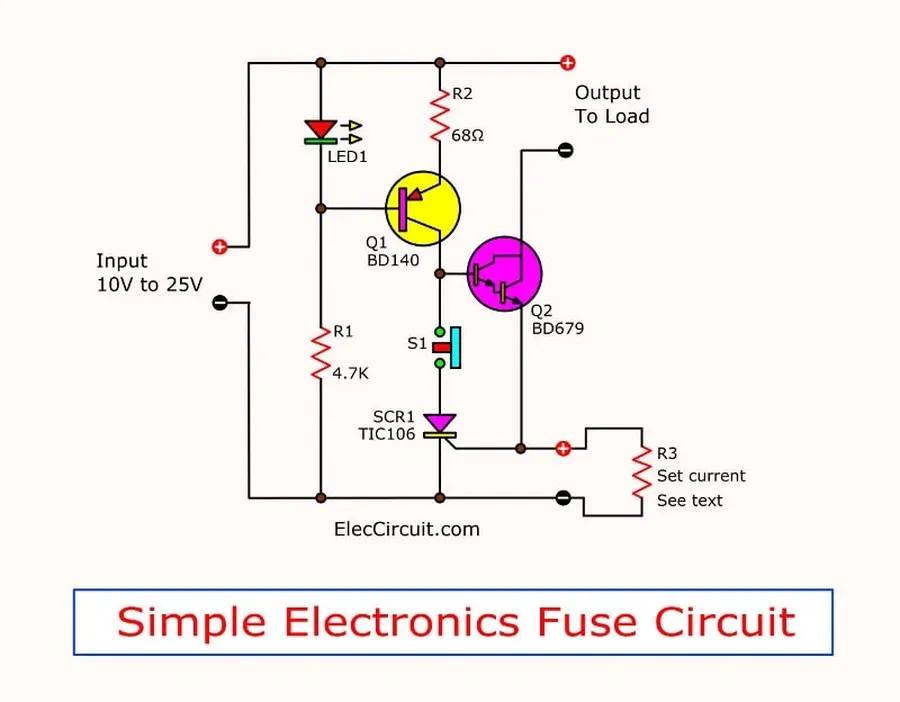

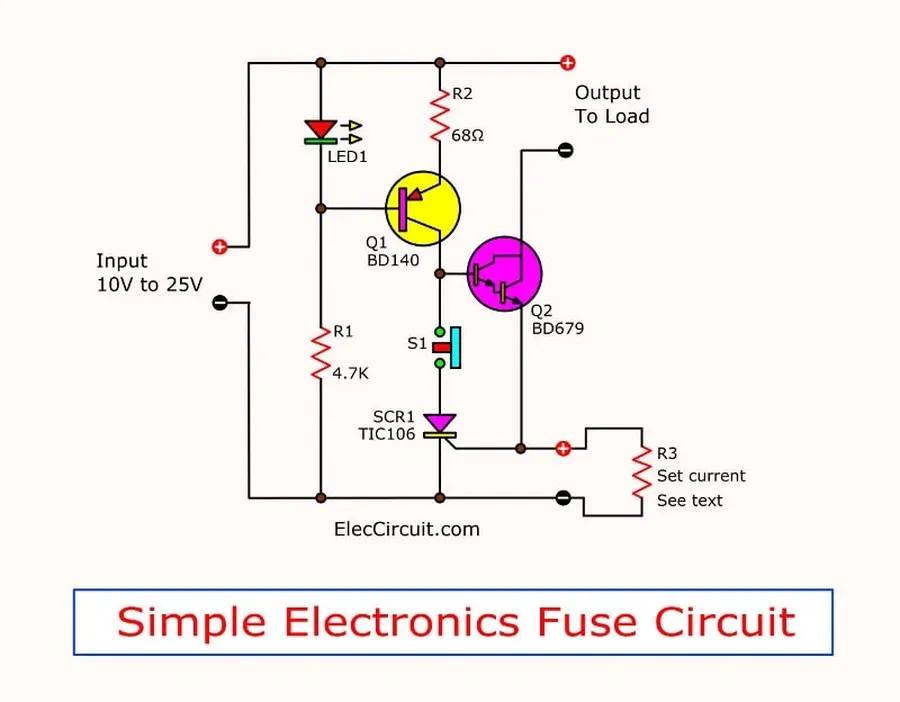

Understanding Fuse Electronics: Safety, Types, and Applications

In our electrically powered world, fuse electronics play a critical, yet often unseen role, safeguarding our devices and homes. From the simplest light bulb to complex machinery, a fuse is a silent guardian against overcurrent, preventing damage, and even fire. This article will shed light on the science, types, and importance of fuse electronics.

What are Fuse Electronics?

Fuse electronics are fundamental safety devices in electrical circuits, acting as sacrificial components designed to protect against overcurrent conditions. They are essentially a weak link intentionally placed in a circuit, designed to fail and interrupt the flow of electricity when the current exceeds a specified level, thereby preventing damage to more expensive and critical downstream components. This protective action is a cornerstone of electrical safety and circuit integrity.

At their core, fuses are comprised of a conductive element (typically a wire or a strip of metal) with a low melting point, encapsulated within a non-conductive housing. When an excessive current flows through this element, the resultant heat melts the element, creating an open circuit and halting the current flow. The speed at which a fuse breaks the circuit can vary significantly depending on design characteristics to suit specific application needs. The selection and correct application of fuse electronics are critical in preventing electrical fires, equipment damage, and potential harm to personnel.

The Science Behind Fuses: How They Work

Fuses operate on a simple yet crucial principle: the controlled melting of a conductive element, known as the fuse wire, to interrupt an electrical circuit when an overcurrent condition arises. This fundamental mechanism is the cornerstone of circuit protection, preventing damage to sensitive electronic components and potentially hazardous situations.

