The Marvel of the Integrated Circuit Chip: A Comprehensive Guide

From smartphones in our pockets to spacecraft exploring the cosmos, the integrated circuit chip is the unsung hero of modern technology. Also known as a microchip or simply a chip, this tiny marvel, packed with interconnected electronic components, is the foundation of the digital age. This article will delve into the world of integrated circuits, exploring their functionalities, types, and historical significance, uncovering the magic within these small yet powerful devices.

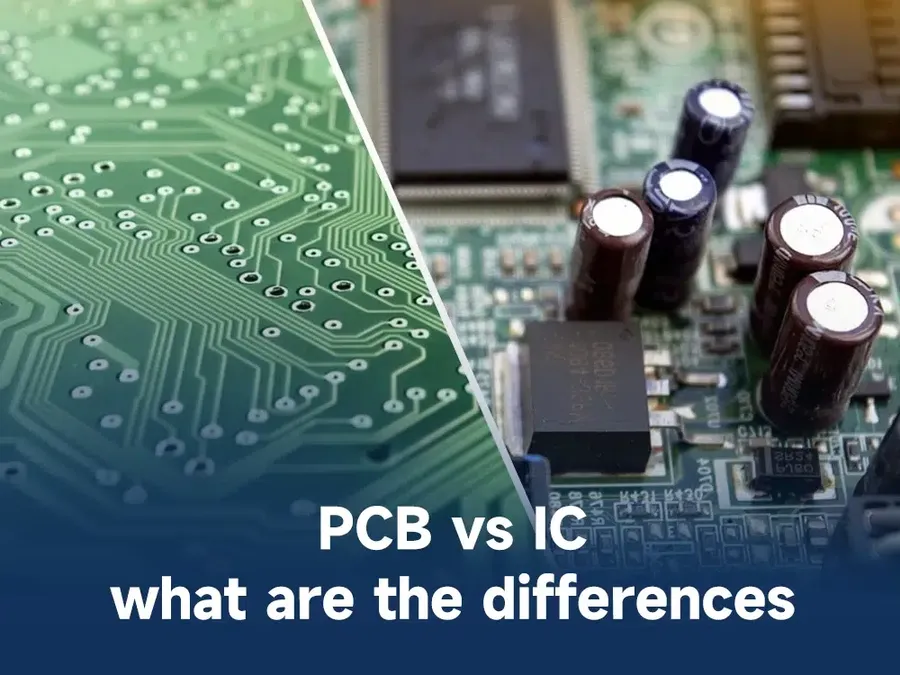

What is an Integrated Circuit Chip?

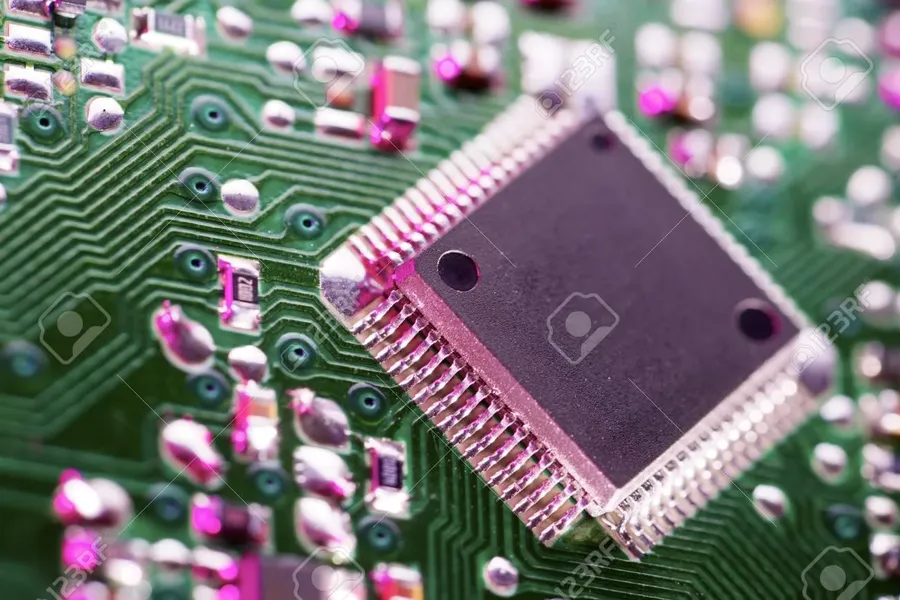

An integrated circuit chip (IC), often called a microchip or chip, is a miniaturized electronic circuit fabricated on a small piece of semiconductor material. These chips are the fundamental building blocks of nearly all modern electronic devices, enabling complex functionality within a compact form factor. At its core, an IC comprises a network of interconnected electronic components such as transistors, resistors, capacitors, and diodes, all formed on a single substrate, typically silicon.

