TDK Capacitors: A Comprehensive Guide to Types, Applications, and Selection

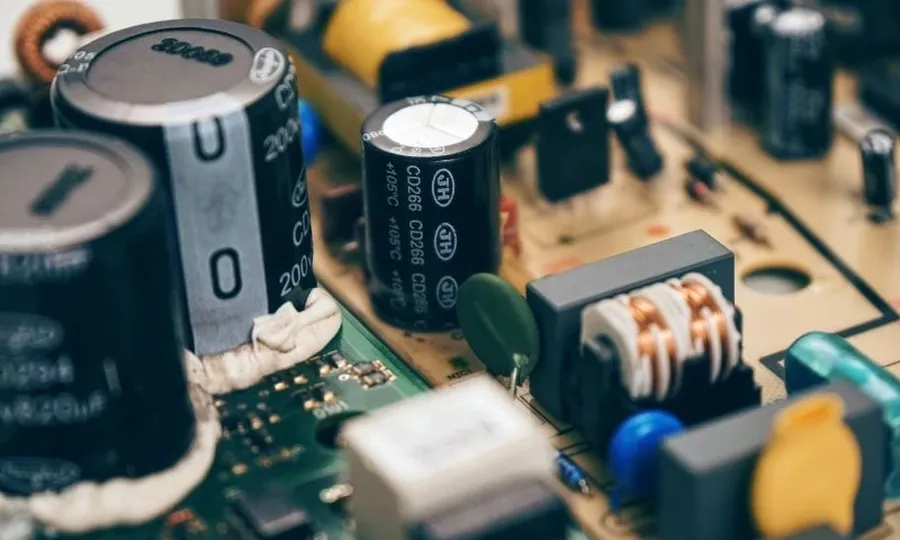

Capacitors are fundamental components in modern electronics, storing electrical energy and playing vital roles in filtering, timing, and energy storage. Among the industry leaders, TDK capacitors stand out for their advanced materials and designs, influencing circuits from smartphones to renewable energy systems. This article delves into the diverse world of TDK capacitors, providing a comprehensive overview for both seasoned engineers and newcomers, focusing on why they are essential in today's interconnected world, their applications, and selection criteria, all centered on the innovations of TDK.

Understanding TDK Capacitor Types

TDK, a global leader in electronic components, offers a diverse portfolio of capacitors tailored to meet a wide spectrum of application needs. These capacitors are broadly categorized into ceramic, film, and aluminum electrolytic types, each distinguished by their unique construction, performance characteristics, and suitability for different applications. Understanding these fundamental differences is crucial for effective component selection.

- Ceramic Capacitors

Primarily composed of ceramic dielectric materials, TDK ceramic capacitors, including Multilayer Ceramic Chip Capacitors (MLCCs), are renowned for their compact size, high-frequency performance, and low equivalent series resistance (ESR). They are widely utilized in various applications, from consumer electronics to automotive systems. - Film Capacitors

TDK film capacitors utilize thin layers of plastic film as the dielectric material, offering superior voltage handling capabilities and high stability over a wide temperature range. They excel in power electronics applications such as motor drives, inverters, and high-speed internet equipment where voltage fluctuations and high reliability are crucial. - Aluminum Electrolytic Capacitors

