Understanding DC Components: A Comprehensive Guide

Just as our bodies rely on a network of blood vessels, modern electronics depend on a network of direct current (DC) components. These components, unseen yet essential, power everything from our smartphones to electric vehicles, playing a critical role in the digital world. This article aims to demystify DC components, explaining their function and applications, helping you understand the fundamental building blocks of modern electrical systems.

What are DC Components?

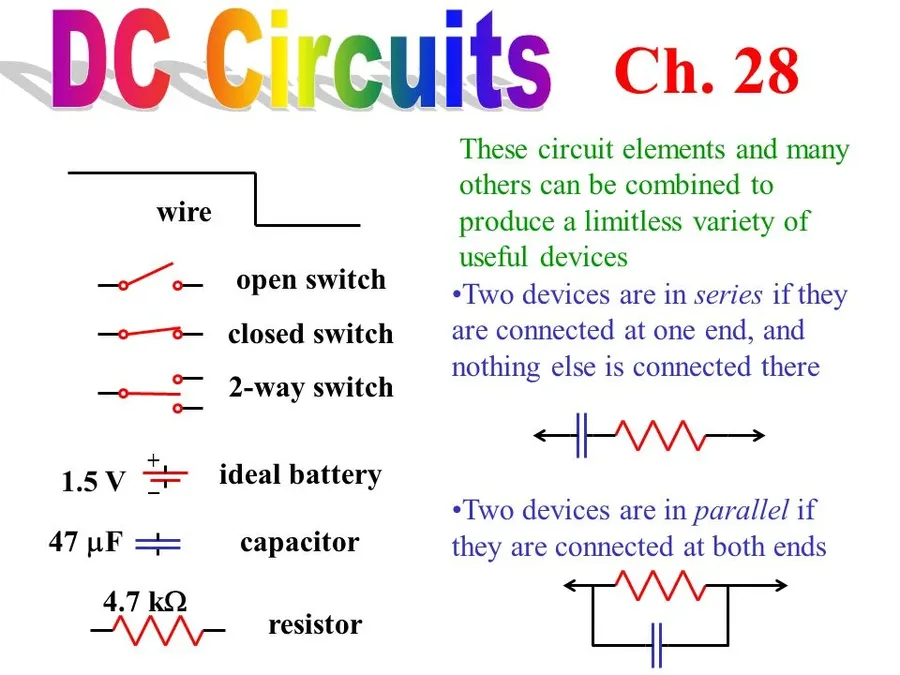

DC components, at their core, are the fundamental building blocks within electrical circuits that operate using direct current (DC). Unlike alternating current (AC) where the flow of charge periodically changes direction, direct current maintains a constant, unidirectional flow. This steady characteristic of DC makes its components essential for powering and controlling various electronic devices and systems, from basic gadgets to sophisticated industrial equipment. Understanding the behavior and applications of DC components is crucial for the design and functionality of modern electronic systems.

Key Types of DC Components

DC (Direct Current) circuits rely on a variety of essential components, each playing a crucial role in controlling and directing electrical energy. These components, while also found in AC circuits, exhibit unique behaviors and functions when operating under direct current. Understanding their individual characteristics is key to designing, troubleshooting, and maintaining effective DC systems.

| Component | Function in DC Circuits | Key Characteristics | Typical Applications |

