The Ultimate Guide to Selecting the Right Mouser Capacitors for Your Project

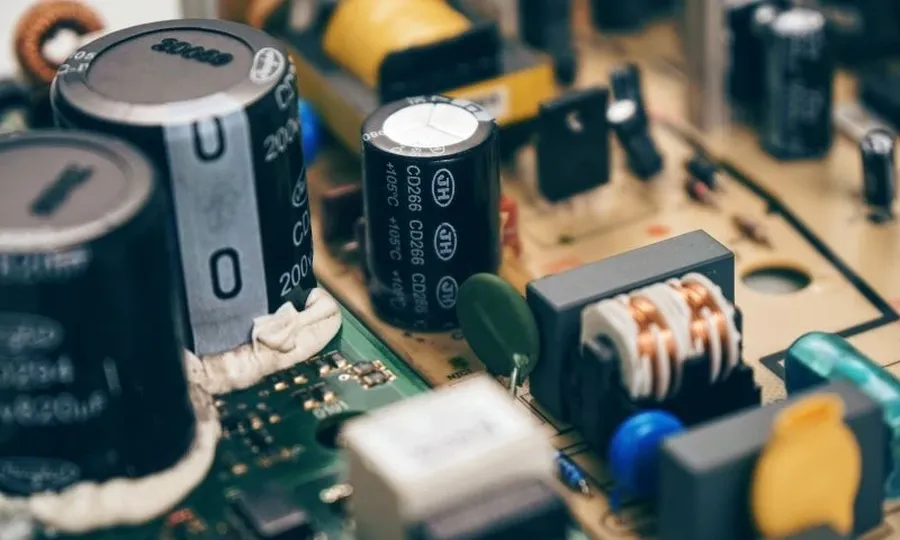

In the fast-paced world of electronics, capacitors play a crucial role, acting as the unsung heroes in circuit boards. Whether you're a seasoned engineer or a hobbyist, understanding the nuances of capacitor selection is key to project success. Mouser Electronics, a trusted distributor, offers a vast array of capacitors from leading manufacturers. This article will demystify the selection process and help you confidently navigate the world of Mouser capacitors, ensuring your designs operate efficiently and reliably. From ceramic to electrolytic and everything in between, we'll break down the types and specifications and help you choose the right capacitor for any project.