At the heart of a fuse lies the fuse wire, a metallic conductor specifically designed with a low melting point. This wire is typically composed of materials like tin, copper, or alloys with carefully selected electrical and thermal properties. The wire’s low resistance allows it to conduct normal operating currents without significant heating. However, when the current exceeds the fuse's rated capacity, the wire’s resistance causes it to heat rapidly due to the increased energy dissipation (Joule heating). This rapid increase in temperature leads to the wire melting and breaking the conductive path, thereby interrupting the flow of electricity and protecting the circuit it safeguards. This process occurs in a fraction of a second, limiting the potential for damage to the circuit. This process is fundamentally governed by Joule's first law: Q = I²Rt, where Q is the heat generated, I is the current, R is the resistance of the fuse wire, and t is time. The fuse is selected to melt before components in the protected circuit are damaged.

| Parameter | Description |

|---|---|

| Fuse Wire | A low-resistance metallic conductor designed to melt when overcurrent occurs. |

| Low Resistance | Allows normal current flow with minimal heating; however, leads to rapid heating with overcurrent. |

| Melting Point | A specific temperature point where the fuse wire melts to interrupt the circuit. |

| Joule Heating | The phenomenon of heat generation in the fuse wire due to the passage of electric current, governed by the equation Q=I²Rt. |

Types of Fuses in Electronics

Fuses are not a one-size-fits-all component; various types exist, each designed to protect circuits under specific conditions. This section provides a detailed overview of these fuse types, focusing on their operational characteristics and typical applications. Understanding these distinctions is crucial for selecting the appropriate fuse for effective circuit protection.

| Fuse Type | Operating Characteristic | Application Examples |

|---|---|---|

| Fast-Acting Fuses | React quickly to overcurrents, providing rapid protection. | Sensitive electronic circuits, semiconductor protection, measurement instruments |

| Slow-Blow (Time-Delay) Fuses | Tolerate brief surges or inrush currents before blowing, preventing nuisance tripping. | Motor circuits, power supplies, inductive loads |

| Ceramic Fuses | Resistant to high temperatures, ideal for higher power applications. | High-power equipment, industrial machinery |

| Glass Fuses | Allow visual inspection of the fuse element, generally for lower power applications. | Consumer electronics, small appliances |