|---|---|---|---|

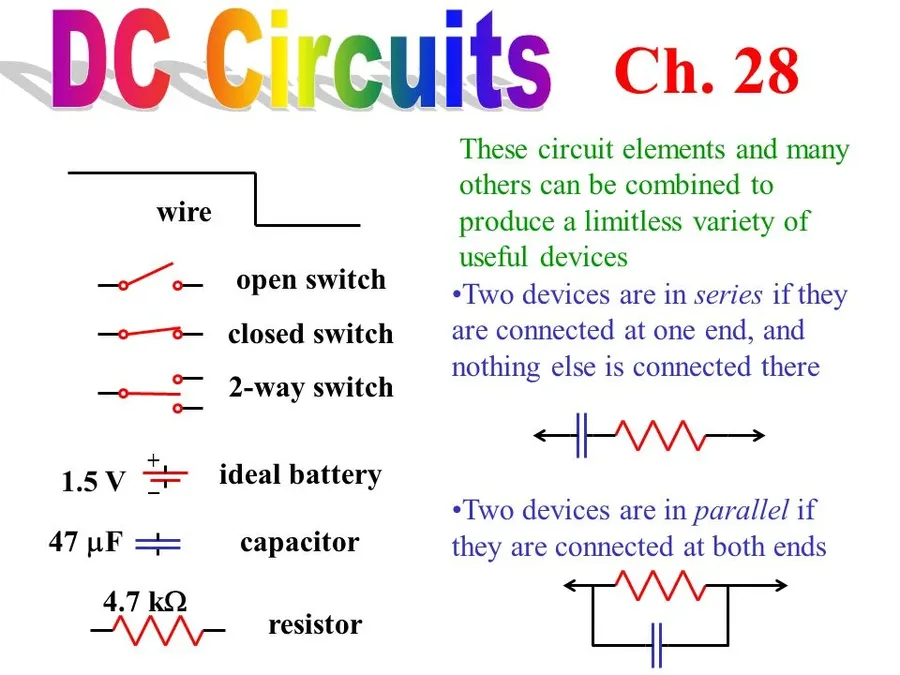

| Diodes | Control current direction | One-way current flow, forward voltage drop | Rectification, signal demodulation, overvoltage protection |

| Rectifiers | Convert AC to DC | Bridge rectifier, full-wave rectifier, half-wave rectifier | Power supplies, battery charging, inverters |

| Transistors | Amplify or switch electronic signals and electrical power | NPN/PNP BJT, MOSFET, JFET | Amplification, switching, voltage regulation |

| Capacitors | Store electrical energy | Capacitance value, voltage rating, ESR | Filtering, energy storage, decoupling |

| Inductors | Store energy in a magnetic field | Inductance value, current rating, resistance | Filtering, energy storage, DC-DC converters |

Diodes: The One-Way Traffic Controller

Diodes are fundamental semiconductor devices in DC circuits, acting as electrical one-way valves by allowing current to flow predominantly in a single direction, from anode to cathode, thereby controlling current direction and enabling voltage regulation. Their behavior is based on the physics of semiconductor materials, creating a potential barrier that restricts current flow in the reverse direction.

Key diode types include:

- Rectifier Diodes

These are designed to convert AC power to DC power by allowing current to pass in one direction only and blocking it in the reverse. They are essential for power supplies. - Zener Diodes

These diodes are engineered to operate in reverse bias, maintaining a constant voltage. They're used in voltage regulation circuits and protection applications. - Safety Diodes

These are typically fast-switching diodes designed to protect circuits from overvoltage or reverse polarity conditions. They ensure equipment safety and integrity.

The significance of diodes in DC circuits is multifaceted:

- Current Direction Control

Diodes enforce a specific direction of current flow, preventing backflow and ensuring correct circuit operation. - Voltage Regulation

Zener diodes provide stable reference voltages that are vital for electronic devices. - Circuit Protection

Safety diodes protect sensitive components from damage due to voltage spikes, reverse polarity or other transient events.

Rectifiers: Converting AC to DC Power

Rectifiers are fundamental components in DC power systems, serving as the crucial bridge in converting alternating current (AC) to direct current (DC). This conversion is essential because most electronic devices operate on DC power, while AC is the standard for power distribution. Rectifiers enable this transformation, providing the necessary DC power for a wide array of applications.

The operation of a rectifier involves using diodes to restrict current flow to one direction. AC power is characterized by its alternating polarity and is represented by a sinusoidal waveform. Rectifiers, through a process called rectification, manipulate this AC input by blocking the negative portion of the cycle. The output of a simple rectifier is a pulsating DC, which, while moving in one direction, still varies over time. More sophisticated rectifier circuits, however, can further smoothen this pulsating DC to provide a more stable DC output.

| Rectifier Type | Description | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Half-Wave Rectifier | Uses a single diode to block one half of the AC waveform, resulting in a pulsed DC output. | Low-power applications, battery chargers | Simple circuit design | Low efficiency, high ripple |

| Full-Wave Rectifier | Uses four diodes arranged in a bridge configuration to convert both halves of the AC waveform into a pulsed DC output. | Power supplies, electronic devices | Higher efficiency compared to half-wave | More complex circuit |

| Bridge Rectifier | A specific type of full-wave rectifier using a bridge configuration of diodes. | Most power supplies, industrial equipment | High efficiency, low ripple | Requires four diodes |

It's important to note that the output of rectifiers is often not a perfectly smooth DC signal. It usually contains some ripple, which refers to the residual AC component remaining after rectification. To mitigate this, smoothing capacitors are typically used in conjunction with rectifiers to produce a more stable and usable DC voltage. This combination of rectifiers and capacitors is at the heart of most DC power supply circuits.