The use of semiconductor materials like silicon is crucial to the function of integrated circuits. Silicon's ability to act as both a conductor and an insulator under varying conditions, combined with precise doping processes, makes it the ideal foundation for these microscopic circuits. The integration of these components on a single chip offers significant advantages, including reduced size, lower power consumption, higher speed, increased reliability, and reduced manufacturing costs compared to discrete electronic components.

| Component | Function | Description |

|---|---|---|

| Transistors | Switching and Amplifying Signals | Semiconductor devices that control the flow of electrical current, acting as electronic switches or amplifiers. |

| Resistors | Current Control | Components that oppose the flow of electrical current, used to limit current or set voltage levels. |

| Capacitors | Energy Storage | Electronic components that store electrical energy in an electric field. Used for filtering and timing circuits |

| Diodes | Current Direction Control | Two-terminal semiconductor devices that allow current to flow primarily in one direction. |

The Functionality of Integrated Circuit Chips

Integrated circuit chips (ICs) are the foundational building blocks of modern electronics, providing a diverse array of functionalities essential to nearly every electronic device. At their core, ICs process data, control electronic devices, amplify signals, and store memory, all by executing complex computations and logical operations. Their versatility stems from the ability to integrate numerous transistors, resistors, capacitors, and other components onto a single semiconductor substrate.

- Data Processing

ICs form the core of microprocessors and microcontrollers, executing instructions and performing calculations necessary for running software and controlling hardware. This includes arithmetic operations (addition, subtraction, multiplication, division), logical operations (AND, OR, NOT), and data manipulation. - Electronic Device Control

ICs function as the brains of electronic devices, managing various operations including power distribution, signal transmission, and user interface control. They are capable of generating control signals, processing sensor data, and implementing complex control algorithms. - Signal Amplification

Analog ICs amplify weak electronic signals to usable levels, essential in communication systems, audio equipment, and sensor interfaces. These amplifiers maintain signal integrity and increase the signal-to-noise ratio for reliable operation. - Memory Storage

ICs act as memory units storing both volatile (RAM) and non-volatile (ROM, Flash) data. These memory chips are vital for program execution and data retention, forming a critical component in computing and embedded systems. - Computation and Logic Operations

ICs utilize fundamental digital logic gates (AND, OR, NOT, XOR, etc.) to carry out logical operations. These gates, comprised of interconnected transistors, enable complex operations like decision-making, data selection, and system control. The computations are all based on manipulation of binary data.

| Function | Description | Example Application |

|---|---|---|

| Data Processing | Executing instructions and performing calculations. | Computer CPUs, embedded controllers in automobiles |

| Electronic Device Control | Managing device operations and signal transmission. | Smartphones, washing machines, industrial control systems |

| Signal Amplification | Boosting weak signals for reliable transmission and processing. | Audio amplifiers, radio receivers, medical sensors |

| Memory Storage | Storing program instructions and data. | RAM, Flash drives, computer hard drives |

| Computation and Logic Operations | Performing logical decisions and data manipulation. | All digital devices |

