Understanding Motor Run Capacitors: How They Power Your World

Have you ever wondered what keeps your air conditioner, refrigerator, or other appliances running smoothly? A seemingly small but crucial component called a motor run capacitor plays a vital role in the operation of many AC motors. Like a tiny, yet powerful energy reservoir, the motor run capacitor helps motors start and continue to operate efficiently, making our daily lives more convenient and comfortable. This article dives into how motor run capacitors work, their importance, and what to do when they fail.

What is a Motor Run Capacitor?

A motor run capacitor is an essential electrical component in single-phase alternating current (AC) induction motors. Its primary function is to create a phase shift in the electrical current supplied to the motor's windings. This phase shift generates a rotating magnetic field, which is fundamental for starting and maintaining the smooth and efficient operation of the motor.

How Does a Motor Run Capacitor Work?

A motor run capacitor functions as an energy storage device, playing a crucial role in the continuous operation of single-phase AC motors. Unlike start capacitors, which are used for brief periods during startup, run capacitors are designed to remain in the circuit during the entire running cycle, providing a continuous phase shift, enhancing the motor’s power factor and overall efficiency.

The fundamental principle behind a run capacitor's operation is the creation of a phase difference between the current flowing through the main and auxiliary windings of the motor. This phase difference generates a rotating magnetic field, which allows the rotor to turn smoothly and continuously. Without the appropriate phase shift, the motor will not be able to function properly, leading to starting issues, reduced efficiency, and potential overheating.

The capacitor achieves this phase shift by storing electrical energy during a portion of the AC cycle and then releasing it back into the circuit in a phase-shifted manner. This allows the motor to operate with improved power factor, drawing current more efficiently from the power supply and leading to less waste in the form of reactive power.

Fundamentally, the capacitor, in conjunction with the motor windings, creates a resonant LC (Inductor-Capacitor) circuit that tunes the current flow to generate the rotating magnetic field. The capacitance value is selected to precisely control this phase difference and optimise motor operation. This continuous delivery of energy is why they are called 'run' capacitors, designed for endurance throughout the motor's active time.

Motor Run vs. Start Capacitors: Key Differences

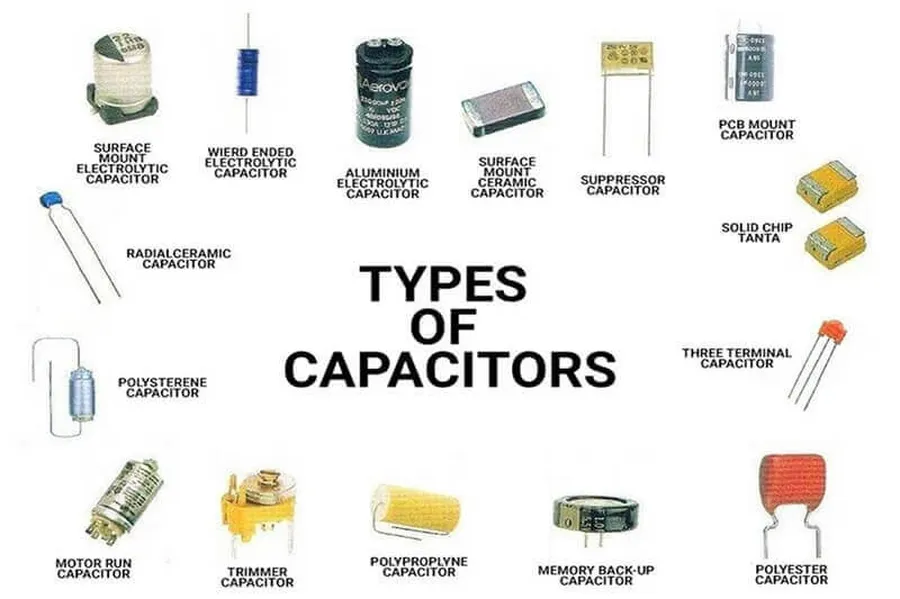

While both motor run and start capacitors are essential components in single-phase AC motors, their design and function differ significantly. Motor run capacitors are designed for continuous operation during the motor's running cycle, whereas start capacitors provide a brief, high-power boost to initiate motor rotation. This fundamental difference dictates their construction, capacitance, and current ratings.