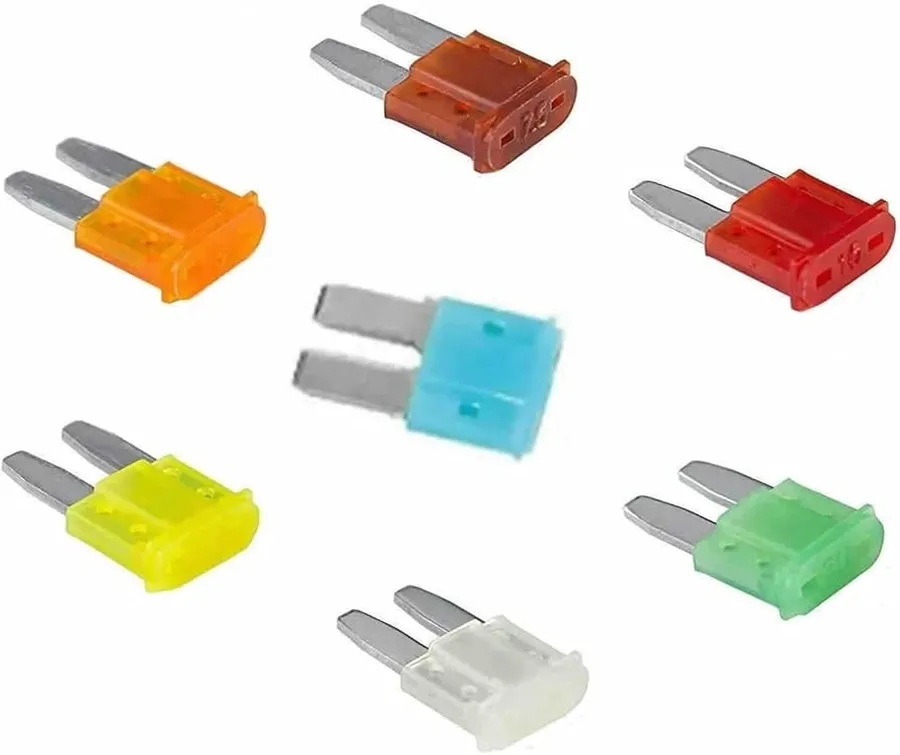

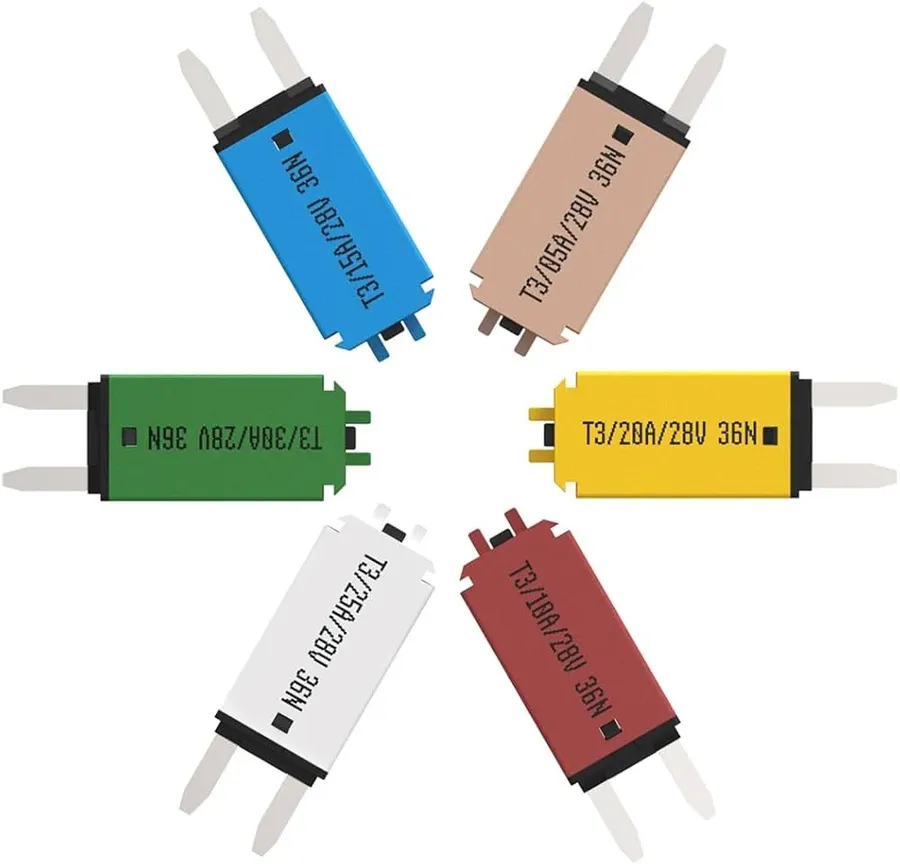

| Automotive Fuses | Designed for the specific conditions of automotive systems, various form factors. | Automobiles, motorcycles, other vehicles |

| Surface Mount Fuses (SMD) | Designed for surface mounting on PCBs, saving space and simplifying assembly. | Portable electronics, compact devices, mobile phones |

| Resettable Fuses (PTC) | Resets automatically after the fault is removed. | Battery protection, computer peripherals, consumer electronics |

Fuse Specifications: Voltage, Current, and Size

Selecting the correct fuse involves understanding its critical specifications: voltage rating, current rating, and physical size. These parameters ensure the fuse operates safely within a circuit, providing overcurrent protection without becoming a hazard itself. Incorrect specification can lead to either nuisance tripping (opening the circuit unnecessarily) or, more dangerously, failure to protect the circuit during an overcurrent event.

| Specification | Description | Importance |

|---|---|---|

| Voltage Rating | The maximum voltage a fuse can handle without failing or arcing. | Must be equal to or greater than the circuit's voltage to prevent insulation breakdown. |

| Current Rating | The maximum current the fuse can carry continuously without melting. | Determines when the fuse will blow, protecting circuit from overcurrent. |

| Physical Size | The physical dimensions of the fuse, including length and diameter. | Must match the fuse holder or socket in the circuit. |

| Breaking Capacity | The maximum current the fuse can safely interrupt. | Must be higher than the potential fault current in the circuit to prevent fire. |

Fuse holders and sockets are essential components in any circuit using fuses, ensuring proper electrical contact and secure placement of the fuse. These holders come in diverse designs to accommodate various fuse sizes and mounting needs. It's crucial that the holder’s specifications, such as voltage and current ratings, align with the fuse being used to maintain circuit safety.

