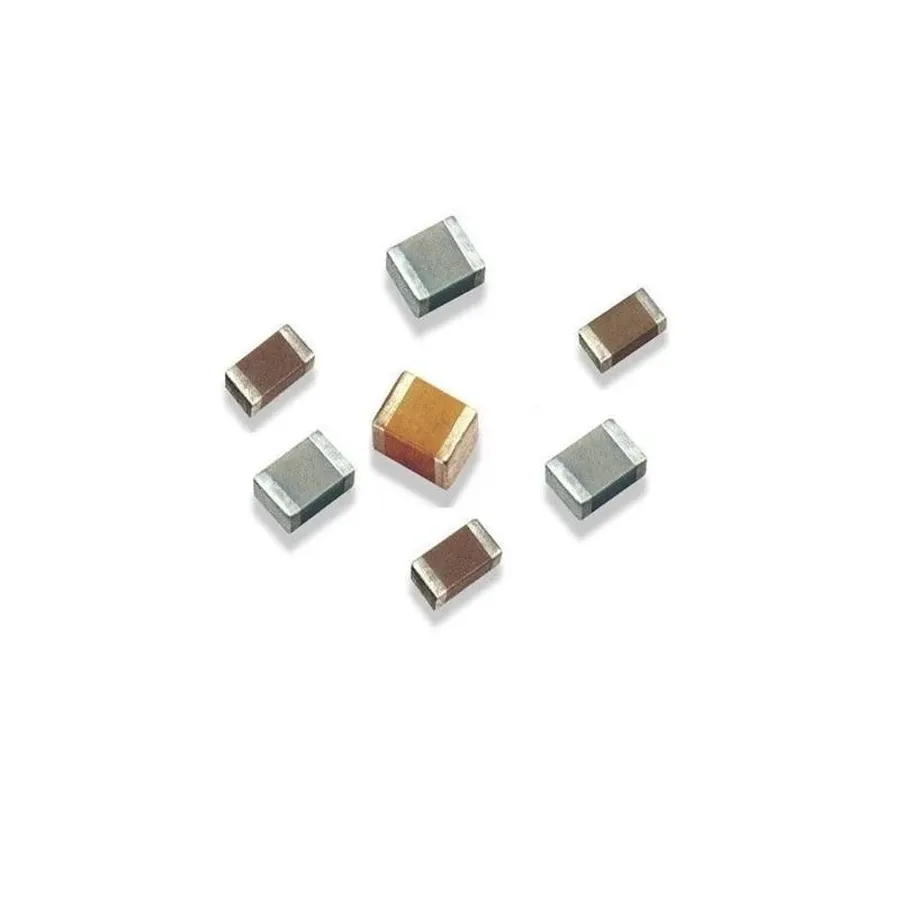

- Ceramic (MLCC) Capacitors

Multilayer Ceramic Capacitors (MLCCs) are the most common type of SMD capacitors. They are non-polarized, which allows for versatile application and are known for their small size, high capacitance values, and low Equivalent Series Resistance (ESR). These capacitors are highly stable with changes in temperature and frequency, making them ideal for applications from bypass to decoupling. - Tantalum Capacitors

Tantalum capacitors offer higher capacitance in a smaller package compared to ceramic capacitors. They are polarized, meaning they must be connected with the correct polarity, and are often used in power rail filtering and applications requiring high capacitance values. Their higher ESR may limit their use in high frequency circuits. - Electrolytic Capacitors

Electrolytic capacitors, either aluminum or tantalum based with a liquid or solid electrolyte, provide extremely high capacitance values. These are polarized, have higher ESR, and are typically larger in size, and are suitable for power filtering or applications needing bulk capacitance but are not optimal for high frequency operation. - Film Capacitors

Film capacitors are characterized by their ability to handle high voltages and currents and are known for their precise capacitance values, low ESR, and low Equivalent Series Inductance (ESL), making them suitable for high frequency or high precision applications, such as in audio equipment.