Motor Run Capacitor Specifications and Types

Motor run capacitors are crucial components in single-phase AC motors, and selecting the correct one requires a thorough understanding of their specifications and available types. These capacitors are characterized by their capacitance, voltage rating, and physical form factor, all of which are critical for ensuring proper motor operation and longevity.

| Specification | Description | Importance |

|---|---|---|

| Capacitance | Measured in microfarads (μF), this indicates the capacitor's ability to store electrical charge. | Directly affects motor torque, starting, and running performance. Must match motor specifications. |

| Voltage Rating | The maximum voltage the capacitor can safely withstand, typically specified in VAC (Volts Alternating Current). | Critical for safety and capacitor lifespan. The rating must be equal to or higher than the circuit voltage. |

| Shape/Form Factor | Common shapes include round, oval, and rectangular, each designed for different mounting scenarios. | Impacts physical installation and space constraints. |

| Operating Frequency | The frequency of the AC power the capacitor is designed to operate at, typically 50Hz or 60Hz. | Ensures proper performance based on power grid frequency. |

| Temperature Rating | Specifies the safe operating temperature range of the capacitor. | Important for environments with varying temperatures to ensure reliability and prevent failure. |

Capacitance is arguably the most critical parameter. It is specified in microfarads (μF) and must precisely match the motor manufacturer's specifications. Using a capacitor with incorrect capacitance will lead to inefficient operation, motor overheating, and premature failure. Common capacitance values range from a few microfarads to several tens of microfarads, depending on the motor size and application. The voltage rating, denoted in VAC (Volts Alternating Current), must also be carefully observed to avoid catastrophic failures; a capacitor's voltage rating should always equal or exceed the voltage of the motor's electrical system. The physical shape or form factor (e.g., round or oval) is primarily an installation concern.

The CBB65 type is a frequently encountered category of motor run capacitors, particularly in air conditioning systems, refrigeration units, and other appliances. These capacitors generally are constructed with a metalized polypropylene film dielectric, are self-healing (in case of a breakdown) , and are encased in an aluminum can, ensuring high reliability and thermal endurance. The CBB65 series come in a variety of standard voltage and capacitance ratings, with each specific model having its unique parameters to match the corresponding motor specifications. It is vital that exact replacements are made based on the motor’s specifications found on the nameplate to ensure proper and safe operations.

Selecting the correct replacement requires careful attention to these specifications; referencing the motor's nameplate and the existing capacitor's markings are paramount. Manufacturers often provide detailed datasheets that outline these parameters for their products. It is not safe to use a capacitor with lower voltage rating or capacitance than the motor's specifications.

When a Motor Run Capacitor Fails: Common Symptoms

A failing motor run capacitor manifests in several telltale signs that indicate its inability to properly support the motor's operation. Recognizing these symptoms early is crucial to prevent further damage and ensure the longevity of the motor. These symptoms often result from the capacitor's degradation, which leads to inefficiencies in the motor's electrical circuit and can cause a variety of operational problems.

- Humming Motor That Won't Start

A common symptom of a failing run capacitor is a humming sound emanating from the motor, without the rotor actually turning. This occurs because the capacitor is no longer providing the necessary phase shift to create a rotating magnetic field required for start-up. This could indicate a complete capacitor failure, often leading to a lack of motor rotation. - Slow Starting or Difficulty in Starting

When the motor has difficulty starting or starts noticeably slower than normal, a weakening run capacitor is often to blame. A deteriorated capacitor can no longer supply the necessary current surge to the motor to overcome initial inertia. The reduced capacitance leads to a weaker magnetic field, resulting in a sluggish start. - Overheating

A faulty run capacitor can cause a motor to overheat. This occurs because the motor draws excess current as it struggles to operate without the proper phase shift. The increased current flow generates extra heat in the motor windings and the capacitor itself, which can accelerate the motor's wear and further damage the capacitor. - Decreased Motor Performance

A motor operating with a failing run capacitor will often exhibit decreased performance, including reduced torque, speed, and efficiency. The lack of proper phase shift means the motor cannot run at its optimal settings, resulting in a drop-off in its output and capability. This decline could be gradual or sudden, depending on the capacitor's level of degradation.

