Understanding MLCC Capacitors: Types, Applications & Selection

In today's ever-evolving landscape of electronic devices, the humble MLCC (multilayer ceramic chip) capacitor plays an indispensable role. From smartphones to sophisticated medical equipment, these tiny components silently facilitate energy storage and signal filtering. But what exactly are MLCC capacitors, and how do they impact our daily lives? This article will delve into the heart of MLCC technology, providing you with a comprehensive understanding of their types, applications, and selection process, drawing a connection between social and technological advancements.

What are MLCC Capacitors?

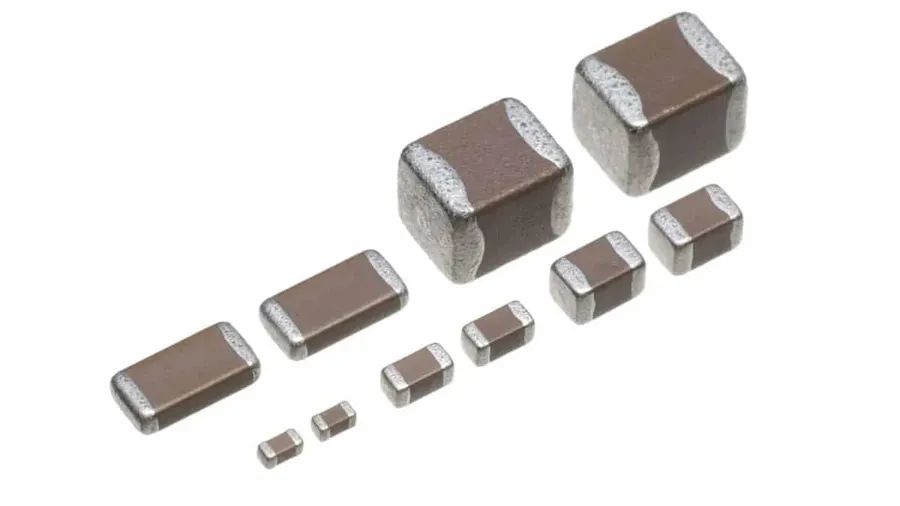

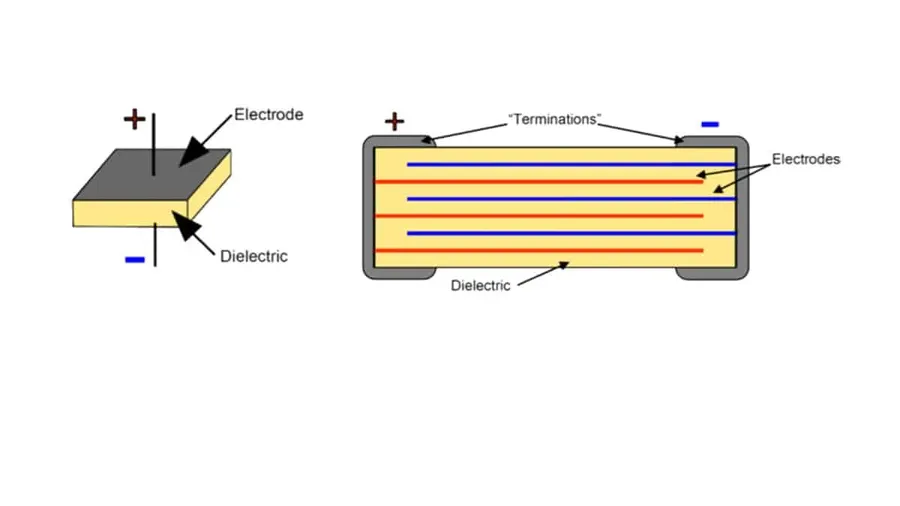

Multilayer Ceramic Capacitors (MLCCs) are a type of capacitor distinguished by their construction involving multiple layers of ceramic dielectric material interspersed with metal electrodes. This layered structure enables high capacitance values within a small physical footprint, making them ubiquitous in modern electronics. Their unique construction directly influences their performance characteristics and suitability for various applications compared to other capacitor types.