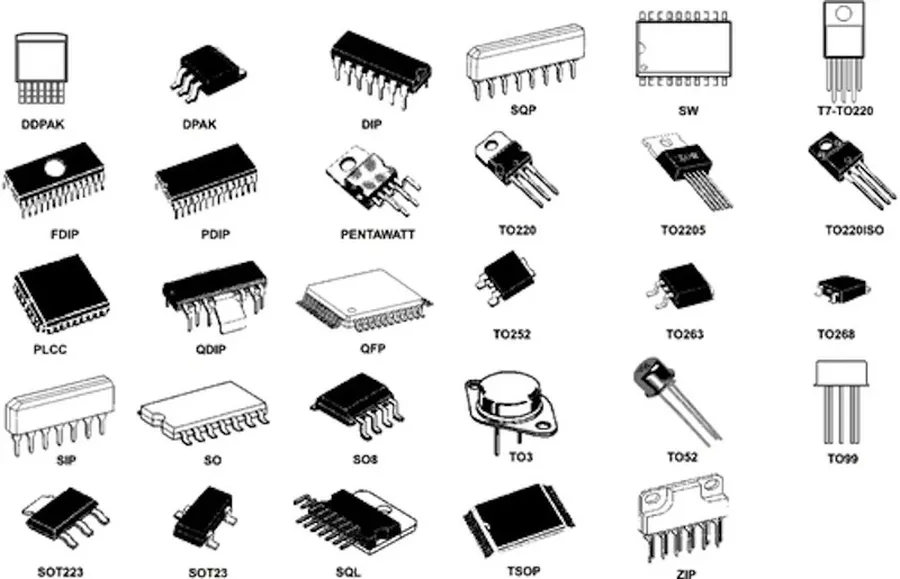

Types of Integrated Circuit Chips

Integrated circuit chips, or ICs, are categorized based on their functionality and applications. This classification allows for efficient design and utilization across diverse electronic systems. The primary categories include Analog, Digital, Mixed-Signal ICs, Microprocessors, Memory Chips, and Application-Specific Integrated Circuits (ASICs), each serving distinct purposes in electronic circuit design and operation.

| Type of IC | Functionality | Applications | Examples |

|---|---|---|---|

| Analog ICs | Process continuous signals such as voltage and current | Amplification, filtering, signal conditioning, and power management | Operational amplifiers, voltage regulators, comparators |

| Digital ICs | Process discrete signals representing binary data (0s and 1s) | Logic operations, data processing, and control functions | Logic gates, microcontrollers, flip-flops |

| Mixed-Signal ICs | Combine analog and digital functionalities on a single chip | Data conversion (ADC/DAC), signal processing in communication systems, and sensor interfaces | ADCs, DACs, CODECs |

| Microprocessors | Central processing unit (CPU) for computation and control | Personal computers, smartphones, embedded systems, and IoT devices | Intel Core series, ARM processors |

| Memory Chips | Store data for access by other components | RAM (Random Access Memory) for temporary storage, ROM (Read-Only Memory) for permanent storage, and flash memory | DRAM, SRAM, Flash memory |

| ASICs (Application-Specific Integrated Circuits) | Custom-designed for specific tasks or applications | Gaming consoles, network routers, and automotive control systems | Graphics processing units (GPUs), Network processing units |

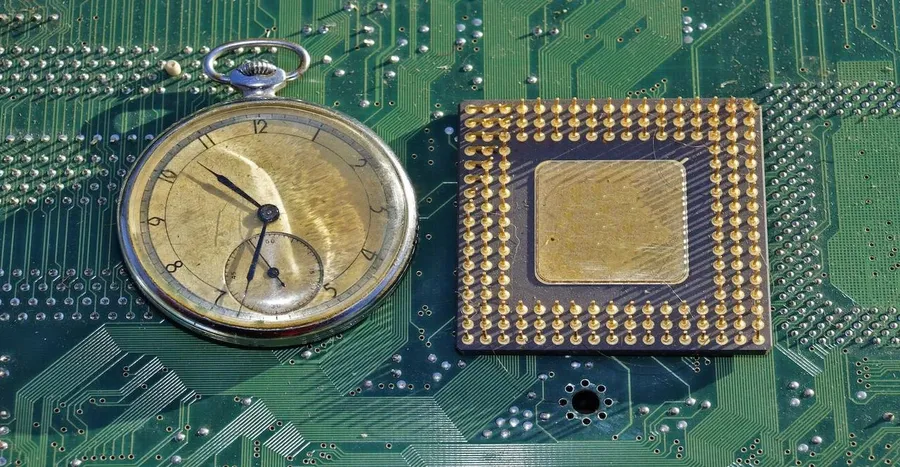

A Brief History of the Integrated Circuit Chip

The integrated circuit chip, a cornerstone of modern electronics, emerged from decades of innovation, transforming electronics from bulky, discrete components to compact, powerful microdevices. This section details the key moments and figures in its development.

The journey of the integrated circuit began long before the first working prototype. The need for smaller, more reliable electronic components drove research and development. The invention of the transistor in 1947 at Bell Labs by John Bardeen, Walter Brattain, and William Shockley was a major turning point, providing a solid-state alternative to the bulky and less efficient vacuum tubes. The transistor not only enabled miniaturization but also improved performance and energy efficiency.

The 1950s saw continued work in creating functional solid-state devices. While individual transistors improved upon vacuum tubes, circuit designs required that discrete components such as resistors and capacitors to be manually assembled and interconnected. It became clear that a method for creating all of these elements as part of an integrated device was needed.