SMD Capacitor Identification: Decoding Markings and Codes

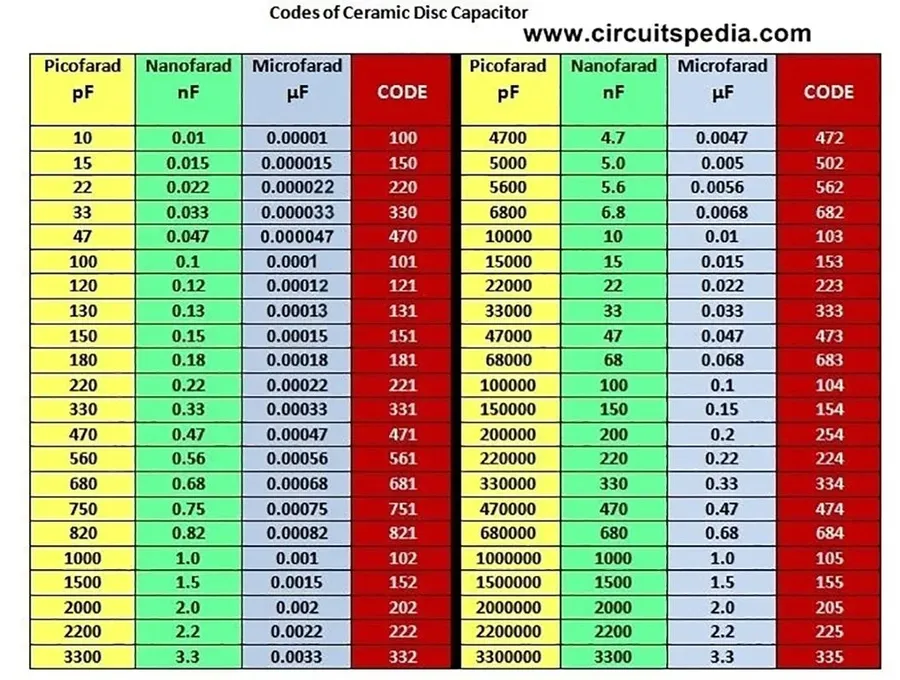

Surface Mount Device (SMD) capacitors, unlike their leaded counterparts, are typically marked with alphanumeric codes rather than printed capacitance values. These codes, while compact, provide essential information about the capacitor’s characteristics, including capacitance, tolerance, and voltage rating. Decoding these markings is crucial for accurate identification and proper usage in electronic circuits.

Understanding the different coding schemes used by manufacturers is essential. Some manufacturers use a three-digit code for capacitance, while others may use a combination of letters and numbers. The following sections will outline these common coding systems and provide examples to aid in accurate interpretation.

It’s also crucial to note that not all SMD capacitors have markings, especially very small ones, and sometimes, these markings are simply manufacturer's internal identifiers. In such cases, you need to rely on other methods for identification, such as the physical size of the component.

| Marking Type | Description | Example |

|---|---|---|

| Three-Digit Code | The first two digits indicate the significant digits of the capacitance value, and the third digit represents the multiplier (the power of 10). The result is in picofarads (pF). | e.g. 103 represents 10 x 10^3 pF or 10,000pF = 10nF |

| Letter-Number Code | A letter denotes the manufacturer, while the following numbers represent the capacitance value. | e.g., 'A104' could represent a 0.1uF capacitor from manufacturer A |

| EIA Standard Codes | Industry-standard codes with defined alphanumeric systems that indicate values, tolerance, and temperature coefficient. | e.g., 'B104K' represents a 0.1uF capacitor with a 10% tolerance. |

It's important to consult the manufacturer’s datasheet for the most accurate information, especially when dealing with less common markings or specialized components. Online resources, SMD component calculators, and manufacturer specifications can be invaluable for determining the characteristics of unmarked capacitors.

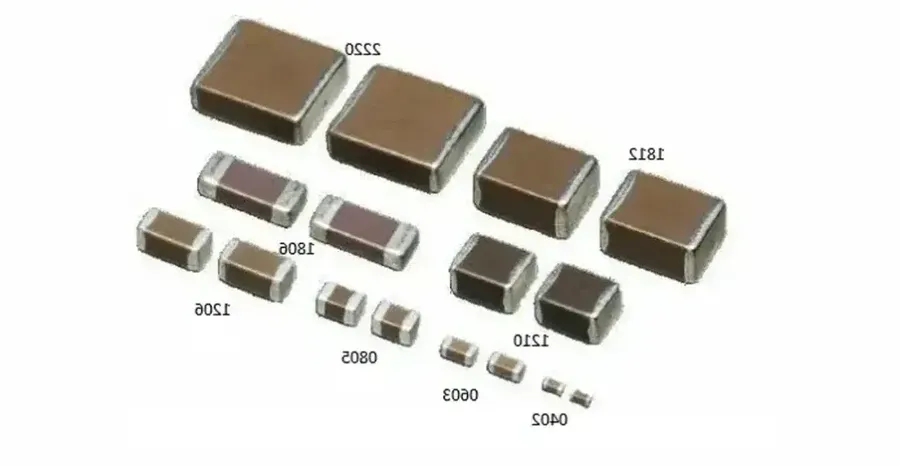

SMD Capacitor Size Charts: Understanding Standard Dimensions

Surface Mount Device (SMD) capacitors are manufactured in standardized case sizes, denoted by a four-digit code, such as 0603, 0805, and 1206. These codes directly correlate to the physical dimensions of the component, facilitating automated assembly and providing a common reference point for design and manufacturing. Understanding these size codes is crucial for selecting appropriate components and ensuring proper board layout.