At the heart of an MLCC lies the ceramic dielectric material, typically composed of materials like barium titanate (BaTiO3) or other similar compounds. These materials exhibit high permittivity, allowing them to store a significant amount of electrical charge. The metal electrodes, commonly made of nickel or copper, are screen-printed onto the ceramic layers, and then stacked and sintered together at high temperatures, forming a monolithic structure. This results in a robust, compact component with exceptional electrical properties.

The capacitance of an MLCC is directly proportional to the number of layers, the area of the electrodes, and the dielectric constant of the ceramic material, and inversely proportional to the thickness of the dielectric layers. These factors are carefully controlled during the manufacturing process to achieve the desired capacitance value with high precision. Unlike some other capacitor types, such as electrolytic capacitors, MLCCs do not have a defined polarity, thus offering more flexibility in circuit design and orientation.

MLCCs differ significantly from other types of capacitors, such as film capacitors and electrolytic capacitors. Film capacitors use thin plastic films as the dielectric and boast high precision and stability but typically have lower capacitance values. Electrolytic capacitors, on the other hand, use an electrolyte as the dielectric, allowing for much larger capacitance values, but they are polarized, have higher equivalent series resistance (ESR), and tend to have lower life expectancy. MLCCs offer a balance, particularly excelling in miniaturization and high-frequency performance, which make them the preferred choice in most electronic designs today.

MLCC Capacitor Types and Classifications

MLCC capacitors are categorized into different classes based on their temperature coefficient, stability, and intended applications. These classifications are primarily determined by the dielectric material used in their construction. Understanding these classifications is crucial for selecting the correct MLCC for a given application. The primary classes are Class 1, Class 2, and Class 3, each exhibiting distinct electrical characteristics.

| Classification | Dielectric Material | Temperature Coefficient | Stability | Typical Applications |

|---|---|---|---|---|

| Class 1 | NP0/C0G | Near zero (very stable) | Extremely stable capacitance with temperature and voltage | High-precision circuits, timing, oscillators, resonant circuits, RF applications |

| Class 2 | X7R | Moderate (capacitance changes with temperature) | Moderate stability; capacitance changes more with temperature and voltage compared to Class 1 | General purpose applications, decoupling, bypass, filtering |

| Class 3 | Y5V | High (capacitance changes significantly with temperature) | Low stability; capacitance changes substantially with temperature and voltage | Bypass, decoupling, in non-critical applications where capacitance drift can be tolerated; often used in low-cost consumer products |

The dielectric material significantly influences the capacitor’s performance. Let's explore some of the commonly used dielectric materials.

- NP0/C0G Dielectric

Characterized by a near-zero temperature coefficient, providing extremely stable capacitance over temperature and voltage. Ideal for high-precision applications. - X7R Dielectric

Offers a moderate temperature coefficient, resulting in moderate capacitance variations with temperature and voltage. A versatile option for general applications. - Y5V Dielectric

Exhibits a high temperature coefficient, which leads to substantial capacitance changes with temperature and voltage. Suitable for less critical applications where capacitance drift is acceptable.

Key Parameters of MLCC Capacitors

Selecting the correct MLCC capacitor requires a thorough understanding of its key parameters. These parameters dictate the capacitor's performance and suitability for a given application. Critical specifications include capacitance, voltage rating, tolerance, temperature coefficient, and Equivalent Series Resistance (ESR). Each of these parameters plays a vital role in ensuring circuit stability and reliability.

| Parameter | Description | Importance |

|---|---|---|

| Capacitance | The ability of the capacitor to store an electrical charge, measured in Farads (F), often expressed as microfarads (µF) or picofarads (pF). | Determines the amount of charge stored, impacting signal filtering, timing, and energy storage. Mismatching the capacitance will lead to circuit malfunction. |

| Voltage Rating | The maximum voltage that can be safely applied across the capacitor without risking damage or failure, which should always exceed the maximum voltage in the circuit. | Ensures the capacitor can withstand operating voltages, preventing dielectric breakdown or damage. Failure to observe this causes the component to fail catastrophically. |

| Tolerance | The allowable deviation from the specified capacitance value, expressed as a percentage (e.g., ±5%, ±10%). | Indicates the precision of the capacitance. Tighter tolerances are critical for sensitive circuits, while loose tolerances are suitable for non-critical applications. |

| Temperature Coefficient | Describes how the capacitance changes with temperature, often specified in parts per million per degree Celsius (ppm/°C). | Crucial for maintaining circuit stability across different temperatures. A low temperature coefficient is often required for stable performance over temperature ranges. |

| ESR (Equivalent Series Resistance) | The internal resistance of the capacitor, which affects its efficiency and heat generation, measured in ohms (Ω). | Impacts the capacitor's ability to handle high-frequency signals. High ESR can lead to power loss and temperature increases, and can impact filtering and decoupling. |