Troubleshooting and Testing Motor Run Capacitors

Accurately diagnosing motor issues often requires testing the run capacitor, a crucial component for motor operation. This section outlines how to safely and effectively test a motor run capacitor using a multimeter to determine if it is functioning correctly and to confirm if it is the cause of motor malfunctions.

Proper testing is critical before considering a replacement. Always ensure the power is completely disconnected to the motor before beginning any testing or replacement procedures. Testing a motor run capacitor primarily involves measuring its capacitance, which should be close to the value stated on the capacitor’s label. Deviations from this value can indicate a failing capacitor.

- Safety First: Disconnect Power

Before any testing, completely disconnect the motor from its power source. This step is paramount for avoiding electrical shock and ensures personal safety. - Discharge the Capacitor

Use an insulated screwdriver with a resistor or a dedicated capacitor discharge tool to safely discharge the capacitor. This prevents a sudden and dangerous release of stored electrical energy. - Prepare Your Multimeter

Set your digital multimeter to measure capacitance (usually denoted by 'uF', 'nF' or 'F'). Ensure the multimeter's test leads are clean and in good condition. - Connect the Multimeter

Connect the multimeter leads to the capacitor terminals. Make sure the leads are securely attached to get an accurate reading. Avoid touching the capacitor terminals directly with your hands. - Record the Capacitance Reading

Compare the reading on the multimeter with the rated capacitance stated on the capacitor's label. A reading that is significantly lower or higher indicates a failing capacitor. Allow the reading to stabilize before recording. - Analyze the Results

A capacitor is generally considered bad if the capacitance reading deviates more than 10% from the rated value. A reading of zero indicates an open circuit within the capacitor, while an infinite reading can mean a short circuit. Both scenarios typically require capacitor replacement.

This method is for testing the capacitor's ability to store charge. Other tests can include visual inspection for signs of bulging or leaks which can also signal capacitor failure.

Replacing a Motor Run Capacitor: A Step-by-Step Guide

Replacing a motor run capacitor, while seemingly complex, can be safely accomplished by following a methodical approach. This section provides detailed instructions on how to select the correct replacement capacitor based on the old unit's specifications, how to safely discharge the old capacitor, and how to properly install the new one in the motor circuit, using appropriate safety measures. Accurate identification of the capacitor's specifications and adherence to safety protocols are critical for a successful replacement and to prevent personal injury or damage to the motor.

- Step 1: Safety First - Disconnect Power

Before starting any work, always disconnect the power supply to the motor. This ensures there is no electrical current running through the circuit, preventing potential electric shock. Use a certified voltage tester to confirm the power is off. Do not rely on the switch alone, as it can be faulty. - Step 2: Identify the Old Capacitor's Specifications

Carefully note the specifications of the old capacitor. The microfarad (μF) rating, voltage rating, and physical dimensions (if possible) are vital for selecting a compatible replacement. Typically this information is printed directly on the capacitor. Use a camera to take pictures of the old unit to aid in proper matching. - Step 3: Discharge the Old Capacitor

Before handling the old capacitor, it is crucial to discharge any stored electrical energy. Use a 20,000 ohm resistor to short across the capacitor terminals to safely release any remaining charge. This step prevents electric shock and is non-negotiable. - Step 4: Remove the Old Capacitor

Carefully disconnect the wires from the old capacitor. Use pliers to remove any connectors or screws securing it. Take a photo before disconnecting any wires for future reference. Note the exact orientation of the capacitor within the unit. - Step 5: Install the New Capacitor

Place the new capacitor in the same location and orientation as the old one. Connect the wires to the new capacitor according to the picture or markings made in Step 4. Ensure the connections are secure to avoid loose wires. - Step 6: Reassemble the Motor Unit

Close up the motor housing and secure any covers or panels. Make sure all components are back in their original positions. Do not skip this step to maintain the unit's integrity. - Step 7: Test the Motor

Reconnect the power supply to the motor. Test the motor by powering it on to ensure it is working correctly. If the motor does not start, disconnect power immediately and revisit all previous steps.

Frequently Asked Questions About Motor Run Capacitors

This section addresses common inquiries about motor run capacitors, clarifying their function, failure modes, and operational necessities. These questions are essential for understanding the role of run capacitors in motor systems.