Understanding Basic Capacitor Types at Mouser

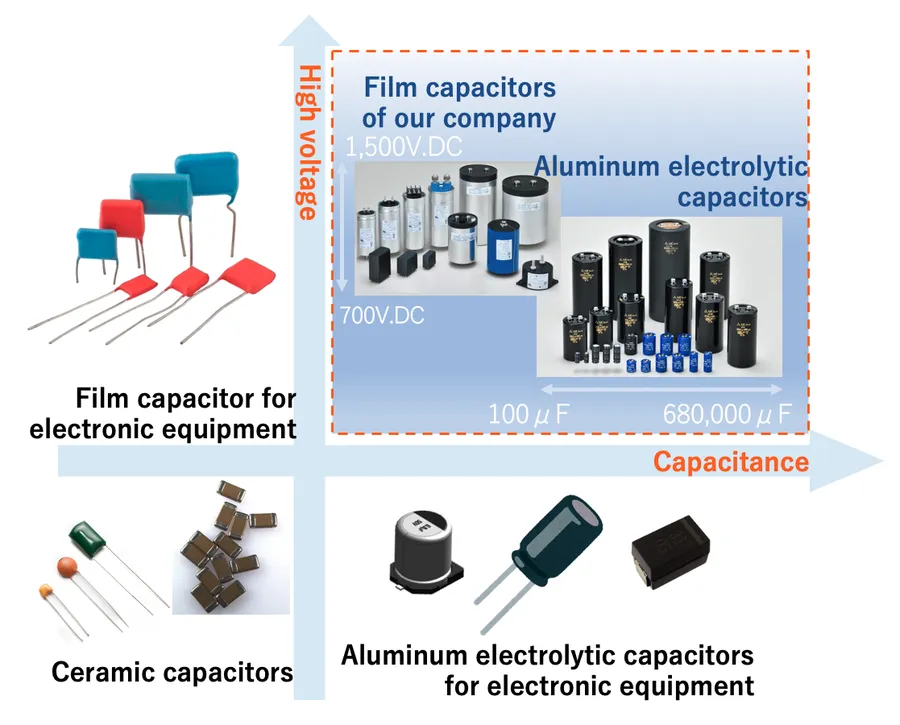

Mouser Electronics offers a comprehensive selection of capacitors, essential components in electronic circuits for storing electrical energy. These components are broadly categorized into ceramic, electrolytic, film, and tantalum capacitors, each distinguished by their construction, performance characteristics, and optimal applications.

Capacitors are fundamental building blocks in electronics, performing crucial functions such as filtering, energy storage, and signal coupling. Understanding the unique properties of each type is essential for selecting the correct component for a given application. This section provides a detailed overview of the basic types available at Mouser.

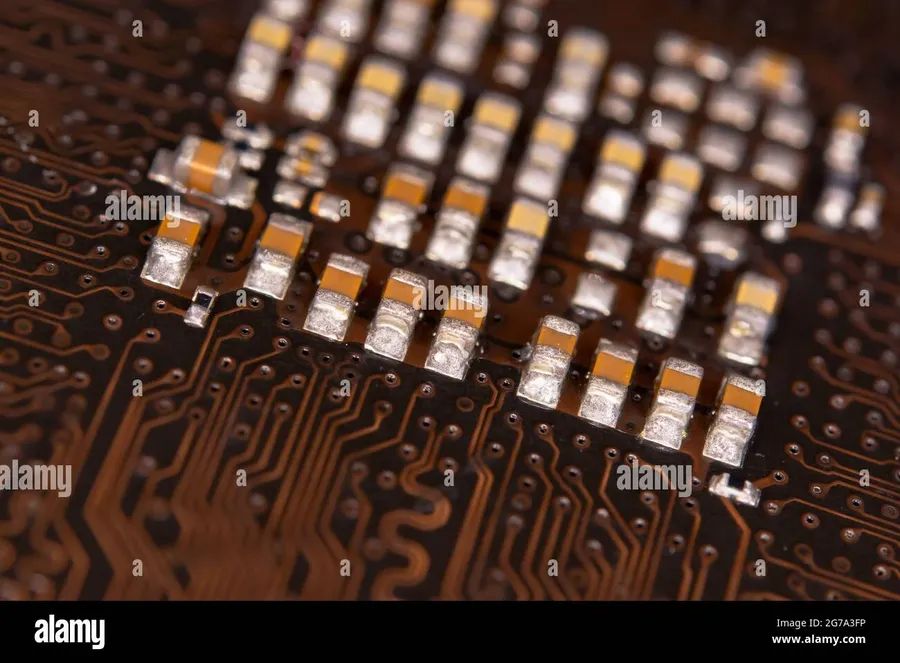

Ceramic Capacitors: Versatile and Compact Solutions

Ceramic capacitors are ubiquitous in modern electronics due to their compact size, excellent high-frequency performance, and cost-effectiveness. These capacitors utilize ceramic materials as their dielectric, offering a wide range of options for various applications. Mouser provides an extensive selection of ceramic capacitors, catering to diverse design needs.

The defining characteristic of ceramic capacitors is their use of ceramic dielectrics, which come in various types, each with its own unique properties influencing temperature stability, capacitance variation with voltage, and overall performance. Common dielectric materials include:

- COG (NP0):

These are Class 1 dielectrics known for their exceptional stability and minimal change in capacitance with temperature, voltage, or time. They are used in high-precision applications where stability is critical. - X7R:

These are Class 2 dielectrics, offering a higher capacitance per unit volume than COG/NP0, but with a less stable capacitance. They are commonly used in applications that do not require high accuracy, where a certain amount of capacitance drift is acceptable. - Y5V:

Also a Class 2 dielectric, Y5V capacitors offer the highest capacitance per volume, but with a wider capacitance variation over temperature and voltage. They are suited to applications where a large capacitance value is needed, and stability is not crucial.