| EIA Size Code | Length (mm) | Width (mm) | Typical Applications |

|---|---|---|---|

| 0201 | 0.6 | 0.3 | High-density, space-constrained applications |

| 0402 | 1.0 | 0.5 | Mobile devices, wearables |

| 0603 | 1.6 | 0.8 | General-purpose, smaller electronics |

| 0805 | 2.0 | 1.25 | Common, general electronics |

| 1206 | 3.2 | 1.6 | Higher power applications |

| 1210 | 3.2 | 2.5 | Higher voltage, higher capacitance applications |

| 1812 | 4.5 | 3.2 | Power supply, larger size for more energy |

| 2220 | 5.6 | 5.0 | High current applications |

Applications of SMD Capacitors

SMD capacitors are ubiquitous in modern electronics, serving a diverse range of functions critical to device performance. Their compact size and reliable performance make them ideal for integration into densely populated circuit boards found in various applications, from consumer electronics to industrial systems.

These components play essential roles in three primary applications: filtering, decoupling, and timing circuits, with specific types of SMD capacitors often preferred for each role due to their unique characteristics.

- Filtering

SMD capacitors, particularly ceramic capacitors (MLCCs), are frequently used in filter circuits to remove unwanted noise and high-frequency interference from electrical signals. Their low equivalent series resistance (ESR) makes them highly effective at bypassing unwanted signals to ground, thereby purifying the desired signal. This is crucial in audio systems, communication devices, and any circuit requiring a clean signal path. - Decoupling

In power distribution networks, SMD capacitors act as local energy storage devices to maintain a stable voltage supply to integrated circuits (ICs). They are placed close to the power pins of ICs to deliver instantaneous power when demand spikes, preventing voltage fluctuations that could disrupt the IC's operation or cause erratic behavior. Ceramic capacitors are most commonly used for decoupling due to their small size and high-frequency response capabilities. - Timing

SMD capacitors, when used in conjunction with resistors and other components, are used to create timing circuits. The time constant (RC constant), which determines how fast the capacitor charges and discharges, can be tuned by varying capacitance and resistance values to create oscillations, delays, and pulse widths. These are fundamental in microprocessors, timers, and other electronic systems requiring precise timing.

SMD capacitors are deployed extensively across a broad range of electronic devices. Here are some specific applications:

- Smartphones

SMD capacitors are critical in smartphone circuits due to the need for very compact, high-performance components. They are used for filtering, decoupling, and timing functions within the RF front-end, power management, and audio sections. - Laptops and Computers

In laptops and computers, SMD capacitors ensure the stability and proper operation of high-speed processors, memory modules, and power management circuits. Their low ESR is critical for managing the high currents and rapid switching that occurs within these systems. - Wearable Devices

Due to their small size, SMD capacitors are perfect for wearables such as smartwatches, fitness trackers, and other compact devices. They maintain stable power delivery and signal integrity. - Automotive Electronics

In automotive systems, SMD capacitors are used extensively for filtering and decoupling in various electronic control units (ECUs), infotainment systems, and advanced driver-assistance systems (ADAS), where they must withstand a wide range of temperatures and harsh environments. - Industrial Equipment

Industrial equipment such as programmable logic controllers (PLCs), power supplies, and control systems require reliable, durable components. SMD capacitors play a role in ensuring signal integrity and operational stability within these devices.

How to Test SMD Capacitors

Testing SMD capacitors is crucial for ensuring the proper functionality of electronic circuits. This section provides a step-by-step guide using a multimeter to assess the condition of SMD capacitors, identify potential faults, and offers practical troubleshooting advice to maintain circuit integrity. Effective testing helps diagnose issues such as open circuits, short circuits, or capacitance value drift.

