Understanding Multilayer Ceramic Capacitors: A Comprehensive Guide

In today's world of ever-evolving technology, electronic devices are becoming increasingly smaller and more powerful. This miniaturization is partly due to components like multilayer ceramic capacitors (MLCCs). Imagine the intricate dance of electrons within your smartphone or laptop; MLCCs are the unsung heroes, regulating and storing electrical energy. This article delves into the fascinating world of MLCCs, exploring their role in modern electronics, their construction, and their diverse applications, as well as comparing them to other capacitor technologies. Let's unpack the secrets behind these vital components.

What are Multilayer Ceramic Capacitors (MLCCs)?

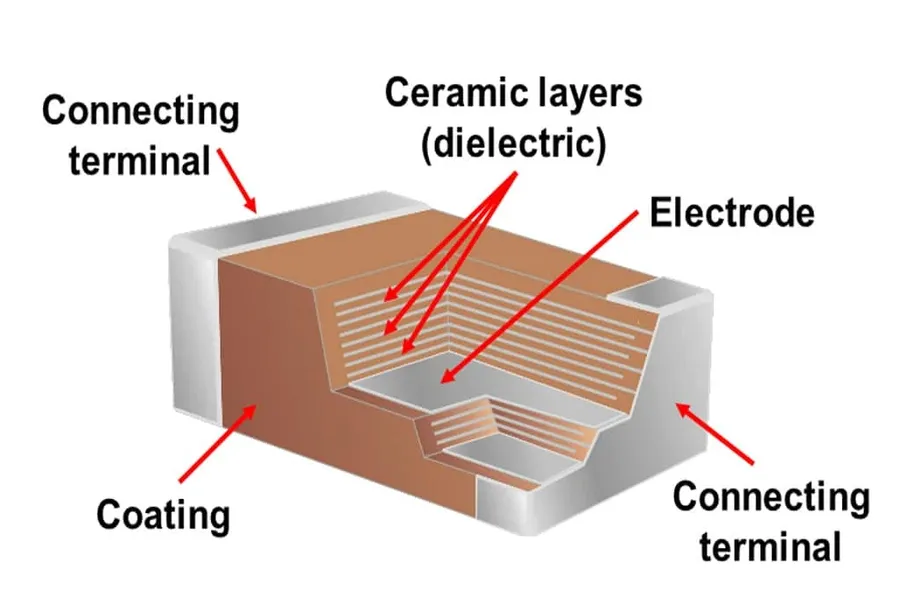

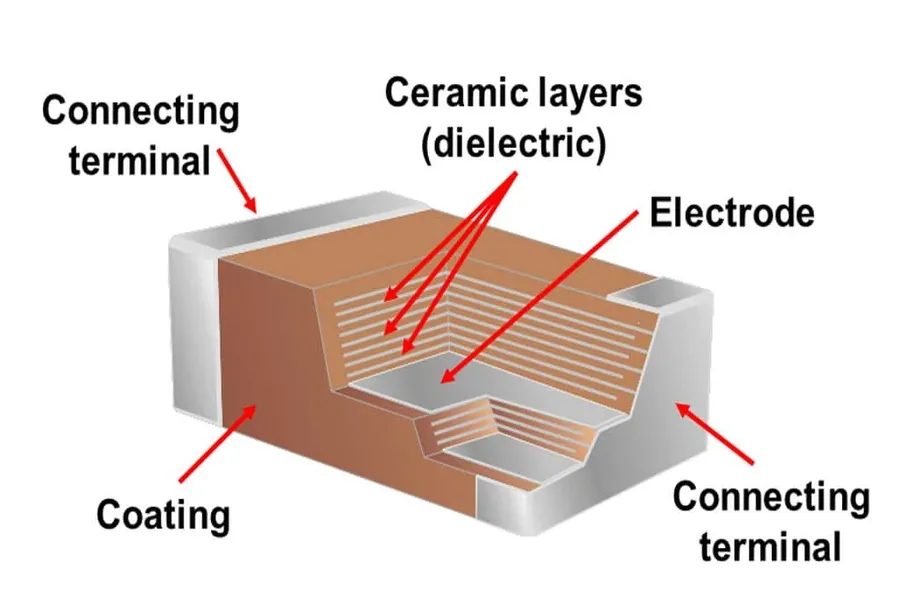

Multilayer ceramic capacitors (MLCCs) are a type of ceramic capacitor characterized by their layered construction, where multiple layers of ceramic dielectric material alternate with metal electrodes. This structure allows for high capacitance values in a small physical size, making them ubiquitous in modern electronics. The ceramic dielectric material, crucial for their function, is often composed of materials such as barium titanate (BaTiO3) or other ceramic formulations with tailored electrical properties.

Construction of MLCCs: A Layer-by-Layer Look

Multilayer Ceramic Capacitors (MLCCs) derive their name from their distinctive layered construction, consisting of alternating layers of ceramic dielectric material and metal electrodes. This intricate architecture is fundamental to their performance characteristics and manufacturing process.

The manufacturing process for MLCCs is complex and requires extreme precision to ensure the integrity and functionality of these components. It involves the following key steps:

- Ceramic Powder Preparation:

The process begins with the careful preparation of ceramic powder, which serves as the dielectric material. The ceramic composition is often a mix of materials like barium titanate, known for its high dielectric constant, with additions to tailor its temperature and voltage characteristics. This powder is rigorously refined to achieve a highly uniform particle size distribution, which is essential for the production of thin, consistent layers. - Tape Casting:

A slurry containing the ceramic powder and a binder is then formed into a thin tape via a process known as tape casting. This step is critical for achieving the desired layer thickness, typically ranging from a few to tens of micrometers. Precise control of the tape thickness and consistency is necessary to ensure uniform electrical properties across the MLCC. - Electrode Printing:

Metallic electrode patterns are printed onto the ceramic tape using specialized screen-printing techniques. These electrodes are typically made from metals like nickel, copper, or silver. The accuracy of the printing process is crucial to prevent shorts and ensure precise overlap between electrodes, as well as the overall capacitance of the component. The pattern will form the internal connection to the terminals. - Layer Stacking and Lamination:

The printed ceramic tapes are precisely stacked, aligning the electrode layers and ceramic layers in the correct sequence, this is crucial to achieve the desired performance and capacitance values. This process involves high precision to ensure the layers are properly aligned and in complete contact, resulting in a monolithic structure. - Firing and Sintering:

The stacked structure is then subjected to a high-temperature firing process, known as sintering. During this stage, the binder is removed, and the ceramic particles fuse together to form a dense, mechanically robust monolithic block. The sintering parameters, such as temperature and duration, are carefully controlled to optimize the ceramic's dielectric properties and overall mechanical strength. - Termination and Packaging:

After sintering, the MLCC is terminated by applying conductive metal coatings to the edges to form the electrical contacts. These terminations are crucial to connect the internal electrode layers to the external circuit. The finished MLCC is then packaged and prepared for use in electronic assemblies.

The precision required at each step of this process is paramount. The thickness of the layers and the alignment of electrodes directly impact the final capacitance, voltage handling, and overall reliability of the MLCC. These parameters are tightly controlled using sophisticated equipment and quality control procedures.

Key Parameters of Multilayer Ceramic Capacitors

Understanding the key parameters of Multilayer Ceramic Capacitors (MLCCs) is crucial for selecting the correct component for a given application. These parameters dictate how the capacitor will perform within a circuit and significantly affect its overall reliability and suitability. Key parameters include capacitance, voltage rating, temperature coefficient, and equivalent series resistance (ESR). Each of these characteristics contributes differently to the capacitor's behavior and should be carefully considered in the design process.