DC Contactors and Relays: Controlling High Power

DC contactors and relays are essential electromechanical devices used to control high-power DC circuits. They act as switches, enabling or interrupting the flow of current, but unlike simple switches, they are often remotely controlled and can handle significantly higher currents and voltages. These devices are crucial in various applications, especially where manual switching is impractical or unsafe.

Key differences exist between contactors and relays. Contactors are generally designed for high-power switching applications, often involving multiple contacts capable of handling large currents, such as those found in industrial machinery or automotive systems. Relays, on the other hand, are typically used for lower power control applications, often acting as an interface between low-power control circuits and higher-power driven circuits. They utilize an electromagnetic coil to mechanically actuate a switch, enabling electrical isolation between the control and the load circuits.

| Feature | DC Contactor | DC Relay |

|---|---|---|

| Typical Current Handling | High (tens to hundreds of amps) | Low to moderate (milliamps to a few amps) |

| Application | High power circuits, industrial, automotive | Control circuits, signal switching, interfacing |

| Number of Contacts | Often multiple poles, designed for main circuit switching | Usually fewer poles, mainly for signal or low-power control |

| Physical Size | Larger, robust build | Smaller, more compact |

| Operating Voltage | Can handle higher voltage systems | Suitable for lower voltage control |

In automotive systems, DC contactors play a crucial role in managing power in electric vehicles and hybrid systems. They are used for battery pack management, controlling the power flow to the traction motor, and engaging auxiliary systems. Similarly, relays are used extensively for controlling various low-power functions, such as lighting, indicators, and other electronic control units. These components ensure that power is delivered effectively and safely within the complex automotive electrical systems.

DC Disconnect Switches: Ensuring Safety in DC Systems

DC disconnect switches are critical safety components within direct current (DC) electrical systems, designed to provide a reliable means of isolating circuits and equipment. Their primary function is to interrupt the flow of DC current, enabling safe maintenance, repair, or emergency shutdown procedures, thereby minimizing the risk of electrical hazards.

Unlike AC systems, DC current does not naturally pass through zero, which makes interrupting it much more difficult. Thus, DC disconnect switches are specifically designed to handle the unique challenges of DC arcing and high DC voltage. These switches play a pivotal role in preventing electrical accidents and damage to equipment.

Here’s a breakdown of key considerations for DC disconnect switches:

- Arc Suppression

DC disconnect switches incorporate mechanisms to mitigate the formation and propagation of electrical arcs, which are more pronounced in DC circuits due to the continuous current flow. Arc chutes, magnetic blowouts, and other arc-quenching techniques are employed to extinguish the arc rapidly and safely. - Voltage and Current Ratings

Switches must be selected based on the operating voltage and current of the DC circuit, ensuring that they can interrupt the full load current without damage or failure. It is crucial to match the switch's specifications to the maximum voltage and current in the system to ensure proper and safe operation. - Construction Materials

The materials used in the switch construction must withstand the electrical and environmental conditions of their application, which may include high temperatures, humidity, or corrosive agents. Insulating materials must resist arc tracking and offer adequate electrical isolation. - Operational Mechanisms

Switches are available with different operational mechanisms, including manual levers, motorized actuators, and remote-controlled options, depending on the needs and complexity of the system. The operational mechanism should allow for reliable and repeatable switching.

The correct installation and maintenance of DC disconnect switches are crucial for the overall safety and reliability of any DC power system. Regular inspections and maintenance should be part of any site safety plan to ensure correct operation in both normal and emergency situations.

| Feature | Description | Importance |

|---|---|---|

| Purpose | Isolating DC circuits for safety | Prevents electrical hazards during maintenance and emergencies |

| Arc Suppression | Mechanisms to extinguish electrical arcs | Ensures safe interruption of DC current |

| Voltage & Current Ratings | Matched to system's electrical load | Avoids switch damage and failures during operation |

| Construction Materials | Durable, resistant to conditions | Guarantees reliable performance in various conditions |

| Operational Mechanisms | Manual, motorized or remote options | Suitable for different system needs and control requirements |

