The Ultimate Guide to 20uF Capacitors: Selection, Usage, and Replacement

In the realm of electronics, the 20uF capacitor is a fundamental component found in a myriad of applications, from powering appliances in our homes to enabling complex machinery in industrial settings. This article will explore the ins and outs of these essential components, detailing their functionality, various types, application, selection, and proper replacement procedures. We will cover the practical use of a 20uf capacitor, touching on social science and technology, in an effort to make the topic less abstract and more understandable, helping you grasp its significance in the tech world.

Understanding 20uF Capacitors: What Does 20uF Mean?

A 20uF capacitor is a fundamental electronic component characterized by its ability to store an electrical charge, with '20uF' indicating its capacitance value of 20 microfarads. Capacitance, measured in farads (F), quantifies a component's capacity to store an electrical charge; a microfarad (uF) is one millionth of a farad. In essence, a 20uF capacitor stores and releases electrical energy, thereby playing a crucial role in controlling the behavior of electronic circuits.

The capacitor's function hinges on its physical structure, consisting of conductive plates separated by a dielectric material. When a voltage is applied, electrical charge accumulates on the plates, creating an electrical field. This stored energy is then released as required, enabling a capacitor to smooth out voltage fluctuations, filter signals, and provide temporary power during voltage dips.

Types of 20uF Capacitors: Run, Start, and More

20uF capacitors are essential components in various applications, primarily categorized into 'run' and 'start' types, each designed for specific operational demands. Understanding these distinctions is crucial for selecting the appropriate capacitor for optimal performance and longevity of the equipment it serves.

| Feature | Motor Run Capacitor (e.g., CBB65) | Start Capacitor |

|---|---|---|

| Primary Function | Continuous operation of AC motors | Providing a high current surge for motor starting |

| Duty Cycle | Designed for continuous use while the motor runs | Designed for intermittent use during motor startup |

| Construction | Typically oil-filled, with metalized film electrodes, often packaged in cylindrical aluminum or plastic casings. | Often electrolytic construction, with a robust surge capacity, typically encased in a cylindrical housing. |

| Voltage Ratings | Commonly rated for 250VAC, 440VAC, 500VAC, and higher, depending on the application | Higher, often 330VAC or higher, rated to withstand high surge voltages |

| Typical Applications | Air conditioners, fans, pumps, compressors and other appliances requiring continuous motor operation. | Used in devices such as air conditioners and refrigerators, where high starting torque is required, but is only needed for short periods. |

| Lifespan | Longer life expectancy under normal operating conditions | Designed for a limited number of starts, with a shorter operational lifespan compared to run capacitors |

| Cost | Generally more expensive due to higher continuous operating requirements. | Typically less expensive, due to less stringent continuous operating requirements. |

It is important to choose the right voltage rating. The voltage rating of the replacement capacitor must meet or exceed the original rating. For example, if the original capacitor is rated for 250VAC, a 440VAC replacement is acceptable but not vice-versa. The specific type of capacitor is determined by the application requirements. Run capacitors, like the CBB65 series, are designed for continuous duty in AC motors, while start capacitors provide a high current surge for initial motor starting. This distinction is critical as using the wrong type can cause premature failure or damage the motor itself. The materials of construction and the physical dimensions (especially diameter and length) may vary and should be considered to be sure that a replacement fits within the available space.

20uF Capacitor Specifications: Voltage, Tolerance and More

Understanding the specifications of a 20uF capacitor is crucial for ensuring its proper function and longevity within an electrical circuit. Key parameters such as voltage rating, tolerance, and frequency response dictate how a capacitor will perform under various operational conditions. These specifications must be carefully considered during capacitor selection to prevent failures and ensure optimal circuit performance.

| Specification | Description | Importance |

|---|---|---|

| Capacitance | The ability of the capacitor to store charge, measured in microfarads (uF). | A 20uF capacitor is designed to store a specific amount of charge, and deviations can affect circuit timing and energy storage. |

| Voltage Rating | The maximum voltage that the capacitor can safely handle without dielectric breakdown. | Exceeding the voltage rating can cause catastrophic failure, leading to component damage or circuit malfunctions. Common voltage ratings for 20uF capacitors include 250VAC, 440VAC and 500VAC. |

| Tolerance | The allowable deviation in actual capacitance from the nominal value, expressed as a percentage. | Tolerance, typically +/- 5% or +/- 10%, affects the precision of circuit operation, particularly in timing or filtering circuits. |

| Frequency Rating | The range of frequencies at which the capacitor performs optimally. | Capacitor performance can degrade at higher frequencies due to internal resistance (ESR) and inductance (ESL). |

| Temperature Range | The range of ambient temperatures within which the capacitor can safely and reliably operate. | Operating outside the specified temperature range can cause premature aging or failure. Typically ranges from -25°C to 85°C, or beyond, depending on application. |

| Physical Dimensions | The size and shape of the capacitor body, including lead type and diameter | Physical dimensions must be considered for PCB layout or mounting and ensure appropriate fit within the device. |

| Terminal Types | The physical connections available, such as solder leads, screw terminals, or quick-connect tabs. | Selecting the correct terminal is crucial for secure and reliable electrical connections. |