The concept of the integrated circuit itself was proposed independently by two individuals: Jack Kilby of Texas Instruments and Robert Noyce of Fairchild Semiconductor. In 1958, Kilby successfully demonstrated the first working integrated circuit, using germanium. Kilby's design was not fabricated on a single die of material. A few months later, in 1959, Robert Noyce introduced an improved design made from silicon, which was more amenable to mass production, and a more sophisticated form of the technology. Noyce’s version of the integrated circuit solved some of Kilby's limitations by adding interconnections on the same substrate using photolithography techniques and metalization.

The crucial difference between these early ICs, and the ones of today, lies in the level of integration. The first ICs contained only a handful of components. As manufacturing technologies advanced, particularly in photolithography and doping, the number of transistors that could be placed on a single chip rapidly increased, ushering in the era of Large-Scale Integration (LSI) and Very Large-Scale Integration (VLSI). In the early 1970’s, the Intel 4004 microprocessor, with thousands of transistors, was one of the first commercially successful examples of LSI. VLSI, which allows for hundreds of thousands, and now billions of transistors on a chip, became possible in the 1980’s.

The development of integrated circuits has not just been about miniaturization, but about performance, cost, and capability. This revolution in electronics has been key to the development of the information age, enabling computers, telecommunications, and the internet.

The Fabrication of an Integrated Circuit Chip

The fabrication of an integrated circuit (IC) chip is a highly complex and multi-step process that transforms raw materials into functional electronic components. This intricate process involves numerous precise procedures, each vital to the final performance and reliability of the chip. The core of IC fabrication lies in manipulating semiconductor materials, primarily silicon, to create the intricate networks of transistors, resistors, and capacitors that constitute the circuit.

The fabrication process can be broadly divided into several key stages:

- Wafer Preparation

The process begins with the growth of ultra-pure silicon crystals, which are then sliced into thin wafers. These wafers serve as the base material for all subsequent fabrication steps. The purity and structural integrity of these wafers are paramount for the functionality of the final chip. - Photolithography

This is a crucial step in which circuit patterns are transferred onto the wafer. It involves coating the wafer with a light-sensitive material (photoresist), exposing the resist to ultraviolet light through a photomask that contains the desired circuit pattern, and then developing the exposed resist, thus leaving the circuit pattern on the wafer. This pattern then protects certain areas from the subsequent processing steps. - Etching

Etching is the process of removing material from the wafer. It uses chemicals or plasmas to selectively remove the unprotected parts of the material according to the pattern left by the photoresist. This step defines the physical shape of the components and the interconnections between them. - Doping

Doping is the process of introducing impurities into the semiconductor material to alter its electrical conductivity. This is typically done through ion implantation or diffusion. The type and concentration of dopants determine whether the silicon acts as a conductor, insulator, or a semiconductor, which is crucial for the creation of transistors and diodes. - Metallization

Metallization involves depositing thin layers of conductive materials, typically metals like copper or aluminum, onto the wafer to create the interconnections between the components. These layers connect the transistors, resistors and other circuit elements to create the designed electronic circuit. This is often achieved through sputtering or other vapor deposition techniques. - Testing