| Parameter | Description | Units | Impact on Performance |

|---|---|---|---|

| Capacitance | The ability of the capacitor to store an electrical charge. | Farads (F), typically microfarads (μF) or picofarads (pF) | Determines the amount of energy stored and the capacitor's effectiveness in filtering and decoupling applications. |

| Voltage Rating | The maximum DC voltage that can be safely applied across the capacitor without risking failure. | Volts (V) | Exceeding this rating can lead to dielectric breakdown and permanent damage. |

| Temperature Coefficient | Describes how the capacitance changes with temperature variations. | Parts per million per degree Celsius (ppm/°C) | Critical for applications that experience varying operating temperatures, affecting circuit stability. NP0/C0G are the most stable, while X7R/X5R etc. have greater capacitance but less stability. |

| Equivalent Series Resistance (ESR) | The total resistance exhibited by the capacitor, including lead resistance, dielectric loss, and electrode resistance. | Ohms (Ω) | Affects the capacitor's ability to handle high frequencies and currents, leading to heating and signal loss. |

Selecting the appropriate MLCC for a specific application involves carefully considering these parameters. For example, a bypass capacitor used in high-frequency digital circuits requires low ESR and a stable temperature coefficient, whereas a capacitor used for energy storage might prioritize high capacitance and a suitable voltage rating. Ignoring these parameters can lead to poor circuit performance or premature capacitor failure.

MLCC Applications in Modern Electronics

Multilayer ceramic capacitors (MLCCs) are integral components in modern electronics, owing to their compact size, high capacitance, and excellent performance characteristics. Their versatility allows them to be deployed in a wide array of applications across diverse industries, enabling critical functions in various electronic circuits.

- Consumer Electronics

MLCCs are ubiquitous in consumer devices such as smartphones, laptops, tablets, and gaming consoles. They serve as decoupling capacitors, providing a stable power supply to integrated circuits (ICs), filtering out noise, and ensuring the smooth operation of these devices. - Automotive Industry

The automotive sector utilizes MLCCs extensively in engine control units (ECUs), infotainment systems, and advanced driver-assistance systems (ADAS). They function in environments with extreme temperature fluctuations and high vibrations, requiring components with high reliability and stability. - Telecommunications

In the telecommunications industry, MLCCs are critical in base stations, mobile communication devices, and network infrastructure. They perform essential roles in signal filtering, impedance matching, and energy storage within high-frequency circuits. - Medical Devices

Medical equipment including imaging systems, pacemakers, and patient monitoring systems rely on MLCCs for their accuracy, reliability, and stability. These capacitors contribute to the safe and precise functioning of critical life-supporting technologies. - Industrial Equipment

Industrial machinery, automated systems, and power supplies use MLCCs due to their ability to function in harsh environments. Their stability, high capacitance, and reliability make them ideal for industrial control circuits. - Aerospace and Defense

In demanding aerospace and defense applications, MLCCs are critical for onboard computers, navigation systems, communication equipment, and power distribution. Their high reliability and performance are crucial in mission-critical scenarios.

| Application | Function | Example Circuit |

|---|---|---|

| Decoupling | Provide a stable power supply by smoothing out voltage fluctuations | Bypass capacitor in a power rail of a microcontroller. |

| Filtering | Remove unwanted noise from a signal | Low-pass filter in an audio amplifier circuit. |

| Energy Storage | Store and release electrical energy as needed | Energy storage in a pulsed laser system. |

| Timing Circuits | Control timing and frequency | Resonator in an oscillator circuit. |