- What is the primary function of a motor run capacitor?

A motor run capacitor's primary function is to create a phase shift in the electrical current supplied to the motor's windings. This phase shift generates a rotating magnetic field, which is crucial for the motor to start and operate efficiently. Unlike a start capacitor, which is only active during startup, a run capacitor remains in the circuit during continuous operation. - What are the typical signs of a failing motor run capacitor?

Common symptoms of a failing motor run capacitor include a motor that hums but fails to start, slow starting speeds, noticeable overheating during operation, and a general decline in motor performance. In some cases, the motor may be unable to start at all. Early identification of these signs can prevent further damage to the motor. - Is it possible for a motor to function without a run capacitor?

While some motors can technically start without a run capacitor, their performance will be significantly compromised. Without the phase shift provided by the capacitor, the motor will likely struggle to reach its designed operating speed, will run inefficiently, and will be prone to overheating. Continuous operation without a run capacitor will drastically shorten the motor's lifespan and may cause permanent damage. Thus, a run capacitor is essential for optimal motor functionality. - How can I determine if my air conditioner's run capacitor is faulty?

If your air conditioner is experiencing symptoms like a humming compressor or fan motor that does not start, or if the system is not cooling effectively, it may indicate a faulty run capacitor. To diagnose this, the capacitor needs to be tested with a multimeter to check its capacitance, comparing the measured reading with the marked value on the capacitor. Proper testing requires discharging the capacitor and using safety precautions, to avoid electrical shocks. If the measured capacitance is significantly below its rating, the capacitor should be replaced. - Can a motor run capacitor cause a motor to overheat?

Yes, a failing or degraded motor run capacitor can cause a motor to overheat. When the capacitor isn't providing the proper phase shift, the motor operates inefficiently, drawing more current, which leads to increased heat generation. The motor's windings can be damaged if this overheating is left unchecked for too long, necessitating costly repairs. A properly functioning run capacitor ensures efficient energy conversion, preventing excessive heat buildup. - How do motor run capacitor voltage and capacitance ratings relate to the motor it powers?

The voltage and capacitance ratings of a motor run capacitor are crucial and must match the motor's requirements. The capacitance, measured in microfarads (uF), determines the amount of phase shift. The voltage rating must be equal to or higher than the motor's supply voltage to ensure that the capacitor can withstand the electrical stress without failing. Using an incorrect capacitor can lead to poor motor performance, overheating, and premature failure. - Are motor run capacitors specific to the type of motor or can they be used universally?

Motor run capacitors are not universal and must be selected based on the specific requirements of the motor they will be used with. The motor's design, power requirements, and operating conditions all dictate the necessary capacitor specifications. Using a capacitor with the wrong voltage, capacitance, or other technical specifications will result in suboptimal motor performance, and is likely to lead to motor failure over time.

Comparative Analysis: Motor Run vs. Start Capacitors

A direct comparison between motor run and start capacitors highlights their distinct roles and operational characteristics within single-phase AC motors. These differences are crucial for understanding their appropriate applications and ensuring optimal motor performance.

| Feature | Motor Run Capacitor | Motor Start Capacitor |

|---|---|---|

| Primary Function | Maintains phase shift and improves power factor during continuous motor operation. | Provides a high current boost for initial motor startup. |

| Duty Cycle | Continuous operation. Designed to carry current throughout the motor's running cycle. | Intermittent operation. Only in the circuit for a short period during startup. |

| Capacitance | Lower capacitance values, typically in the range of a few to several tens of microfarads (µF). | Higher capacitance values, can range from tens to hundreds of microfarads (µF). |

| Current Rating | Designed to handle continuous current flow. | Designed for high peak current for short durations. |

| Construction | Typically made with oil-filled or dry film capacitors for robust continuous use. | Usually electrolytic capacitors which have a higher capacitance per unit volume, suitable for short durations. |

| Life Cycle | Designed for a long operational lifespan due to robust construction. | Shorter life cycle compared to run capacitors because of their higher current and voltage rating requirements in short bursts. |