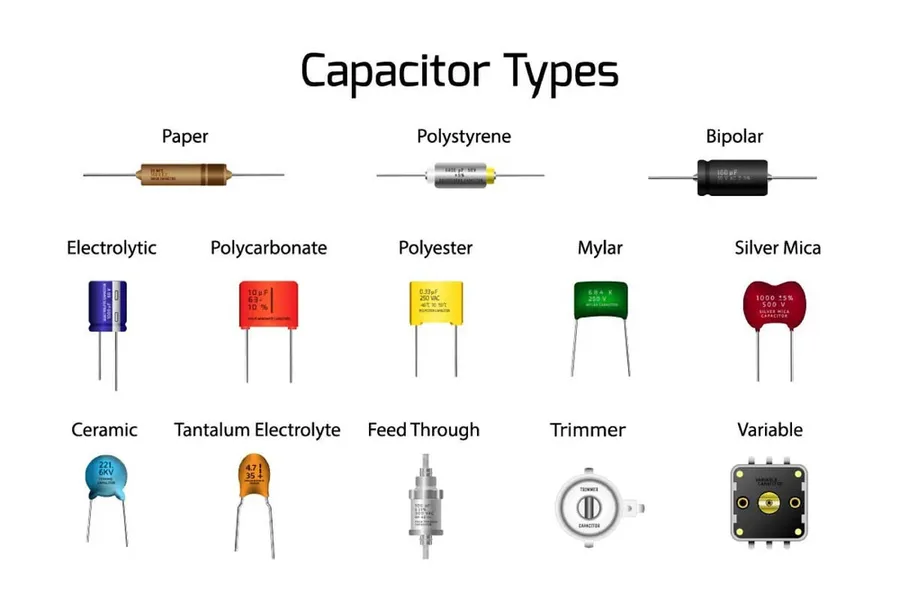

| Material Used | The dielectric material used in capacitor construction (e.g., polypropylene, ceramic, electrolytic) | Dielectric material impacts the capacitor's electrical properties, lifespan, and suitability for different applications. 20uF capacitors are commonly Polypropylene film. |

Applications of 20uF Capacitors: Where Are They Used?

20uF capacitors are essential components in various electrical and electronic systems, playing a crucial role in energy storage and circuit stabilization. Their applications span across numerous sectors, from home appliances to industrial equipment. This section details the typical uses of 20uF capacitors, highlighting their specific roles in diverse applications.

- Air Conditioners and Heat Pumps

In air conditioning and heat pump systems, 20uF capacitors are commonly used as motor run capacitors. They provide the necessary phase shift to start and maintain the operation of AC motors that drive compressors and fans. These capacitors ensure efficient and smooth functioning, reducing stress on the motor. - Fans

Similar to air conditioners, 20uF capacitors are frequently used in various types of fans, including ceiling fans, exhaust fans, and industrial fans. They facilitate the starting and running of the fan motors, allowing for a steady and controlled operation of the fan blades, ensuring effective airflow. - Power Tools

Many power tools, like grinders, drills, and saws, rely on 20uF capacitors to provide the initial surge of energy required to start their motors. They also help to stabilize the motor during operation, ensuring that the tool runs smoothly and efficiently. This is essential for maintaining the tool's performance and prolonging its lifespan. - Audio Equipment

In audio systems, 20uF capacitors are employed for filtering and decoupling purposes, playing a critical role in maintaining the sound quality. They filter out unwanted noise or ripple in the power supply, ensuring that the audio signals are clear and distortion-free. They also help to couple AC signals and block DC. - Power Supply Filtering

Beyond the applications mentioned, 20uF capacitors are also utilized in power supplies for filtering purposes. They smooth out voltage fluctuations, reducing the risk of damage to sensitive electronics, contributing to the overall stability and reliability of the power supply. These capacitors remove unwanted noise and ripple to provide a clean and stable DC output.