- Gather Necessary Equipment

You'll need a digital multimeter capable of measuring capacitance, a steady hand, and a well-lit workspace. A pair of tweezers can also be useful for handling small SMD components. - Power Down the Circuit

Before testing any component, ensure the circuit is completely powered off and any residual charge is discharged. This is a critical safety precaution and also ensures accurate measurements. - Set the Multimeter to Capacitance Mode

Turn on your multimeter and select the capacitance measurement mode (usually indicated by 'F' or 'Farads'). If your multimeter has multiple capacitance ranges, start with the highest range to avoid overloading. - Prepare the Capacitor for Testing

If the capacitor is installed on a circuit board, it's best to test it in-circuit first. If more precise measurements are needed, carefully remove the capacitor from the circuit. - Connect the Multimeter Probes

Connect the multimeter probes to the terminals of the SMD capacitor. For in-circuit testing, place the probes on the solder pads or component terminals. For out-of-circuit testing, make sure the probes make good contact with the capacitor’s terminals. - Record the Capacitance Reading

Observe the capacitance reading displayed on the multimeter. Compare this reading with the rated capacitance value specified in the capacitor's datasheet or markings. Note any significant deviations. - Interpret the Reading

A healthy capacitor should show a reading close to its specified capacitance value. A very low or zero reading suggests an open circuit or failed component, while a short circuit will result in a reading of zero ohms in the resistance mode, or very high capacitance reading. Variations beyond the capacitor's tolerance rating (usually indicated on the component) suggest the capacitor is either out of tolerance or faulty. - Test for Shorts and Leakage (Optional)

Use the multimeter's resistance mode to check for shorts across the capacitor. A very low resistance reading indicates a short. While in resistance mode, also observe the resistance value over time, a slow decrease in resistance suggests excessive leakage which may indicate a failing component.

When troubleshooting, consider these points: Variations in readings when testing in-circuit may be affected by parallel components. If readings are not as expected, remove the component to test it out of circuit. Check the rated voltage of your multimeter, do not exceed this when testing, as this may damage your multimeter or capacitor. Always replace faulty SMD components with equivalent capacitors and ensure they are installed in the correct orientation.

SMD Capacitor Replacement Guide

Replacing SMD capacitors requires careful technique and appropriate tools to ensure the integrity of both the component and the circuit board. This guide provides practical advice for safely removing and installing these components, minimizing the risk of damage.

- Essential Tools

Gather the necessary tools: a temperature-controlled soldering iron with a fine tip, desoldering braid or pump, tweezers, and optionally, a hot air rework station for more complex replacements. A magnifying glass or microscope is recommended for detailed work and inspection. - Preparation

Before commencing, ensure the power to the circuit is disconnected. Note the orientation of the capacitor, particularly if it is polarized, to prevent incorrect re-installation. Take a clear picture before removal as reference. - Desoldering

Apply gentle heat to the solder joints of the capacitor using the soldering iron. Once molten, use the desoldering braid or pump to remove the solder. Work carefully to avoid overheating or lifting the pads from the PCB. For multilayer PCBs or boards with thermal vias, a hot air rework station may be required to ensure even heat distribution. - Component Removal

Once the solder is removed from both pads, gently lift the capacitor using tweezers. Avoid applying excessive force which may damage the component or the pads. - Pad Preparation

Clean the pads on the circuit board with a desoldering braid and apply a small amount of new flux. This will help ensure proper solder flow when installing the new component. Lightly tin the pads before positioning the new capacitor. - Component Placement

Position the new capacitor using tweezers, ensuring it is aligned with the pads. If the capacitor is polarized, align it correctly based on the orientation markings. Carefully align the component on the pads, using the previously taken reference pictures as needed. Ensure it is flush with the board. - Soldering

Apply heat to each pad with the soldering iron and introduce a small amount of solder, ensuring proper wetting of the pads and capacitor termination. Do not use excessive solder to prevent bridging of the solder. Once finished, allow the board to cool before inspecting. - Post-Soldering Inspection

Inspect the solder joints for proper connection and check that the capacitor is firmly seated on the board using magnification. The solder joints should be shiny and smooth. Check the surrounding components to make sure they haven’t been disturbed or overheated during the replacement procedure. Verify the functionality of the circuit post-replacement.

SMD Capacitor vs. SMT Capacitor: What’s the Difference?

The terms SMD (Surface Mount Device) and SMT (Surface Mount Technology) are often used interchangeably in the electronics industry, which can cause confusion. However, they represent different but related concepts. Understanding this distinction is crucial for anyone involved in electronics manufacturing and design.

