Tantalum Capacitors: Unveiling Their Power in Modern Electronics

From smartphones to sophisticated medical equipment, electronic components like the tantalum capacitor are essential to our daily lives. But what exactly makes tantalum capacitors so important and how do they work? This article delves into the unique properties, applications, and considerations when choosing tantalum capacitors, offering a comprehensive guide for both enthusiasts and professionals alike.

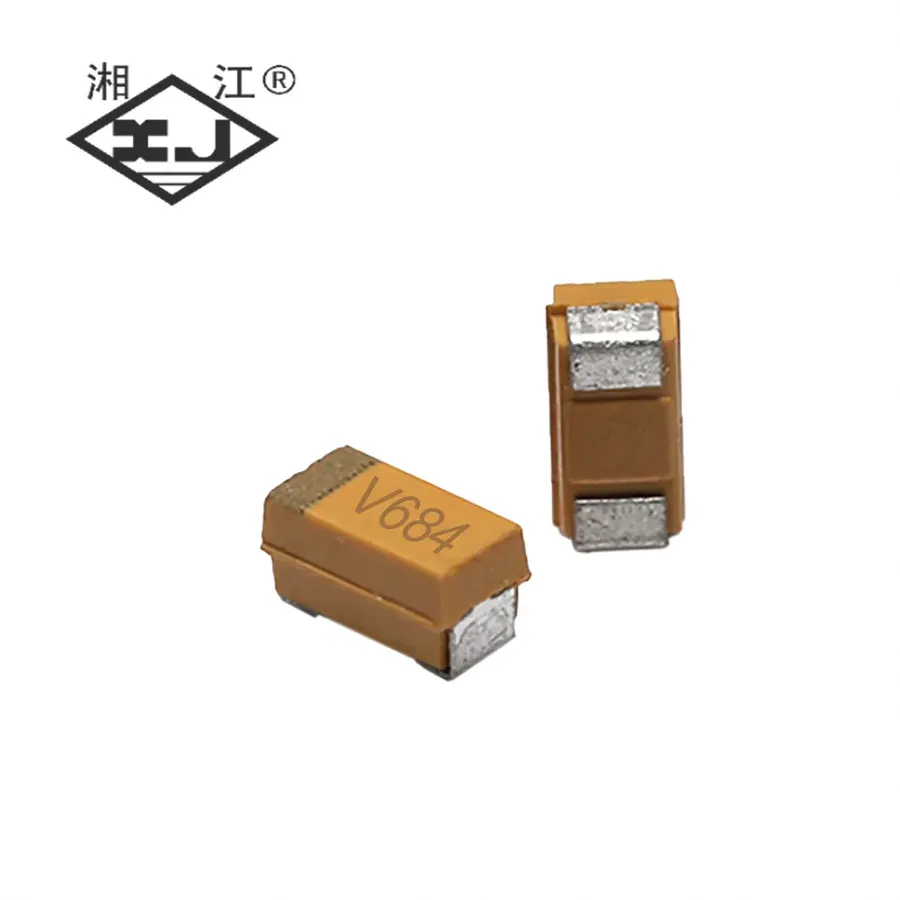

What is a Tantalum Capacitor?