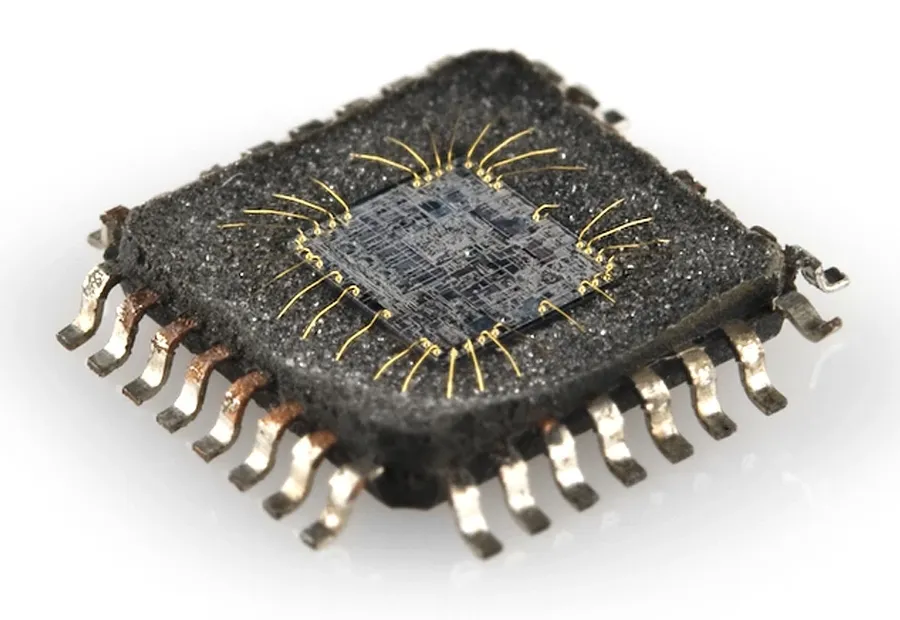

After all the fabrication steps are completed, the chips undergo rigorous testing to verify their functionality and performance. This includes electrical tests using specialized equipment that applies signals and checks output to verify that the circuit functions as intended. This step also involves the segmentation of the wafers into individual dies, and the dies which have passed the tests are then assembled into the final product.

IC fabrication faces several challenges, including the need for extreme precision, the handling of toxic chemicals, and the control of contamination. Advancements in IC manufacturing are constantly addressing these challenges with improved techniques, materials, and automation. For example, the move to smaller feature sizes, such as nanometer-scale transistors, has required significant innovations in photolithography, etching, and deposition processes. The industry is always striving to enhance yield, reduce costs and develop higher performance chips.

The Impact of Integrated Circuit Chips on Society

Integrated circuit (IC) chips have profoundly reshaped modern society, acting as the fundamental building blocks of nearly all electronic devices. Their impact extends across diverse sectors, driving innovation and enabling exponential technological growth. The pervasive influence of ICs is evident in areas from personal computing and communication to sophisticated transportation systems and advanced medical technologies.

The impact is not merely incremental; it is transformative. Consider the proliferation of smartphones, the expansion of global communication networks, the enhanced safety and efficiency of modern vehicles, and the advancements in healthcare diagnostics and treatment – all are fundamentally enabled by the capabilities of the integrated circuit.

| Sector | Impact of Integrated Circuit Chips | Examples |

|---|---|---|

| Computing | Enable high-speed data processing, storage, and retrieval. | Personal computers, servers, cloud computing infrastructure, data centers |

| Communication | Facilitate wireless communication, data transmission, and global connectivity. | Smartphones, mobile networks, satellites, internet routers |

| Transportation | Control engine management systems, navigation systems, and safety features. | Automotive control systems, aircraft avionics, GPS devices, railway signaling |

| Healthcare | Power diagnostic equipment, medical imaging, and implantable devices. | MRI machines, pacemakers, patient monitoring systems, surgical robots |

| Entertainment | Enhance audio/video quality, gaming experiences, and virtual reality. | Gaming consoles, televisions, media players, virtual reality headsets |

| Industrial Automation | Enable automated manufacturing processes, industrial control systems, and robotics. | Robotics in manufacturing, industrial process control, automated assembly lines |

The miniaturization and increasing power of ICs continue to drive down costs and increase accessibility to advanced technology. This continuous cycle of innovation and accessibility fosters further development and has a cascading impact on numerous fields, contributing to the ongoing evolution of our technological landscape.

Integrated Circuit Chip Advancements and Future Trends

The relentless pursuit of enhanced performance and miniaturization continues to drive the evolution of integrated circuit (IC) technology. Current advancements focus on pushing the boundaries of what's physically possible with semiconductor materials and fabrication techniques. Looking ahead, emerging technologies promise to revolutionize computing and electronics.

Key advancements in IC technology include:

- Nanoscale Transistors

The relentless shrinking of transistor sizes to nanoscale dimensions, measured in nanometers (billionths of a meter), allows for higher transistor density on a single chip, leading to improved performance and energy efficiency. Advanced lithography techniques, such as extreme ultraviolet (EUV) lithography, are crucial in enabling this miniaturization. - 3D Integration

Moving beyond traditional 2D chip layouts, 3D integration stacks multiple layers of ICs vertically. This approach significantly increases component density and reduces signal path lengths, thus improving performance and reducing power consumption. Techniques such as Through-Silicon Vias (TSVs) enable the interconnection of different layers. - New Materials

Research into new materials beyond traditional silicon, such as gallium nitride (GaN), silicon carbide (SiC), and graphene, offers the potential for improved performance, especially in high-power and high-frequency applications. These materials often exhibit superior properties in terms of electron mobility, thermal conductivity, and breakdown voltage.