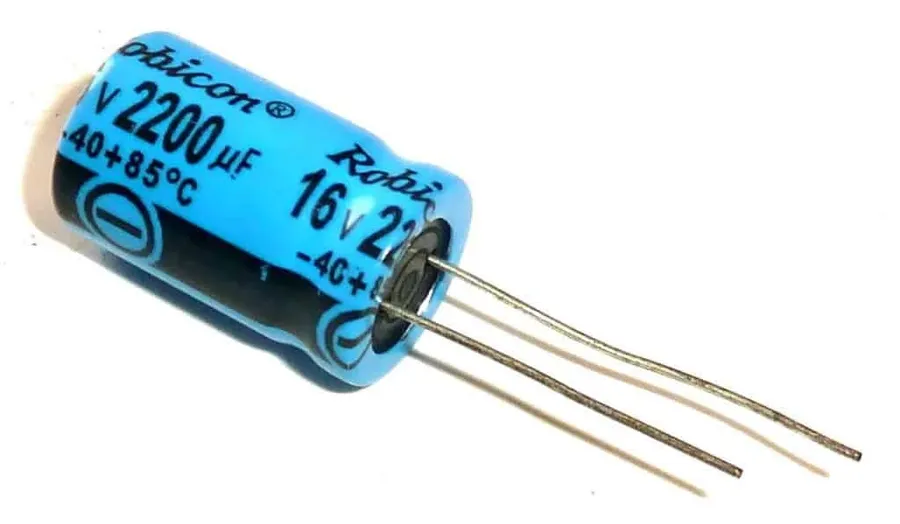

TDK's aluminum electrolytic capacitors, particularly the snap-in type, feature an aluminum foil electrode and an electrolytic solution to achieve high capacitance values. They are ideal for filtering, energy storage, and power smoothing in applications with less stringent size constraints.

| Capacitor Type | Dielectric Material | Key Characteristics | Typical Applications |

|---|---|---|---|

| Ceramic | Ceramic | Compact size, High frequency, Low ESR | Consumer electronics, Automotive, High-frequency circuits |

| Film | Plastic Film | High voltage, High stability, Low loss | Motor drives, Inverters, Power electronics |

| Aluminum Electrolytic | Aluminum Foil and Electrolyte | High capacitance, High energy storage, cost effective | Power supplies, Filtering, Energy storage |

Multilayer Ceramic Chip Capacitors (MLCCs)

TDK's Multilayer Ceramic Chip Capacitors (MLCCs) are fundamental components in modern electronics, distinguished by their compact size, low resistance, and exceptional performance in high-frequency applications. These capacitors, constructed with alternating layers of ceramic dielectric and conductive electrodes, are crucial for a range of uses, from signal decoupling to energy storage, particularly in demanding automotive and industrial environments.

| Feature | Description | Benefit |

|---|---|---|

| Low Equivalent Series Resistance (ESR) | Reduced resistance within the capacitor. | Enhanced performance, minimized energy loss, and improved power handling efficiency. |

| High-Frequency Performance | Excellent performance in high-frequency circuits. | Ideal for applications like signal decoupling in fast-switching circuits. |

| Compact Size | Small physical footprint. | Allows for high-density circuit board designs, crucial in portable devices. |

| Unique Designs | Specialized designs to meet specific application needs. | Enhanced performance, allowing engineers to fine-tune circuit characteristics for specific applications. |

| Reduced Failure Rates | Manufactured with strict process controls for high reliability. | Increased system longevity and cost-effectiveness |

| Automotive Grade MLCCs | MLCCs designed to operate under harsh automotive environments. | High temperature stability, humidity resistance, and vibration endurance for dependable operation. |

TDK Film Capacitors: Features and Benefits

TDK film capacitors, particularly the EPCOS line, are engineered for applications demanding high voltage resistance, exceptional voltage stabilization, and minimal energy dissipation. Their construction and materials provide robustness, making them ideal for challenging electrical environments.

These capacitors utilize thin layers of dielectric film, such as polypropylene or polyester, which are metallized to create electrodes. This design enables high precision in capacitance values and robust performance, suitable for diverse applications, including motor controls, inverters, and high-speed data communication equipment.

| Feature | Description | Benefit |

|---|---|---|

| High Voltage Resistance | Capable of withstanding high voltage levels without breakdown. | Ensures reliable operation in high-power applications. |

| Voltage Stabilization | Effectively minimizes voltage fluctuations. | Provides stable and consistent performance in dynamic power conditions. |

| Low Energy Losses | Designed to minimize energy dissipation. | Increases overall efficiency of the system. Reduces heat generated in the circuit |

| Self-Healing Capability | Some film capacitors have the ability to self-heal after dielectric breakdown. | Increases the reliability and longevity of the capacitor. |

| Wide Temperature Range | Function across a wide range of temperatures. | Versatility for deployment in diverse operating environments. |

The EPCOS line within TDK's film capacitor offerings is particularly noteworthy for its advanced materials and construction techniques, leading to superior electrical performance. These capacitors are critical in maintaining signal integrity and system reliability in demanding applications.

