Sourcing Electronic Supply: A Comprehensive Guide for Professionals

In today's rapidly evolving technological landscape, reliable electronic supply is the backbone of innovation. Whether you are a seasoned engineer, a budding maker, or a purchasing manager, efficient sourcing of electronic components is crucial for the successful completion of your projects and products. This guide explores the various aspects of electronic supply, from understanding different types of suppliers to optimizing your supply chain, ensuring that you have the knowledge to make informed decisions and secure a stable supply of necessary electronic components.

Understanding Different Types of Electronic Supply Distributors

The electronic component supply chain is complex, with various types of distributors playing distinct roles. Understanding the differences between authorized, independent, and franchise distributors is crucial for making informed purchasing decisions. Each type offers unique advantages and disadvantages regarding pricing, authenticity, and supply availability, impacting the overall procurement strategy.

| Distributor Type | Description | Pros | Cons |

|---|---|---|---|

| Authorized Distributors | Directly contracted by the component manufacturer to distribute their products. | High level of product authenticity, manufacturer warranty support, access to latest datasheets and information. | Potentially higher prices, less flexibility on order quantities, limited access to end-of-life or obsolete parts. |

| Independent Distributors | Purchase components from various sources and resell them to customers. | Can provide competitive pricing, access to hard-to-find components, flexibility on order quantities. | Higher risk of counterfeit components, limited traceability, less direct manufacturer support. |

| Franchise Distributors | Similar to authorized distributors, but typically cover a broader range of manufacturers with a regional focus. | Strong supplier relationships and good product knowledge, relatively high reliability and reasonable pricing. | May not offer the full range of parts from a specific manufacturer compared to authorized distributors. |

Navigating Online Electronic Supply Marketplaces

Online electronic supply marketplaces have revolutionized how professionals source components, offering vast inventories, detailed specifications, and competitive pricing. These platforms provide a centralized location to access a diverse range of electronic components, streamlining the procurement process.

Key online distributors such as Mouser, DigiKey, and Newark, have become integral to the global supply chain, each providing a unique blend of products and services. Understanding their specific benefits, search functionalities, and service offerings is crucial for effective component sourcing.

- Mouser Electronics

Mouser is known for its broad product selection, excellent customer support, and detailed product information. Their website is designed for engineers, offering advanced search filters and technical resources to aid in component selection. They are particularly strong in new product introductions and cater to both prototyping and mass production. - Digi-Key Electronics

Digi-Key is renowned for its extensive inventory, often stocking large quantities of components. They offer an exceptionally wide range of products, from semiconductors to passive components. Their efficient shipping and order fulfillment processes make them a preferred supplier for many design and manufacturing companies. Their website also has a large database of technical specifications and application notes. - Newark

Newark (also known as element14 in some regions) focuses on serving the needs of electronic design engineers and maintenance professionals, offering a wide selection of components, tools, and test equipment. They also provide online technical communities and design resources to support their customers with their projects, with a strength in products for industrial applications.

| Feature | Mouser | Digi-Key | Newark |

|---|---|---|---|

| Product Range | Very Broad | Extensive | Wide |

| New Product Introductions | Strong | Good | Moderate |

| Technical Resources | Excellent | Excellent | Good |

| Customer Support | Excellent | Good | Good |

| Focus | Engineers, Prototyping, Production | Wide Range, Efficient Fulfillment | Engineers and Maintenance Professionals |

When using these platforms, it's advisable to compare prices, lead times, and available quantities. Utilizing advanced search filters, such as filtering by technical specifications and manufacturer, can greatly improve the efficiency of your procurement process.