Multilayer Ceramic Capacitor vs. Other Capacitor Types

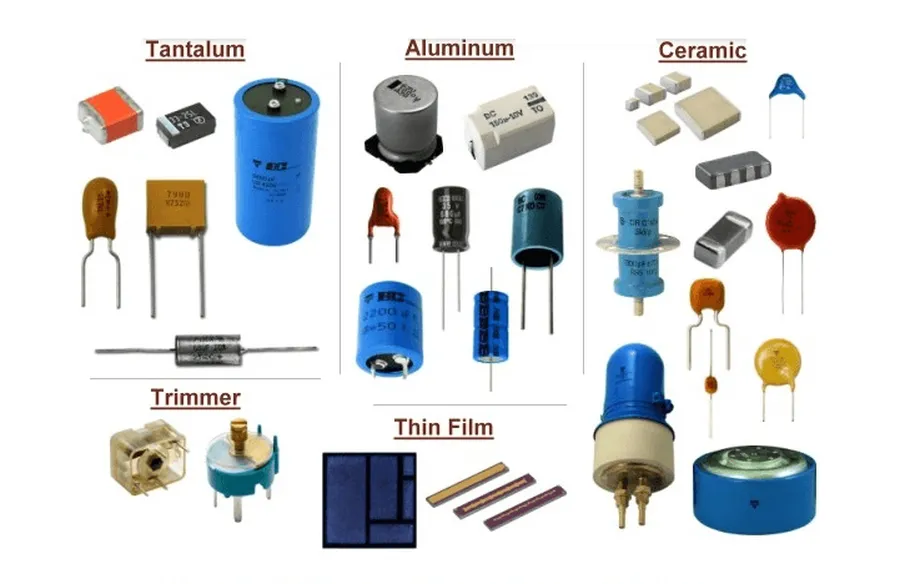

Multilayer ceramic capacitors (MLCCs) distinguish themselves from other capacitor types through a unique combination of properties, making them suitable for a wide array of applications. This section provides a comparative analysis of MLCCs with electrolytic and single-layer ceramic capacitors, highlighting key differences in size, performance, and cost.

| Feature | MLCC | Electrolytic Capacitor | Single-Layer Ceramic Capacitor |

|---|---|---|---|

| Capacitance Range | High (pF to µF) | Very High (µF to F) | Low (pF to nF) |

| Size | Small | Larger | Small |

| Voltage Rating | Moderate to High | Moderate | High |

| ESR | Low | Higher | Low |

| Frequency Response | Excellent | Poor | Good |

| Polarity | Non-Polarized | Polarized | Non-Polarized |

| Cost | Moderate | Low | Low |

| Typical Applications | Decoupling, filtering, signal processing | Bulk energy storage, power supply filtering | High-frequency circuits, RF applications |

The comparison above highlights key distinctions: MLCCs offer a good balance of high capacitance in a small size with low ESR, making them ideal for many modern electronic applications. Electrolytic capacitors excel at very high capacitance but are larger, polarized, and have higher ESR which limits their high-frequency performance. Single-layer ceramic capacitors offer high voltage ratings and low ESR but typically have lower capacitance values, making them suitable for specialized applications, such as high-frequency circuits.

Advantages of Using Multilayer Ceramic Capacitors

Multilayer ceramic capacitors (MLCCs) offer a compelling combination of performance characteristics that make them highly advantageous in modern electronics. Their benefits stem from their unique construction and material properties, which contribute to their widespread adoption across diverse applications. The following sections outline these advantages in detail.

- Small Size and High Volumetric Efficiency

MLCCs are renowned for their compact dimensions, which allow for high component density on circuit boards. This is especially crucial for miniaturized electronic devices where space is a premium. Their multilayer structure enables a large capacitance value within a small physical footprint. - High Capacitance Values

MLCCs provide a wide range of capacitance values, from picofarads (pF) to microfarads (μF). This broad range allows designers to choose the precise capacitance required for a specific circuit, improving both efficiency and functionality. - Low Equivalent Series Resistance (ESR)

The low ESR of MLCCs minimizes power losses and heat generation, making them highly suitable for high-frequency applications. The reduced impedance contributes to efficient energy transfer and reduced noise in the circuit. - High Reliability and Stability

MLCCs exhibit exceptional reliability, with minimal performance degradation over time. They are also highly stable across a wide range of operating conditions, including temperature and voltage fluctuations. This stability leads to dependable operation and a longer lifespan for electronic devices. - Temperature Stability

MLCCs often offer excellent temperature characteristics, with minimal change in capacitance over a specified temperature range, which is critical for applications that experience variable thermal environments. Different ceramic materials are selected to achieve different temperature coefficients depending on application requirements. - Non-Polarized Nature

Unlike electrolytic capacitors, MLCCs are non-polarized, allowing for easy placement in circuits without the need to consider polarity. This characteristic simplifies circuit design and reduces the possibility of incorrect installation. - High Frequency Performance