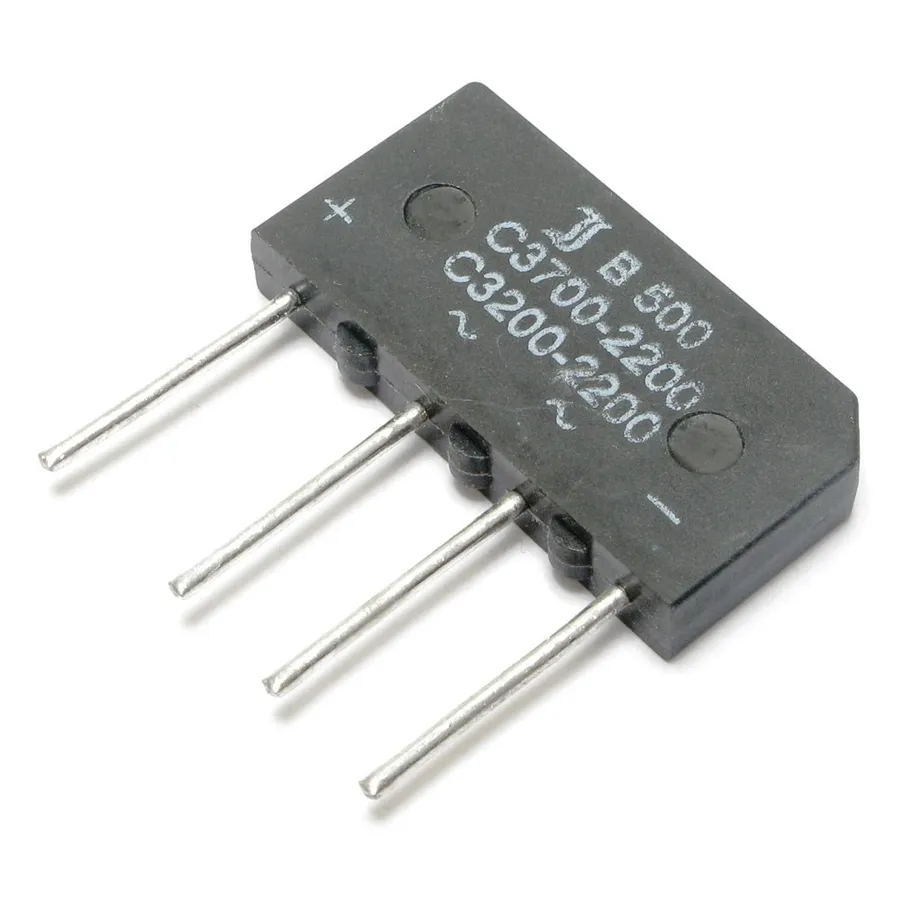

DC Components in a PV System

Photovoltaic (PV) systems, which convert sunlight into electricity, rely heavily on various DC components to function effectively. These components are crucial for the safe and efficient generation and transmission of solar power. Understanding the role of each component is essential for designing, installing, and maintaining a robust PV system.

| Component | Function | Importance |

|---|---|---|

| PV Modules (Solar Panels) | Generate DC electricity when exposed to sunlight. | Primary energy source of the PV system; their efficiency determines the system's output. |

| DC Connectors | Facilitate the connection between solar panels and other components. | Provide secure, reliable, and weatherproof connections, minimizing power loss and potential hazards. |

| DC Fuses | Protect the system from overcurrents and short circuits. | Safeguard components from damage due to electrical faults, enhancing the system's longevity and safety. |

| DC Cabling | Transmit DC power from panels to the inverter or charge controller. | Carries generated power, must be sized correctly to avoid voltage drops, heat generation and be rated for the environment. |

| Combiner Boxes | Combine the outputs of multiple strings of PV modules into fewer circuits. | Simplify wiring, improve system organization, and provide a central point for disconnects and overcurrent protection. |

| DC Disconnect Switches | Allow manual isolation of DC components for maintenance and emergency situations. | Enable safe access for maintenance or repairs and protect personnel during potential hazardous conditions |

The health and proper functioning of these DC components are vital for the overall efficiency and longevity of a PV system. Any degradation or failure in these components can lead to reduced power output, system downtime, and potential safety hazards.

Frequently Asked Questions About DC Components

This section addresses common inquiries about DC components, providing clear and concise answers to enhance understanding of their role in electrical and electronic systems. These FAQs aim to clarify fundamental concepts and practical applications of DC components.

- What exactly are DC components?

DC components refer to elements within an electrical circuit that operate with direct current (DC). Unlike alternating current (AC), which periodically reverses direction, DC flows consistently in one direction. These components are designed to manage, regulate, or utilize this unidirectional current flow. Examples include resistors, capacitors, diodes, and transistors within DC circuits. - What are the key components of a typical DC power system?

A DC power system typically comprises several essential components including a power source (such as a battery or rectifier), conductors (wires and cables), protective devices (fuses and circuit breakers), control elements (switches and relays), and load devices (resistors, motors, or electronic circuits). The power source provides the DC electrical energy, while other components facilitate its efficient distribution and utilization. - What is the fundamental difference between AC and DC components?