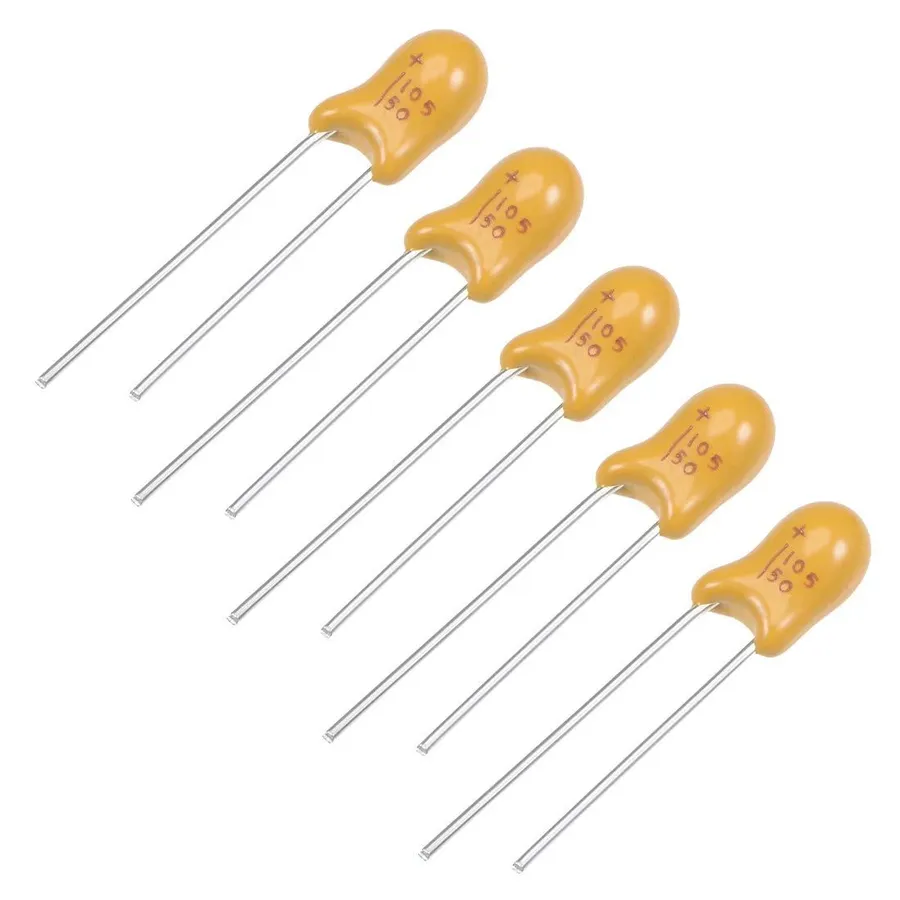

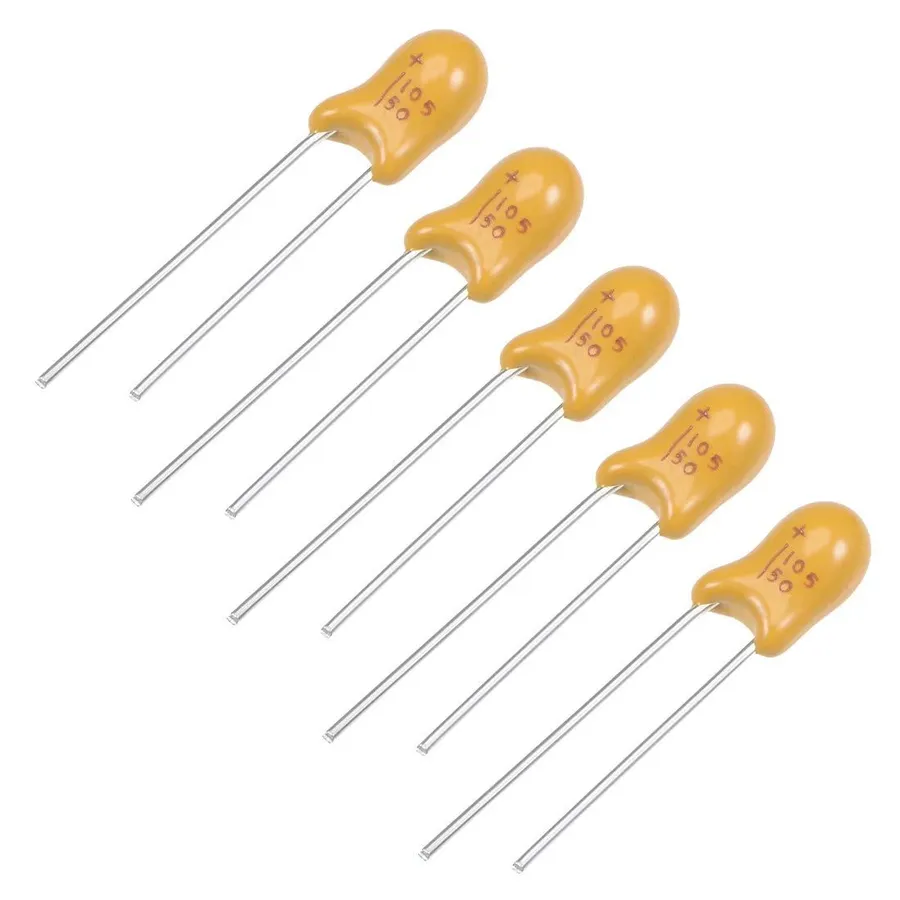

Tantalum capacitors are a specialized type of electrolytic capacitor distinguished by their use of tantalum metal as the anode material. This design choice imparts several key advantages, notably their compact size, high capacitance values, and exceptional stability across a range of operating conditions. These characteristics make them well-suited for demanding applications where space is limited and reliability is paramount.