When selecting ceramic capacitors from Mouser, the dielectric material is a key parameter to consider alongside capacitance value, voltage rating, tolerance, and package size. The choice depends on the specific requirements of your circuit.

Mouser's extensive inventory includes ceramic capacitors in various form factors, such as surface mount (SMD) and through-hole, as well as a wide selection of case sizes and voltage ratings. This variety ensures that engineers can find the ideal component for their projects, whether it is a high-frequency decoupling application or general-purpose filtering.

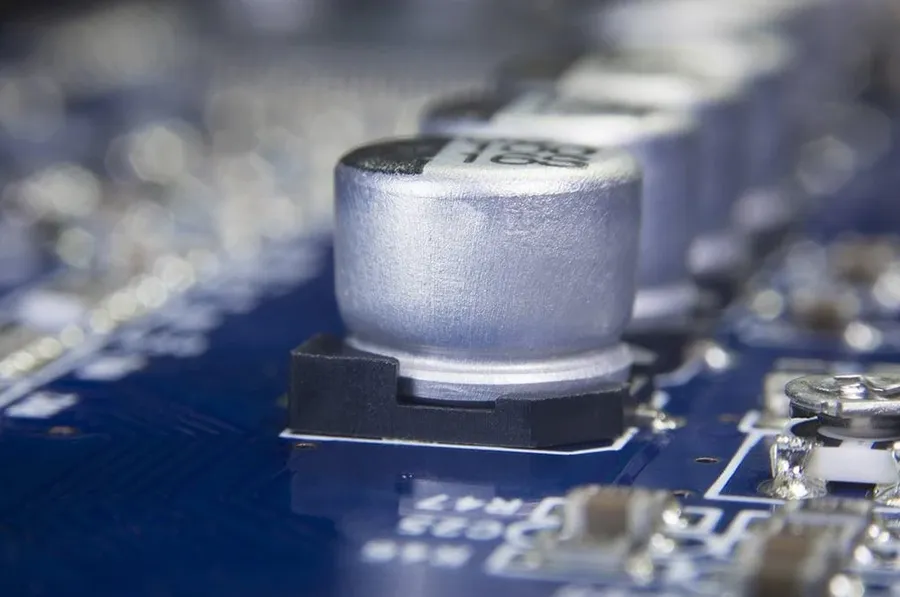

Electrolytic Capacitors: High Capacitance for Power Applications

Electrolytic capacitors are characterized by their high capacitance values, making them ideal for energy storage and power applications. They are essential components in power supplies and filtering circuits due to their ability to store a large electrical charge in a relatively small package. Mouser offers a diverse selection of electrolytic capacitors, encompassing both aluminum and tantalum types, each with distinct performance characteristics and application suitability.

Electrolytic capacitors utilize an electrolyte to achieve a high dielectric constant, resulting in significantly higher capacitance compared to ceramic or film capacitors of similar size. This high capacitance makes them especially suitable for applications that require a large amount of energy storage or effective filtering of low-frequency signals.

Mouser's inventory includes a wide array of electrolytic capacitors, designed to meet the specific requirements of diverse applications, ranging from basic power smoothing to advanced energy storage solutions. Understanding the differences between aluminum and tantalum electrolytic capacitors is crucial for effective design.

- Aluminum Electrolytic Capacitors

These are the most common type of electrolytic capacitors, known for their high capacitance per volume and cost-effectiveness. They are typically used in applications like power supply filtering, where bulk energy storage is needed. Aluminum electrolytic capacitors are polarized, meaning they must be installed with the correct polarity to prevent damage. Mouser's selection includes a broad range of voltage and capacitance options. - Tantalum Electrolytic Capacitors

Tantalum capacitors offer higher stability and reliability compared to aluminum electrolytic capacitors, though they generally come at a higher cost and have lower voltage ratings. They are often preferred in high-performance filtering applications where reliability is critical. Tantalum capacitors are also polarized and Mouser provides them in various surface mount and leaded configurations.