Emerging future trends in IC technology include:

- Quantum Computing

Quantum computing utilizes quantum mechanical phenomena to perform complex calculations that are impossible for classical computers. Quantum ICs, such as superconducting quantum bits (qubits), represent a significant departure from traditional transistor-based chips and have the potential to revolutionize fields like drug discovery, materials science, and cryptography. - Neuromorphic Chips

Neuromorphic computing aims to mimic the structure and function of the human brain to achieve efficient pattern recognition and machine learning tasks. These chips utilize artificial neurons and synapses to process information in a parallel and energy-efficient manner, promising breakthroughs in artificial intelligence and cognitive computing. - Bio-Integrated Electronics

Bio-integrated electronics seeks to merge electronic components with biological systems to enable advanced biomedical devices, implantable sensors, and neural interfaces. This field combines semiconductor technology with biomaterials and biocompatible design to create innovative solutions for healthcare and medical research.

These advancements and trends underscore the ongoing role of the integrated circuit chip as a critical driver of technological progress, impacting diverse sectors and shaping the future of electronics and computing. The convergence of these technologies promises revolutionary changes in the way we interact with and utilize technology in the years to come.

Frequently Asked Questions About Integrated Circuit Chips

This section addresses common queries about integrated circuit chips (ICs), providing clear and insightful answers based on fundamental principles. We aim to clarify the core concepts and practical considerations surrounding ICs.

- What is the primary function of an integrated circuit chip?

An integrated circuit chip primarily functions as an electronic circuit fabricated on a small piece of semiconductor material, typically silicon. Its function can vary widely, from amplifying signals to performing complex digital logic operations. Fundamentally, it consolidates many electronic components like transistors, resistors, and capacitors into a single miniature device to perform specific tasks, such as data processing, memory storage, or controlling electronic devices. - Can an integrated circuit chip be repaired?

In most cases, individual integrated circuit chips are not repaired. Their intricate, microscopic structure and the complex processes involved in their manufacturing make repair highly impractical and often impossible. Instead, faulty ICs are typically replaced. While some specialized rework might be done in specific scenarios during assembly process, it isn't repair in the traditional sense. It's more a question of reworking at a larger level. - Who is credited with inventing the first integrated circuit chip?

The invention of the integrated circuit is typically credited to two individuals working independently: Jack Kilby at Texas Instruments and Robert Noyce at Fairchild Semiconductor. Kilby demonstrated the first working IC in September 1958, while Noyce independently conceived and fabricated an IC with improved features including interconnection capabilities in early 1959. Both their innovations revolutionized electronics. - What are the main applications of integrated circuit chips?

Integrated circuits have an incredibly broad range of applications spanning nearly every area of modern technology. They are central to computing devices like CPUs and GPUs, used in memory modules (RAM, ROM, Flash), found in communication systems (smartphones, routers), control systems, and countless other electronic devices. Their versatility stems from their ability to perform highly complex functions with minimal size and power consumption. - How does the fabrication process affect the performance of integrated circuits?

The fabrication process of integrated circuits significantly impacts their performance. The precision of photolithography, the purity of materials, and the control of doping and etching steps directly affect transistor size, density, and operational characteristics. Advanced fabrication techniques enable smaller feature sizes, higher transistor counts, and improved performance characteristics. Variations in these processes can lead to differences in device speed, power consumption, and reliability, illustrating why manufacturing techniques is extremely critical. - What are some future trends in integrated circuit technology?

Future trends include the continued miniaturization of transistors via new fabrication technologies, moving towards 3D integration to stack multiple chips vertically, the exploration of new semiconductor materials with superior electron mobility, and the development of novel circuit architectures like neuromorphic chips to mimic human brains. Quantum computing is also a significant area of exploration, promising to revolutionize computational capabilities. - How do integrated circuit chips contribute to energy efficiency in electronic devices?

Integrated circuit chips contribute to energy efficiency through their miniature size and high level of integration, leading to reduced power consumption per function. Also, advances in semiconductor process technology allows for lower voltage and current operation, significantly reducing power waste. Furthermore, sophisticated power management features and architectures are commonly implemented within integrated circuits to dynamically adjust power consumption based on the workload, thereby optimizing battery life in devices. Overall they have a profound impact on reducing energy wastage.

The integrated circuit chip is more than just a tiny piece of technology; it’s the cornerstone of our modern digital world. Its continuous evolution has reshaped industries and transformed our daily lives, proving that even the smallest components can have the most significant impact. As we look towards the future, the ingenuity embedded within these integrated circuits will undoubtedly continue to drive technological innovation and further define the limits of human achievement.

AnyPCBA

AnyPCBA