Fuse Applications Across Industries

Fuse electronics are indispensable components across a wide spectrum of industries, serving as critical overcurrent protection devices. Their role is paramount in safeguarding electrical and electronic systems from damage caused by excessive current, ensuring operational safety and reliability in diverse applications. This section outlines the widespread use of fuses in several key sectors.

- Power Distribution

In power distribution systems, fuses are vital at various levels, from substations to individual circuit breakers in homes. They protect against overloads and short circuits, preventing catastrophic failures and ensuring a stable power supply. - Home Appliances

Fuses are incorporated into a vast range of household appliances, including refrigerators, microwaves, washing machines, and televisions. These fuses are specifically designed to protect the appliance's internal circuitry, preventing damage from power surges or faults that could lead to fire hazards. - Computers and Electronics

In computers and electronic devices, fuses provide vital protection for sensitive electronic components. They shield circuits from overcurrent conditions that can result from faulty power supplies or device malfunctions, thereby safeguarding expensive hardware. - Automotive Industry

Fuses play a crucial role in automotive electrical systems. They protect various car circuits, including headlights, brake lights, power windows, and engine control units, preventing damage from electrical faults and ensuring the proper functioning of vehicle safety systems and other electrical components. - Industrial Machinery

Industrial machinery relies heavily on fuses for safeguarding complex systems. These fuses are used in motor control circuits, power supplies for industrial robots, and other automated equipment, ensuring the safe operation and longevity of expensive industrial machinery.