MLCCs exhibit low parasitic inductance, which enables them to operate effectively at high frequencies, a critical advantage for modern digital circuits and RF applications. This makes them a superior choice for high-speed signal processing.

| Advantage | Description | Impact |

|---|---|---|

| Miniaturization | Compact size allows high-density packaging. | Enables smaller and more portable devices. |

| Wide capacitance range | Available in wide range of capacitance values. | Flexibility in circuit design and application. |

| Low ESR | Reduced resistive losses in the capacitor. | Higher energy efficiency and lower heat generation. |

| Reliability | Consistent operation over time. | Longer operational life of devices. |

| Temperature stability | Stable capacitance with changing temperature. | Consistent performance in varying environment. |

| Non-polarized | Can be inserted without polarity considerations | Simplified design and installation. |

| High-frequency performance | Effective at high frequency due to low parasitic inductance. | Essential for high-speed digital and RF applications. |

Disadvantages and Limitations of Multilayer Ceramic Capacitors

While multilayer ceramic capacitors (MLCCs) offer numerous advantages, they also have limitations that need to be considered for reliable performance. These limitations primarily stem from their material properties and construction, making them susceptible to certain stresses and failure modes.

- Mechanical Stress Susceptibility:

MLCCs are brittle and prone to cracking under mechanical stress, such as bending or vibration, which can lead to a reduction in capacitance or complete failure, especially during assembly or in applications with high mechanical demands. - Temperature Limitations:

While MLCCs generally have a wide operating temperature range, extreme temperatures can affect their performance. High temperatures can accelerate degradation and potentially lead to failure, while very low temperatures may reduce capacitance. It's critical to operate MLCCs within their specified temperature range. - Voltage Sensitivity:

Although MLCCs have high voltage ratings, prolonged exposure to voltages near or above the rated level can cause accelerated aging and reduced lifespan. Additionally, some types of MLCCs exhibit capacitance variations with applied voltage, a phenomenon known as voltage coefficient of capacitance. - Failure Modes:

Common failure modes include cracking, delamination (separation of ceramic and electrode layers), and dielectric breakdown, often due to mechanical stress, thermal shock, or overvoltage. These can result in short circuits or open circuits, leading to system malfunctions. - Aging Effects:

MLCCs can experience a phenomenon known as 'aging,' where the capacitance decreases over time, especially at elevated temperatures. Manufacturers provide aging rates in their datasheets, which should be considered when calculating the capacitor's long-term performance. - Piezoelectric Effect:

MLCCs exhibit a piezoelectric effect, where mechanical stress can generate a voltage and vice-versa. In certain applications, this effect can cause unwanted noise or interference. Careful design consideration is needed for sensitive circuits.

Proper design, handling, and application of MLCCs are crucial to mitigate these limitations. Selecting the correct type and rating, implementing protective measures like stress relief in designs, and operating within the specified environmental conditions can ensure reliable and long-term performance.

Frequently Asked Questions About Multilayer Ceramic Capacitors (MLCCs)

This section addresses common queries regarding Multilayer Ceramic Capacitors (MLCCs), clarifying their distinctions, applications, and characteristics. We aim to provide clear and concise answers to help you better understand these essential electronic components.

- What exactly are multilayer ceramic capacitors (MLCCs)?

MLCCs are capacitors constructed from multiple layers of ceramic dielectric material interleaved with metal electrodes. This layered structure increases capacitance within a smaller physical volume. The ceramic material provides the dielectric properties, while the metal electrodes facilitate the storage of electrical charge. - What is the difference between a ceramic capacitor and an MLCC?

While all MLCCs are ceramic capacitors, not all ceramic capacitors are MLCCs. The key difference lies in their structure: a single-layer ceramic capacitor has a single layer of dielectric material, whereas an MLCC has multiple layers stacked together. This layering allows MLCCs to achieve much higher capacitance values compared to single-layer counterparts while maintaining compact dimensions. - What differentiates single-layer and multilayer ceramic capacitors?