Aluminum Electrolytic Capacitors: Snap-In Solutions

TDK's snap-in aluminum electrolytic capacitors are designed for general-purpose applications requiring high capacitance and efficient filtering in a compact form factor. These capacitors are particularly suited for environments where space is limited, while still delivering robust performance in filtering and energy storage applications. A prime example of this is the B43659 series which encapsulates TDK's approach to miniaturization without sacrificing performance.

The B43659 series is an important case study for understanding the benefits of snap-in electrolytic capacitors in power electronics. Specifically designed for printed circuit board (PCB) mounting, these components are instrumental in power supplies, converters, and inverters. The B43659 series stands out because of its high ripple current capability, high capacitance values, and a long service life, making it a dependable solution for industrial and commercial electronic applications. The design of these capacitors facilitates simple installation, enhancing manufacturing processes, and reduces the overall size of the board.

| Feature | Benefit | Application |

|---|---|---|

| Snap-in Design | Ease of mounting on PCBs, reduces manufacturing time and costs. | Power supplies, converters, inverters, industrial equipment |

| Compact Size | Suitable for space constrained applications, miniaturizes electronic designs. | Consumer electronics, automotive, portable devices |

| High Ripple Current | Efficient heat dissipation, improved durability, enables stable operation in power circuits. | Power electronics, renewable energy systems, automotive inverters |

| High Capacitance | Enhanced energy storage capabilities, improves power filtering performance. | Energy storage, power filtering, DC link applications |

| Long Service Life | Reliable operation, reduces maintenance, suitable for long-term use. | Industrial applications, power grids, high-reliability systems |

Selecting the Right TDK Capacitor: Key Considerations

Selecting the correct TDK capacitor is crucial for optimal circuit performance and reliability. This process involves careful consideration of several key parameters and application-specific requirements, ensuring the chosen component meets the demands of the design.

To effectively choose the correct TDK capacitor, understanding the interplay of capacitance, voltage rating, temperature stability, size constraints, and the specific application environment is essential. Ignoring these factors can lead to component failure or reduced circuit performance.

- Capacitance

The capacitance value (measured in Farads) determines the amount of charge the capacitor can store. Selection depends on the circuit's timing, filtering, and energy storage requirements. Consider the required tolerances and how the value might change over temperature and time. Refer to TDK datasheets for specific capacitance tolerance characteristics. - Voltage Rating

The voltage rating indicates the maximum voltage a capacitor can withstand without failure. It's imperative to select a capacitor with a voltage rating that exceeds the maximum operating voltage of the circuit. Using a capacitor below the rated voltage can lead to premature failure. TDK's product documentation provides detailed voltage ratings. - Temperature Range

Capacitor performance varies with temperature. Selecting a capacitor with an appropriate temperature range is vital for reliable operation. TDK capacitors are available in various temperature ranges (e.g., -55°C to 125°C), suitable for diverse environmental conditions. Consider both operating and storage temperature ranges specified in the datasheets. - Size and Package

The physical size and packaging of the capacitor are critical, particularly in compact electronic devices. TDK offers a variety of package sizes, from tiny surface mount components to larger through-hole units. Selection should align with the PCB layout and the dimensional constraints of the application. Check the mechanical drawings in the datasheet to ensure proper fit. - Application Specific Requirements

Different applications have unique demands. For instance, high-frequency circuits might require capacitors with low ESR (Equivalent Series Resistance), while automotive applications demand high reliability and extended operating temperature ranges. Understanding these specific needs will guide the correct component selection. Consult TDK's application notes for specific recommendations.