Key Characteristics of Tantalum Capacitors

Tantalum capacitors exhibit several distinguishing characteristics that make them suitable for specific applications in modern electronics. These key attributes include their polarized nature, high capacitance-to-volume ratio, exceptional frequency response, and robust temperature stability.

- Polarized Nature

Tantalum capacitors are polarized, meaning they have a designated positive and negative terminal. Incorrect polarity during circuit installation can lead to damage or failure. This polarization is a crucial factor in their application and requires careful attention during circuit design and assembly. - High Capacitance-to-Volume Ratio

These capacitors are known for their high capacitance relative to their physical size. This high volumetric efficiency allows for significant energy storage in small devices, making them ideal for space-constrained applications. - Superior Frequency Response

Tantalum capacitors offer excellent performance over a wide frequency range, making them suitable for high-frequency applications where low impedance and minimal signal loss are critical. Their low equivalent series resistance (ESR) contributes to this characteristic. - Temperature Stability

They exhibit relatively stable performance over a wide range of temperatures compared to some other capacitor types. This temperature stability is important in applications where environmental conditions may vary significantly, such as automotive or aerospace electronics.

Tantalum vs. Other Capacitor Types: A Detailed Comparison

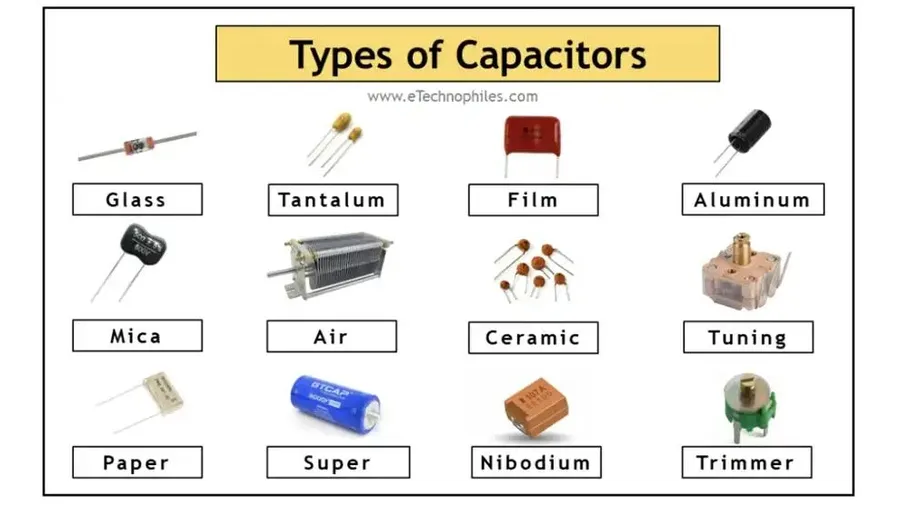

Tantalum capacitors, while offering distinct advantages, are not universally superior to all other capacitor types. A comparative analysis with ceramic and electrolytic capacitors is essential to understand their respective strengths, limitations, and appropriate use cases. This section provides a detailed comparison, highlighting key differences.

| Characteristic | Tantalum Capacitor | Ceramic Capacitor | Electrolytic Capacitor (Aluminum) |

|---|---|---|---|

| Capacitance Range | Medium to High (µF) | Low to Medium (pF to µF) | High (µF to mF) |

| Voltage Rating | Low to Medium (up to ~100V) | Low to High (Few V to KV) | Medium to High (Typically up to 500V) |

| Polarity | Polarized | Non-Polarized (Generally) | Polarized |

| Temperature Stability | Good | Excellent | Moderate |

| Frequency Response | Good | Excellent | Poor |

| ESR (Equivalent Series Resistance) | Low | Very Low | High |

| Leakage Current | Low | Very Low | High |

| Size | Small to Medium | Very Small | Large |

| Cost | High | Low | Low |

| Lifespan | Moderate to High | High | Moderate |

| Main Applications | Power filtering, decoupling in high reliability applications | Bypass, coupling, filtering | Power smoothing, large energy storage |

| Failure Mode | Short Circuit when overstressed | Generally fails open | Can fail both short or open |

Advantages of Using Tantalum Capacitors

Tantalum capacitors offer distinct advantages in electronic circuit design, primarily due to their unique material properties. These benefits include high volumetric efficiency, low leakage current, and exceptional stability across a broad spectrum of frequencies and temperatures. These characteristics make them a preferred choice for demanding applications where performance and reliability are paramount.