The primary difference lies in the nature of the current flow. AC components deal with alternating current, which periodically changes direction, while DC components manage direct current that flows consistently in one direction. This distinction affects how components are designed and the circuits they operate in. For example, transformers and inductors are vital in AC systems but serve different roles in DC circuits. - How is a DC component value typically calculated?

The method for calculating DC component values depends on the type of component. For a resistor, Ohm's law (V=IR) is used to find the relationship between voltage, current, and resistance. Capacitance values are determined by their physical construction and the dielectric material between their plates. Inductors' values are based on their physical parameters and core material. Measurements are often used to verify these calculations in practice. - What role do capacitors play in DC circuits?

In DC circuits, capacitors primarily act as energy storage devices, accumulating charge when voltage is applied and releasing it when the circuit demands it. They also serve a critical role in filtering out noise or unwanted voltage fluctuations. In essence, capacitors help to stabilize and smooth the DC voltage within the circuit, preventing sudden changes in current. - Why are diodes considered essential DC components?

Diodes are crucial in DC circuits due to their ability to allow current to flow in only one direction. This one-way functionality is vital for rectifying AC power into DC power, protecting circuits from reverse polarity damage, and directing the flow of current within complex electronic assemblies. Diodes are essential in various applications, from power conversion to signal rectification. - How are DC components tested for faults?

Testing DC components for faults involves specific methods based on the type of component. Resistors are checked for their resistance value using a multimeter. Capacitors are tested for capacitance and leakage. Diodes are tested for forward voltage drop and reverse leakage. Transistors are assessed for their gain and operation. Proper fault diagnosis typically involves a multimeter, and sometimes more specialized test equipment like an oscilloscope to observe waveform anomalies.

Applications of DC Components Across Industries

DC components are fundamental to a diverse array of industries, underpinning the operation of countless devices and systems. Their unique ability to provide stable, unidirectional current makes them indispensable in sectors ranging from consumer electronics to large-scale industrial applications.

Let's examine specific applications across several key sectors:

- Electronics Manufacturing

DC components such as diodes, transistors, and capacitors are the building blocks of integrated circuits (ICs) and printed circuit boards (PCBs). These components regulate voltage and current within electronic devices, ensuring stable and efficient operation. From smartphones to complex medical equipment, DC components are integral to their function. - Automotive Industry

Modern vehicles rely heavily on DC systems for various functions. DC components power the engine control unit (ECU), lighting systems, infotainment systems, and safety features. Electric vehicles (EVs) and hybrid electric vehicles (HEVs) especially depend on DC systems for battery management, power delivery to the motor, and overall vehicle control. DC-DC converters are critical for efficient power management. DC contactors and relays are also used in automotive systems to control high-power circuits. - Telecommunications

DC power is essential for telecommunications infrastructure, including base stations, switches, and network equipment. Rectifiers convert AC power from the grid to the DC required for these systems to function reliably. Additionally, many portable devices such as cell phones, GPS devices and satellite communications heavily rely on DC power for operation. - Renewable Energy

In solar photovoltaic (PV) systems, DC components are crucial. Solar panels generate DC power, which then passes through DC cabling, fuses, and combiner boxes before being converted to AC for grid use or storage. DC disconnect switches are critical to the safety of the entire system. Efficient management of DC power is necessary to optimize the performance of a renewable energy system. - Industrial Applications

DC components are found in numerous industrial applications, including motor drives, power supplies for automation equipment, and control systems in manufacturing plants. In industrial environments, robust and reliable DC components are needed to maintain high productivity, from power distribution to precision control. - Aerospace Industry

Aerospace systems require lightweight, reliable, and high-performance DC components for flight control systems, communications, and various other systems. DC power supplies are critical for powering equipment, from navigation systems to passenger comforts and life support systems. - Medical Devices

Medical devices, including imaging equipment, patient monitoring systems, and life-support machines, rely heavily on stable DC power supplies. DC components within these devices must meet stringent reliability and safety requirements. The precision of DC power delivery is fundamental to the accuracy of diagnostic results and reliability of treatment.

Understanding DC components is fundamental to comprehending modern electronics and electrical systems. From simple diodes controlling current to sophisticated contactors managing high-power applications, each component plays a vital role in our technology-driven world. As technology advances, DC components will continue to form the foundation of innovation across various industries, enabling both the everyday devices and cutting-edge technologies we depend on. This article has equipped you with a foundational knowledge of their core function and applications.

AnyPCBA

AnyPCBA