Frequently Asked Questions About Fuse Electronics

This section addresses common inquiries regarding fuse electronics, providing clear, concise answers to enhance understanding of these critical safety devices.

- What exactly is a fuse in electronics?

A fuse is an overcurrent protection device used in electrical and electronic circuits. It contains a thin wire or a metal strip designed to melt and break the circuit when the current exceeds a predetermined level, thus protecting downstream components from damage. This sacrificial element prevents damage to the more expensive components in a circuit. - What is the primary function of a fuse?

The core function of a fuse is to protect electrical and electronic circuits from overcurrents, which can be caused by short circuits, overloads, or component failures. By interrupting the circuit when a fault occurs, it prevents fires, equipment damage, and potential harm to users. - How does a fuse differ from a circuit breaker?

While both fuses and circuit breakers protect against overcurrents, they operate differently. A fuse is a one-time use device that needs replacement after it 'blows', whereas a circuit breaker is a reusable, electro-mechanical device that trips and can be reset. Circuit breakers are generally more expensive but offer convenience. Fuses are typically simpler and more reliable for certain applications. - What is the purpose of a fuse box, and what is it commonly called now?

A fuse box, often also referred to as a 'distribution board', 'panel board', or 'circuit breaker panel' is a central location where multiple electrical circuits are protected by individual fuses or circuit breakers. Its primary purpose is to distribute power safely and provide a convenient access point for disconnecting or protecting different circuits in a building or a device. In modern contexts, 'circuit breaker panel' is becoming the standard term, with fuse box referring to older installations. - How do I choose the correct fuse for my application?

Selecting the right fuse involves considering both its voltage and current ratings. The fuse's voltage rating must be equal to or greater than the voltage of the circuit. The current rating of the fuse should be slightly above the normal operating current of the circuit. This prevents nuisance tripping while still providing protection against fault currents. It's also essential to choose the correct fuse type for the application (fast-acting, slow-blow etc). Refer to manufacturer's documentation or consult a professional electrician if in doubt. The physical size of the fuse must also be compatible with the fuse holder. - What happens when a fuse 'blows'?

When a fuse 'blows,' it means that the current flowing through it exceeded its rated current capacity. This excessive current causes the thin wire or metal strip inside the fuse to melt, creating an open circuit. The circuit is then interrupted, preventing further current from flowing, and protecting the connected components. - Can I replace a fuse with one of a different rating?

No, it is critical to replace a blown fuse with a fuse that has the exact same ratings (voltage, current, and type). Using a fuse with a lower rating may result in nuisance tripping while using a higher rating can lead to insufficient protection and potentially damage components or cause a fire. Always refer to the equipment's documentation for fuse specifications.

Advantages and Disadvantages of Using Fuses

Fuses, as fundamental components in circuit protection, offer a blend of benefits and limitations that engineers must consider when designing electrical systems. Their simplicity and reliability make them a staple, but their one-time use nature requires careful planning and consideration in applications.

| Feature | Advantages | Disadvantages |

|---|---|---|

| Cost | Cost-effective; Fuses are generally inexpensive compared to other protection devices. | One-time use. Fuses must be replaced after they blow, incurring recurring costs. |

| Reliability | Highly reliable due to simple design; Fuses provide dependable overcurrent protection when correctly sized. | Can be unreliable if improperly sized or installed, leading to nuisance tripping or failure to protect equipment. |

| Response Time | Fast-acting fuses can respond quickly to overcurrent conditions, protecting sensitive electronic components. | Slow-blow fuses may allow minor overcurrents for short periods, potentially damaging certain devices, if not properly chosen. |

| Simplicity | Simple to understand and use; Fuses require no external power source and are easy to install. | Limited function; They cannot reset themselves, requiring manual replacement. |

| Size and Space | Compact and available in various sizes, suitable for space-constrained applications. | Fuse replacement can be challenging in tightly packed circuit boards. |

| Safety | Effective in preventing equipment damage and electrical fires due to overcurrents. | Incorrect fuse selection can pose a safety hazard, such as the incorrect rating or improper installation. |

Best Practices for Fuse Electronics Handling and Replacement

Proper handling and replacement of fuse electronics are critical for ensuring the safety and reliability of electrical systems. Mishandling can lead to damage, improper function, and even safety hazards. This section provides practical guidelines to avoid common pitfalls.