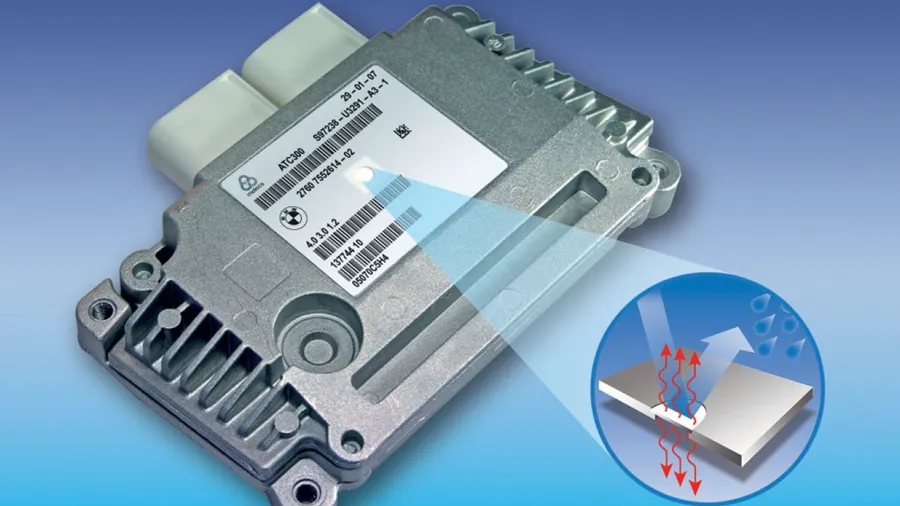

The Importance of Component Authenticity and Traceability

Ensuring the authenticity and traceability of electronic components is paramount in mitigating the risks associated with counterfeit parts, which can lead to significant performance issues, system failures, and even safety hazards. Robust traceability practices are vital for maintaining supply chain integrity and verifying the provenance of each component from manufacturing to integration.

The presence of counterfeit components in the supply chain poses a considerable threat across various sectors, including aerospace, medical devices, automotive, and consumer electronics. These counterfeit parts often fail to meet stringent performance specifications, reliability standards, and may contain hazardous materials, undermining the integrity of finished products. Moreover, the use of non-genuine components can introduce vulnerabilities in security-sensitive applications, thus compromising overall system safety and reliability.

Traceability in the electronic supply chain refers to the ability to track each component's journey, from the point of origin at the manufacturer, through distribution, to its final integration into a product. This process involves the utilization of marking technologies, labeling, and digital records to establish an unbroken chain of custody, enabling clear identification of the component's production lot, fabrication location, and any subsequent handling or processing. The establishment of a solid traceability system is an essential aspect of verifying the authenticity and history of electronic components.

Utilizing reputable suppliers is the cornerstone of any risk mitigation strategy against counterfeit electronic components. Authorized distributors, franchise distributors, and certified independent distributors are more likely to provide genuine parts that adhere to the manufacturer's specifications. They typically possess stringent quality control procedures, comprehensive traceability systems, and established relationships with the Original Component Manufacturers (OCMs) which facilitate a more secure supply chain. By prioritizing suppliers who can furnish comprehensive component information, including certifications, manufacturers can ensure that they are purchasing genuine and reliable electronic parts.

Furthermore, advanced testing techniques play a vital role in verifying component authenticity, employing techniques like X-ray inspection, die analysis, and electrical parameter testing to identify counterfeit parts. Such testing is indispensable to validating compliance, especially for high-reliability sectors such as aerospace, military and medical devices, wherein component performance impacts mission-critical operations. Component traceability, through material certifications and meticulous documentation, also supports robust recall procedures and quality control protocols, which ultimately bolster product integrity.

Optimizing Your Electronic Supply Chain for Efficiency and Cost Savings

A robust and efficient electronic supply chain is paramount for maintaining profitability and competitiveness. Optimizing this chain involves strategic approaches to procurement, contract negotiation, inventory management, and proactive cost reduction initiatives.

By adopting these strategies, businesses can reduce costs, minimize delays, and secure a reliable source of high-quality components. Effective supply chain management is not just about reducing expenses; it's about creating a competitive advantage through operational excellence.