Selecting the Right 20uF Capacitor: A Practical Guide

Selecting the appropriate 20uF capacitor is crucial for ensuring the reliable and efficient operation of electrical equipment. This guide outlines the critical factors to consider when choosing a 20uF capacitor, emphasizing voltage compatibility, temperature range, and tolerance, and the risks of using an incorrect capacitor.

| Parameter | Description | Importance |

|---|---|---|

| Capacitance | Rated at 20uF | Must match the application's requirements precisely. A mismatch can lead to improper function. |

| Voltage Rating | The maximum voltage the capacitor can safely handle. (e.g., 250VAC, 440VAC, 500VAC) | Should be equal to or greater than the application's operating voltage. Insufficient voltage rating can result in capacitor failure. |

| Tolerance | Permissible deviation from the rated capacitance (e.g., ±5%, ±10%). | Affects the accuracy of the capacitor's performance. Choose based on application precision needs. |

| Temperature Range | The range of operating temperatures within which the capacitor functions effectively. | Capacitors can have significant changes in performance or lifespan outside their rated temperature range. This factor is especially important in environments with extreme temperatures. |

| Type | Start or run capacitor, each designed for specific motor applications. | Using the incorrect type will lead to premature failure and operational issues. |

| Physical Dimensions | The size of the capacitor. Important for physical fit in an electronic component or device. | Must physically fit in the allocated space and may have mounting requirements. |

A critical aspect of selection is ensuring that the capacitor's voltage rating is equal to or higher than the application's operating voltage. Selecting a capacitor with a voltage rating lower than needed can lead to immediate failure or significantly reduce the capacitor's lifespan, potentially damaging other components in the system. Additionally, the capacitor’s operating temperature range must be suitable for the environment of the system. A start capacitor and a run capacitor must never be interchanged.

Replacing a 20uF Capacitor: Safety Precautions and Step-by-Step Instructions

Replacing a 20uF capacitor requires careful adherence to safety protocols and a systematic approach to ensure proper functionality and prevent potential hazards. This section provides a detailed guide for safely replacing a 20uF capacitor, emphasizing safety precautions and offering step-by-step instructions.

Before starting the replacement, it's crucial to understand the inherent risks associated with capacitors. They store electrical energy and can deliver a dangerous shock even when the power is turned off. Therefore, discharging the capacitor is the first and most important step.

Here's a comprehensive guide to ensure a safe and successful replacement:

- Gather Necessary Tools and Safety Equipment

Ensure you have insulated gloves, safety glasses, a properly insulated screwdriver (preferably with a discharge resistor), a multimeter, and the correct replacement 20uF capacitor, matching the original voltage and type specifications. - Disconnect Power Source

Completely disconnect the power source to the appliance or device where the capacitor is located. Double-check that the power is off by using a multimeter to test the circuit. - Discharge the Capacitor

Before touching the capacitor, it is essential to discharge it. Use an insulated screwdriver with a discharge resistor or a dedicated capacitor discharging tool to short the terminals. This process ensures there is no residual voltage in the component. Verification with a multimeter is critical to ensure the voltage is reduced to zero. - Document Wiring Configuration

Take a clear photograph or draw a detailed diagram of the existing wiring connections to the capacitor. This record is important for ensuring the correct reconnection of the replacement unit. - Remove the Old Capacitor

Carefully disconnect the wires from the old capacitor, noting the orientation of each wire if applicable, and remove the old capacitor from its mounting location. Do not force any connections. - Install New Capacitor

Mount the new 20uF capacitor in the same location as the old one, ensuring it is securely fastened. Connect the wires to the appropriate terminals according to your previous documentation or diagram, ensuring tight and secure connections. - Double-Check Connections

Verify all wiring connections against the documented configuration to ensure no errors were made. Ensure all connections are secure and will not come loose with vibration. - Reapply Power and Test

Restore power to the appliance or device. Test the operation to confirm the capacitor has been properly replaced and the system is functioning correctly. If the issue remains, recheck all steps and consult a professional if needed.

Troubleshooting and Common Issues with 20uF Capacitors

20uF capacitors, like all electronic components, are subject to degradation and failure. Recognizing common issues and understanding how to diagnose them is crucial for maintaining the performance and safety of electronic equipment. This section details common failure modes and how to use a multimeter to assess a 20uF capacitor's health.

- Common Failure Modes

Capacitor failures typically manifest in a few common ways: bulging or swelling of the casing, which indicates internal pressure buildup due to electrolyte degradation; physical damage such as cracks or leaks; and electrical failures such as open circuits, short circuits, or a decrease in capacitance below the specified tolerance. - Bulging or Swelling

This is a clear visual sign of a failing capacitor. The internal components of the capacitor break down or overheat, creating pressure. This commonly occurs in electrolytic capacitors when their electrolyte dries out, resulting in increased internal resistance and heat generation. - Physical Damage

Cracks, leaks, or broken terminals are indicators of external damage that can compromise the capacitor's integrity and lead to malfunction. Exposure to excessive heat or physical stress are the main causes of this type of damage. - Electrical Failure

An open circuit means no current can pass through the capacitor, a short circuit allows current to pass without any resistance, and a decrease in capacitance means the capacitor is no longer storing the correct amount of charge. This may be caused by internal component degradation.