- High Volumetric Efficiency

Tantalum capacitors achieve a high capacitance-to-volume ratio, allowing for significant energy storage in a compact form factor. This is particularly crucial in miniaturized electronics, where space is at a premium. - Low Leakage Current

Tantalum capacitors exhibit exceptionally low leakage current compared to other electrolytic capacitors. This minimizes energy loss and makes them ideal for applications where battery life is critical or when minimal current draw is necessary. - Superior Frequency Response

Their performance remains consistent across a wide range of frequencies, meaning their capacitance does not drop dramatically as the signal frequency increases. This makes them suitable for high-speed applications, such as decoupling and filtering in digital circuits. - Excellent Temperature Stability

Tantalum capacitors show minimal change in their capacitance and other electrical parameters over a broad operating temperature range. This stability ensures reliable performance in diverse and challenging environmental conditions. - Long Service Life

When used within specified parameters, tantalum capacitors demonstrate a long operating lifetime with a lower degradation rate compared to other types of electrolytic capacitors.

Disadvantages and Limitations of Tantalum Capacitors

While tantalum capacitors offer numerous advantages, it is crucial to acknowledge their inherent limitations. These include sensitivity to reverse polarity, potential for catastrophic failure under stress, and a higher cost relative to other capacitor types. Understanding these drawbacks is essential for proper circuit design and component selection.

- Polarity Sensitivity

Tantalum capacitors are polarized devices, meaning they must be connected in the correct orientation (positive to positive, negative to negative) in a circuit. Applying reverse polarity can lead to dielectric breakdown and failure. - Failure Modes

Tantalum capacitors are susceptible to failure when subjected to overvoltage or excessive ripple current. This can manifest as a short circuit, often resulting in a thermal runaway that can damage the capacitor and surrounding components. - Cost

Tantalum capacitors typically have a higher cost compared to ceramic or aluminum electrolytic capacitors of comparable capacitance and voltage ratings. This can be a significant factor when designing cost-sensitive applications. - Limited Availability in High Voltages

While tantalum capacitors excel at higher capacitance ratings, they are not commonly available in very high voltage ratings, limiting their use in some high-power applications. Aluminum electrolytic capacitors are often preferred in high-voltage scenarios. - Higher ESR Compared to Ceramics

At higher frequencies, tantalum capacitors generally exhibit a higher Equivalent Series Resistance (ESR) than comparable ceramic capacitors. This higher ESR can lead to increased heat generation and reduced efficiency in high-frequency circuits.

Tantalum Capacitor Applications: Where Are They Used?

Tantalum capacitors are indispensable components in a wide array of electronic applications, owing to their unique combination of high capacitance, compact size, and reliable performance. Their versatility makes them suitable for roles ranging from power conditioning in everyday electronics to critical applications in demanding environments.

- Consumer Electronics

In devices such as smartphones, laptops, and tablets, tantalum capacitors are used extensively for power filtering, decoupling, and smoothing. Their compact size and high capacitance are crucial for the miniaturization and efficient power management of these devices. They ensure stable power delivery to sensitive components, preventing signal noise and performance degradation. - Automotive Electronics

The automotive industry utilizes tantalum capacitors in engine control units (ECUs), airbag systems, anti-lock braking systems (ABS), and infotainment systems. Their stability across a wide temperature range and their reliability under harsh operating conditions make them suitable for these demanding applications. The need for robust, long-lasting components in automotive applications makes tantalum capacitors an essential component. - Aerospace and Military

In aerospace and military equipment, tantalum capacitors are found in radar systems, communication equipment, and flight control systems. Their high reliability and ability to withstand extreme conditions are vital for mission-critical operations. Their performance stability across various altitudes and temperatures is essential in the design of aerospace systems. - Medical Devices