To further aid in capacitor selection, TDK provides comprehensive online tools and selection guides. These resources allow engineers to filter capacitors based on parameters such as capacitance, voltage, temperature range, package size, and more. Utilizing these resources will streamline the selection process and ensure you're choosing the optimal TDK capacitor for the specific application.

Ultimately, the successful implementation of TDK capacitors hinges upon a thorough understanding of your design requirements and the meticulous consideration of all critical parameters in relation to the TDK capacitor specifications.

TDK Capacitor Applications in Modern Electronics

TDK capacitors are fundamental components in a vast array of modern electronic devices and systems, owing to their diverse range of types and performance characteristics. Their applications span across numerous sectors, from consumer electronics to heavy industrial equipment, playing a crucial role in ensuring the reliable and efficient operation of these technologies.

- Smartphones and Mobile Devices

TDK MLCCs (Multilayer Ceramic Chip Capacitors) are extensively used in smartphones and other mobile devices due to their compact size, low ESR (Equivalent Series Resistance), and excellent high-frequency performance. They provide stable power delivery, filter noise, and ensure the smooth operation of various circuits, including the power management system, RF (Radio Frequency) modules, and audio components. Their small form factor is crucial for the miniaturization of mobile devices. - Automotive Electronics

In the automotive sector, TDK capacitors are vital in various applications, such as engine control units (ECUs), power steering systems, and infotainment systems. The robust nature of TDK capacitors, particularly their high-temperature stability and vibration resistance, makes them ideal for the harsh conditions found in automotive environments. They are also essential in advanced driver-assistance systems (ADAS) and electric vehicle (EV) powertrains. - Renewable Energy Systems

TDK film capacitors and aluminum electrolytic capacitors are essential in renewable energy systems, such as solar inverters and wind turbine converters. Film capacitors, known for their high voltage and high current handling capabilities, play a critical role in the energy conversion process. Aluminum electrolytic capacitors, with their ability to store large amounts of energy, are used for DC link and filtering applications, ensuring the efficient and reliable operation of these systems. - Industrial Equipment and Power Supplies

TDK capacitors are widely utilized in various industrial applications, including power supplies, motor drives, and welding equipment. Their ability to withstand high voltage and high temperature conditions, along with low losses, makes them suitable for heavy-duty industrial environments. Aluminum electrolytic capacitors are commonly used in power supplies for their high capacitance and voltage ratings, while film capacitors are used in motor drives for their low energy loss and extended lifespan. - Consumer Electronics

Besides smartphones, TDK capacitors can be found in numerous other consumer electronics, such as laptops, TVs, and gaming consoles. MLCCs are particularly common for decoupling and filtering in digital circuits. TDK's film capacitors, with their durability, are incorporated into many power adapters and audio systems where high performance and reliability are critical. - Medical Equipment

TDK capacitors are crucial in medical equipment, including diagnostic tools, monitoring devices, and treatment systems. High reliability and precision are paramount in medical applications. TDK capacitors provide stable power delivery and signal integrity, ensuring the safety and reliability of these sensitive devices. Their low failure rate and consistent performance are critical for ensuring patient safety.

TDK Capacitors vs. Competitors: A Comparative Analysis

A critical aspect of selecting capacitors involves a thorough comparison between different manufacturers. This section provides a comparative analysis of TDK capacitors against key competitors, such as Murata, focusing on technological advantages, reliability metrics, and application-specific performance, with particular attention to DC Bias performance and advanced material innovations. This comparison provides insight into TDK's competitive edge.