MLCC Capacitor Applications

MLCC capacitors are ubiquitous in modern electronics due to their versatility and performance characteristics, finding applications across numerous circuits and industries. Their small size, high capacitance values, and relatively low cost make them essential components in everything from simple consumer devices to complex industrial and medical equipment.

- Decoupling and Bypass Applications

MLCCs are widely used for decoupling power supply lines, reducing noise and voltage fluctuations, ensuring stable operation of electronic components. They also act as bypass capacitors, diverting high-frequency noise to the ground, preventing it from interfering with sensitive circuitry. - Signal Filtering

MLCCs, often used in conjunction with inductors or resistors, are fundamental components in filters designed to pass or block specific frequencies. They are employed in a range of filter topologies, such as low-pass, high-pass, band-pass, and notch filters, crucial for audio processing, signal conditioning, and communications systems. - Timing Circuits

In timing circuits, MLCCs, combined with resistors, provide the necessary time constant to control the oscillation frequency, creating stable clock signals for microcontrollers, digital systems, and various other applications. - Consumer Electronics

MLCCs are fundamental components in smartphones, tablets, computers, televisions, and audio equipment, contributing to their reliable operation and performance through decoupling, signal filtering, and timing functions. - Automotive Systems

MLCCs are deployed in automotive applications including engine control units (ECUs), infotainment systems, advanced driver-assistance systems (ADAS), and electric vehicle (EV) systems, providing reliable performance in harsh environments with extreme temperature variations and vibrations. - Medical Devices

MLCCs are essential in medical devices such as pacemakers, diagnostic equipment, and monitoring systems, requiring high reliability and precision for critical medical functions. - Industrial Equipment

MLCCs are used in industrial control systems, robotics, and power supplies, delivering the necessary stability and filtering to ensure smooth operation of complex industrial processes.

Advantages and Disadvantages of MLCC Capacitors

MLCC capacitors, while ubiquitous in modern electronics due to their favorable characteristics, also present certain limitations. Understanding both their advantages and disadvantages is crucial for effective component selection in various applications. This section provides a balanced analysis of the strengths and weaknesses of MLCCs, enabling engineers to make informed decisions.

| Feature | Advantages | Disadvantages |

|---|---|---|

| Size | Extremely small, facilitating miniaturization of electronic devices. | May be challenging to handle during assembly due to small size, especially for manual placement. |

| Capacitance | High capacitance values in relatively small packages, enabling higher circuit density. | Capacitance can vary significantly with applied voltage and temperature, particularly for Class 2 and Class 3 dielectrics. |

| Cost | Generally low cost, making them suitable for mass-produced electronics. | Cost may increase for high-precision or high-reliability MLCCs. |

| Performance | Low Equivalent Series Resistance (ESR) and Equivalent Series Inductance (ESL), beneficial for high-frequency applications. | Susceptible to voltage sensitivity (capacitance changes with applied voltage); can exhibit piezoelectric effects (microphonics). |

| Reliability | Long lifespan with proper handling and operation. | Prone to mechanical cracking during board flexing or thermal shock; aging effects can lead to capacitance drift over time. |

| Application | Wide range of applications across various industries. | Not suitable for applications requiring very high precision or stability over a wide range of conditions. |

MLCC Selection Guide: A Practical Approach

Selecting the correct MLCC capacitor is crucial for optimal circuit performance and reliability. This guide provides a systematic approach to choosing the appropriate MLCC based on application requirements, emphasizing practical considerations for project planning.