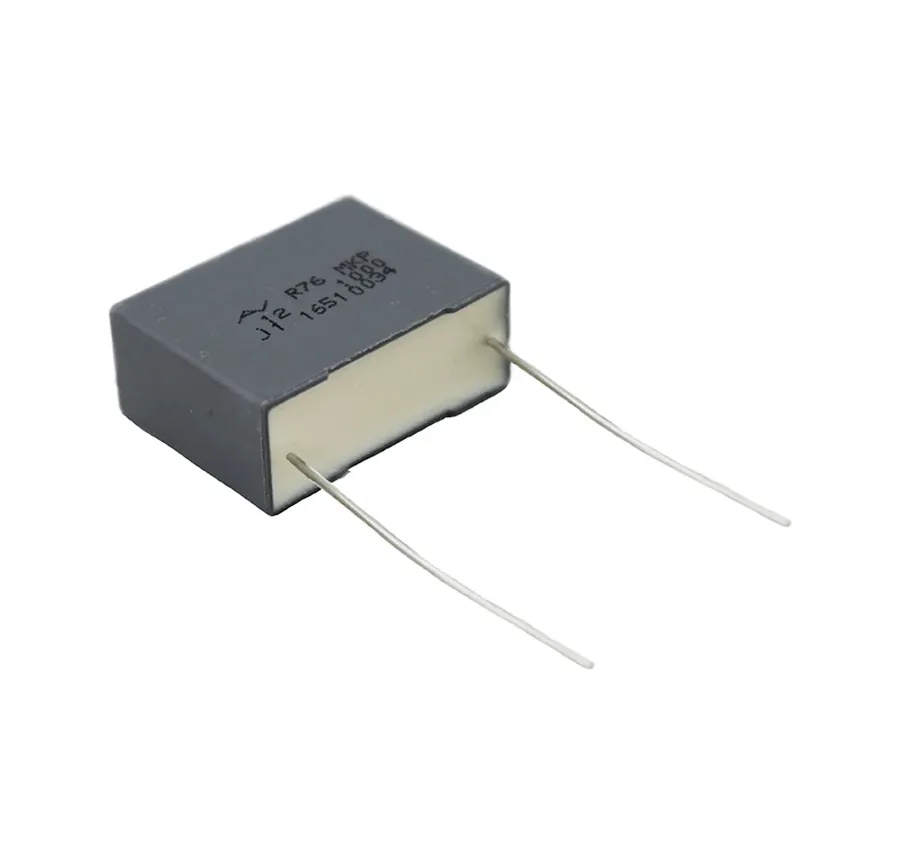

Film Capacitors: Precision and Stability for Specialized Needs

Film capacitors stand out for their exceptional precision and stability, making them ideal for specialized applications requiring consistent performance over time and varying conditions. Unlike other capacitor types, film capacitors utilize a thin dielectric film, such as polypropylene, polyester, or other polymers, providing superior performance characteristics for circuits demanding high reliability and low drift.

Mouser offers a wide array of film capacitors catering to diverse needs, including different film materials, voltage ratings, and package sizes.

- Key Advantages of Film Capacitors:

High precision, excellent stability over temperature and time, low equivalent series resistance (ESR), and high reliability. - Applications:

Precision timing circuits, audio equipment, high-frequency circuits, filtering, and resonant circuits.

| Parameter | Film Capacitor | Ceramic Capacitor | Electrolytic Capacitor |

|---|---|---|---|

| Precision | High | Medium | Low |

| Stability | High | Medium | Low |

| ESR | Low | Medium | High |

| Cost | Medium to High | Low | Low |

When choosing a film capacitor from Mouser, consider the specific material and construction. For instance, polypropylene capacitors are often preferred for their low dissipation factor and high insulation resistance, while polyester film capacitors are valued for their wide range of capacitance values.