| Feature | TDK | Murata | Comments |

|---|---|---|---|

| DC Bias Performance | Superior | Good | TDK typically exhibits less capacitance drop under DC bias conditions, crucial for stable circuit performance. |

| Operating Temperature Range | Wide (-55°C to +150°C) | Wide (-55°C to +125°C) | TDK offers options with higher temperature ratings, ideal for extreme environmental conditions. |

| Reliability | High | High | Both manufacturers demonstrate high reliability, but TDK's focus on materials science leads to enhanced longevity in specific applications. |

| Material Innovation | Advanced Ceramics | Standard Ceramics | TDK's use of proprietary advanced ceramics results in superior performance and reduced size for the same capacitance. |

| Application Focus | Automotive, Industrial, High-Frequency | General Purpose, Consumer Electronics | TDK's product range is particularly well-suited for demanding applications requiring precision and robustness. |

| Capacitance Range | Wide | Wide | Both offer extensive ranges, but TDK's advanced materials enable higher capacitance in smaller footprints. |

| ESR Performance | Low | Moderate | TDK's focus on low ESR materials reduces energy losses and heat generation. |

| Product Availability | Good | Good | Both manufacturers have strong supply chains, but specific TDK components may have lead time advantages. |

| Cost | Slightly Higher | Competitive | TDK's enhanced performance may come with slightly higher costs, but provides better value in demanding applications. |

Frequently Asked Questions About TDK Capacitors

This section addresses common questions about TDK capacitors, providing practical guidance on datasheets, part numbers, sourcing, failure modes, and specifications. Our goal is to equip you with the knowledge needed to effectively select and utilize TDK capacitors in your applications.

- Where can I find TDK capacitor datasheets?

TDK capacitor datasheets are primarily available on the official TDK website. Navigate to the 'Product' section, locate the relevant capacitor series, and then download the datasheet from the product page. Datasheets are typically provided in PDF format, detailing specifications, performance characteristics, and other essential information. In addition, some electronic component distributors also provide datasheets on their product pages. Always verify the datasheet revision and confirm that it matches the component version that you have. - How do I interpret TDK capacitor part numbers?

TDK capacitor part numbers are alphanumeric codes that contain critical information about the component. They indicate the type of capacitor, size, capacitance value, voltage rating, temperature coefficient, and other specific characteristics. The exact structure of the part number varies depending on the capacitor series and type, but generally the part number breakdown is available in the datasheet of the product. Consult the TDK datasheet or the TDK website documentation for a detailed breakdown of the part number structure. By carefully analyzing the part number, you can quickly identify whether it meets your application needs. - How do I source genuine TDK capacitors?

To ensure you are purchasing genuine TDK capacitors, it is advisable to buy from TDK's authorized distributors. These distributors are listed on TDK's official website. Purchasing from these suppliers guarantees component authenticity and ensures you receive components that meet the original specifications. Avoid purchasing from unofficial sources as there is a high risk of counterfeit or substandard parts, which may cause system failures. Check for the distributor's credentials and certifications and verify the origin and packaging of the products to further ensure that components are genuine. - What are the typical failure modes of TDK capacitors?

TDK capacitors, while generally highly reliable, can fail due to several factors. Common failure modes include exceeding voltage or current ratings, overheating (particularly electrolytic types), mechanical stress, and humidity (especially for non-hermetically sealed components). MLCCs may suffer from cracking if incorrectly mounted on PCBs. Electrolytic capacitors typically fail due to electrolyte dry-out with time and temperature. Degradation of the dielectric material can lead to performance issues, such as capacitance drift and increased leakage current. To minimize failures, always operate capacitors within specified ratings and in a proper environmental conditions. - What is DC Bias in TDK MLCC capacitors and how does it affect performance?

DC Bias refers to the voltage applied across a capacitor. In TDK MLCC (Multilayer Ceramic Capacitors), the applied DC voltage can cause a reduction in effective capacitance, particularly for high-capacitance MLCCs made with class II dielectrics. The reduction in capacitance can be substantial. This effect is caused by the polarization of the ceramic dielectric material under DC bias. Therefore, you need to check the DC bias characteristic curve in the datasheet to understand the behavior of the device. For the correct selection of a capacitor, it is essential to consider the DC bias effect in your design, especially in high precision applications and filter circuits. Consider using capacitors with more stable dielectrics for such circuits. - How do temperature variations affect TDK capacitor performance?