- Determine the Required Capacitance Value

Begin by calculating the necessary capacitance for your application. Consider the circuit's operating frequency, impedance, and any specific requirements dictated by datasheets of the ICs involved. Factors like decoupling, filtering, and timing will greatly impact the capacitance needed. Note that the effective capacitance can be impacted by DC bias and temperature. - Assess the Operating Voltage

Choose an MLCC with a voltage rating that is significantly higher than the maximum expected voltage in your circuit. A general rule of thumb is to select a capacitor with a voltage rating at least 50% greater than the working voltage. This safety margin accounts for voltage spikes, transients, and ensures reliable operation. - Evaluate Temperature Range and Stability

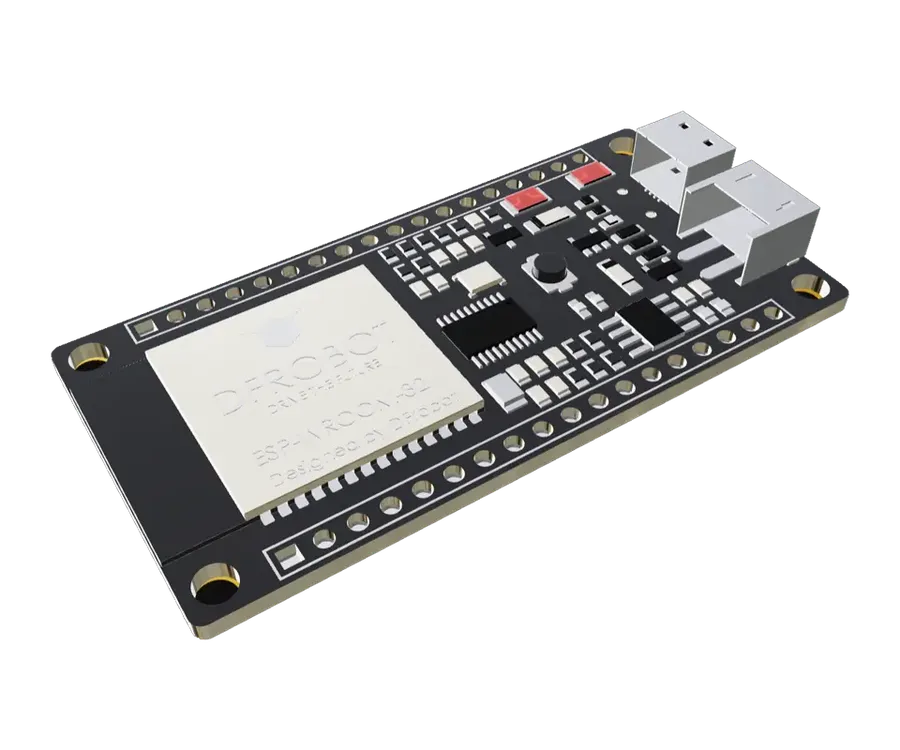

The operating temperature range is critical, and it needs to be within the operating limits of your application. MLCC capacitors have different temperature characteristics, as described by the EIA Classifications, Class 1 (C0G/NP0) has the highest stability, Class 2 (X7R, X5R) offers a good balance, and Class 3 (Y5V) is suitable for less stringent requirements. Select a capacitor class that maintains sufficient capacitance within your project's temperature range. - Consider the Circuit Environment

The physical and environmental aspects of your project will dictate the form factor of your MLCC capacitor. This involves selecting the size (footprint), lead arrangement (SMT vs. through-hole) and the type of packaging (bulk, tape reel etc). Other considerations include the presence of humidity, shock, and vibration. - Evaluate Tolerance Requirements

Capacitance tolerance defines the acceptable deviation of the actual capacitance from its nominal value. Common tolerance values are ±5%, ±10%, or ±20%. The appropriate tolerance choice hinges on the application sensitivity. Tighter tolerances incur a higher cost. - Check Equivalent Series Resistance (ESR)

ESR affects power dissipation and ripple voltage in the circuit. Low ESR capacitors are preferred in applications where minimizing heat generation is paramount, such as in high-frequency switching power supplies. This factor is commonly found in the datasheet. - Review Datasheets Carefully

Always refer to the MLCC capacitor datasheet provided by the manufacturer. Datasheets specify all electrical and mechanical characteristics. Pay close attention to temperature and voltage coefficients, ESR, and other critical specifications. Verify that the capacitor is REACH and ROHS compliant for environmental safety.