Key Parameters to Consider When Selecting Mouser Capacitors

Selecting the correct capacitor from Mouser's extensive catalog requires a thorough understanding of key electrical parameters. These parameters directly influence circuit performance and reliability. Primary considerations include capacitance, voltage rating, temperature coefficient, and tolerance, each of which plays a critical role in how the capacitor functions within a given circuit.

- Capacitance

Capacitance, measured in Farads (F), is the fundamental property of a capacitor, indicating its ability to store electrical charge. Choosing the correct capacitance is crucial for circuit functionality, whether it's for energy storage, filtering, or timing applications. Mouser offers a wide range of capacitance values to suit diverse needs. - Voltage Rating

The voltage rating specifies the maximum DC or AC voltage a capacitor can safely withstand without risk of dielectric breakdown. Selecting a capacitor with an adequate voltage rating, with a margin of safety, is essential to prevent premature failure and ensure long-term reliability. Mouser provides capacitors with a wide variety of voltage ratings. - Temperature Coefficient

The temperature coefficient indicates how the capacitance value changes with temperature variations. It is usually expressed in parts per million per degree Celsius (ppm/°C). In environments with significant temperature variations, understanding and selecting a capacitor with a suitable temperature coefficient is crucial to maintain circuit stability. Mouser lists detailed temperature coefficient data for its capacitors. - Tolerance

Tolerance represents the allowable deviation of a capacitor's actual capacitance value from its nominal value, typically expressed as a percentage. Tighter tolerances (e.g., ±1%) are crucial for precision circuits, while less stringent requirements can accommodate wider tolerances (e.g., ±20%). Mouser offers a range of tolerance options to meet varying design requirements.

Matching Capacitors to Circuit Needs

Selecting the appropriate capacitor for a circuit is crucial for optimal performance and reliability. This section provides practical guidance on matching Mouser's extensive capacitor offerings to specific circuit applications, encompassing filtering, decoupling, timing, and energy storage. The goal is to align capacitor characteristics with project requirements, leveraging Mouser's broad selection.

Here's a breakdown of capacitor selection considerations based on common circuit needs:

- Filtering Circuits

For smoothing voltage fluctuations or removing unwanted frequencies, consider using ceramic capacitors for high-frequency filtering due to their low ESR and excellent high-frequency response. Electrolytic capacitors, especially aluminum types, excel in low-frequency filtering and power supply smoothing due to their high capacitance, particularly for larger decoupling needs. Film capacitors can provide precision in filtering applications that require stable capacitance and low loss. - Decoupling Applications

Decoupling capacitors minimize noise on power rails. Ceramic capacitors are commonly used due to their low ESL and ability to provide a low impedance path for high-frequency noise. Strategically placed near the IC's power pins, these capacitors act as a local energy reservoir, reducing voltage dips. For bulk decoupling requirements, consider using electrolytic capacitors in parallel with smaller ceramic capacitors to handle a wider spectrum of noise. - Timing Circuits

In timing circuits, choose capacitors with stable capacitance over temperature and voltage. Film capacitors are excellent for timing applications due to their stability and precision. Ceramic capacitors with stable dielectrics like NP0/C0G are also suitable for accurate timing, especially when higher frequencies are involved. Avoid electrolytic capacitors, as they are not precise enough for timing applications. - Energy Storage

Electrolytic capacitors, both aluminum and tantalum, are preferred for energy storage applications due to their high capacitance values. Aluminum electrolytic capacitors are more cost-effective for larger energy storage needs, while tantalum capacitors can offer higher reliability and performance in smaller packages. Consider the ESR for energy storage applications, which can impact charge/discharge performance.