Temperature variations significantly impact capacitor performance. Capacitance, equivalent series resistance (ESR), and leakage current can all change with temperature. TDK capacitors, including MLCCs, film capacitors, and electrolytic capacitors, all experience some level of temperature variation. MLCCs often exhibit capacitance drift at high temperatures. Film capacitors generally have good temperature stability. Electrolytic capacitors have a strong temperature dependency, with significant performance degradation in low and high temperature extremes. Always refer to the capacitor datasheet for the temperature characteristics, and select capacitors with appropriate temperature range and stability for the target application. - How can I determine the ESR (Equivalent Series Resistance) of TDK capacitors?

ESR (Equivalent Series Resistance) is a critical parameter, especially for high-frequency and high-current applications. Datasheets will often provide typical ESR values, usually at a certain frequency, which may be frequency dependent. However, these are often just typical values. If precise measurements are needed, use an impedance analyzer at the operating frequency. In practice, the ESR of a capacitor increases with frequency and decreases with the increase of temperature. Therefore, it is crucial to take ESR into account during high-frequency power applications.

Future Trends in TDK Capacitor Technology

The capacitor industry is undergoing a period of rapid innovation, driven by the ever-increasing demands of modern electronics for higher performance, smaller size, and greater reliability. TDK is at the forefront of these advancements, actively researching and developing new materials and designs to meet these evolving needs. This section will explore some of the emerging trends and technologies that are shaping the future of TDK capacitors.

- Miniaturization and Integration

A key trend is the continued drive towards miniaturization of capacitors, with a focus on developing smaller, higher capacitance components to enable smaller, more integrated electronic devices. This includes research into 3D packaging techniques and embedded capacitor technologies. - Advanced Materials

TDK is investing in research into new materials with enhanced electrical and thermal properties. These include novel ceramics, polymers, and composite materials aimed at improving capacitance density, temperature stability, and voltage handling capabilities. Furthermore, the exploration of nano-materials opens up possibilities for achieving unprecedented levels of performance. - High-Temperature Capacitors

The automotive and industrial sectors require capacitors that can withstand harsh operating conditions. This trend is pushing TDK towards the development of capacitors with improved high-temperature performance and durability, along with enhanced resistance to mechanical stress and vibration. - Low-ESR and Low-ESL Designs

To minimize energy losses and improve efficiency in high-speed applications, TDK is focused on creating capacitors with lower Equivalent Series Resistance (ESR) and Equivalent Series Inductance (ESL). Advanced designs and conductive materials play a significant role in achieving these low values. - Integration with Power Electronics

TDK is exploring the integration of capacitors with other power electronic components, such as inductors and semiconductors, to create more compact and efficient power modules. This approach can reduce overall size, cost, and complexity of electronic systems. - Solid-State Electrolytes

The ongoing research into solid-state electrolytes promises to enhance safety and reliability, and extend the operating temperature range of capacitors. TDK is exploring different solid-state materials to replace liquid electrolytes used in conventional capacitors. - Self-Healing Capacitors

The development of self-healing capacitors, which can repair internal faults caused by electrical stress or physical damage, will significantly improve reliability and lifespan. TDK is exploring innovative approaches to enable self-healing capabilities.

In conclusion, TDK capacitors are pivotal in the electronics industry, offering a wide array of solutions for various applications. From high-precision MLCCs to robust film capacitors, their commitment to innovation ensures that TDK remains at the forefront of capacitor technology, enabling advancements across numerous fields. Whether it's miniaturizing devices or increasing energy efficiency, TDK capacitors play a key role in shaping our technological landscape. As we move towards the future, TDK’s continued commitment to research and development will undoubtedly provide even more advanced solutions, making TDK capacitors an essential partner in the evolution of electronics.

AnyPCBA

AnyPCBA