MLCC Capacitor Mounting and Handling

Proper mounting and handling of Multilayer Ceramic Capacitors (MLCCs) are crucial to ensure their long-term reliability and performance within electronic circuits. These delicate components require careful attention during assembly to avoid physical damage and thermal stress that can lead to failure.

The following practices should be followed to maintain the component's integrity:

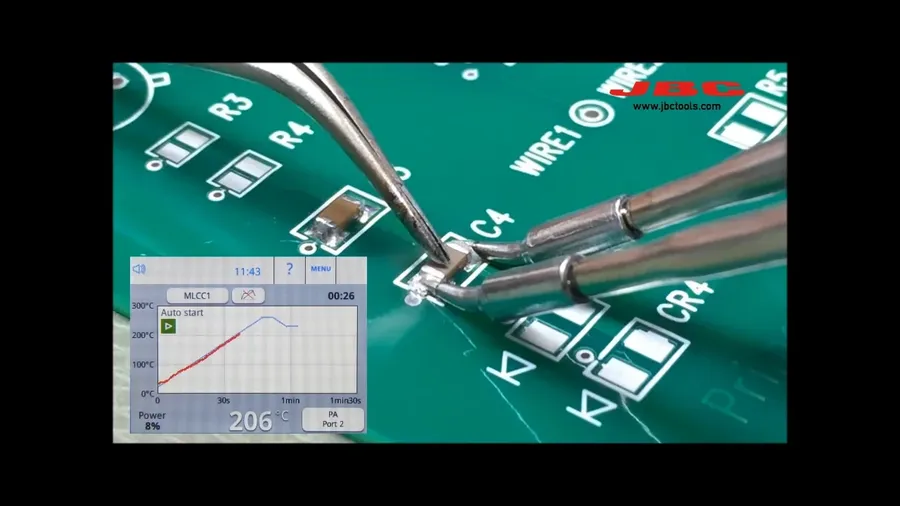

- Soldering Techniques

Use appropriate soldering temperatures and times. Excessive heat can cause thermal shock, potentially cracking the ceramic dielectric. Consider using reflow soldering with a controlled temperature profile for surface-mount MLCCs. Hand soldering should be done with care, utilizing a temperature-controlled iron and avoiding direct contact with the component body. - Avoiding Physical Stress

MLCCs are susceptible to mechanical stress. Avoid bending, twisting, or dropping the components. When placing them on the circuit board, ensure they sit flat and do not experience excessive pressure. Use proper pick-and-place equipment for automated assembly lines and avoid any manual handling that might damage them. - Preventing Thermal Shock

Sudden changes in temperature can induce stress on the capacitor. This is particularly important during soldering processes. Ensure the temperature ramp-up and cool-down cycles are gradual, avoiding abrupt temperature changes. Preheating the components and board can help mitigate thermal shock. When cleaning assembled boards, avoid rapid changes in temperature due to cleaning solvents. - Handling Precautions

Use appropriate handling tools (tweezers with soft tips) or gloves when handling MLCCs to prevent contamination and physical stress. Avoid touching the capacitor's ceramic body with bare hands, as oils and contaminants can affect the component and soldering. Store MLCCs in a dry, temperature-controlled environment, protected from humidity and physical damage.

Frequently Asked Questions about MLCC Capacitors

This section addresses common inquiries regarding MLCC (Multilayer Ceramic) capacitors, providing concise answers to help users understand their properties, applications, and selection process. These frequently asked questions (FAQs) aim to clarify key concepts and practical considerations, drawing from both common user queries and expert insights.

- What does MLCC stand for?

MLCC stands for Multilayer Ceramic Capacitor. This refers to the capacitor's construction, which consists of multiple layers of ceramic dielectric material interleaved with metal electrodes. - How do I choose between an MLCC and a film capacitor?

The choice depends on the application requirements. MLCCs are generally smaller and have lower ESR (Equivalent Series Resistance), making them suitable for high-frequency decoupling and bypass applications. Film capacitors typically offer higher precision, better stability, and handle higher voltages with lower sensitivity, making them preferred in audio circuits or high-voltage applications. Consider size, frequency, precision and temperature stability when choosing. - Can I replace a tantalum capacitor with an MLCC?