- Safe Handling of Fuses

Always de-energize the circuit before handling any fuse. Use insulated tools to prevent electrical shock. Avoid touching the metallic parts of the fuse with bare hands to prevent corrosion and potential damage. Fuses should be stored in a dry, clean place away from extreme temperatures and humidity to prevent degradation of the fuse element. - Choosing the Correct Replacement Fuse

Ensure that the replacement fuse matches the original fuse's voltage, current rating and physical size to prevent damage to the electrical equipment and ensure proper circuit protection. Mismatched fuse ratings can cause either a fire hazard (if too high) or nuisance tripping (if too low). Refer to the equipment's user manual or schematics for the proper fuse specifications. - Steps for Replacing a Burnt-Out Fuse

Before replacing a fuse, always confirm that the circuit is de-energized using a voltage tester. Visually inspect the new fuse to ensure it is not damaged. Align the replacement fuse correctly in the fuse holder or socket, ensuring a secure and snug fit. Avoid forcing a fuse into a holder that does not fit properly. Ensure that the fuse is inserted completely into the fuse holder to provide reliable electrical connection and avoid hot spots caused by high resistance. After replacing the fuse, energize the circuit and test that the equipment is functioning correctly. - Preventative Maintenance for Fuses

Regularly inspect fuse holders and sockets for signs of corrosion, damage or overheating. Periodically clean fuse holders and sockets with a non-conductive cleaner to ensure good electrical connections. Maintain a record of fuse replacements, noting the reason for replacement and the date to help in troubleshooting circuit issues. Develop a schedule to inspect and replace fuses that have exceeded their rated service life and implement a preventative replacement program.

The Future of Fuse Electronics: Trends and Innovations

The field of fuse electronics is not static; it's continually evolving to meet the demands of modern technology. Innovations are focusing on enhanced functionality, increased reliability, and the integration of smart capabilities. This section explores some of the key trends shaping the future of fuse technology, including resettable and smart fuses.

- Resettable Fuses

Also known as polymeric positive temperature coefficient (PPTC) devices, these fuses do not need physical replacement after an overcurrent event. They increase their resistance dramatically when heated due to excessive current, effectively stopping the flow. Once the current returns to normal and the fuse cools, it returns to its low resistance state, allowing the circuit to function again. This reduces downtime and maintenance costs, particularly in applications where replacing a fuse may be challenging or impossible. - Smart Fuses

Smart fuses are incorporating microelectronics to provide advanced functionality, going beyond simple overcurrent protection. They can provide real-time data on the current flowing through the circuit, temperature, and other vital parameters. This data can be utilized for diagnostics, predictive maintenance, and remote monitoring, which can improve the overall efficiency and reliability of electronic systems. Smart fuses are increasingly being integrated into systems where detailed monitoring and control are critical. - Integration with IoT and Smart Systems

The trend is toward integrating fuse electronics with the Internet of Things (IoT). This integration allows fuses to communicate their status and environmental conditions, which provides a higher degree of control and enables predictive maintenance. For example, in smart grids, such real-time feedback can enhance system stability and protection against faults. - Miniaturization and Advanced Materials

Ongoing advancements in materials science are leading to smaller and more efficient fuses, making them suitable for use in compact electronics and wearables. Furthermore, new materials with improved temperature stability and higher breaking capacities are constantly being researched and incorporated into fuse designs.

Fuse electronics, though simple in appearance, are a crucial cornerstone of electrical safety. Understanding their function, types, and proper application can significantly reduce risks of electrical damage and ensure the longevity of electronic devices. As we move towards more advanced electrical systems, fuse technology will continue to evolve, adapting to new challenges and requirements, reinforcing their role as essential guardians in our tech-driven world.

AnyPCBA

AnyPCBA