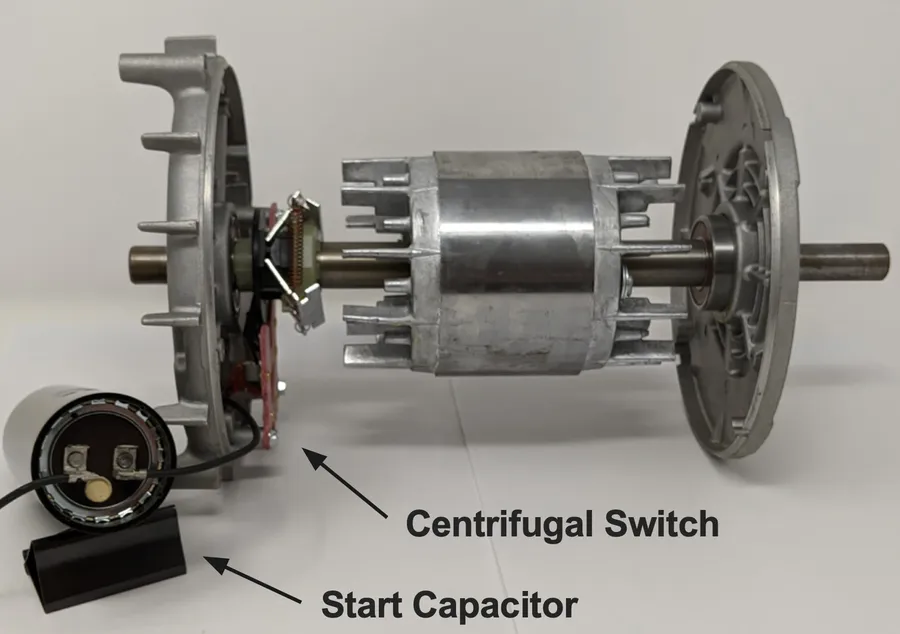

| Connection in Circuit | Permanently connected in series with one of the motor windings. | Connected in series with one of the motor windings and is usually switched out of the circuit by a centrifugal switch or a relay once the motor reaches a certain speed. |

| Impact on Power Factor | Improves the motor's power factor during operation, leading to higher efficiency. | Does not impact the power factor during continuous operation. It aids only during startup phase. |

| Physical Size | Often smaller physical size for a given voltage. | Often larger physical size for a given voltage rating due to its higher capacitance value. |

Extending the Life of Your Motor Run Capacitor

To maximize the operational lifespan of a motor run capacitor and ensure reliable motor performance, several preventative measures should be consistently applied. These measures largely revolve around maintaining suitable operating conditions and performing routine checks.

- Ensure Proper Ventilation

Adequate ventilation is crucial. Overheating is a major cause of capacitor failure, so proper airflow around the capacitor is essential for dissipating heat. Avoid placing capacitors in enclosed spaces where heat can accumulate. - Avoid Extreme Temperatures

Motor run capacitors have specified operating temperature ranges. Operating outside of these ranges can lead to premature degradation and failure. Protect them from excessive heat or cold, and keep them within the manufacturer's recommended temperature limits. - Regular Maintenance Checks

Regular inspection of the capacitor is necessary. Look for physical signs of damage, such as bulging, leaks, or cracks. Also, test the capacitor using a multimeter to verify that it remains within its specified capacitance range. Routine checks can reveal early signs of degradation, enabling timely replacement. - Correct Installation

Improper installation can also shorten capacitor lifespan. Always make sure that the replacement capacitor has the correct voltage and capacitance ratings, and is properly wired in the circuit according to the motor’s specifications. Incorrect installation can lead to overcurrent and overheating. - Protect Against Moisture and Corrosion

Moisture and corrosion can degrade the electrical and physical integrity of a capacitor. Where possible, protect the capacitor from exposure to damp environments. If moisture is a unavoidable, choose a capacitor with a hermetically sealed case.

Motor run capacitors are small but crucial components in many of the single-phase AC motors that power our homes and industries. Understanding how these motor run capacitors work, recognizing the signs of failure, and knowing how to test and replace them can significantly extend the life and efficiency of your motors. Properly functioning motor run capacitors are vital for efficient operation and play a critical role in our modern technological infrastructure, and ensuring you choose the correct one is important to motor functionality and the longevity of your motors. By understanding and maintaining these parts, you ensure optimal efficiency for years to come, and keep our world spinning.

AnyPCBA

AnyPCBA