When browsing Mouser’s extensive catalog, filter based on these characteristics. For example, when selecting a capacitor for high-frequency filtering, select ceramic capacitors with suitable voltage and temperature ratings and a suitable case size. When needing large capacitance for energy storage, electrolytic capacitors with a higher capacitance value will be necessary. This targeted approach, utilizing Mouser’s filtering options, ensures efficient component sourcing and optimal circuit performance.

Navigating Mouser's Catalog: Tips for Efficient Capacitor Sourcing

Effectively utilizing Mouser's extensive online catalog is crucial for sourcing the precise capacitors required for your projects. This section provides a step-by-step guide and tips to navigate Mouser's website, ensuring efficient identification and procurement of components.

To maximize efficiency, the following steps should be considered:

- Start with a Specific Search Term

Begin your search with the most specific term possible. For instance, instead of just 'capacitor,' try 'ceramic capacitor 10uF 0805' to narrow down the results immediately. - Utilize the Parametric Search Filters

Mouser's parametric search filters are essential for refining your search. Key parameters to filter by include capacitance, voltage rating, dielectric material, tolerance, operating temperature range, case size/package, and manufacturer. Employ these filters to accurately target your desired specifications. - Explore the 'Category' Filtering Options

Use the 'Category' filters on the left navigation bar to select capacitor-specific subcategories such as ceramic, electrolytic, tantalum, or film. This reduces irrelevant listings. - Check the 'In Stock' Filter

Ensure to select the 'In Stock' filter to view only currently available parts, saving time and avoiding potential backorders. - Leverage the Manufacturer Filter

If you have a preferred manufacturer for reliability or compatibility, utilize the manufacturer filter to prioritize their components. Mouser provides options for filtering by many different manufacturers. - Use the 'Packaging' Filter

Filter by packaging type (e.g., tape and reel, cut tape, bulk) to match your production process and needs. This filter will be helpful if you have automated assembly needs. - Compare Product Specifications

Carefully compare the specifications of the selected components from the results, with specific attention to the datasheets and datasheets provided by the manufacturer. It is important to compare multiple products before making your selection. - Utilize Mouser's 'My Project' Feature

Save preferred parts to the 'My Project' feature for quick access during future orders, or to share the component list with team members. This ensures consistency in component selection across projects. - Take Advantage of Mouser's 'Compare' Function

Mouser's 'Compare' function enables side-by-side comparisons of part numbers allowing you to compare different parts based on their specs, packaging, datasheets, and more.

Frequently Asked Questions About Mouser Capacitors

This section addresses common questions about selecting and using capacitors, particularly those available from Mouser Electronics. These insights are based on industry standards and expert knowledge, aiming to provide clear guidance for your component selection process.

- Which capacitor manufacturer is best?

There isn't a single 'best' capacitor manufacturer, as quality and suitability depend heavily on the specific application and required performance parameters. Reputable manufacturers like Murata, TDK, AVX, and KEMET are known for producing reliable components. The choice should be based on the specific capacitor type, performance specifications, and the manufacturer's reputation for quality and consistency within that product line. It's important to review datasheets and compare specifications before making a choice. - What are the most reliable types of capacitors?

Reliability varies significantly by capacitor type. Generally, ceramic capacitors are highly reliable for general-purpose applications due to their stability and low failure rates. Tantalum capacitors offer excellent reliability with higher capacitance values, but they can be sensitive to voltage spikes. Film capacitors excel in precision applications with high reliability and stability. Electrolytic capacitors, while offering the highest capacitance, have a shorter lifespan and are more prone to degradation over time, with aluminum electrolytics being less reliable than tantalum. The optimal choice for reliability hinges on the operating conditions and expected life of the circuit. - What is a CBB61 capacitor used for?

A CBB61 capacitor is a type of metallized polypropylene film capacitor commonly used in AC motor applications. These capacitors are designed for starting or running single-phase AC motors, such as those found in fans, pumps, and air conditioners. They provide the necessary phase shift to initiate and maintain motor rotation. They are valued for their good electrical performance and high reliability for such applications. - Which capacitors last the longest?