Testing a 20uF capacitor with a multimeter can give valuable insights into its condition. The multimeter should be capable of measuring capacitance, and it’s important to ensure that the capacitor is discharged before testing, to prevent damaging the multimeter or creating a safety hazard.

- Testing Procedure with a Multimeter

Firstly, ensure the capacitor is disconnected from the circuit and completely discharged. Set the multimeter to capacitance measurement mode. Connect the multimeter probes to the capacitor terminals, matching polarity if the capacitor is polarized. The multimeter will display the measured capacitance value. Compare the reading with the capacitor's rated 20uF value, and take note of any significant deviations which may be caused by capacitance drift. - Interpreting the Readings

A reading close to 20uF within the tolerance range (typically ±5% to ±10%) indicates the capacitor is likely functioning within acceptable parameters. A significantly lower reading indicates the capacitor has lost its capacity and needs replacement. A reading of zero, or very low resistance may indicate a short circuit. In other cases, an open circuit will show no reading at all. The specific mode displayed by the multimeter will vary based on the specific model. - Safety Precautions

Always discharge capacitors before handling or testing them. Use insulated tools to prevent electrical shocks. If the capacitor appears swollen or damaged, avoid handling it directly, as some capacitors can release harmful chemicals or cause electrical burns. Wear appropriate protective gear like eye protection and gloves if necessary. Consider using an insulated discharge tool if the capacitor may still be charged.

Frequently Asked Questions About 20uF Capacitors

This section addresses common questions regarding 20uF capacitors, aiming to provide clear and concise answers to typical user queries, enhancing understanding and practical application.

- What does 20 uF mean on a capacitor?

The notation '20 uF' on a capacitor signifies its capacitance, which is 20 microfarads. A farad (F) is the base unit of capacitance, representing a capacitor's ability to store an electrical charge. A microfarad (uF) is one millionth of a farad (10^-6 F). Therefore, a 20uF capacitor can store a specific amount of electrical charge, which is crucial for its function in various electronic circuits. - Is it okay to use a higher uF capacitor instead of a 20uF capacitor?

While using a capacitor with a slightly higher uF value might seem permissible, it is generally not recommended without thorough understanding and testing. A higher capacitance can alter the timing, frequency or performance of the circuit in ways it was not designed for, potentially leading to erratic operation or damage. It's always best to adhere to the manufacturer's specified value for optimal performance. - What does uF stand for on a capacitor?

The abbreviation 'uF' on a capacitor stands for microfarad. As mentioned earlier, a microfarad is a unit of capacitance equivalent to one millionth of a farad, which is the standard unit of capacitance. This indicates the amount of electrical charge the capacitor can store. - What are typical applications for a 20 uF capacitor?

20uF capacitors are commonly used in a variety of applications, including: starting and running AC motors, particularly in air conditioning units, heat pumps, and fans. They are also found in power tools like grinders, and audio equipment. Additionally, they can be used in power supply filtering, where the capacitor smooths out voltage ripples. - Can I replace a 20uF capacitor with a 20uF capacitor that has a higher voltage rating?

Yes, it is generally safe to replace a 20uF capacitor with another 20uF capacitor that has a higher voltage rating. The voltage rating indicates the maximum voltage the capacitor can safely handle. Using a capacitor with a higher voltage rating will not affect the circuit's operation, but will provide an added safety margin against overvoltage conditions, making it a generally acceptable practice. - How do I know if my 20uF capacitor is bad?

Common signs that a 20uF capacitor may be faulty include bulging or swelling of the capacitor casing, leakage of electrolyte (for some types), or if the device it's installed in is not performing as expected. Additionally, a multimeter can be used to measure the capacitor's capacitance; if the reading is significantly different from the rated 20uF, it may be failing. Refer to section 7 for detailed troubleshooting using a multimeter. - Are there different types of 20uF capacitors, and which is best for my application?

Yes, there are different types of 20uF capacitors including motor start, motor run, and general-purpose capacitors. Motor run capacitors, often encased in metal (like CBB65 types), are designed for continuous operation in AC motors. Motor start capacitors are typically non-continuous operation, providing a high-torque boost for starting. The best type will depend on the specific circuit, power requirements and usage (continuous or intermittent operation). Refer to section 2 for detailed capacitor types and specifications.

The 20uF capacitor, though small, is a vital component in many devices we use daily, from powering motors to refining audio signals. Understanding its function, types, and proper handling can empower you to maintain and repair your electronics safely and efficiently. When dealing with a 20uF capacitor, always adhere to safety protocols and carefully follow manufacturer specifications to ensure optimal functionality and longevity. In the future, advancements in capacitor technology might offer more efficient and compact solutions, but the principles of its usage and replacement will likely remain essential knowledge for anyone working with electronics.

AnyPCBA

AnyPCBA