Yes, in many applications, MLCCs can replace tantalum capacitors, often with advantages in terms of cost, size, and availability, although they may have different failure modes. MLCCs are not as sensitive to reverse polarity. Check ESR, capacitance, and voltage rating, along with the necessary reliability for your specific application to ensure compatibility. - How do I interpret MLCC datasheets?

MLCC datasheets contain crucial information, including capacitance value, voltage rating, tolerance, temperature coefficient, and dimensions. Carefully examine these specifications to determine compatibility with your design requirements. The datasheet should also specify the dielectric material (e.g., NP0/C0G, X7R, Y5V), which impacts temperature stability and performance. Pay close attention to the 'case size' as this defines the physical dimensions of the component. - What are typical applications for MLCC Capacitors?

MLCCs are widely used in decoupling and bypass applications, power supplies, signal filtering, timing circuits, and are common in consumer electronics, automotive, medical devices, and industrial equipment due to their small size, high capacitance, and low cost. - What are the limitations of MLCC capacitors?

Despite their advantages, MLCCs have some drawbacks. They can exhibit voltage sensitivity, which reduces their effective capacitance at high voltages. They are also susceptible to microphonics (generating noise from mechanical vibrations) and are prone to cracking due to physical stress or thermal shock during assembly, therefore require careful handling. - What is the difference between Class 1, Class 2, and Class 3 MLCCs?

MLCCs are classified based on their dielectric material's temperature coefficient, stability, and other performance characteristics. Class 1 (e.g., NP0/C0G) offers the highest stability and lowest temperature coefficient. Class 2 (e.g., X7R) provides a higher capacitance per volume but is less stable. Class 3 (e.g., Y5V) has the highest capacitance per volume but is the least stable and should be used with care and within specified operating parameters. Select the class appropriate for the applications environmental and reliability requirements.

Future Trends and Innovations in MLCC Technology

The field of Multilayer Ceramic Capacitors (MLCCs) is undergoing continuous evolution, driven by the ever-increasing demands of modern electronics for miniaturization, enhanced performance, and sustainability. Current research focuses on pushing the boundaries of MLCC technology through material science, manufacturing process advancements and innovative design strategies.

- Miniaturization and Increased Capacitance

A primary focus is on reducing the physical size of MLCCs while simultaneously increasing their capacitance. This involves exploring new dielectric materials with higher permittivity and refining manufacturing processes to create thinner ceramic layers. The goal is to provide more capacitance in smaller footprints, critical for devices where space is limited. - Advanced Dielectric Materials

Research is actively exploring novel dielectric materials beyond current standards like X7R, NP0/C0G and Y5V. These new materials aim to improve temperature stability, voltage linearity, and reduce the impact of DC bias on capacitance. The challenge lies in developing these materials that can be produced cost-effectively and reliably at an industrial scale. - Enhanced Performance at High Frequencies

With increasing operating frequencies in modern electronics, there is a need for MLCCs with improved performance at higher frequencies. This involves optimizing the design and material properties to reduce Equivalent Series Inductance (ESL) and Equivalent Series Resistance (ESR), which become more critical at high frequencies. This improvement will also lead to MLCCs being better suited for high-speed signal integrity applications. - Integration of MLCCs with Other Components

Researchers are also exploring integrating MLCCs with other components, which involves the development of System in Package (SiP) and integrated passive devices (IPD) technologies, this approach aims to reduce board space requirements, improve system performance, and also enable more compact and efficient electronic designs. - Eco-Friendly Manufacturing Processes

Environmental concerns have led to investigations into greener manufacturing processes for MLCCs. This includes reducing the use of harmful chemicals, optimizing energy consumption, and designing components for easier recyclability. This is part of a broader initiative to ensure sustainable production of electronic components.

In summary, MLCC capacitors are essential in modern electronics, owing to their compact design and high capacitance. Through understanding the different types, specifications, and application, selecting the correct MLCC components becomes a pivotal process for the success of electronic designs. This knowledge helps engineers to build reliable and efficient electronics, ensuring that even the smallest components like MLCC capacitors play a major role in shaping our connected world and influencing advancements in social life and technology.

AnyPCBA

AnyPCBA