The lifespan of a capacitor is influenced by factors like temperature, voltage, and operating frequency. Film capacitors generally have the longest lifespan, as they are less susceptible to degradation over time. Ceramic capacitors also have a long life expectancy, particularly when operated within their rated parameters. Electrolytic capacitors, especially aluminum types, have the shortest lifespan due to the drying of their electrolyte, which degrades their performance over time. Tantalum capacitors offer a longer lifespan than aluminum electrolytics but can be affected by overvoltage conditions. Always operating capacitors within their specification and temperature limits will help ensure a longer lifespan. - How do I choose the right capacitor for my specific application?

Selecting the right capacitor requires careful consideration of your application's demands. Start by identifying the required capacitance value, voltage rating, and operating temperature range. Consider the circuit's frequency response and stability needs. For high-frequency decoupling, ceramic capacitors are often preferred. For bulk energy storage, electrolytic capacitors are more suitable. For precision timing or audio circuits, film capacitors are a good choice. Always refer to datasheets to ensure that the chosen capacitor meets the specific requirements of your design. - What does ESR mean in relation to capacitors?

ESR, or Equivalent Series Resistance, is a crucial parameter for capacitors, indicating the internal resistance of a capacitor, particularly at higher frequencies. Lower ESR values translate to higher efficiency and reduced heat generation, which is important in applications such as power supply filtering or decoupling, where low impedance is required. Electrolytic capacitors, due to their internal structure, tend to have higher ESR than ceramic or film capacitors. Choosing capacitors with an appropriate ESR for your application is essential for efficient circuit operation. - How do temperature and voltage affect capacitor performance?

Temperature and voltage play critical roles in capacitor performance. Capacitance values can change with temperature, a phenomenon defined by the temperature coefficient of the capacitor. High temperatures can shorten the lifespan of electrolytic capacitors. Voltage affects the performance of all capacitor types, and exceeding the rated voltage can lead to damage or premature failure. Derating the voltage and operating temperature is important to ensure reliable capacitor performance over time. Always consult the capacitor datasheet for specific temperature and voltage coefficients and guidelines.

Mouser Capacitors: A Practical Comparison Table

Selecting the right capacitor for a project hinges on a clear understanding of each type's characteristics. This comparative table of Mouser capacitors provides a concise overview, enabling engineers and hobbyists to quickly identify the optimal component based on application needs.

| Capacitor Type | Pros | Cons | Recommended Applications |

|---|---|---|---|

| Ceramic | Small size, high frequency response, low cost, non-polarized | Limited capacitance, capacitance changes with voltage and temperature | High frequency decoupling, filtering, bypass applications, resonant circuits |

| Electrolytic (Aluminum) | High capacitance, relatively low cost, widely available | Lower frequency operation, polarity sensitive, higher equivalent series resistance (ESR), limited lifespan | Power supplies, bulk energy storage, low frequency filtering |

| Electrolytic (Tantalum) | High capacitance, stable performance, compact size, more robust than aluminum electrolytic | Higher cost, limited voltage, can fail catastrophically if overstressed, polarity sensitive | High-performance filtering, bypass capacitor in critical and harsh environments |

| Film | High precision, stable performance, low loss, high voltage capability | Larger size, higher cost, temperature limitation | Precision timing, audio circuits, high frequency, high voltage applications, protection circuits |

Choosing the right capacitor is critical for the success of any electronic project. This guide has provided a comprehensive overview of Mouser capacitors, from understanding the basic types to navigating the Mouser catalog, emphasizing the importance of selecting components with the appropriate parameters for different applications. By understanding these fundamentals, you are better equipped to confidently choose from Mouser's vast selection and ensure the reliability and optimal performance of your next electronic design. Remember to leverage Mouser's vast resources and diverse capacitor options to push the boundaries of your projects and innovate without constraint, keeping an eye on the ever-evolving technology landscape. With Mouser capacitors you are well-equipped for your next design.

AnyPCBA

AnyPCBA