- Streamlining Procurement Processes

Evaluate and optimize your current procurement workflows. Leverage e-procurement systems to automate tasks, reduce manual errors, and improve overall efficiency. Implement clear approval processes and ensure that all purchase orders are accurately documented. - Negotiating Contracts

Develop strong relationships with suppliers to secure favorable terms. Explore volume discounts and establish long-term agreements. Consider multiple suppliers to mitigate risks of supply chain disruptions and leverage competitive pricing. Prioritize suppliers who are willing to provide value-added services such as VMI (Vendor Managed Inventory) programs. - Managing Inventory

Implement inventory management techniques such as Just-in-Time (JIT) and cycle counting to minimize holding costs while ensuring adequate stock levels. Employ forecasting tools to predict demand accurately, reducing the risk of overstocking or shortages. Regularly assess the life cycle of components and plan for obsolescence proactively. - Identifying Opportunities for Cost Reduction

Analyze spending patterns to identify areas for cost optimization. Focus on reducing logistics costs by optimizing transportation routes and consolidating shipments. Explore value engineering, investigate potential alternative components with similar functionality, and consider bulk purchasing where appropriate. Implement quality control measures to minimize costs associated with defects.

Finding Specialized or Hard-to-Find Electronic Components

Locating specialized or obsolete electronic components requires a strategic approach beyond typical distribution channels. This section details methods for sourcing hard-to-find parts through niche distributors, broker networks, and other specialized resources.

The challenge in sourcing obsolete or specialized electronic components lies in their limited availability and higher associated risks such as counterfeiting. These challenges require a multi-faceted approach that includes identifying the right specialized supplier networks, performing due diligence and planning for longer lead times.

- Niche Distributors

Niche distributors specialize in particular types of components or manufacturers. Researching and establishing relationships with such distributors may be the key to acquiring specific, hard-to-find parts. They often focus on older or less common parts that larger distributors may not carry. - Broker Networks

Electronic component brokers act as intermediaries, leveraging their extensive networks to locate parts. While brokers can be effective, it is essential to ensure their reliability and reputation through thorough due diligence. - Online Marketplaces Focused on Obsolete Parts

Some online platforms specialize in the trade of obsolete or hard-to-find electronic components. These platforms can be useful resources, but it's important to verify the authenticity and reliability of the sellers. - Component Data Sources

Utilize component databases, like those available through IHS Markit or Silicon Expert, which can help identify the availability of parts and alternative component options. These tools offer comprehensive part information, including lifecycle status. - Direct Manufacturer Contact

In some cases, contacting the original component manufacturer or their authorized representatives can lead to the discovery of remaining stocks or suitable alternatives, though this is often a more protracted process. - Reverse Engineering and Redesign

When sourcing is not feasible, reverse engineering or redesigning the board to use components with existing supply chains can be an option, although it is more costly and time consuming

Electronic Supply Considerations for Prototyping and Mass Production

Sourcing strategies for electronic components must drastically adapt between the prototyping and mass production phases due to differing priorities and scale. Prototyping emphasizes flexibility and rapid iteration, while mass production prioritizes cost-effectiveness and supply chain stability.

During prototyping, the primary concern is quickly acquiring small quantities of components to test and iterate designs. This often involves working with distributors offering low minimum order quantities (MOQs) and fast shipping, potentially at higher per-unit costs. In mass production, the focus shifts to securing large volumes of components at the lowest possible price, requiring meticulous supply chain management and supplier negotiations.

The table below highlights key differences in electronic supply considerations between prototyping and mass production:

| Consideration | Prototyping | Mass Production |

|---|---|---|

| Component Quantity | Small quantities, often single units or small batches | Large volumes, potentially tens of thousands or more |

| Cost per Unit | Typically higher due to low order quantities and expedited shipping | Aggressively negotiated to achieve the lowest possible price |

| Lead Time | Shorter lead times are prioritized for rapid iteration and experimentation | Longer lead times are expected, requiring careful planning and forecasting |

| Supplier Relationships | Focus on distributors that are flexible and responsive | Emphasis on establishing long-term partnerships with reliable suppliers |

| Component Authenticity | Verification important, especially for critical or specialty components, but not as heavily scrutinized as mass production | Strict process required, including full traceability and regular audits to avoid counterfeit components |

| Inventory Management | Minimal inventory, orders are placed on an as-needed basis | Strategic inventory management and forecasting is critical to prevent shortages or overages |

| Component Selection | Flexibility to experiment with different components | Rigid qualification processes are established to ensure consistency, reliability and compatibility |