Single-layer ceramic capacitors consist of a single ceramic dielectric layer between two electrodes, limiting their capacitance. Multilayer ceramic capacitors, as the name implies, use multiple layers of ceramic dielectric and electrodes, allowing for a much higher capacitance in the same or smaller package size. MLCCs are chosen for applications needing higher capacitance and miniaturization, whereas single-layer ceramic capacitors are more commonly used for simple, low-capacitance applications or where space is not a constraint. - How do MLCCs compare to other types of capacitors?

Compared to electrolytic capacitors, MLCCs excel in high-frequency performance, have lower ESR (Equivalent Series Resistance), and can withstand higher temperatures, but are generally smaller in capacitance values. MLCCs do not have polarity, unlike electrolytic capacitors. Film capacitors are another common type with higher voltage tolerance. MLCCs are selected for their compact size, good performance characteristics in high-frequency circuits, and reliability, but they are generally not chosen for applications requiring the very high capacitance values offered by electrolytic capacitors. - Why are MLCCs so widely used in electronics?

MLCCs are favored for their small size, high capacitance values, low ESR (Equivalent Series Resistance), excellent stability over a wide range of temperatures, and high reliability. These characteristics make them ideal for numerous applications, from decoupling and filtering to energy storage, in a wide range of electronic devices, including smartphones, laptops, and automotive systems. - What are some common failure modes for MLCCs?

Common failure modes include cracking (often due to mechanical stress during assembly or usage), delamination (separation of layers due to stress or thermal cycling), and dielectric breakdown due to overvoltage. These failure modes can be mitigated with careful handling, appropriate voltage and temperature derating during component selection and robust assembly processes. Moreover, selecting MLCCs with flexible termination can significantly enhance reliability in applications subject to mechanical stress. - How do I choose the right MLCC for a specific application?

Selecting the appropriate MLCC involves considering factors such as capacitance, voltage rating, temperature coefficient, size constraints, and desired operational frequency. The capacitance value is determined by the application's electrical requirements, the voltage rating should be higher than the maximum circuit voltage to ensure a safety margin, and the temperature coefficient must be suitable for the operating temperature range. Consulting datasheets and following design guidelines are essential to guarantee long-term reliability and performance.

Future Trends in Multilayer Ceramic Capacitor Technology

The field of multilayer ceramic capacitor (MLCC) technology is in constant evolution, driven by the ever-increasing demands of modern electronics for smaller, more efficient, and higher-performing components. Future advancements are focused on miniaturization, increased capacitance, reduced Equivalent Series Resistance (ESR), and the development of new materials to meet these challenges.

Miniaturization continues to be a primary focus, with research directed towards producing ever smaller MLCCs without sacrificing performance. Simultaneously, efforts are underway to enhance the capacitance of MLCCs within the existing and smaller form factors, enabling higher energy storage capabilities in compact devices. Lowering ESR is another key area of development, as it directly impacts the efficiency and heat dissipation of MLCCs. Finally, researchers are actively exploring new ceramic materials with improved dielectric properties, higher temperature stabilities, and greater mechanical strength to expand the operational limits of MLCCs.

| Trend | Description | Impact |

|---|---|---|

| Miniaturization | Reducing the physical size of MLCCs. | Enables smaller electronic devices and higher component density. |

| Higher Capacitance | Increasing the amount of charge MLCCs can store within the same or smaller size. | Improves energy storage capabilities and reduces the number of components needed. |

| Lower ESR | Decreasing the internal resistance of MLCCs. | Enhances efficiency, reduces heat generation, and improves signal integrity. |

| New Materials | Developing advanced ceramic materials with superior dielectric and mechanical properties. | Expands the operational limits of MLCCs and allows for use in more demanding applications. |

Multilayer ceramic capacitors are a cornerstone of modern electronics, with their unique combination of small size, high capacitance, and reliability. Their evolution continues to play a critical role in advancing technology, from mobile devices to sophisticated medical equipment. As demand for smaller, more efficient, and reliable electronics grows, so will the importance of further advancements in MLCC technology, especially in areas like higher temperature operation and greater capacitance density. The continuous development of MLCCs will be a key driver of progress in the electronic industry and beyond.

AnyPCBA

AnyPCBA