SMD refers to the electronic *component* itself, such as a capacitor, resistor, or integrated circuit, that is designed to be mounted onto the surface of a printed circuit board (PCB). In contrast, SMT refers to the *process* of assembling electronic circuits by mounting SMDs directly onto the surface of the PCB, without the need for through-hole leads. In short, SMD is what is mounted, and SMT is how it's mounted.

| Feature | SMD (Surface Mount Device) | SMT (Surface Mount Technology) |

|---|---|---|

| Definition | The component itself, designed for surface mounting. | The process of mounting components on a PCB. |

| Scope | Refers to physical components. | Refers to the manufacturing method. |

| Relationship | Components used in SMT. | The technology of mounting SMD components. |

| Examples | SMD capacitors, SMD resistors, SMD ICs. | Automated pick-and-place machines, reflow soldering. |

Fundamentally, an SMD capacitor is a capacitor that is specifically designed to be used in the SMT process. Therefore, when you encounter the term 'SMT capacitor,' it essentially means the same thing as an 'SMD capacitor'—a capacitor designed for surface mounting. Although they are used synonymously, it's important to understand the underlying difference in concepts to maintain clarity and precision when discussing electronics design and manufacturing. This clear distinction between the component and the process helps avoid ambiguities in documentation, technical communication, and design discussions.

Frequently Asked Questions About SMD Capacitors

This section addresses common questions regarding SMD capacitors, providing clarity on their identification, function, and practical considerations. We delve into areas such as distinguishing them from resistors, understanding polarity, and comparing different capacitor types, and provide quick reference information for 'SMD capacitor codes' and 'SMD capacitor values'.

- What exactly is an SMD capacitor?

An SMD (Surface Mount Device) capacitor is a type of capacitor designed to be mounted directly onto the surface of a printed circuit board (PCB). Unlike traditional leaded capacitors, they do not have wires or leads. They are smaller and more compact making them suitable for high-density circuit boards. - How can I identify the capacitance and other electrical parameters of an SMD capacitor?

SMD capacitors often have markings or codes that indicate their capacitance value, tolerance, and voltage rating. These markings are not standardized across all manufacturers, but they usually follow industry-standard codes. A detailed explanation of these codes and their interpretation is essential for proper identification. - What is the difference between SMD and SMT capacitors?

SMD (Surface Mount Device) and SMT (Surface Mount Technology) are often used interchangeably. SMT refers to the technology and method of mounting components on the surface of a PCB, while SMD refers to the components themselves, such as capacitors, resistors, etc. So, an SMD capacitor is a type of component that is used in SMT. - What distinguishes an SMD capacitor from an electrolytic capacitor?

Electrolytic capacitors, whether traditional or SMD, generally have higher capacitance values, typically greater than 1uF. They are also polarized which means they have a designated positive and negative terminal. SMD ceramic capacitors, specifically MLCCs(Multilayer Ceramic Capacitors), tend to have lower capacitance values, typically less than 1uF, are not polarized, and are used for a wide variety of applications that do not need high capacitance. - How do I differentiate an SMD capacitor from an SMD resistor?

SMD capacitors and resistors are both passive components but have different functions. Visually, resistors are usually black with metallic end caps, and often have a single marking, while capacitors can be different colors (often light tan) or even metallized, and often have a two or three character code. If there is any doubt, use a multimeter. Resistors will typically measure in ohms (Ω) while capacitors are designed to charge and discharge current and will read open until fully charged. Using a multimeter on a capacitor, you should see the impedance rise over time. - Do SMD capacitors have polarity, and how can I identify it?

Most SMD ceramic capacitors, such as MLCCs, are not polarized. However, certain types, like electrolytic and tantalum SMD capacitors, do have a defined polarity. These polarized SMD capacitors often have a marking, such as a stripe or a band, to indicate the negative terminal. Always refer to the datasheet for specific polarity markings to avoid improper circuit operation. - Where can I find a comprehensive SMD capacitor code chart or datasheet?

SMD capacitor manufacturers offer datasheets that detail specifications and markings for each of their products. A comprehensive SMD capacitor code chart can be found in these datasheets or by referring to reliable component databases like those on the manufacturer's websites or on distributors like Digikey or Mouser. Be aware that not all manufacturers use the same markings, and different component sizes might use different encoding schemes.

SMD capacitors, though tiny, are fundamental to the functionality of modern electronics. This guide has navigated the complex landscape of these components, from their diverse types and markings to their applications and testing procedures. As electronics continue to shrink and evolve, the importance of understanding and working with SMD capacitors will only grow. This ensures that even a tiny SMD capacitor can play its significant role effectively, driving innovation and technology further. Whether you're a hobbyist or an engineer, this knowledge forms the backbone of handling and deploying SMD components in any electronic design.

AnyPCBA

AnyPCBA