Frequently Asked Questions about Electronic Supply

This section addresses common queries regarding electronic supply, encompassing lead times, minimum order quantities, shipping regulations, and the impact of global supply chain dynamics. Understanding these elements is crucial for efficient procurement and project planning.

- What are typical lead times for electronic components?

Lead times vary significantly based on component type, manufacturer, and current market conditions. Common components may have lead times of a few days to weeks, while specialized or custom parts could extend to several months. Factors like production capacity, material availability, and geopolitical events can also impact these times. Always confirm lead times with your supplier at the time of order. - What are the standard minimum order quantities (MOQs) in the electronic supply industry?

MOQs are set by suppliers to optimize their production and inventory management, and vary significantly. For common, off-the-shelf components, MOQs might be relatively low, even as few as one unit. However, for specialized or custom parts, MOQs can be quite high. Negotiating MOQs may be possible for larger projects or with established vendor relationships. Confirming MOQs for each component is critical before placing orders to avoid inventory overages or delays. - How do international shipping restrictions affect electronic component orders?

International shipping is subject to various regulations, tariffs, and embargoes that can impact order fulfillment and costs. Restrictions vary by country and component type and must comply with the import/export laws of the involved countries. Electronic components may be subject to specific tariffs, import duties, and licensing requirements, so it is important to understand the required documentation before order placement to ensure compliance with the law and avoid delays. - How does the global supply chain impact the availability and pricing of electronic components?

Global supply chains are susceptible to disruptions caused by events ranging from natural disasters and pandemics to political instability and trade disputes, and this has implications for both lead times and prices. The semiconductor industry, in particular, faces challenges due to complex supply chains involving multiple manufacturers, suppliers, and logistics. Awareness of these vulnerabilities is essential for effective risk management and cost planning when purchasing components. - What steps can I take to mitigate the risk of counterfeit electronic components?

The risk of purchasing counterfeit components can be reduced by using only authorized distributors and verified suppliers. Confirming that your supplier has a robust quality control process, including traceability programs and inspection protocols, can further minimize risk. Furthermore, regularly inspecting component packaging and labeling for authenticity and comparing parts to manufacturer specifications is crucial to detecting any potential counterfeits before use. - Can I negotiate pricing for electronic components?

Pricing for electronic components can often be negotiated, particularly for large-volume orders or if establishing long-term partnerships with suppliers. Utilizing procurement strategies that emphasize volume discounts, and building strong relationships with suppliers, can positively impact component pricing. The pricing structure for each component is based on many factors including volume, demand, and existing market pressures. - What are some alternative options for sourcing hard-to-find electronic components?

When confronted with hard-to-find components, consider using specialized brokers and independent distributors that may specialize in obsolete or rare parts. Using online databases for sourcing parts, attending industry conferences, and making inquiries directly with manufacturers are other options to consider. Always verify the legitimacy and reliability of the supplier to ensure that your parts are authentic and meet performance specifications.