Tantalum capacitors are used in life-support equipment, pacemakers, implantable defibrillators, and diagnostic tools. Their high reliability and low leakage current are critical for the accuracy and safety of these devices. The performance consistency and high integrity of tantalum capacitors make them a preferred choice for these life-critical applications. - Industrial Equipment

From automation systems to power supplies, tantalum capacitors are used to ensure stable operation and noise reduction. They contribute to the precise control and performance consistency required for industrial processes. Their robustness and reliability make them an important component in industrial environments that require dependable and robust performance. - Telecommunications

Tantalum capacitors are employed in telecommunication devices and infrastructure, including routers, base stations, and networking equipment, for power filtering, noise suppression, and signal conditioning. Their reliability and stability help maintain the integrity of telecommunication networks and systems.

Frequently Asked Questions About Tantalum Capacitors

This section addresses common inquiries about tantalum capacitors, focusing on their polarity, handling, failure modes, and replacement procedures. These FAQs provide concise, authoritative answers to ensure a clear understanding of their use and limitations.

- What are the primary uses of tantalum capacitors?

Tantalum capacitors are primarily used in applications requiring high capacitance in a small size, such as power filtering, decoupling, and smoothing in electronic circuits. Their stability and low leakage current make them suitable for sensitive and critical circuits, including those in consumer electronics, automotive systems, aerospace, and medical equipment. - What are the main drawbacks of tantalum capacitors?

The primary downsides of tantalum capacitors include their sensitivity to reverse polarity, which can cause failure, their potential for catastrophic failure if overstressed, and their higher cost compared to other capacitor types like ceramic or aluminum electrolytic capacitors. Additionally, they can exhibit a phenomenon called 'inrush current' on startup that needs to be considered during design to avoid damage. - What distinguishes tantalum capacitors from other types of capacitors?

Tantalum capacitors differ from other types like ceramic and aluminum electrolytic capacitors primarily in their construction and performance characteristics. Unlike ceramic capacitors, tantalum capacitors offer higher capacitance for a given volume and better stability. They also tend to have lower equivalent series resistance (ESR) than aluminum electrolytic capacitors. However, they are more sensitive to reverse voltage than both, making polarity a critical design factor. - What happens if a tantalum capacitor is connected with reverse polarity?

Connecting a tantalum capacitor with reverse polarity can lead to several failure modes. Firstly, it can cause a buildup of gas within the capacitor, which can result in physical rupture, potentially causing damage to the surrounding components. Furthermore, reverse polarity will cause the capacitor's dielectric layer to weaken, leading to a short circuit. This can result in heat generation and, in severe cases, a fire hazard. Therefore, proper polarity must always be observed during installation and operation. - How should tantalum capacitors be handled to prevent damage?

To prevent damage, tantalum capacitors must be handled carefully. Avoid excessive mechanical stress, such as bending the leads or dropping them. During soldering, strictly adhere to the recommended temperature profile and avoid excessive heating, as it can damage the capacitor's dielectric layer. When placing the capacitors in a circuit, be certain of correct polarity before any power is applied. Avoid applying voltages that exceed the rated voltage and ensure that the current is kept within specified levels. - What are common failure modes of tantalum capacitors?

Common failure modes for tantalum capacitors include short circuits caused by reverse polarity, inrush current, or overvoltage, which can lead to a catastrophic failure, often manifested as smoke, flames, or complete component disintegration. Another failure mode can be due to the degradation of the dielectric layer over time, particularly when operating near the rated temperature, resulting in increased leakage current and capacitance loss. Poor soldering can also cause failure. - How should tantalum capacitors be replaced?

When replacing a tantalum capacitor, ensure the replacement has the same or higher voltage, capacitance, and temperature rating. Check the datasheet carefully. Always observe the correct polarity. Use proper soldering techniques, avoiding overheating, and excessive pressure on the component. When replacing surface mount devices, take extra care to align and solder correctly using rework stations, otherwise you could cause more damage.

Tantalum Capacitor Selection Guide and Practical Tips

Selecting the appropriate tantalum capacitor for an application requires careful consideration of several key parameters to ensure optimal performance and reliability. This section provides a practical guide to help engineers and designers make informed decisions, covering crucial specifications and handling techniques to prevent premature failure.