Comparing Key Electronic Supply Distributors: A Quick Reference Table

Selecting the right electronic supply distributor is crucial for any project, whether it's prototyping or mass production. This section offers a comparative overview of major distributors, focusing on key factors that influence purchasing decisions. The aim is to provide a practical guide for professionals navigating the complex landscape of electronic component procurement, ensuring informed choices based on varied project requirements.

| Distributor | Product Range | Lead Time | Customer Support | Specialization | Pricing | MOQ | Geographic Coverage |

|---|---|---|---|---|---|---|---|

| Mouser Electronics | Extensive, wide selection of components and products. | Typically fast; 1-3 days for in-stock items. | Highly rated; provides technical assistance and online support. | Broad product line, good for both development and production. | Competitive; tiered pricing available for bulk orders. | Low minimum order quantities on many items. | Global. |

| DigiKey Electronics | Vast inventory, known for a wide range of component availability. | Very quick; typically same-day shipping for in-stock items. | Excellent; offers comprehensive online documentation and engineer support. | Focus on component selection for design engineers and prototyping | Competitive; volume pricing available. | No minimum order quantity for many parts. | Global. |

| Newark (Farnell) | Broad selection including components, test equipment, and tools. | Varies; some items have longer lead times depending on the manufacturer. | Good; provides email, phone, and online support. | More oriented towards industrial electronics and maintenance | Moderate; can be higher on some specialty items. | MOQ varies. | Global. |

| Arrow Electronics | Large selection of components, focusing on larger-scale production solutions | Varies significantly based on manufacturer and part availability | Good support, focused on account management for larger clients | Primarily caters to large volume manufacturing and production. | Competitive pricing for larger volume orders. | MOQ varies. | Global. |

| Avnet | Wide range of components, with strong focus on embedded systems and solutions. | Varies; can be project based with longer lead times for certain product. | Comprehensive support, especially for design and engineering needs. | Offers solutions and support for embedded systems, IoT, and AI | Competitive pricing. | MOQ varies. | Global. |

The Future of Electronic Supply Chains

The electronic supply chain is undergoing a rapid transformation driven by advancements in technology and shifting global dynamics. Emerging trends such as artificial intelligence (AI) and new digital platforms are poised to revolutionize how electronic components are sourced, managed, and delivered. These innovations promise increased efficiency, greater transparency, and more robust resilience within the supply chain.

- AI-Driven Component Sourcing

AI algorithms are increasingly being used to predict demand, optimize inventory levels, and identify potential supply chain disruptions. These intelligent systems can analyze vast datasets to proactively recommend the most efficient sourcing strategies, reducing lead times and minimizing risks. This includes algorithmic matching of parts requirements to available inventory across multiple suppliers, enhancing speed and reducing human error. - Blockchain for Traceability

The adoption of blockchain technology is enhancing traceability and transparency within the supply chain. By recording every transaction and movement of components on a secure, immutable ledger, blockchain makes it easier to verify the authenticity of parts, reduce counterfeit risks, and increase accountability at every stage of the process. This also offers a significant improvement in managing recall events with faster identification of affected items. - Digital Platforms and E-Procurement

The rise of online marketplaces and e-procurement platforms dedicated to electronic components is transforming the way buyers and sellers connect. These platforms offer enhanced search functionalities, real-time pricing, and access to a wider network of suppliers. They simplify the procurement process and improve price transparency while fostering competition and providing greater access to information. - Predictive Analytics for Demand Forecasting

Advanced analytics tools are being deployed to forecast future demand patterns. These systems analyze historical data, market trends, and external factors to predict fluctuations in supply and demand. This proactive approach empowers organizations to make informed decisions about inventory management and production planning, minimizing shortages or surpluses, and allowing better management of cash flow. - Sustainable and Circular Supply Chains

There is growing emphasis on implementing sustainable practices within the electronic supply chain. This includes initiatives for responsible sourcing of materials, waste reduction, and the promotion of a circular economy that focuses on reuse and recycling of components. This also includes the use of materials which are biodegradable and the reduction of environmental impact.

Mastering electronic supply is essential for staying competitive in the electronics industry. By understanding the nuances of sourcing, from online marketplaces to specialized suppliers, professionals can ensure access to quality components while optimizing their supply chain. This guide provides a practical foundation for navigating the complex world of electronic supply, empowering readers to make informed choices and secure a reliable flow of crucial electronic components. By leveraging the insights shared here, you can confidently address your project's needs and stay ahead in the dynamic tech landscape.

AnyPCBA

AnyPCBA