- Key Selection Parameters

Selecting the right tantalum capacitor depends on several crucial electrical parameters and environmental considerations. - Capacitance Value

Choose a capacitor with a capacitance value that meets the circuit's requirements. Consider tolerances; typical tolerances for tantalum capacitors range from ±5% to ±20%. - Voltage Rating

Ensure that the capacitor's voltage rating exceeds the maximum voltage in the application. It's recommended to select a capacitor with a voltage rating at least 20% higher than the operating voltage for enhanced reliability. - Equivalent Series Resistance (ESR)

ESR impacts the capacitor's performance, especially at higher frequencies. Lower ESR is preferable for applications with high current and ripple requirements. Consider ESR variations across temperature and frequency. - Temperature Range

Select a capacitor with an appropriate operating temperature range to match the environmental conditions of the application. Tantalum capacitors have wide operating temperature ranges, often from -55°C to +125°C. Select a capacitor that operates well within your temperature parameters to maintain its performance characteristics. - Case Size and Mounting Style

Choose a case size and mounting style (SMD or through-hole) that fit the available board space and assembly process. Common SMD case sizes include 0603, 0805, 1206, and larger variations. Through-hole styles also exist, often with axial or radial leads. - Polarity

Tantalum capacitors are polarized; incorrect connection can lead to immediate damage. Always double-check the polarity markings (+ side usually indicated with a stripe on the case) and follow circuit design. Verify the polarity markings during PCB layout and board population. - Handling Precautions

Tantalum capacitors are sensitive to mechanical and thermal stress; avoid excessive heat, mechanical shock, and vibration during handling and soldering to prevent internal damage and failure. - Proper Soldering Techniques

Use appropriate soldering profiles for reflow or manual soldering to prevent thermal stress. Too high temperature or duration can cause degradation of the capacitor. Avoid over soldering and check the component’s data sheet for temperature limitations during soldering.

Future Trends in Tantalum Capacitor Technology

The trajectory of tantalum capacitor technology is marked by continuous innovation aimed at enhancing performance, reducing size, and expanding application possibilities. Current research and development efforts are heavily focused on advancements in materials science, miniaturization techniques, and performance optimization, which collectively are propelling the technology forward.

- Advanced Materials

Research into new tantalum powders with higher surface areas and improved dielectric materials is ongoing. These advancements aim to increase capacitance density and reduce equivalent series resistance (ESR), thereby improving overall capacitor performance and efficiency. For instance, the exploration of modified tantalum oxides and the incorporation of other dopants are showing promising results in achieving enhanced dielectric properties and thermal stability. - Miniaturization and Integration

The trend towards miniaturization continues to drive innovation in tantalum capacitor manufacturing. Smaller case sizes and higher capacitance values in miniature packages are being developed to meet the demands of increasingly compact electronic devices. Additionally, research is being done to integrate tantalum capacitors directly into semiconductor substrates or package them using advanced techniques such as 3D packaging, which helps in reducing the footprint of electronic circuits. - Enhanced Performance Characteristics

Efforts are also being made to improve the performance characteristics of tantalum capacitors. This includes the development of capacitors with reduced leakage current, lower ESR, and improved high-frequency performance. Furthermore, research focuses on enhancing their reliability and robustness under harsh environmental conditions, including elevated temperatures and humidity. This involves the use of new encapsulation materials and innovative designs that improve the structural integrity of the capacitors. - Green and Sustainable Technologies

The industry is increasingly focusing on environmentally friendly manufacturing processes and sustainable materials. This includes reducing the environmental impact of tantalum extraction and promoting the use of recycled or alternative materials. Researchers are also exploring novel manufacturing techniques that minimize waste and energy consumption, aligning with global sustainability goals and regulations. - Smart and Adaptive Capacitors

The concept of 'smart' capacitors, where capacitors can adapt their characteristics based on circuit conditions, is also being explored. This includes the development of capacitors with integrated sensors for monitoring temperature, voltage, and current, as well as active control mechanisms that can alter capacitance or impedance in real-time. These smart capacitors will enable advanced power management systems and optimize the efficiency and performance of electronic circuits.

Tantalum capacitors, though small, play an outsized role in the modern world of electronics. Understanding their properties, advantages, and limitations allows for their effective use, ensuring reliable power delivery across a wide spectrum of devices. From powering everyday gadgets to fulfilling critical roles in specialized industries, the future of tantalum capacitors appears bright as the technology continues to advance, further cementing its importance in our increasingly electrified society.

AnyPCBA

AnyPCBA